Waste heat recovery furnace

A waste heat recovery and cooling cylinder technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as serious air leakage of coolers, loss of sintered ore, and increased power of assembly fans, so as to reduce power consumption and fully heat Exchange, the effect of small power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the waste heat recovery furnace as the present invention will be described based on the drawings.

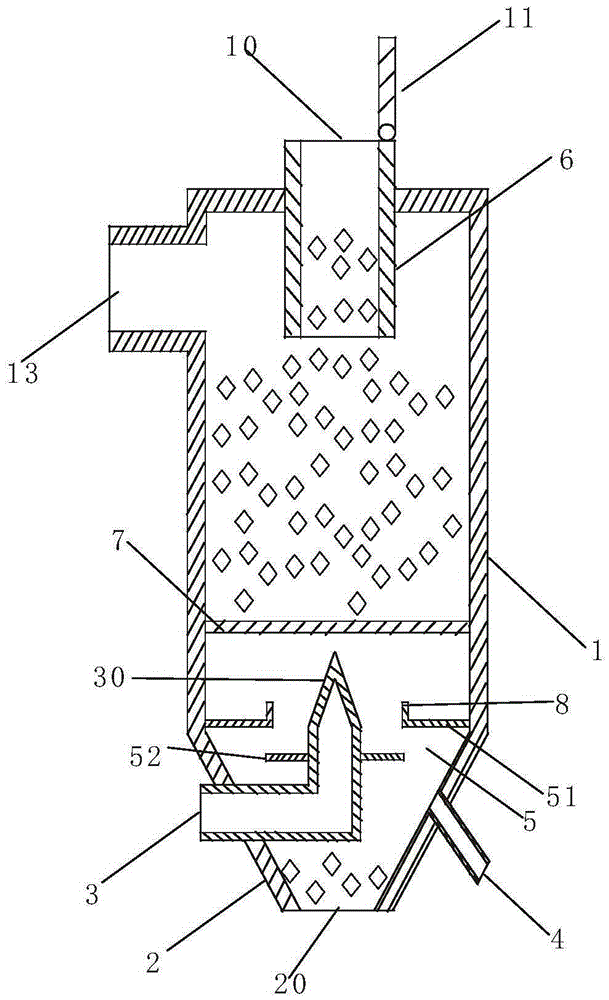

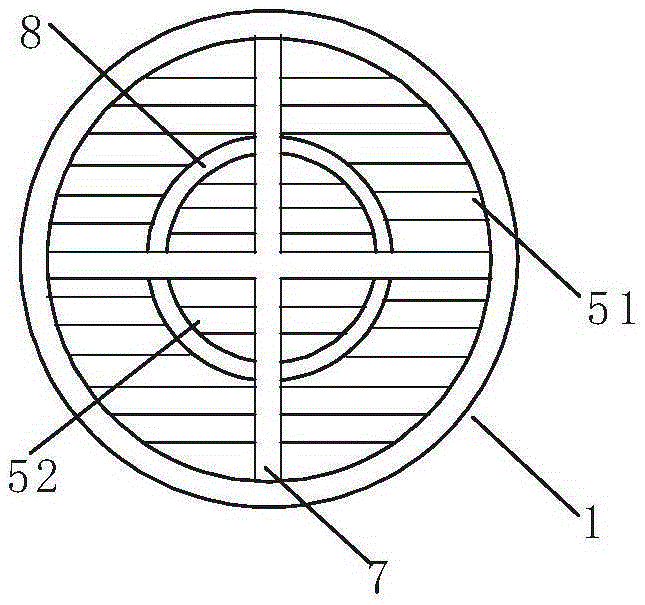

[0027] figure 1 It is a schematic cross-sectional view showing the waste heat recovery furnace of the present invention. figure 2 A schematic plan view showing the discharge mechanism of the waste heat recovery furnace of the present invention.

[0028] Such as figure 1 As shown, the waste heat recovery furnace of the present invention has a cooling cylinder 1, a feed port 10 is provided on the upper surface of the cooling cylinder 1, and a sealing cover 11 that seals the feed port is arranged at the feed port 10. An air outlet 13 is formed on the side wall of the upper end of the cylinder 1, and the air outlet 13 is connected to an induced draft fan (not shown).

[0029] A cone-shaped cold silo 2 is connected to the lower end of the cooling cylinder 1, a discharge port 20 is formed at the lower end of the cold silo 2, and a vibration discharger (not shown) is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com