Environmentally-friendly cold heading oil with epoxidized vegetable oil as base oil, and preparation method thereof

A technology for epoxidizing vegetable oil and epoxidizing soybean oil, which is applied in the directions of base materials, petroleum industry, lubricating compositions, etc., can solve the problems of ecological environment pollution and poor biodegradability, and achieves pollution reduction, high flash point, good The effect of biodegradable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

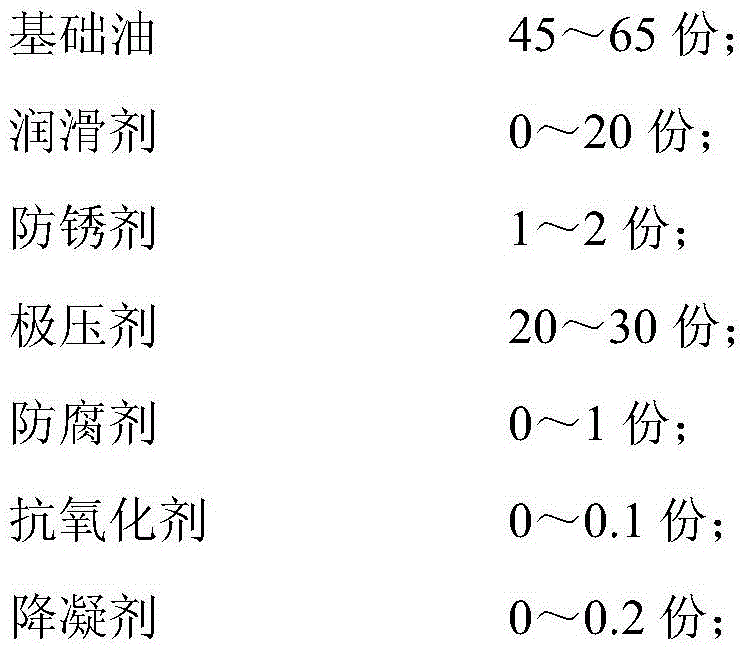

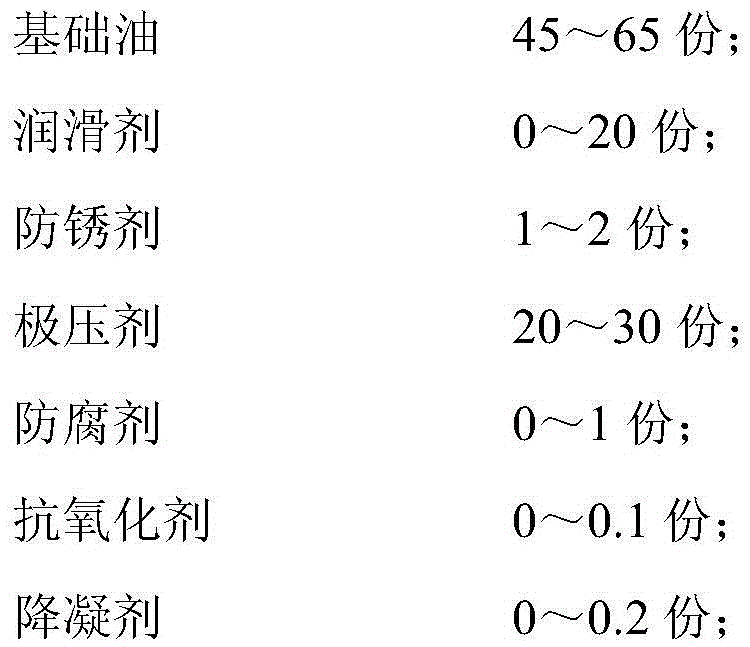

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment prepares environment-friendly cold heading oil according to the following steps:

[0024] First, weigh 45g of epoxidized soybean oil (the kinematic viscosity at 40°C is 34mm 2 / s). Add to the blending kettle, then add 20g of trimethylolpropane fatty acid ester, 10g of chlorinated paraffin S-52, 15g of sulfurized lard, 4g of sulfur-containing extreme pressure agent RC2540, 1g of oily phosphoric acid Esters, warmed up slightly to 55°C, stirred for 30min; then added a mixture of 1g of sodium petroleum sulfonate and 1g of benzotriazole, 0.8g of benzisothiazolinone and 0.2g of 3-iodo-2- The mixture of propynyl butyl carbamate, continue to stir for 40min; finally add 0.1g of TBHQ and 0.2g of polymethacrylate pour point depressant (SANYO's ACLUBEP-2100), and stir for another 30min to obtain the product .

[0025] The appearance of the obtained product is a tan transparent viscous liquid, and the maximum non-jamming load PB value can reach 180kg.

Embodiment 2

[0027] First, weigh 55g of epoxidized soybean oil (the kinematic viscosity at 40°C is 34mm 2 / s). Add to the blending kettle, then add 10g of trimethylolpropane fatty acid ester, 10g of chlorinated paraffin S-52, 15g of sulfurized lard, 4g of sulfur-containing extreme pressure agent RC2540, 1g of oily phosphoric acid Esters, warmed up slightly to 55°C, stirred for 30min; then added a mixture of 1g of sodium petroleum sulfonate and 1g of benzotriazole, 0.8g of benzisothiazolinone and 0.2g of 3-iodo-2- The mixture of propynyl butyl carbamate, continue to stir for 40min; finally add 0.1g of TBHQ and 0.2g of polymethacrylate pour point depressant (SANYO's ACLUBEP-2100), and stir for another 30min to obtain the product .

[0028] The appearance of the obtained product is a tan transparent viscous liquid, and the maximum non-jamming load PB value can reach 170kg.

Embodiment 3

[0030] First, weigh 65g of epoxidized soybean oil (the kinematic viscosity at 40°C is 34mm 2 / s) into the blending kettle, then add 10g of chlorinated paraffin S-52, 15g of vulcanized lard, 4g of sulfur-containing extreme pressure agent RC2540, and 1g of oily phosphate, slightly warm up to 55°C, and stir for 30min; then Then add the mixture of 1g of sodium petroleum sulfonate and 1g of benzotriazole, the mixture of 0.8g of benzisothiazolinone and 0.2g of 3-iodo-2-propynyl butyl carbamate, Continue stirring for 40 minutes; finally add 0.1 g of TBHQ and 0.2 g of polymethacrylate pour point depressant (ACLUBEP-2100 from SANYO), and stir for another 30 minutes to obtain the product.

[0031] The appearance of the obtained product is a brown transparent viscous liquid, and the maximum non-jamming load PB value can reach 160kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com