High-grade road hard asphalt and preparation method thereof

A hard asphalt, high-grade technology, applied in the direction of building components, climate change adaptation, building insulation materials, etc., can solve the problems of preparing road asphalt, anti-aging performance of unlisted asphalt, inconvenience of asphalt construction, etc., and achieve great economic benefits and social benefits, improving poor anti-aging performance, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

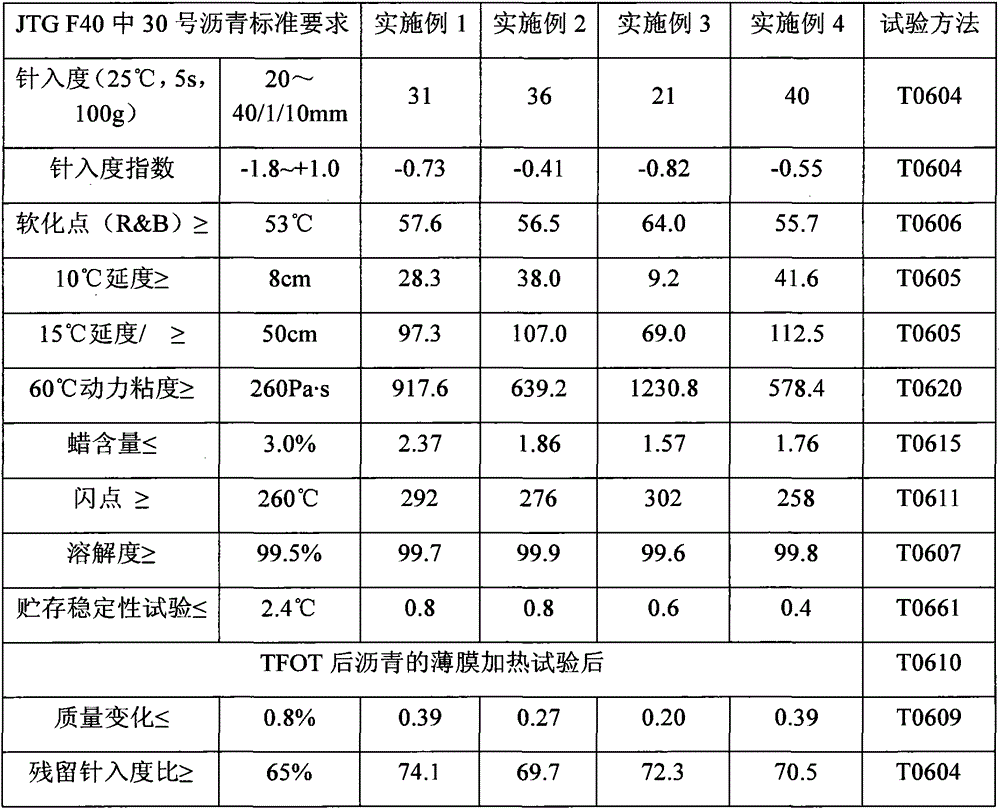

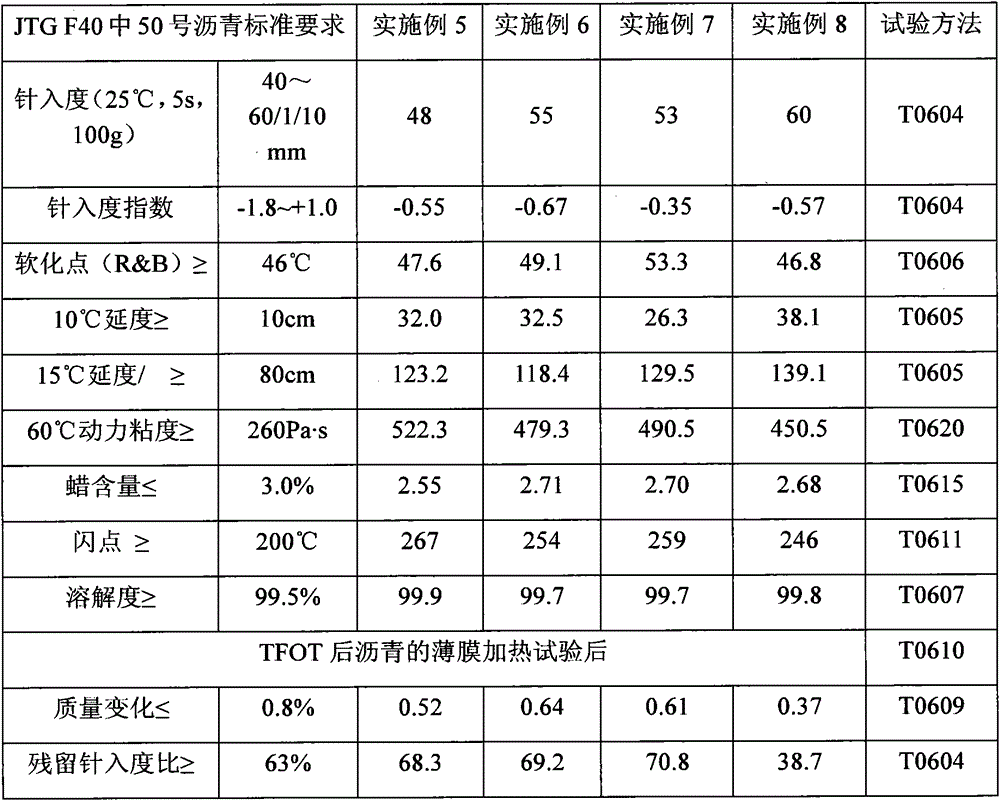

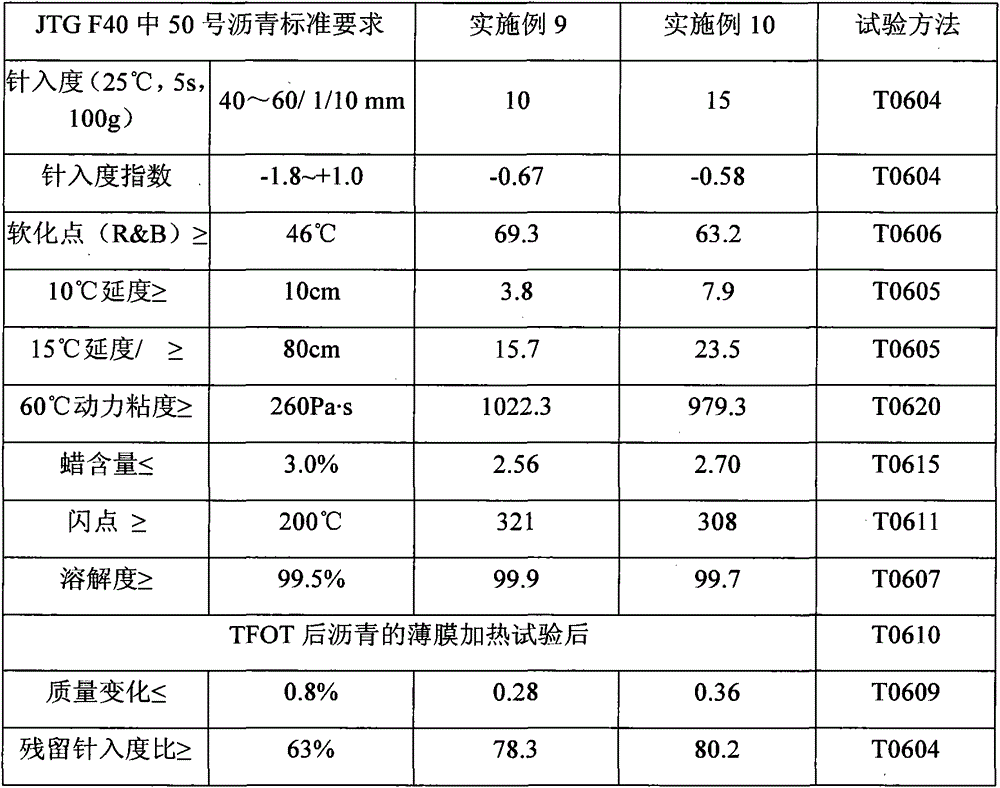

Embodiment 1

[0034] A kind of high grade road hard asphalt

[0035] Raw materials: (weight percent)

[0036] Butane deoiled asphalt 53%, cutting temperature is 34.8% of topping oil slurry at 365°C, furfural extracts oil 10%, polymer modifier is SBS (its molecular structure is star structure, S / B composition is 30 / 70, the molecular weight is 220000), the dosage is 2%, and the auxiliary agent is polymer sulfur S40, and the dosage is 0.2%.

[0037] Prepared by:

[0038] Blend the deoiled asphalt and the topping oil slurry according to the above ratio and heat to 160°C, prepare the asphalt blend under the stirring state with a rotating speed of 200rpm, then add the extracted oil, and prepare the blended asphalt under the stirring state with a rotating speed of 250rpm ; Slowly add polymer modifier SBS to the blended asphalt at a heating temperature of 170°C and a shearing speed of 3000rpm, and shear for 20 minutes; continue to slowly add additives at a high-speed shearing state with a rotati...

Embodiment 2

[0040] 48% butane deoiled asphalt, 36.8% topping oil slurry with a cutting temperature of 382°C, 12% naphthenic oil, polymer modifier is SBS (its molecular configuration is star structure, S / B composition 30 / 70, the molecular weight is 220000), the dosage is 3%, and the auxiliary agent is polymer sulfur S40, and the dosage is 0.2%.

