A mine explosion-proof diesel engine tail gas purification device and method

A tail gas purification device, explosion-proof diesel engine technology, applied in the direction of exhaust devices, chemical instruments and methods, noise reduction devices, etc., can solve the problems of not meeting the requirements for the use of coal mine electrical equipment, ammonia leakage, and small pollution capacity, and achieve the goal of overcoming Easy to poison and deactivate, improve service life, and excellent purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

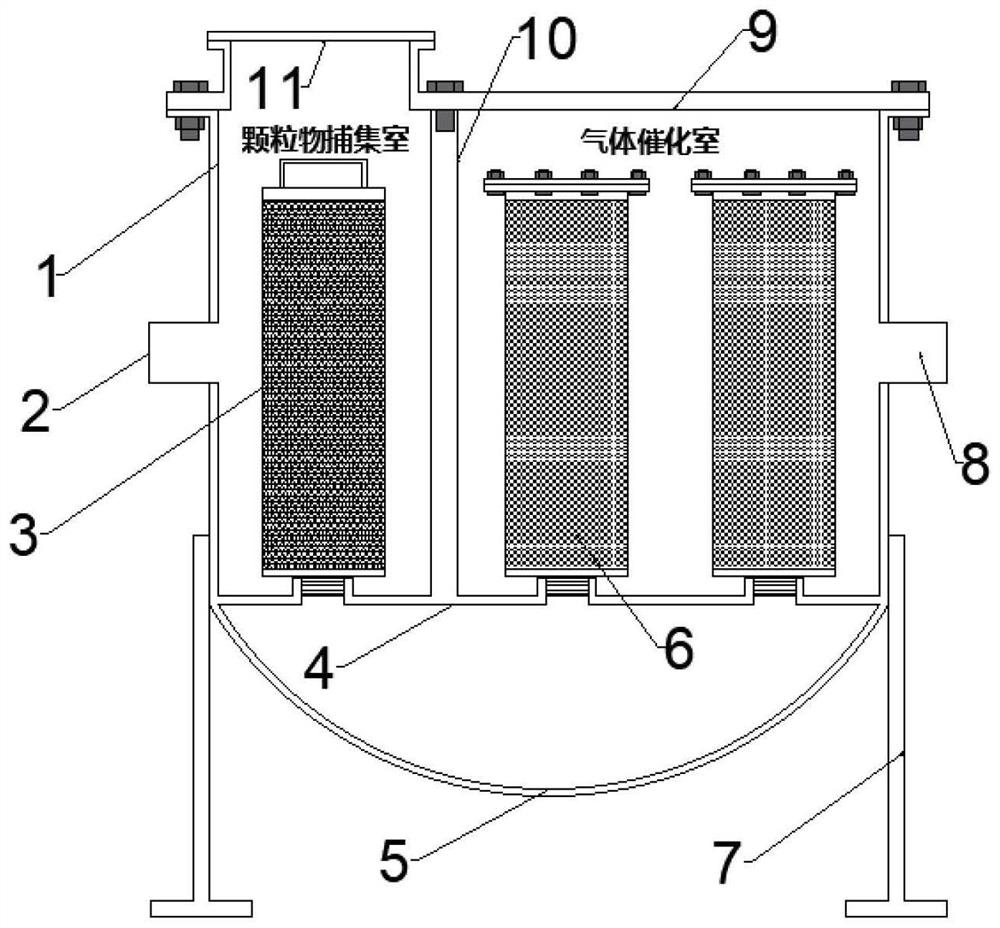

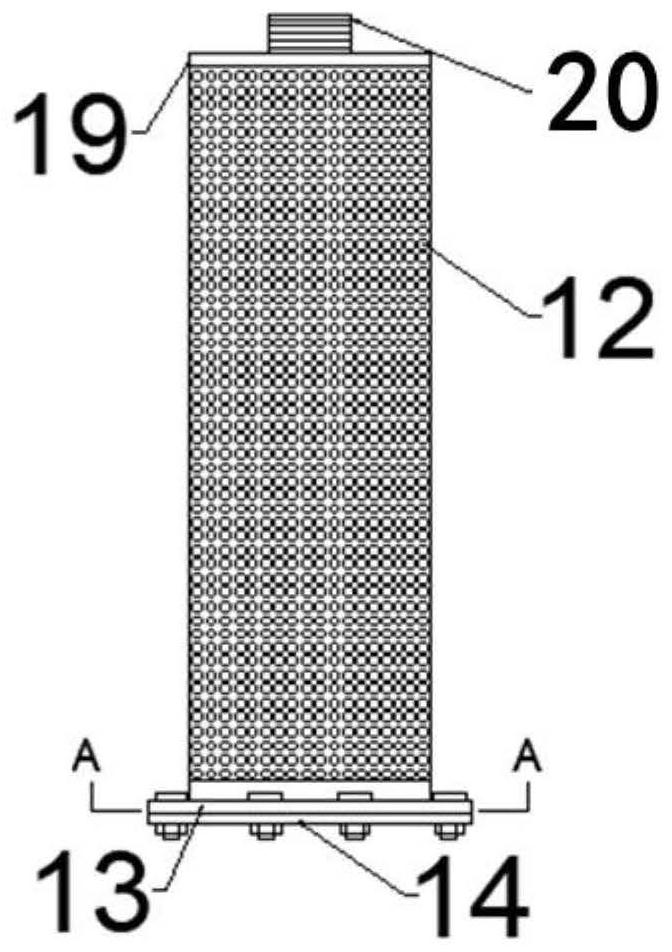

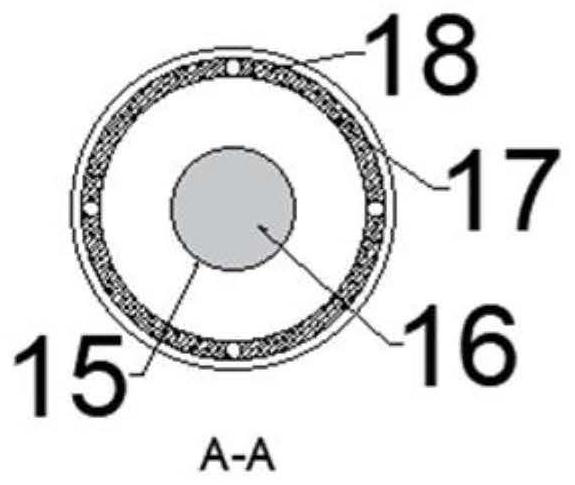

[0057] A metal filter element 3 coated with polytetrafluoroethylene coating on the surface is set in the particle collection chamber, and a metal filter element 3 is set in the middle of the particle collection chamber, and the filtering area of a single metal filter element 3 is 1.5m 2 ; There are two purification cylinders 6 equipped with granular catalysts in the purification chamber 1, and the purification area of a single purification cylinder is 0.8m 2 . The active components of the granular catalyst in the purification cylinder 6 are metal oxides of Cu, Fe and Co, and the prepared granular catalyst is 5 mesh, and the usage amount is 2 kg.

Embodiment 2

[0059] Two metal filter elements 3 coated with polytetrafluoroethylene coating on the surface are installed in the particulate matter collection chamber, the two metal filter elements 3 are symmetrically distributed, and the filtering area of a single metal filter element 3 is 1.5m 2 ; There are 4 purification cylinders 6 equipped with granular catalysts in the purification chamber 1, and the purification area of a single purification cylinder is 0.8m 2 . The active components of the granular catalyst in the purification cylinder 6 are metal oxides of Cu, Fe and Co, and the prepared granular catalyst is 5 mesh, and the usage amount is 2 kg.

[0060] The Weichai HS4105ZLD four-cylinder diesel engine was used for the test at a speed of 1000r / min. The exhaust gas first enters the particulate matter collection chamber, and is first physically intercepted by the modified metal filter element 3, so that most of the black smoke particles in the exhaust gas are intercepted and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com