A process and device for continuous treatment of high-concentration organic wastewater

An organic wastewater and high-concentration technology, applied in gas treatment, natural water treatment, water/sewage treatment, etc., can solve the problems of limited biological treatment capacity, environmental pollution, flash explosion, etc., to ensure continuous and stable operation, and simple process flow , the effect of reducing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

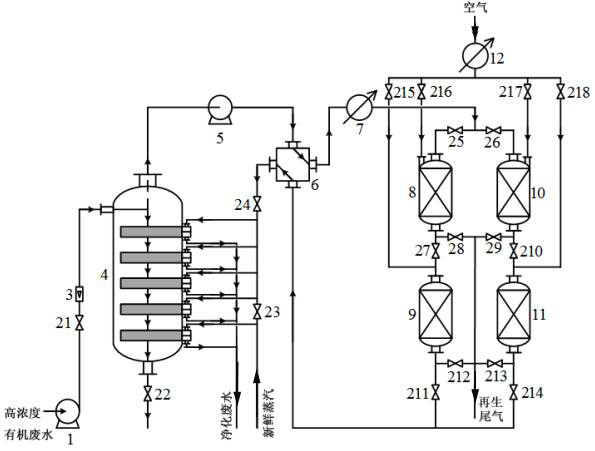

[0039] as per figure 1 The device shown is a process for continuous treatment of high-concentration organic wastewater:

[0040] First all filling zinc oxide desulfurizer in the first desulfurizer 8 and the second desulfurizer 10, and all filling platinum alumina catalyst (its composition is 0.5wt% Pt / al 2 o 3 ).

[0041] The temperature of the first preheater 7, the second preheater 12, the first desulfurizer 8 and the first catalytic burner 9 are all raised to 300°C by electric heating, and fresh water steam is used as the heat source at first. The layer evaporator 4 is heated, and the heat pump 5 is turned on, so that the absolute pressure in the multilayer evaporator 4 is 85 kPa. After the device is stabilized, it is transported by the feed pump 1, and the biodiesel production wastewater enters the multi-layer evaporator 4 through the first valve 21 and the liquid flow meter 3 in turn for evaporation and separation, and generates 95°C waste water steam containing ligh...

Embodiment 2

[0045] as per figure 1 The shown device carries out the process of continuous treatment of high-concentration organic wastewater, and its operation steps are repeated in Example 1, the difference being the following two points:

[0046] 1. The desulfurizers of the first desulfurizer 8 and the second desulfurizer 10 are all replaced with iron oxide desulfurizers;

[0047] 2. Replace the wastewater raw material with grease epoxy reaction wastewater with an initial chemical oxygen demand of about 5000mg / L (that is, wastewater produced after the epoxy reaction of biodiesel, formic acid and hydrogen peroxide), and the rest of the operating steps are the same as in Example 1.

[0048] After treatment, the chemical oxygen demand (COD) of the oil epoxy reaction wastewater can be reduced from the initial 5000mg / L to less than 50 mg / L, and the removal rate can reach more than 99%, reaching the first-class industrial sewage discharge standard; the sulfur in the wastewater The content is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com