Catalytic oxidation unit for treating tail gas of internal combustion engine as well as preparation method and application thereof

A technology of catalytic oxidation and internal combustion engine, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, mechanical equipment, etc., can solve the problems of not effectively solving low-temperature cold start, and cannot reduce the demand for precious metals, so as to improve low-temperature catalytic activity and avoid Sulfur poisoning, avoiding the effect of excessive back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

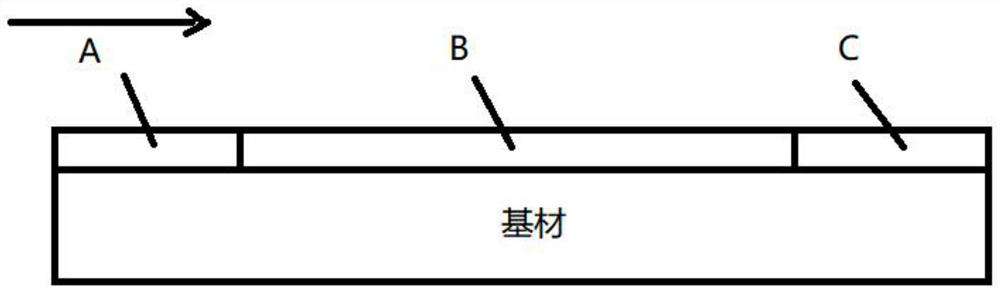

[0064] The method for preparing a catalytic oxidation unit for treating exhaust gas of an internal combustion engine provided by an embodiment of the present invention includes the following steps:

[0065] (1) Prepare the first slurry required for the first coating. The first slurry contains carrier, platinum nitrate and palladium nitrate. The mass ratio of Pd and Pt is controlled to be (1~3):1, and the carrier particle size is 3 ~5μm; use the method of upper feeding or lower feeding to coat the substrate with a length of L for the first time, and the coating depth is the sum of the length of the first coating area and the length of the second coating area L 1 ; After the coating is completed, after drying and calcination, the Pt concentration in the catalyst coating of the first coating area and the second coating area is finally obtained to be 7-22g / cft;

[0066] (2) Prepare the impregnation solution required for impregnation, the impregnation solution contains platinum ion...

Embodiment 1

[0073] In this example, the base material is 400cpsi cordierite, the carrier is alumina, the auxiliary agent is 0.5% cerium oxide, the mass ratio of Pt and Pd in the active component (Pt+Pd) of the whole unit is 2:1, the activity of the whole unit The composition (Pt+Pd) has an average density of 30 g / cft.

[0074] The method for preparing a catalytic oxidation unit for treating exhaust gas of an internal combustion engine provided in this embodiment comprises the following steps:

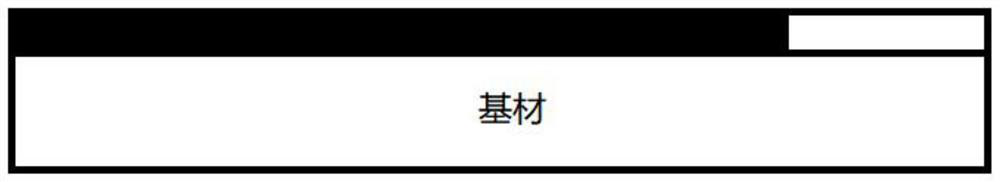

[0075] (1) First coating:

[0076] Preliminarily mix the carrier, additives and binders to prepare a mixed powder; mix deionized water and glacial acetic acid to prepare a dispersant; add the dispersant to the mixed powder to obtain a slurry; add half of the volume of the slurry Zirconium balls are used as the grinding medium, the frequency of the ball mill is set to 40HZ, and the ball mill is stopped after 1 hour to obtain a carrier with a particle size of 3-5 μm; the average particle size of ...

Embodiment 2

[0087] In this example, the base material is 400cpsi cordierite, the carrier is alumina, the auxiliary agent is 0.5% cerium oxide, the mass ratio of Pt and Pd in the active component (Pt+Pd) of the whole unit is 2:1, the activity of the whole unit The composition (Pt+Pd) has an average density of 30 g / cft.

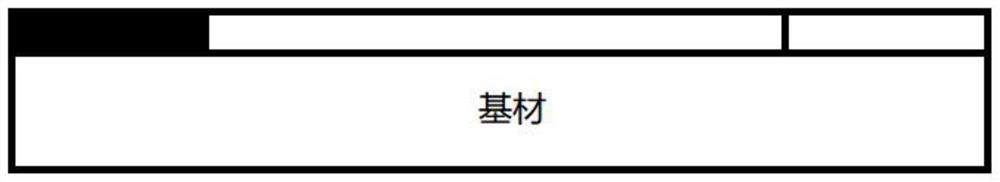

[0088] The preparation method of the catalytic oxidation unit for treating exhaust gas of internal combustion engine provided in this example is basically the same as that of Example 1, except that the first coating area and the second coating area of the catalytic oxidation unit for treating exhaust gas of internal combustion engine provided in this example are The thickest part of the layer area and the third coating area are both 50 μm, and the thinnest part is 25 μm.

[0089] (1) First coating:

[0090] The coating depth is the sum of the lengths of the first coating area and the second coating area, the mass ratio of Pt and Pd in the first slurry is 3:1, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com