Processing method of molybdenum mineral dressing waste water

A treatment method and technology for mineral processing wastewater, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of repeated acid-base adjustment of wastewater, large fluctuations in effluent water quality, and many types of dosing, etc. Achieve the effects of easier recovery after cleaning, lower operating costs, and improved water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The wastewater from a molybdenum mine in Hunan was tested as the raw water. The influent water quality fluctuated, SS 300-400mg / L, COD60-80mg / L, Zn 0.1-0.5mg / L, Pb 0-0.2mg / L, Cu 0.3- 0.5mg / L, pH 8-9.

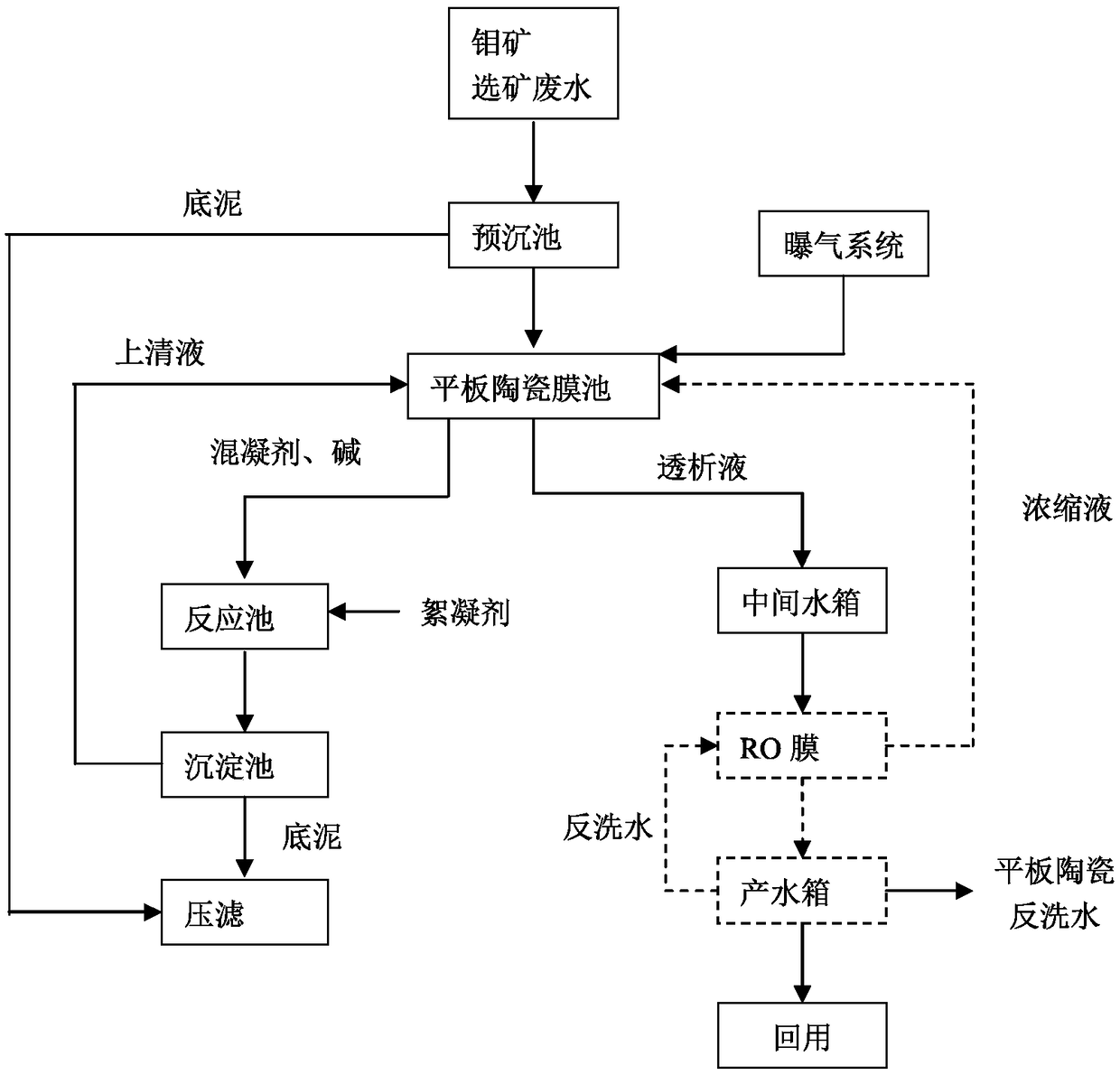

[0032] Such as figure 1 As shown, the operating parameters of this process are as follows: the raw water enters the pre-settling tank, and the settling time is 4h. The supernatant of the pre-sedimentation tank enters the flat ceramic membrane tank, the material of the flat ceramic membrane is silicon carbide, the pore size is 0.2 μm, and the area of the membrane module is 100m 2 , each run for 9 minutes, stop for 1 minute, the suction negative pressure is -10 ~ -20KPa, and the membrane flux is 300-400LMH. Backwashing is performed every 60 minutes, the backwashing time is 30s, the pressure is 2bar, and the backwashing flux is 800LMH. After backwashing, the membrane flux can be restored to 400LMH. The aeration continues, the air-to-water ratio is 10:1, and the fan pres...

Embodiment 2

[0035] The wastewater from a molybdenum mine in Luoyang, Henan Province was tested as raw water. The influent water quality fluctuated, SS 200-1000mg / L, COD 50-70mg / L, silicate <400mg / L, pH 7-9.

[0036] Such as figure 1 As shown, the operating parameters of this process are as follows: the raw water enters the pre-settling tank, and the settling time is 1h. The supernatant of the pre-sedimentation tank enters the flat ceramic membrane tank, the material of the flat ceramic membrane is alumina, the pore size is 0.1 μm, and the area of the membrane module is 2.5m 2 , run for 8 minutes, stop for 2 minutes, suction negative pressure is -5 ~ -20KPa, membrane flux 100-200LMH. Backwashing is performed every 60 minutes, the backwashing time is 30s, the pressure is 2bar, and the backwashing flux is 300LMH. After backwashing, the membrane flux can be restored to 200LMH. The aeration is carried out intermittently, every 30 minutes after stopping, it runs for 1 minute, the air-water ...

Embodiment 3

[0040] A molybdenum mine beneficiation wastewater in Henan was used as raw water for testing, and the influent water quality fluctuated, SS 7000-10000mg / L, COD 200-300mg / L, Zn 3-5mg / L, Pb 2-3mg / L, As0-0.03mg / L, pH 6.0-7.0.

[0041] Such asfigure 1 As shown, the operating parameters of this process are as follows: the raw water enters the pre-settling tank, and the settling time is 12h. The supernatant of the pre-sedimentation tank enters the flat ceramic membrane tank, the material of the flat ceramic membrane is cordierite and alumina, the pore diameter is 0.2μm, and the membrane module area is 50m 2 , every time it runs for 8.5 minutes, stop for 1.5 minutes, the suction negative pressure is -10 ~ -30KPa, and the membrane flux is 150-250LMH. Backwashing is performed every 30 minutes, the backwashing time is 60s, the pressure is 2bar, and the backwashing flux is 500LMH. After backwashing, the membrane flux can be restored to 500LMH. The aeration continues, the air-to-water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com