Magnetorheological fluid recovery device and method based on centrifugal separation effect

A technology of magnetorheological fluid and centrifugal separation, applied in the direction of centrifugal separation of water/sewage treatment, magnetic liquid, chemical instruments and methods, etc., can solve the problems of energy waste, magnetorheological fluid difficulty, environmental pollution, etc., and achieve the reduction of equipment Volume, not easy to settle, ensure the effect of rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

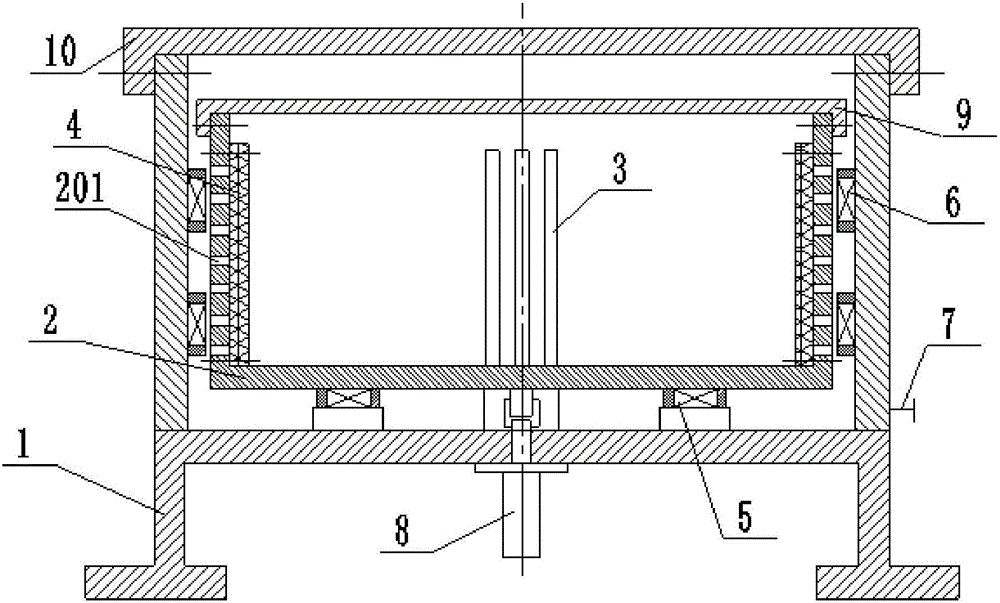

[0039] Such as figure 1 As shown, a magnetorheological fluid recovery device based on centrifugal separation in this embodiment includes an outer barrel body 1 , an inner barrel body 2 , an adsorption tube 3 and a filter screen 4 . Wherein, the inner barrel body 2 is installed in the outer barrel body 1 through bearing rotation, specifically in this embodiment, the bottom of the inner barrel body 2 and the outer barrel body 1 are supported and connected by a thrust bearing 5, and the outer side wall of the inner barrel body 2 A lateral bearing is installed between the inner wall of the outer barrel body 1, the thrust bearing 5 supports the rotation of the inner barrel body 2, and the lateral bearing ensures the rotation stability of the inner barrel body 2, effectively reducing the damage caused by uneven force and vibration of the inner barrel body 2. The resulting vibration and noise of the whole machine also improves the structural strength of the whole machine. The inner ...

Embodiment 2

[0046] A magnetorheological fluid recovery device based on centrifugal separation in this embodiment is further optimized and improved on the basis of Embodiment 1. We know that during the rotation of the inner barrel body 2, the magnetic substance has a tendency to approach the filter screen 4 under the action of centrifugal force, so that under the action of the magnetic field force, the magnetic substance needs to overcome the centrifugal force and approach the adsorption tube 3, so it must be ensured that the magnetic substance is under the influence of centrifugal force. The magnetic field force is greater than the centrifugal force, so that the magnetic substance will not stick to the filter screen 4, but it is limited by the comprehensive factors such as the limitation of the magnetic field size, the small rotating speed, the ineffective separation of the magnetic substance and the carrier liquid, the magnetic saturation of the magnetic substance, and the processing effic...

Embodiment 3

[0048] This embodiment provides a method for recycling magnetorheological fluid. The magnetorheological fluid recovery device based on centrifugal separation in Example 2 is used to treat the magnetorheological fluid, and the diameter of the filter hole 201 is specifically limited to 2mm. The mesh number of net 4 is at 2400 mesh. The magnetorheological fluid to be treated is a magnetorheological fluid with oleic acid as the main component of the surfactant, the main dispersed particles are hydroxyl iron powder, the magnetic saturation is 2.5T, and the carrier liquid is dimethyl silicone oil; and in this embodiment The magnetorheological fluid waste to be treated is the solution after its use exceeds its shear fatigue life, and at this time, the variation of its zero-shear viscosity and adjustable multiple exceeds ±10% during the inspection process. The specific operation steps are as follows:

[0049] ① Preliminary treatment of the magnetorheological fluid, so that the main d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com