[0041] Prepared by:

[0042] Blend deoiled asphalt and topping oil slurry according to weight percentage and heat to 170°C, prepare an asphalt blend under stirring at a rotating speed of 100rpm, then add extracted oil, and prepare blended asphalt under stirring at a rotating speed of 250rpm; Slowly add the polymer modifier SBS to the blended asphalt at a heating temperature of 175°C and a shearing speed of 3500rpm, and shear for 20 minutes; continue to slowly add additives under a high-speed shearing state with a rotational speed of 4500rpm, and shear for 25 minutes; After the shearing is completed, stir and develop for 2 hours under the stirring...

Embodiment 3

[0044] Pentane deoiled asphalt 65%, cutting temperature is 15.4% of topping oil slurry at 410°C, intermediate base oil 15%, polymer modifier is SBS (its molecular configuration is a linear structure, and the S / B composition is 30 / 70, the molecular weight is 110000), the dosage is 4.5%, the auxiliary agent is selected elemental sulfur, and the dosage is 0.1%.

[0045] Prepared by:

[0046] Blend the deoiled asphalt and topping oil slurry according to the weight percentage and heat to 170°C, prepare the asphalt blend under the state of stirring at a rotating speed of 300rpm, then add the extracted oil, and prepare the blended asphalt under the state of stirring at a rotating speed of 300rpm; Slowly add the polymer modifier SBS to the blended asphalt at a heating temperature of 180°C and a shearing speed of 3500rpm, and shear for 25 minutes; continue to slowly add additives under a high-speed shearing state with a rotational speed of 3500rpm, and shear for 20 minutes; After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com