A kind of high temperature resistant lubricating oil base oil and preparation method thereof

A high-temperature-resistant lubricating oil and base oil technology, applied in the field of lubricating oil, can solve the problems of low flash point and poor oxidation stability of castor oil, and achieve the effects of high flash point, good wear resistance, and good oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

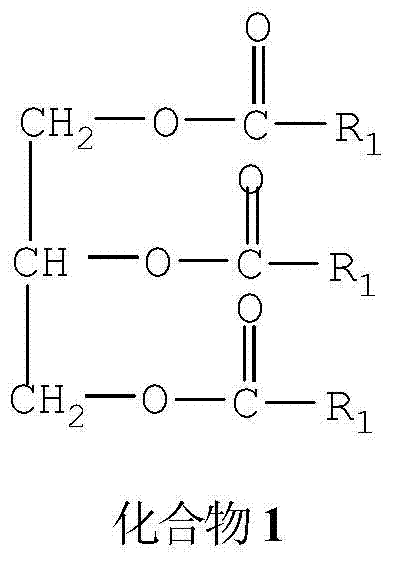

[0027] 1. Preparation of compound 1

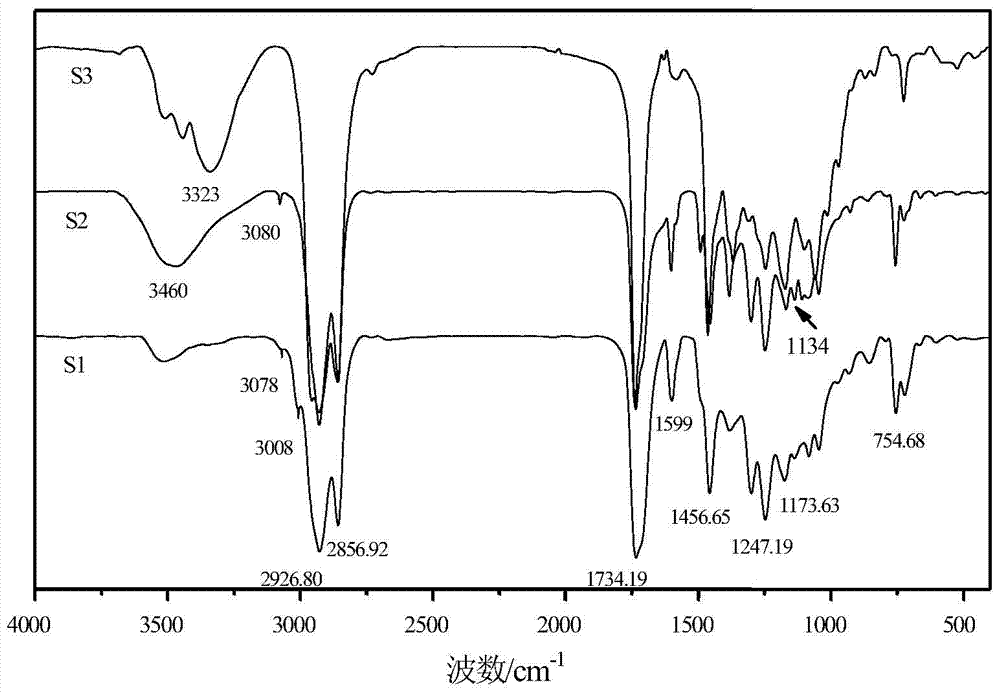

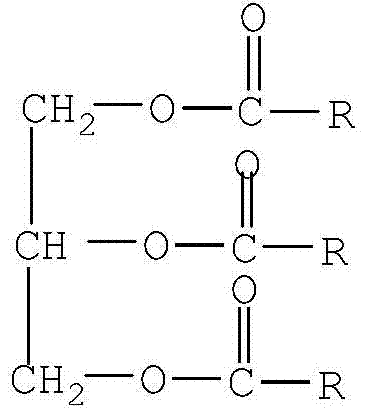

[0028] Put 100g castor oil into a three-necked flask equipped with reflux condenser and constant speed stirrer, heat up to 80℃, add 69g 2-ethoxybenzoic acid and 2.5g NaH 2 PO 4 , The reaction was stirred at a constant temperature of 310 rpm for 4 hours, cooled to room temperature, allowed to stand for stratification, the product was washed with boiling water to neutrality, and dehydrated by rotary evaporation at 0.02MPa and 86~93℃ to obtain compound 1. Its chemical reaction The equation is as follows:

[0029]

[0030] Where R 0 representative R 1 representative

[0031] 2. Preparation of compound 2

[0032] Add 50g of compound 1 into a three-necked flask equipped with a reflux condenser and a constant-speed stirrer. The temperature was raised to 50℃, and then 15g of acetic acid and 32.5g of 30% H were added dropwise to the three-necked flask. 2 O 2 The mixed solution of the solution and 1.0g concentrated sulfuric acid (98% by mass) was stirred ...

Embodiment 2

[0041] 1. Preparation of compound 1

[0042] Put 100g castor oil into a three-necked flask equipped with reflux condenser and constant speed stirrer, heat up to 90℃, add 50g 2-ethoxybenzoic acid and 2.0g NaH 2 PO 4 The reaction was stirred at a constant temperature of 310 revolutions / min for 3 hours, cooled to room temperature, allowed to stand for stratification, the product was washed with boiling water to neutrality, and dehydrated by rotary evaporation at 0.02MPa and 86-93°C to obtain compound 1.

[0043] 2. Preparation of compound 2

[0044] Put 40g of compound 1 into a three-necked flask equipped with a reflux condenser and a constant-speed stirrer, the temperature was raised to 60℃, and then 8g of acetic acid and 20g of 30% H were added dropwise to the three-necked flask. 2 O 2 The mixed solution of the solution and 0.4g of concentrated sulfuric acid (98% by mass) was stirred at 400 rpm for 2 hours, cooled to room temperature, allowed to stand for stratification, and the produc...

Embodiment 3

[0048] 1. Preparation of compound 1

[0049] Put 100g castor oil into a three-necked flask equipped with reflux condenser and constant speed stirrer, heat up to 70℃, add 100g 2-ethoxybenzoic acid and 5.0g NaH 2 PO 4 The reaction was stirred at a constant temperature of 310 rpm for 5 hours, cooled to room temperature, and allowed to stand for separation. After the product was washed with boiling water to neutrality, it was dehydrated by rotary evaporation at 0.02MPa and 86-93°C to obtain compound 1.

[0050] 2. Preparation of compound 2

[0051] Put 40g of compound 1 into a three-necked flask equipped with a reflux condenser and a constant-speed stirrer, the temperature was raised to 40℃, and then 20g of acetic acid and 40g of 30% H were added dropwise to the three-necked flask. 2 O 2 The mixed solution of the solution and 1.2g of concentrated sulfuric acid (98% by mass) was stirred for 5 hours at a constant temperature of 400 revolutions / min, cooled to room temperature, and allowed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com