Dust suction filter

A filter and filter core technology, applied in suction filters and other directions, can solve the problems of increasing the volume and manufacturing cost of the vacuum filter, shortening the replacement cycle of the HEPA filter, and reducing the dust removal effect of the dust box. Efficiency, the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

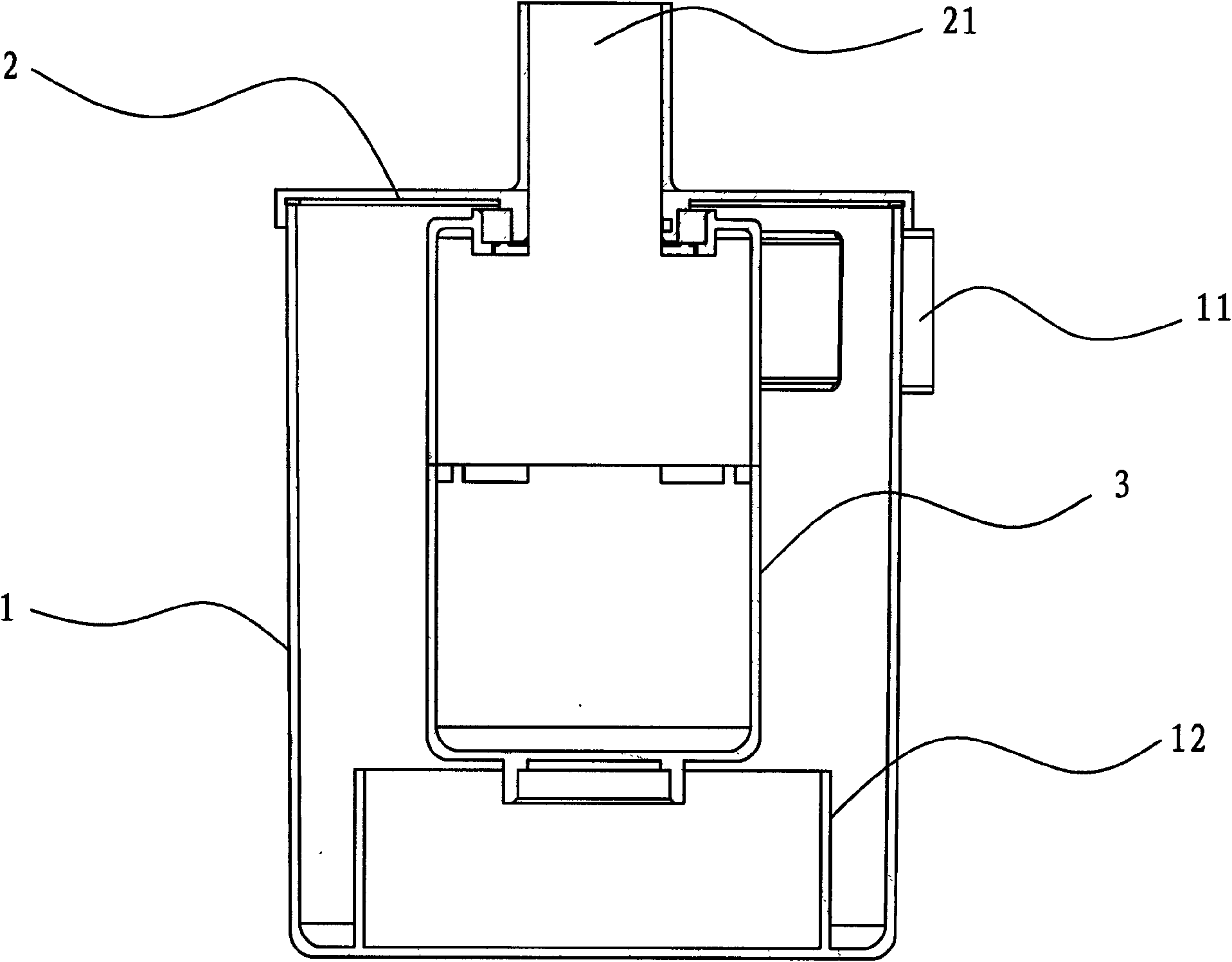

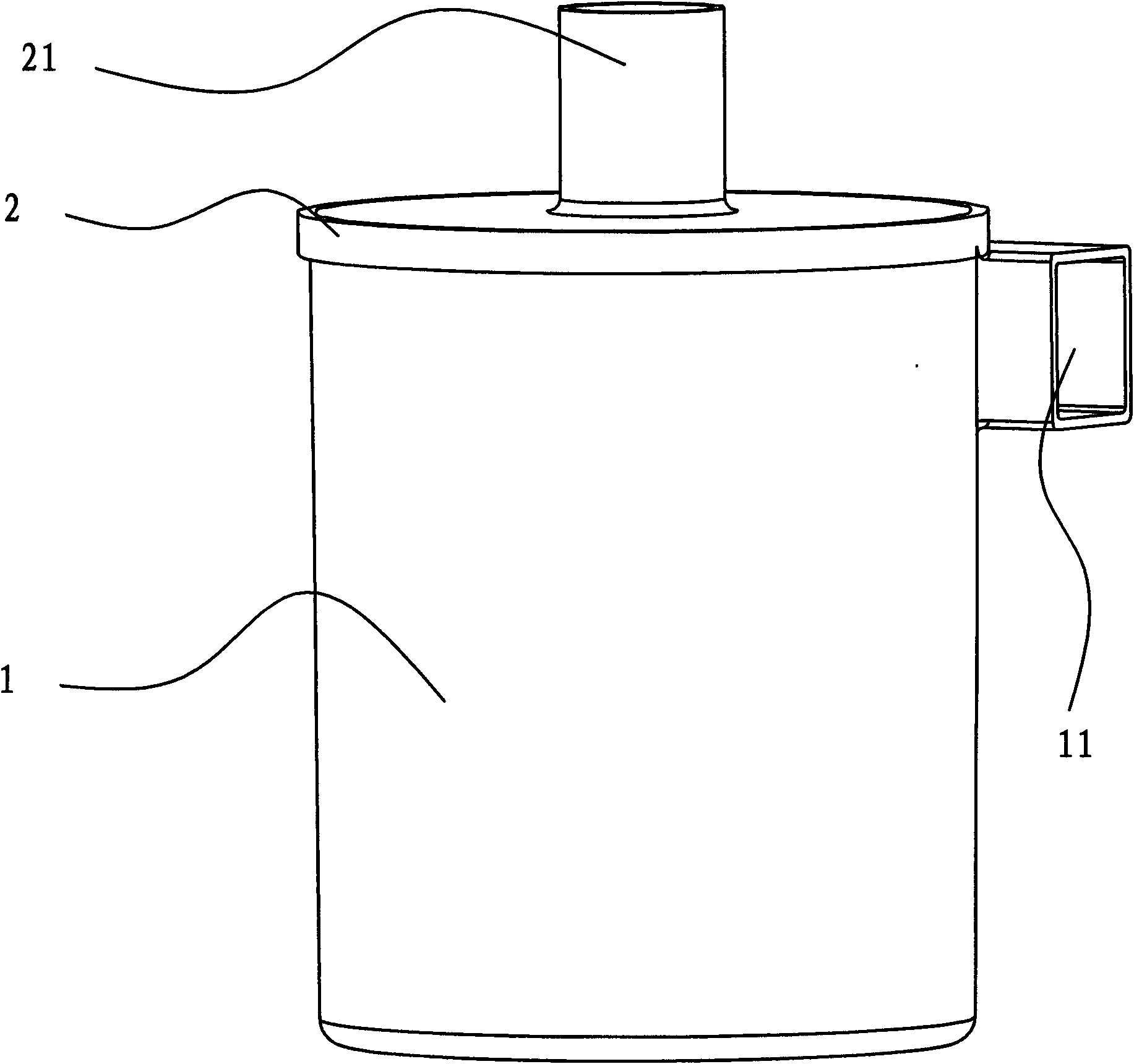

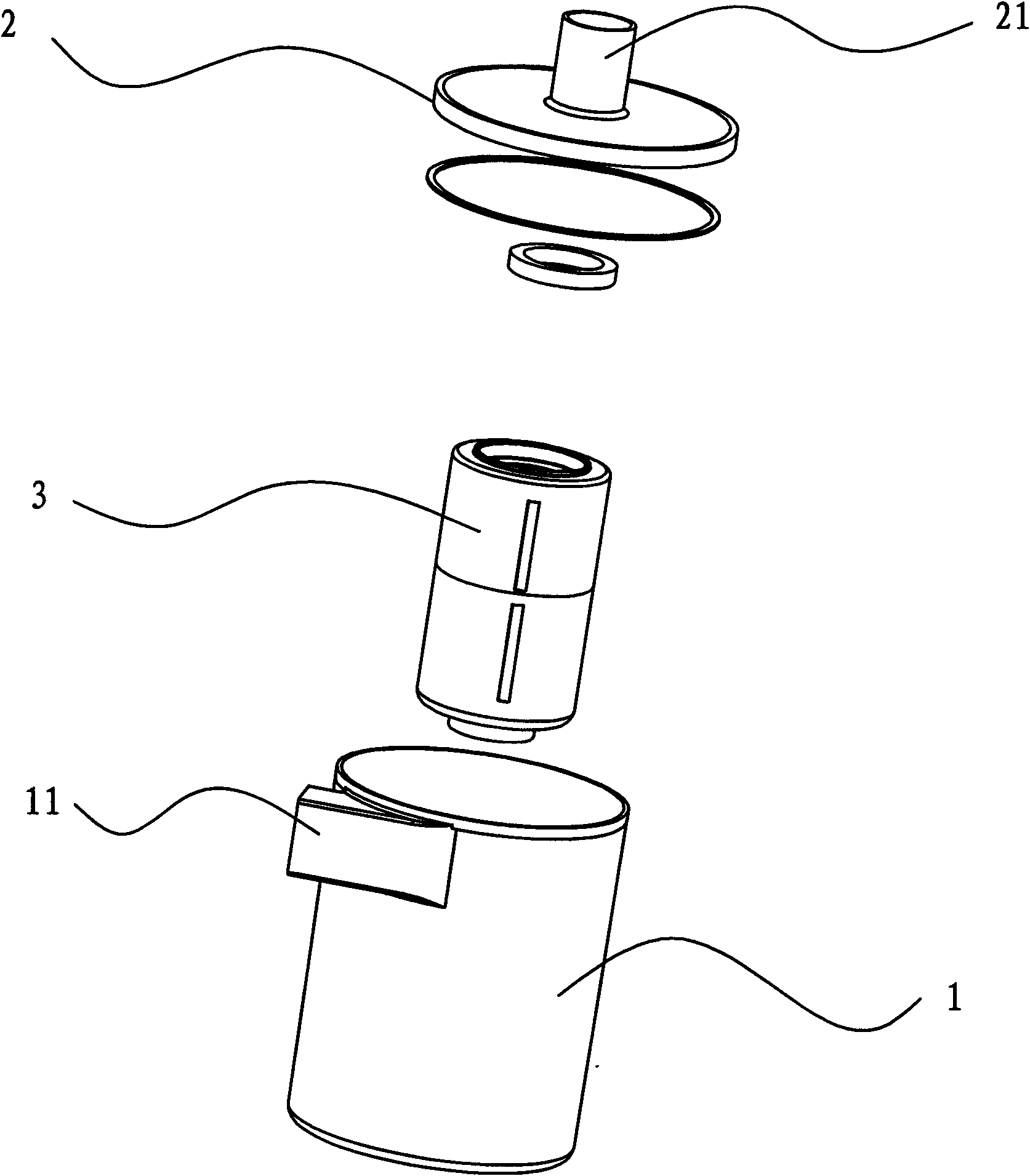

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a dust suction filter, including a dust box 1, a sealing cover 2, a filter core 3 is also vertically hoisted in the dust box 1, and an air inlet 11 arranged on the dust box 1 and an air inlet 11 arranged on the sealing cover 2 Outlet 21, the inner bottom of the dust box 1 is provided with a bone 12, the bone 12 is in the space between the filter core 3 and the side wall of the dust box 1, and the top of the bone 12 is not higher than the bottom of the filter core 3. Bone position 12 is the wheel rim shape that protrudes at dust box 1 bottom. When the vacuum cleaner works and sucks air, the air enters the dust box 1 through the air inlet 11 on the dust box 1, and forms a rotating vortex in the dust box 1. The rotating vortex formed in this way is actually a small tornado, but the tornado has the following Characteristics: The wind in a tornado is always cyclonic, the air rotates rapidly around the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com