Cooling structure for settling chamber top of electric furnace and manufacturing method of cooling structure

A technology of cooling structure and manufacturing method, which is applied in the direction of furnace cooling devices, etc., can solve the problems of large environmental pollution, large heat loss, and agglomeration of dust bag, and achieve the effects of protecting the environment, reducing heat loss, and reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

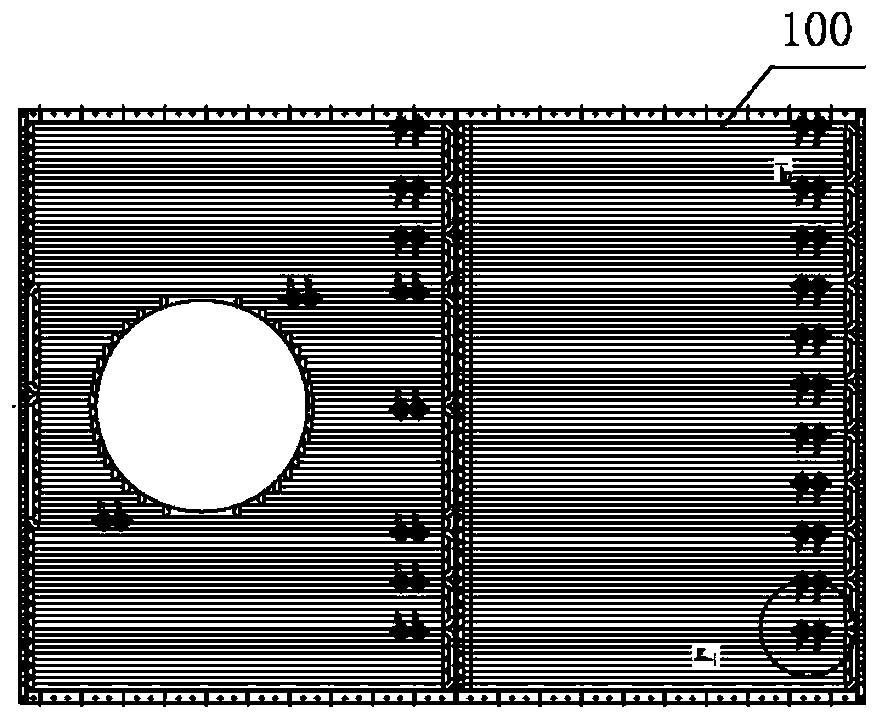

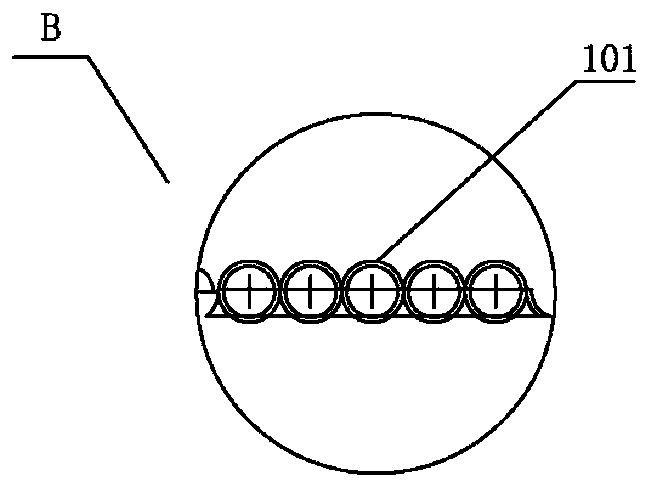

[0026] refer to figure 1 It is a preferred embodiment of the present invention, and the cooling structure of the roof of the electric furnace settling chamber includes a water cooling plate 200 on the roof of the settling chamber and a plurality of rivets fixedly connected to the bottom surface of the water cooling plate on the roof of the settling chamber. The space is fixed and connected as a whole by a diamond-shaped steel mesh 203, and at the same time, the rivets and the diamond-shaped steel mesh are covered with a heat-insulating coating 205.

[0027] As one of the preferred solutions, the rivet adopts a V-shaped rivet 204, which is welded and fixed on the bottom surface of the water-cooled plate on the top of the settling chamber.

[0028] As one of the preferred solutions, the rivet is welded and fixed with the diamond-shaped steel mesh to form a whole.

[0029] As one of the preferred solutions, the thickness of the diamond-shaped expanded metal is more than 6 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com