Gasification device for solid fuel and method for producing synthetic gas

A technology of solid fuel and gasification device, which is applied in the manufacture of combustible gas, combined combustion mitigation, petroleum industry, etc., and can solve problems such as heat loss, large water consumption, and hidden dangers of continuous operation of waste heat boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

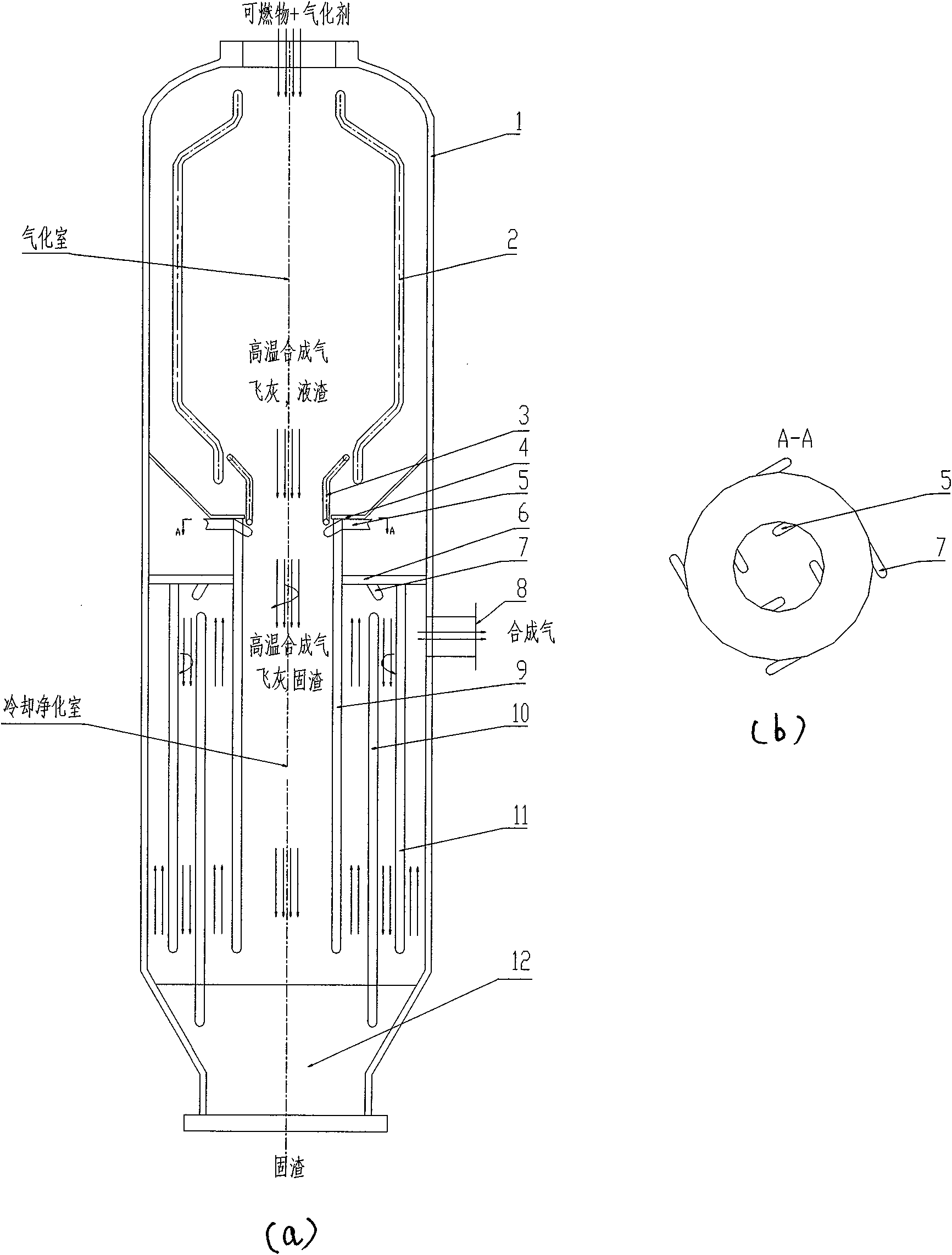

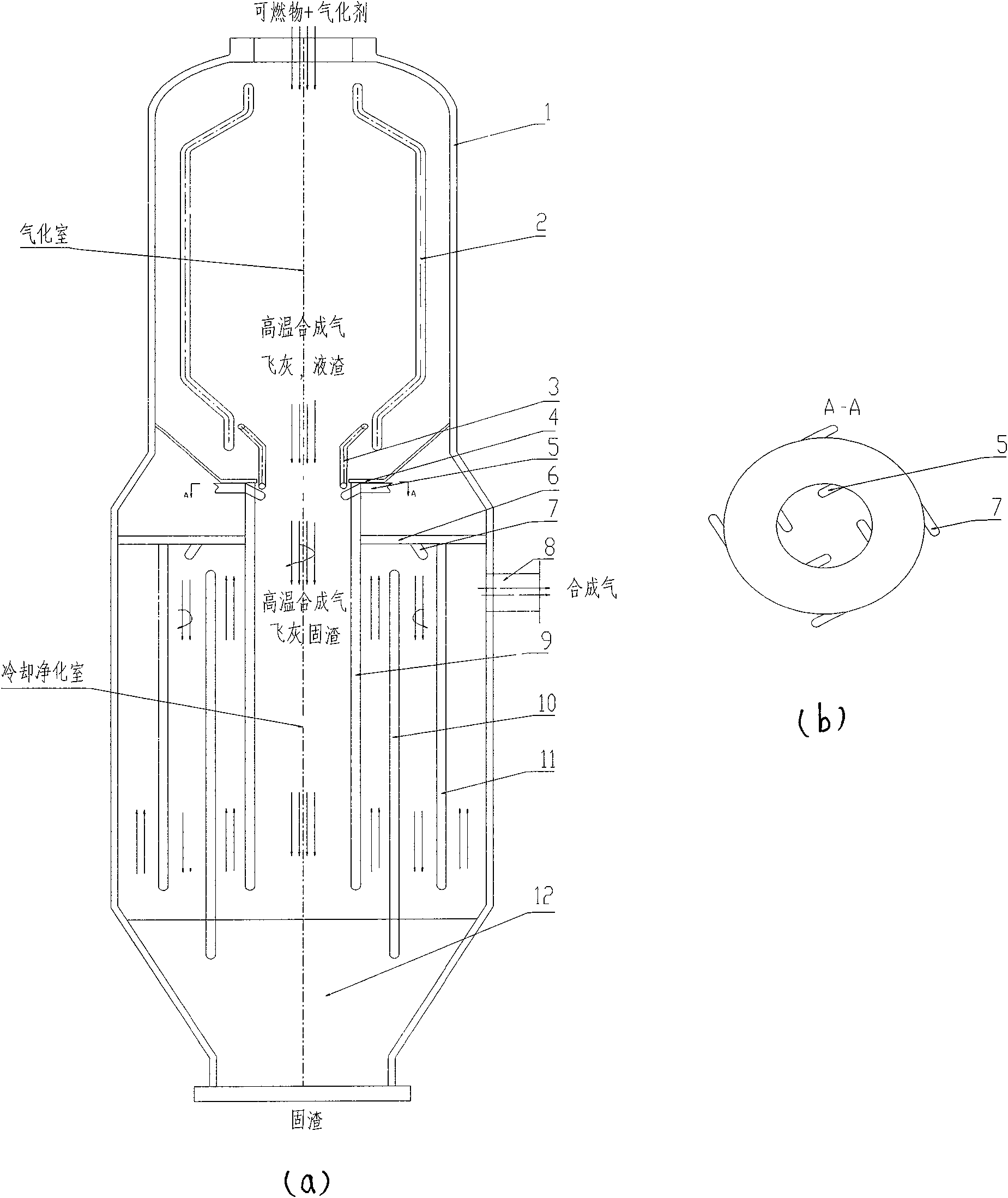

[0027] The principle of the present invention and preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0028] The basic principle of the present invention is: inject combustibles (such as pulverized coal) and gasification agents (such as air, oxygen and other oxidants) into the gasification zone through the burner, and control the ratio of combustibles and gasification agents so that both Under the conditions of high temperature and high pressure in the gasification zone (temperature 1200℃~2000℃, pressure 2Mpa~10Mpa), a rapid and incomplete reaction occurs, and the high-temperature synthesis gas (mainly composed of carbon monoxide and hydrogen), liquid slag and fly ash (mainly The composition is inorganic salt) flows down through the slag outlet.

[0029] The pulverized coal and gasification agent enter the gasification chamber through the inlet of the gasification chamber on the upper part of the shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com