Experiment system for superhigh temperature bag duster

A technology of bag filter and experimental system, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of high flue gas temperature, erosion and wear, uneven air mixing, etc., and achieve excellent filtration performance, The effect of small steel plate area and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

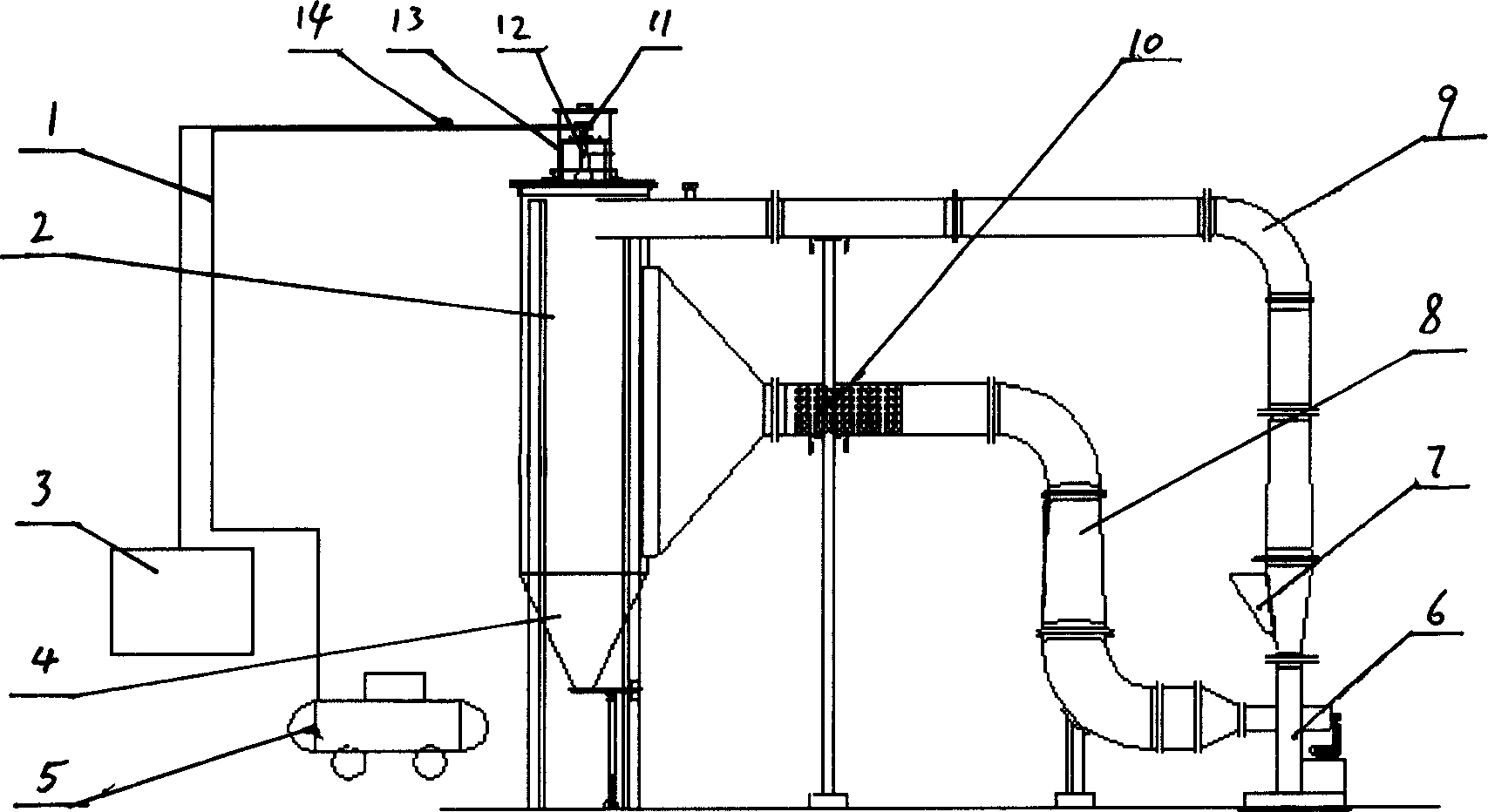

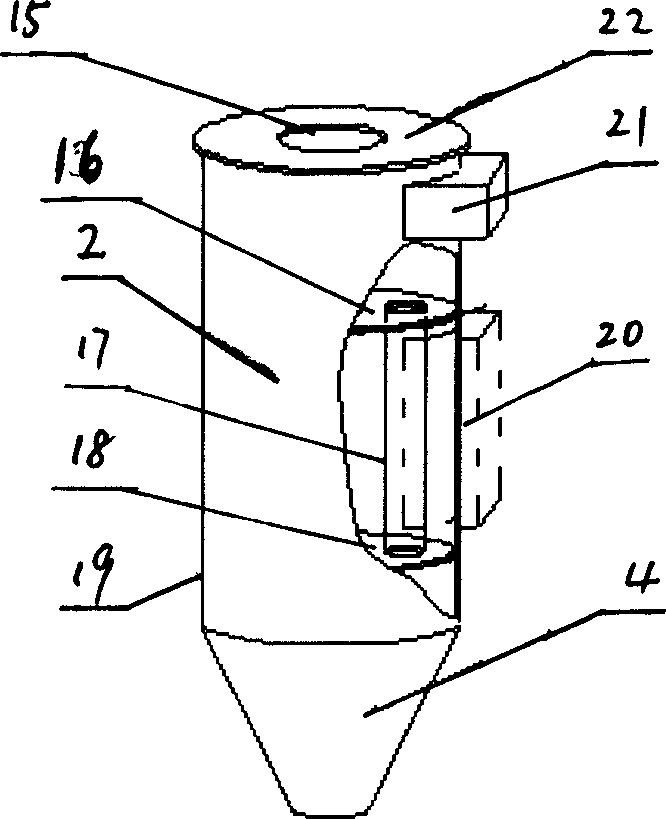

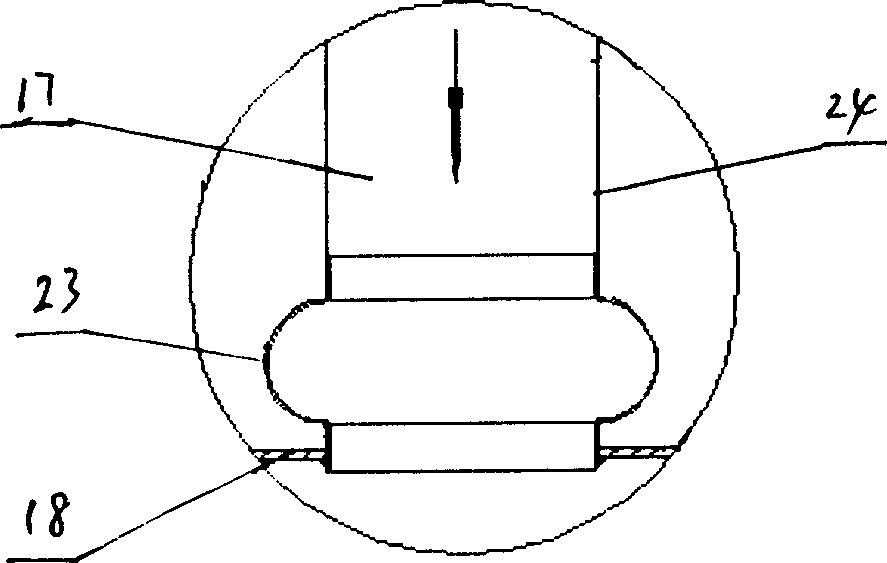

[0023] The present invention includes an ultra-high temperature bag filter 2, a control device 3 and a compressed air source 5. The high temperature bag filter 2 consists of a cover plate 22, a cylindrical barrel 19, an upper flower plate 16, a lower flower plate 18 and a conical ash Composed of bucket 4, a flue gas inlet 21 and a flue gas outlet 20 are processed on the side wall of the ultra-high temperature bag filter 2, and a filter bag 17 is installed between the upper flower plate 16 and the lower flower plate 18; The air inlet pipeline 9 is connected between the flue gas inlet 21 of the ultra-high temperature bag filter 2 and the air outlet of the fan 6, and the ash adding device 7 is installed on the side wall of the air inlet pipeline 9. A simulated heating device 10 and an air outlet pipeline 8 are sequentially i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com