Nuclear power water feed pump mechanical seal magnetic filter

A magnetic filter and mechanical seal technology, which is applied in the direction of fixed filter element filter, filtration separation, magnetic separation, etc., can solve the problems of large flushing water volume, long flushing time, poor economy, etc., and achieve fast flow speed and dirt holding Large capacity, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

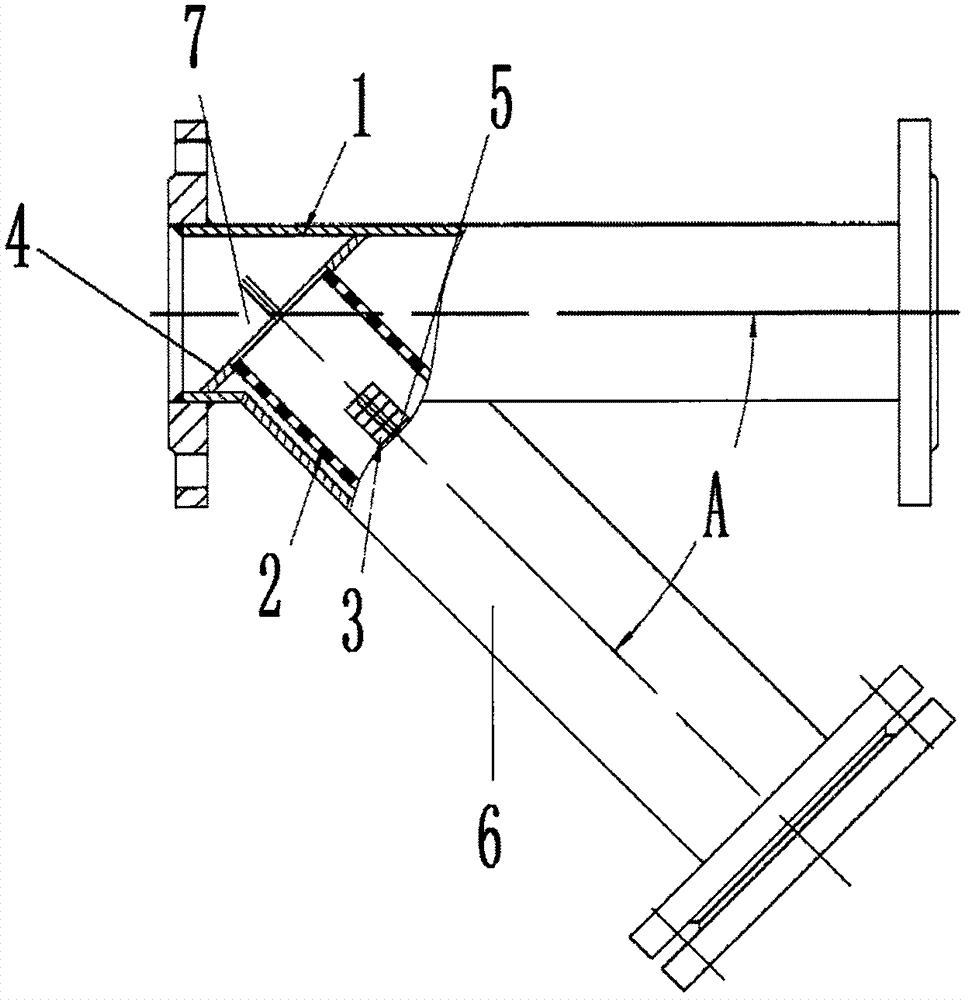

[0014] see figure 1 , a mechanical seal magnetic filter for a nuclear power feed water pump, comprising an overflow cylinder body 1 and a cylindrical filter 6 fixed at the end of the overflow cylinder body 1 and arranged in a Y shape with the overflow cylinder body; cylindrical The angle A between the filter 6 and the body of the overflow cylinder is 35° to 50°. In a preferred embodiment of the present invention, the angle A between the cylindrical filter 6 and the body of the flow cylinder is 45°. The inlet port 4 of the filter 6 extends into the inside of the barrel body 1 and is fixed by the connecting sleeve 7, and the center point of the inlet port of the cylindrical filter 6 coincides with the central axis of the inner diameter of the barrel body 1; The inside of the cylindrical filter 6 is equipped with an annular filter cover 2, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com