Non-asphalt-based non-curing rubber waterproof coating and preparation method thereof

A non-curing rubber, non-asphalt-based technology, applied in the direction of fireproof coatings, wax coatings, coatings, etc., can solve the problems of volatilization, a large number of harmful substances, anti-aging performance, high temperature heat resistance and low temperature, and achieve bright colors and excellent Adhesive performance and the effect of extending the waterproof life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

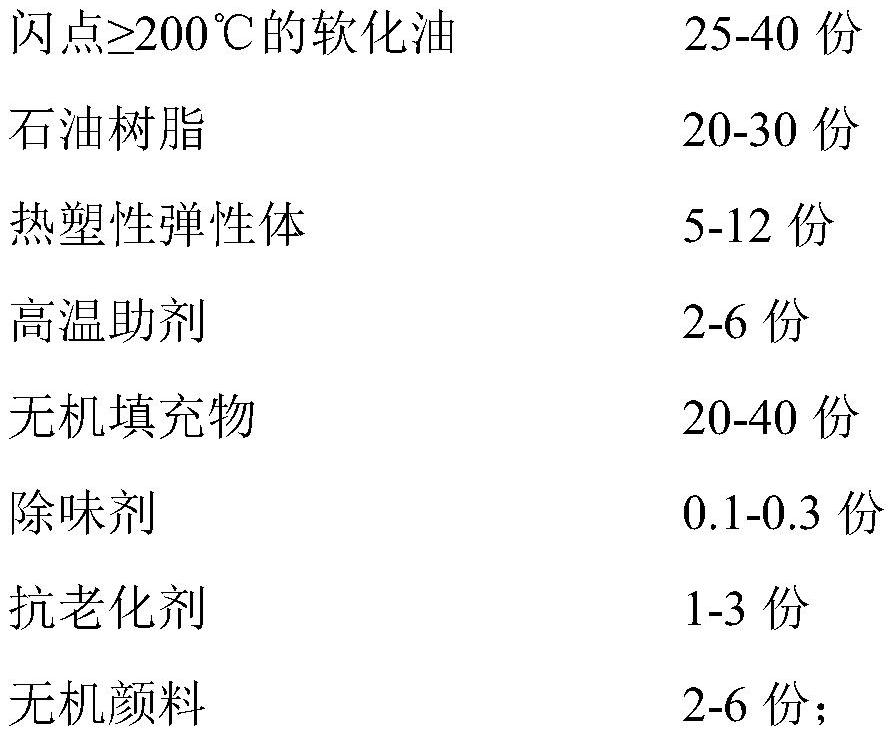

[0038] A non-asphalt-based non-curing rubber waterproof coating according to the present invention mainly includes the following components prepared according to the following weight fraction ratio:

[0039]

[0040] The preparation method of described non-asphalt-based non-curing rubber waterproof coating comprises the following steps carried out in sequence:

[0041] (1) Heating the aromatic oil to 110°C, then adding C5 petroleum resin, heating to 140°C while stirring at a speed of 500r / min, and stirring for 1 hour;

[0042] (2) Add styrene-butadiene-styrene block copolymer to the mixture obtained in step (1), heat to 175°C while stirring at a speed of 500r / min, and stir for 2.5h;

[0043] (3) Add polyethylene wax powder, iron oxide red, antioxidant 1076 and deodorant to the mixture obtained in step (2), and stir for 1 h at a speed of 500 r / min;

[0044] (4) Add fly ash to the mixture obtained in step (3), and stir for 1.5 h at a speed of 500 r / min to obtain the non-asph...

Embodiment 2

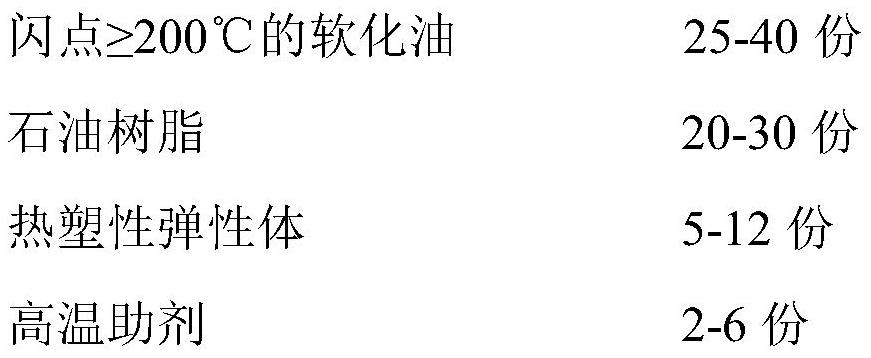

[0046] A non-asphalt-based non-curing rubber waterproof coating according to the present invention mainly includes the following components prepared according to the following weight fraction ratio:

[0047]

[0048]

[0049] The preparation method of described non-asphalt-based non-curing rubber waterproof coating comprises the following steps carried out in sequence:

[0050] (1) Heat the lubricating oil to 100°C, then add C9 petroleum resin, heat to 130°C while stirring at a speed of 550r / min, and stir for 1.5h;

[0051] (2) Add styrene-butadiene-styrene block copolymer and styrene-isoprene-styrene block copolymer to the mixture obtained in step (1), while stirring at a speed of 450r / min Heat to 180°C and stir for 2h;

[0052] (3) Add polypropylene wax powder, chromium oxide green, antioxidant 1024 and deodorant to the mixture obtained in step (2), and stir for 3h at a speed of 450r / min;

[0053] (4) Add talcum powder to the mixture obtained in step (3), and stir for ...

Embodiment 3

[0055] A non-asphalt-based non-curing rubber waterproof coating according to the present invention mainly includes the following components prepared according to the following weight fraction ratio:

[0056]

[0057] The preparation method of described non-asphalt-based non-curing rubber waterproof coating comprises the following steps carried out in sequence:

[0058] (1) Heat the high white oil to 120°C, then add C5C9 copolymerized petroleum resin, heat to 150°C while stirring at a speed of 450r / min, and stir for 2 hours;

[0059] (2) Add styrene-butadiene-styrene block copolymer and polystyrene-butadiene copolymer to the mixture obtained in step (1), heat to 170°C while stirring at a speed of 550r / min, and stir 3h;

[0060] (3) Add polyamide wax powder, iron blue, antioxidant 1098 and deodorant to the mixture obtained in step (2), and stir for 2h at a speed of 550r / min;

[0061] (4) Add light calcium carbonate to the mixture obtained in step (3), and stir for 1 hour at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com