Anti-dazzle coating and anti-dazzle hardening film

A hardened film and coating technology, applied in polyurea/polyurethane coatings, coatings, instruments, etc., can solve the problems of poor clarity and flash point of the anti-glare hardened film, heavy flash point, and inability to meet the requirements of high-definition display devices. , to achieve excellent leveling, reduce the effect of flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the present invention, the preparation method of the antiglare coating preferably comprises the following steps:

[0047] Mix urethane acrylate polymer with 6-functionality and above, acrylate monomer with 3-functionality and above, photoinitiator and organic solvent, stir to obtain the mixture, and then continue to add anti-glare particles with a particle size of ≤500nm, particle size The anti-glare particles of 1-3 μm, the silicone leveling agent and the acrylic leveling agent are fully stirred evenly to obtain the anti-glare coating.

[0048] In the present invention, the urethane acrylate polymer with a hexafunctionality and above, the acrylate monomer with a trifunctionality and above, the antiglare particles with a particle diameter of ≤500 nm, the antiglare particles with a particle diameter of 1 to 3 μm, The types, dosages and sources of photoinitiators, silicone-based leveling agents, acrylic leveling agents and organic solvents are the same as those of poly...

Embodiment 1

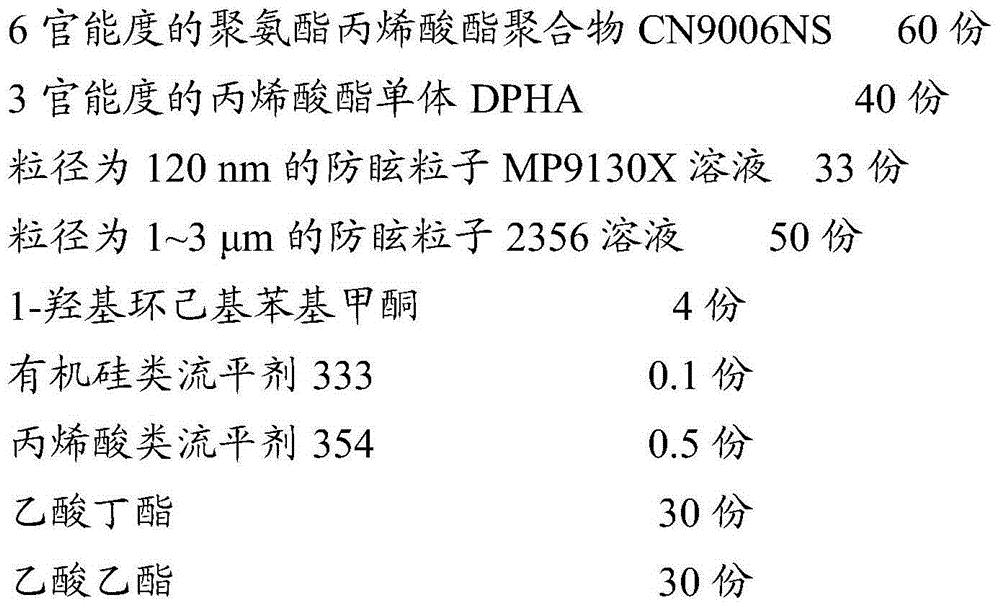

[0074] The components of the anti-glare coating include by weight:

[0075]

[0076]In 60 parts of urethane acrylate polymer CN9006NS (manufactured by Sartomer) and 40 parts of 3-functionality acrylate monomer DPHA (manufactured by Guojing Chemical), add 4 parts of 1-hydroxycyclohexyl phenyl ketone (Tianjin Manufactured by Tianjiao Chemical Co., Ltd.); obtain the mixture after being diluted with 60 parts of mixed solvents comprising butyl acetate and ethyl acetate with a relative weight ratio of 1:1, then add 33 parts of MP9130X solution (solid content is 30%, The particle diameter is 120nm, and the dispersion liquid is acetic acid-1-methoxy-2-propyl ester, manufactured by Evonik), 50 parts of antiglare particles 2356 solution (solid content is 10%, particle diameter is 2~3μm, dispersed Liquid is a mixture of cyclohexanone, toluene, xylene and ethylbenzene, manufactured by Gifu, Japan) and 0.1 part of silicone leveling agent 333, 0.5 part of acrylic leveling agent 354 (both...

Embodiment 2

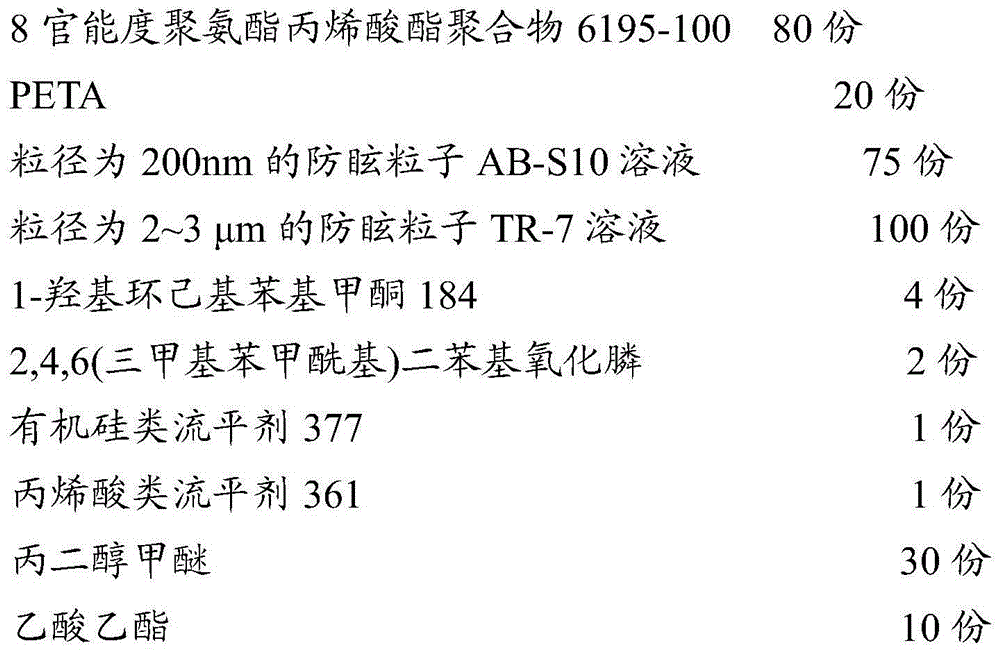

[0080] The components of the anti-glare coating include by weight:

[0081]

[0082] To 80 parts of 6195-100 oligomer (manufactured by Changxing Chemical Industry Co., Ltd.) and 20 parts of PETA (manufactured by Changxing Chemical Industry Co., Ltd.), add 4 parts of photoinitiator 184 and 2 parts of 2,4,6 (Trimethylbenzoyl) diphenylphosphine oxide (TPO) (both manufactured by Tianjin Tianjiao Chemical Co., Ltd.); obtain the mixture after diluting 30 parts of propylene glycol methyl ether and 10 parts of ethyl acetate, and then add 75 Parts of antiglare particle AB-S10 solution (solid content is 20%, particle diameter is 200nm, dispersion liquid is methyl isobutyl ketone, produced by Shanghai Nagase Trading Company), 100 parts of antiglare particle TR-7 solution (solid content 10%, the particle size is 2 ~ 3μm, the dispersion liquid is a mixture of cyclohexanone, toluene, xylene and ethylbenzene, made in Gifu, Japan) and 1 part of silicone leveling agent 377, 1 part of acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com