Environment-friendly volatile punching oil composition and application thereof

A volatile and composite technology, applied in the field of metal parts stamping, can solve the problems of easy pollution of the environment, health hazards, environmental damage, etc., and achieve the effects of easy biodegradation, cost reduction, and no residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

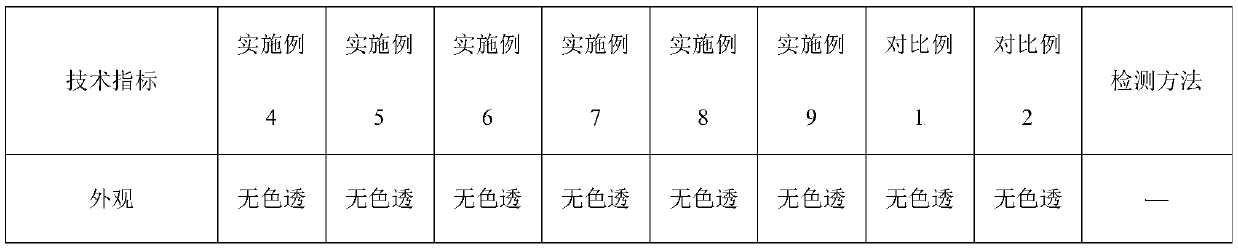

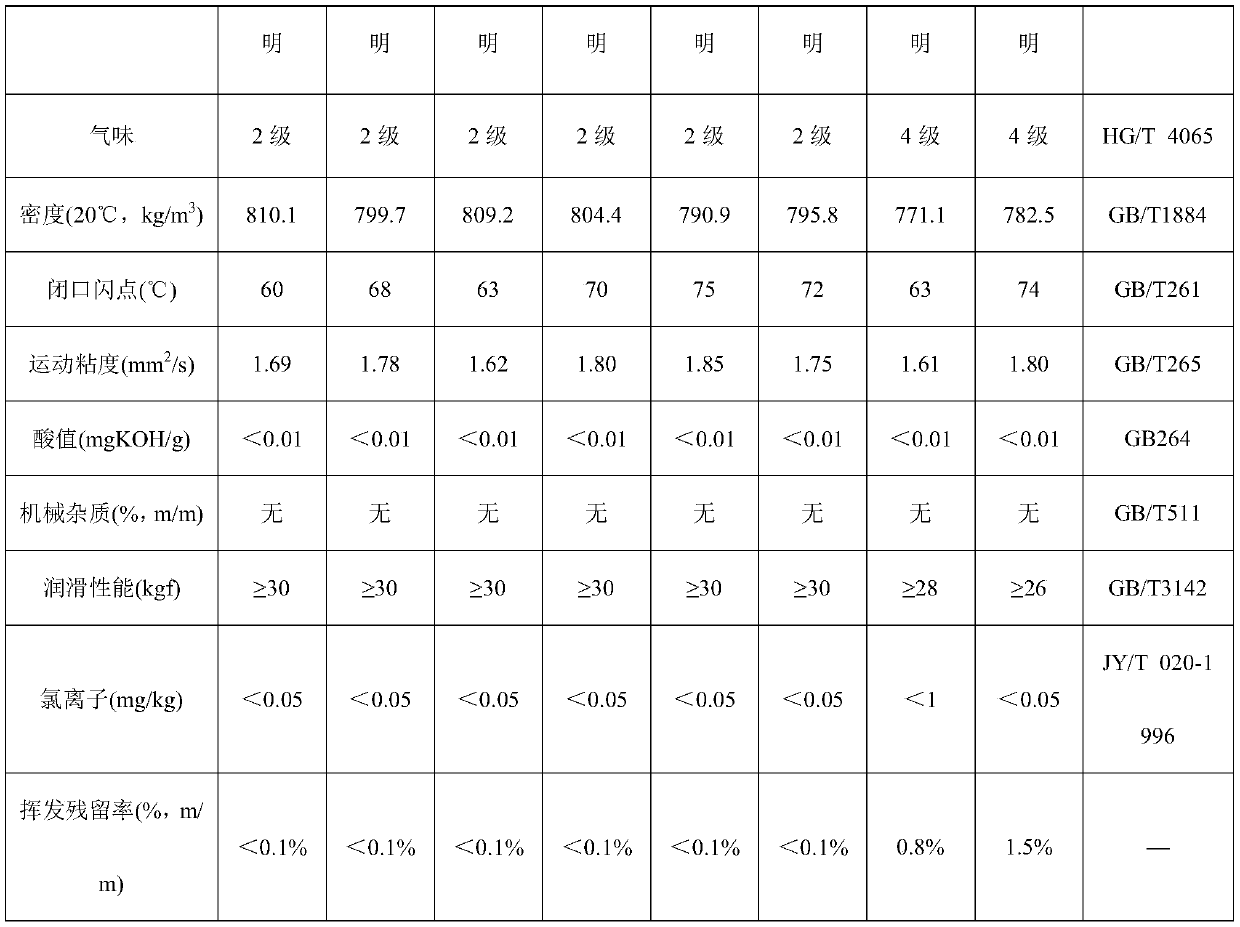

Examples

Embodiment 1

[0019] This embodiment provides a volatile stamping oil composition. The preparation method of the volatile stamping oil composition is as follows: first weigh 850 g of turpentine oil and 150 g of hydrocarbon solvent base oil for later use; then, the above-mentioned weighed turpentine oil, The hydrocarbon solvent base oil is placed in the reaction kettle and stirred evenly until transparent. The stirring overshoot temperature is controlled at 20-40° C., the stirring speed is 150 rpm, and the stirring time is 15-20 minutes. The volatile stamping oil composition can be obtained. Among them, the hydrocarbon solvent base oil is iso-eicosane in carbon number.

Embodiment 2

[0021] This embodiment provides a volatile stamping oil composition. The preparation method of the volatile stamping oil composition is as follows: first weigh 720 g of turpentine oil, 250 g of hydrocarbon solvent base oil, and 30 g of volatile lubricant, and set aside; then, the The above weighed turpentine, hydrocarbon solvent base oil and volatile lubricant are placed in a reaction kettle and stirred evenly until transparent. The stirring overshoot temperature is controlled at 20-40° C., the stirring speed is 150 rpm, and the stirring time is 15-20 minutes. The volatile stamping oil composition can be obtained. Wherein, the hydrocarbon solvent base oil is a mixture of 125g carbon number iso-hexadecane and 125g n-eicosane; the volatile lubricant is n-hexanol.

Embodiment 3

[0023] This embodiment provides a volatile stamping oil composition. The preparation method of the volatile stamping oil composition is as follows: first weigh 790 g of turpentine oil, 200 g of hydrocarbon solvent base oil, and 10 g of volatile lubricant for later use; then, the The above weighed turpentine, hydrocarbon solvent base oil and volatile lubricant are placed in a reaction kettle and stirred evenly until transparent. The stirring overshoot temperature is controlled at 20-40° C., the stirring speed is 150 rpm, and the stirring time is 15-20 minutes. The volatile stamping oil composition can be obtained. Wherein, the hydrocarbon solvent base oil is a mixture of 50g Isopar L, 50g Somentor31 and 100g ExxoslD110; the volatile lubricant is a mixture of 5g isomerized cetyl alcohol and 5g n-cetyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com