Mixed type polybasicester plasticizer and preparation method thereof

A technology of ester plasticizer and polybasic acid, which is applied in the field of polyester waste recycling, can solve problems such as not being able to meet practical application requirements, and achieve excellent heat resistance, processing convenience, easy operation, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

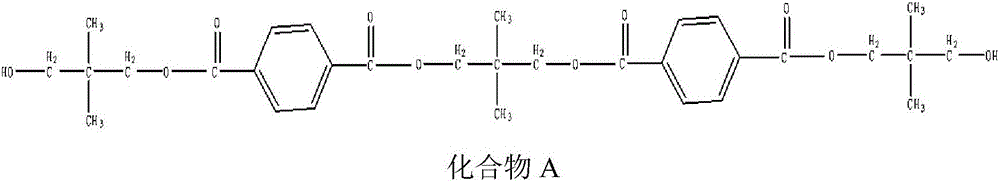

Image

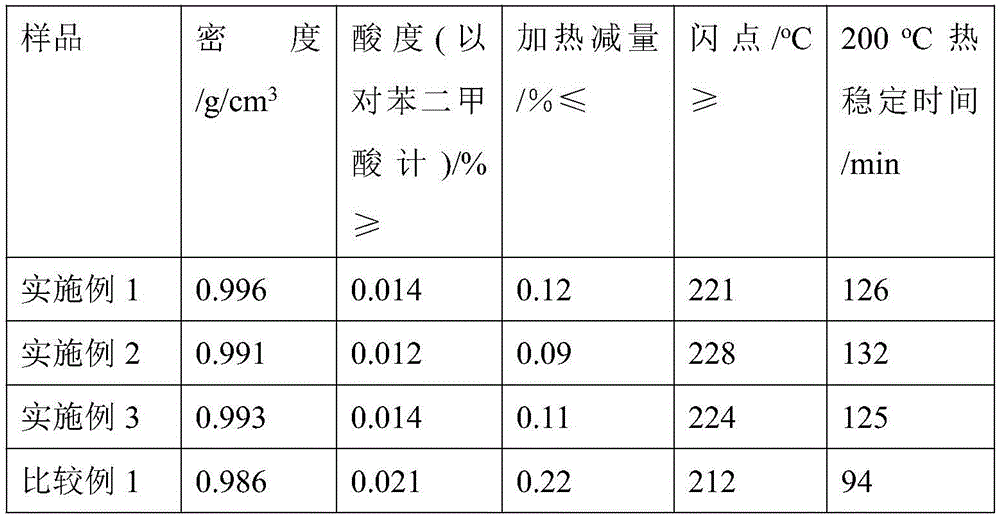

Examples

Embodiment 1

[0031] First prepare mixed polybasic acid ester plasticizer of the present invention according to the following method, this method may further comprise the steps:

[0032] 1) Add pulverized polyester waste, neopentyl glycol and catalyst 1,3-diethylimidazolium fluoride borate in the reaction vessel, the weight of the three is 20g, 68g and 1.8g respectively;

[0033] 2) Stir the reaction mixture and allow it to heat up slowly at a rate of 14° C. / h;

[0034]3) When the temperature is higher than 190°C, control the temperature of the reaction mixture between 190-210°C, and the reaction time is 5h;

[0035] 4) Cool down to 140-150°C, separate undegraded polyester waste; cool the residue to room temperature and dry to obtain a light yellow paste substance; the average molecular weight Mn of the light yellow paste substance is 574; hydroxyl value test The result was 196 mgKOH / g; 92% of the light yellow paste substance was Compound A.

[0036] 5) Add the above-mentioned light yello...

Embodiment 2

[0040] First prepare mixed polybasic acid ester plasticizer of the present invention according to the following method, this method may further comprise the steps:

[0041] 1) Add pulverized polyester waste, neopentyl glycol and catalyst 1,3-diethylimidazolium borofluoride in the reaction vessel, the weight of the three is 20g, 75g and 2.2g respectively;

[0042] 2) Stir the reaction mixture and allow it to heat up slowly at a rate of 15° C. / h;

[0043] 3) When the temperature is higher than 190°C, control the temperature of the reaction mixture between 190-210°C, and the reaction time is 6h;

[0044] 4) Cool down to 140-150°C, separate undegraded polyester waste; cool the residue to room temperature and dry to obtain a light yellow paste substance; the average molecular weight Mn of the light yellow paste substance is 521; hydroxyl value test The result was 209 mgKOH / g; 86% of the light yellow paste substance was Compound A.

[0045] 5) Add the above-mentioned light yellow ...

Embodiment 3

[0049] First prepare mixed polybasic acid ester plasticizer of the present invention according to the following method, this method may further comprise the steps:

[0050] 1) Add pulverized polyester waste, neopentyl glycol and catalyst 1,3-diethylimidazolium borofluoride in the reaction vessel, the weight of the three is 20g, 84g and 2g respectively;

[0051] 2) Stir the reaction mixture and make it warm up slowly at a rate of 16° C. / h;

[0052] 3) When the temperature is higher than 190°C, control the temperature of the reaction mixture between 190-210°C, and the reaction time is 8h;

[0053] 4) Cool down to 140-150°C to separate undegraded polyester waste; the residue is cooled to room temperature and dried to obtain a light yellow paste substance; the average molecular weight Mn of the light yellow paste substance is 643; hydroxyl value test The result was 201 mgKOH / g; 88% of the light yellow paste substance was Compound A.

[0054] 5) Add the above-mentioned light yell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com