Preparation method of high speed engine base oil

A base oil and engine technology, applied in the field of base oil, can solve the problems such as base oil performance needs to be improved, and achieve the effects of saving non-renewable resources, high flash point, and reducing fuel gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

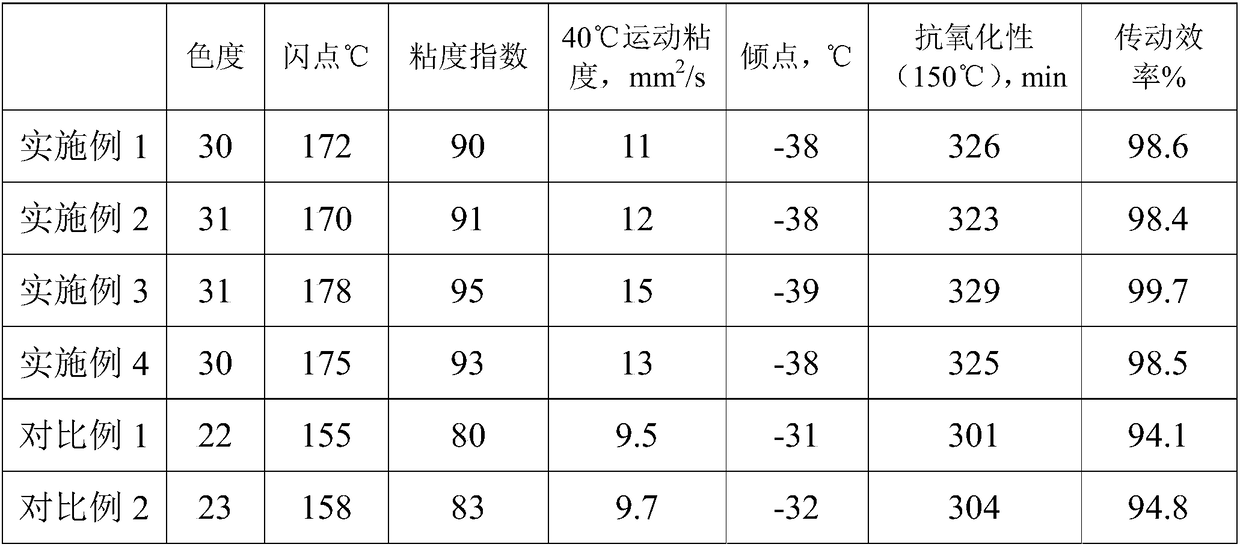

Examples

Embodiment 1

[0024] A preparation method of high-speed engine base oil, comprising the following steps:

[0025] S1. Preheating: Put the raw material oil into the heating furnace for heating, and heat it to 325°C;

[0026] S2. Hydroisomerization: Send the heated raw oil to the first hydrogenation reactor for hydroisomerization reaction. The reaction temperature is 300°C, the hydrogen partial pressure is 12.5MPa, and the volume space velocity of the feed liquid is 1.5h -1 , hydrogen oil volume ratio is 450:1, generates the first reaction product;

[0027] S3. Hydrofining: Send the first reaction product to the second hydrogenation reactor for hydrofining reaction. The reaction temperature is 220°C, the hydrogen partial pressure is 14MPa, and the volumetric space velocity of the feed liquid is 1.2h -1 , hydrogen oil volume ratio is 1000:1, obtains the second reaction product;

[0028] S4. High and low pressure separation: the second reaction product enters the cold high-pressure separator...

Embodiment 2

[0033] A preparation method of high-speed engine base oil, comprising the following steps:

[0034] S1. Preheating: Put the raw material oil into the heating furnace for heating, and heat it to 335°C;

[0035] S2. Hydroisomerization: Send the heated raw oil to the first hydrogenation reactor for hydroisomerization reaction. The reaction temperature is 350°C, the hydrogen partial pressure is 16MPa, and the volumetric space velocity of the feed liquid is 1.5h -1 , hydrogen oil volume ratio is 450:1, generates the first reaction product;

[0036] S3. Hydrofining: send the first reaction product to the second hydrogenation reactor for hydrofining reaction, the reaction temperature is 260°C, the hydrogen partial pressure is 16MPa, and the volumetric space velocity of the feed liquid is 1.2h -1 , hydrogen oil volume ratio is 1000:1, obtains the second reaction product;

[0037] S4. High and low pressure separation: the second reaction product enters the cold high-pressure separat...

Embodiment 3

[0042] A preparation method of high-speed engine base oil, comprising the following steps:

[0043] S1. Preheating: Put the raw material oil into the heating furnace for heating, and heat it to 330°C;

[0044] S2. Hydroisomerization: Send the heated raw oil to the first hydrogenation reactor for hydroisomerization reaction. The reaction temperature is 330°C, the hydrogen partial pressure is 14MPa, and the volumetric space velocity of the feed liquid is 1.5h -1 , hydrogen oil volume ratio is 450:1, generates the first reaction product;

[0045]S3. Hydrofining: Send the first reaction product to the second hydrogenation reactor for hydrofining reaction, the reaction temperature is 240°C, the hydrogen partial pressure is 15MPa, and the volumetric space velocity of the feed liquid is 1.2h -1 , hydrogen oil volume ratio is 1000:1, obtains the second reaction product;

[0046] S4. High and low pressure separation: the second reaction product enters the cold high-pressure separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com