Film type evaporator for recovering waste heat of semi-coke quenching

A film evaporator and film technology, applied in the field of coal chemical industry, can solve the problems of lack of effective technical measures and treatment devices, multi-site maintenance and labor consumption, discontinuous water spray, etc., and achieve good waste heat recovery effect and good heating effect. , the effect of fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

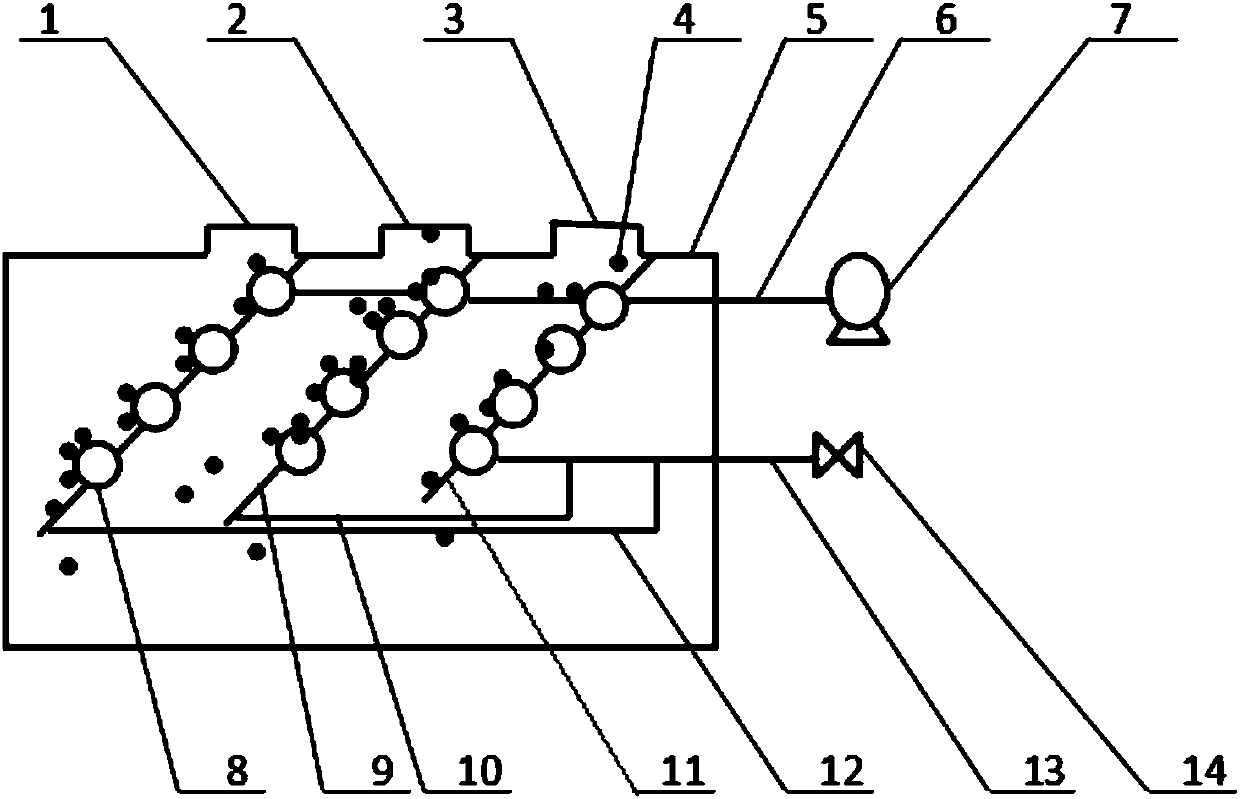

[0018] see figure 1 , the film evaporator disclosed by the present invention for recovering blue coke quenching waste heat includes a coke quenching pool 5, and the top of the coke quenching pool 5 is provided with a coke discharge port I1, a coke discharge port II2 and a coke discharge port III3. The membrane tube I 8, the membrane tube II 9 and the membrane tube III 11 are respectively connected to the lower part. The semi-coke 4 falls into the coke quenching tank from the coke discharge port I1, the coke discharge port II 2 and the coke discharge port III 3 along the membrane tube I 8, membrane tube II 9 and membrane tube III 11 below it respectively. 5 in. A water inlet pipe 6 is connected to the tops of the membrane pipe I8, the membrane pipe II 9 and the membrane pipe III 11, and its inlet is connected with the water pump 7. The steam pipe I 12 is connected un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com