High-flux cartridge filter element

A security filtration and high-throughput technology, applied in the field of water treatment, can solve the problems of unsatisfactory, accumulation, and reduce the effective filtration area of the filter element, so as to improve the service life, increase the pollution-holding capacity, and avoid the effect of flux drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

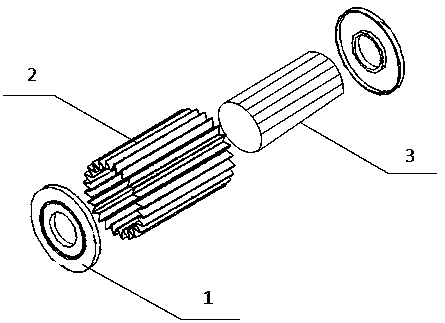

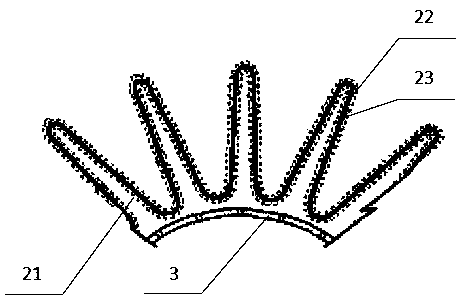

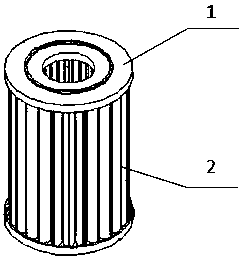

[0011] Such as figure 1 , 2 3. A large flux security filter element provided by the present invention is characterized in that it includes upper and lower end caps 1, an inner support frame 21, a filter medium middle layer 22, an outer fixed frame 23, and an inner sleeve 3. The inner layer support frame 21, the filter medium middle layer 22, and the outer layer fixed frame 23 are tightly fitted together, attached to the inner layer sleeve 3, and fixed on the upper and lower end covers 1 of the filter element by hot-melt bonding, The middle layer 22 of the filter medium is a folded polypropylene material whose density gradually increases from the outside to the inside, and the pores gradually decrease. The shape of the folds of the middle layer 22 is adapted.

[0012] The middle layer 22 of the filter medium of the large-flux security filter element provided by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com