Composite filter paper manufacturing method and device capable of improving surface dust holding capacity

A manufacturing method and technology of filter paper, applied in lamination devices, separation methods, chemical instruments and methods, etc., can solve the problems of unstable spinning, difficult to realize industrial production, complex structure, etc., and achieve long service life and convenient production , High filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Use polypropylene non-woven fabric with an average diameter of 29.5µm and an average pore diameter of 37.2µm as the base fabric; dissolve glass fiber slices in acetone to prepare a 6% superfine fiber solution;

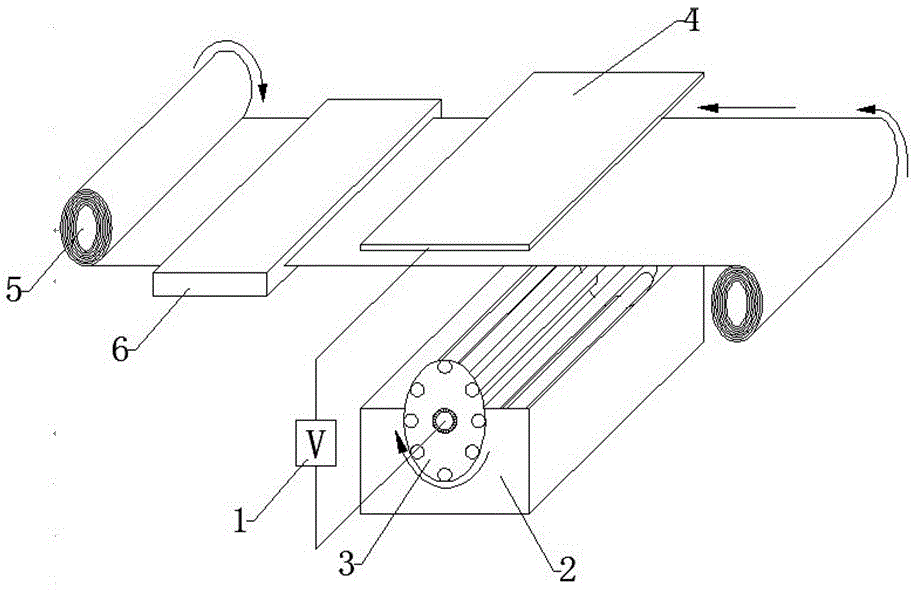

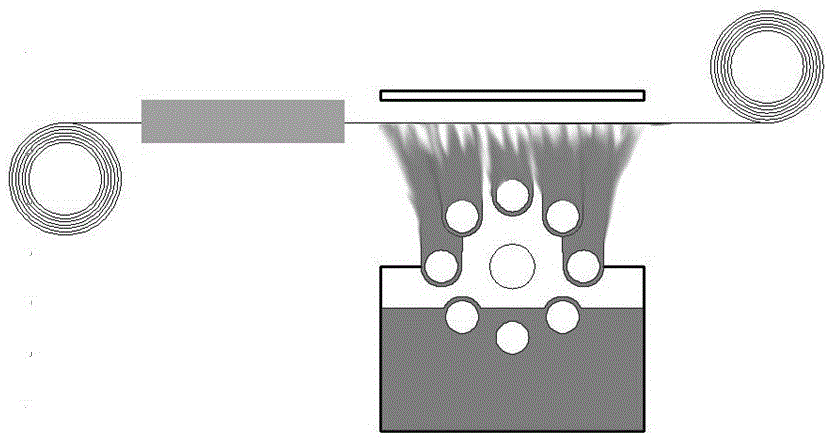

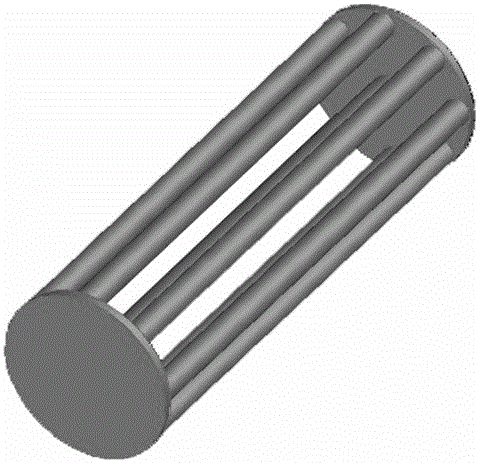

[0026] (2) The length of the collecting electrode plate 4 is 80cm, and the diameter of the drawing drum electrode 3 is D 3 =50cm, there are 8 cylinders evenly fixed around the drum axis. The output voltage of the high-voltage electric field generator 1 is 35kv, and the distance between the collecting electrode plate 4 and the electrode axis of the wire drawing drum is 20cm. A part of the drawing roller electrode 3 is immersed in the microfiber solution, and the submerged part is 0.3D 3 .

[0027] (3) Under the action of a high-voltage electrostatic field formed between the wire drawing drum electrode 3 and the collecting electrode plate 4, the filamentous fiber solution carried by the wire drawing drum electrode adheres to the base fabric, and the organic ...

Embodiment 2

[0029] (1) Use polyester (PET) non-woven fabric with an average diameter of 19.5 µm and an average pore diameter of 17.2 µm as the base fabric; dissolve cellulose fiber slices in chloroform to prepare a 7% superfine fiber solution;

[0030] (2) The length of the collecting electrode plate 4 is 70cm, and the diameter of the drawing drum electrode 3 is D 3 =40cm, there are 6 cylinders evenly fixed around the drum axis. The output voltage of the high-voltage electric field generator 1 is 40kv, and the distance between the collecting electrode plate 4 and the electrode axis of the wire drawing drum is 15cm. A part of the drawing roller electrode 3 is immersed in the microfiber solution, and the submerged part is 0.2D 3 .

[0031] (3) Under the action of a high-voltage electrostatic field formed between the wire drawing drum electrode 3 and the collecting electrode plate 4, the filamentous fiber solution carried by the wire drawing drum electrode adheres to the base fabric, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com