Two-section gasifying device of entrained-flow bed and gasifying method of two-section gasifying device

A technology of gasification device and entrained bed, which is applied in two-stage entrained bed gasification device and its gasification field, can solve the problems of carbon conversion rate, temperature distribution and unreasonable flow field of liquid slag discharge, and achieve the goal of using Long service life, reasonable temperature field distribution in the furnace, and the effect of improving the carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

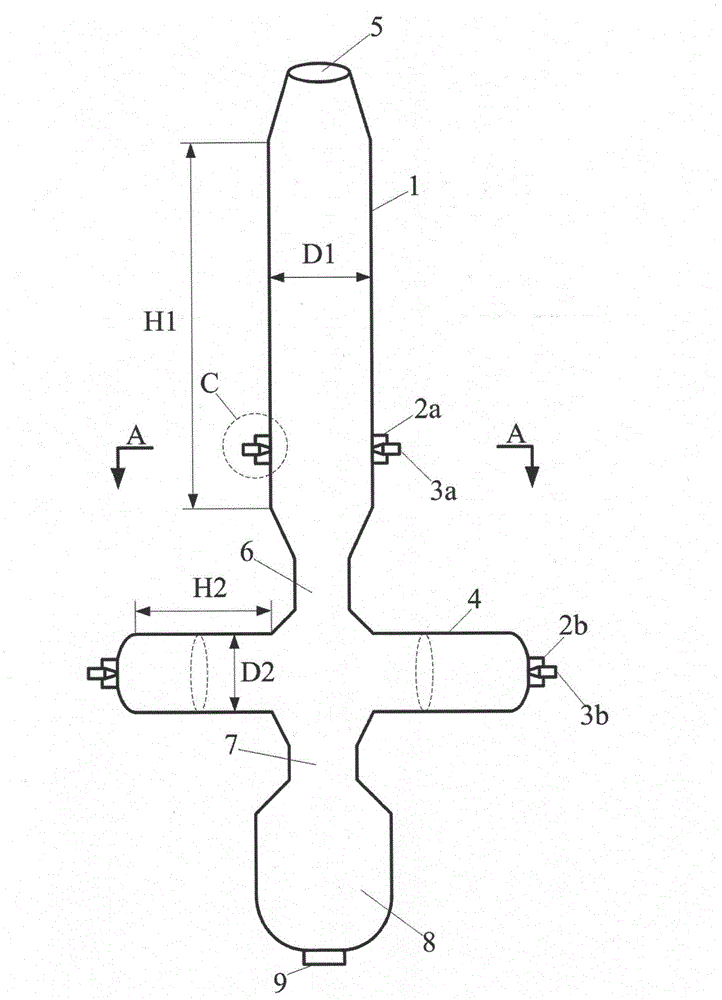

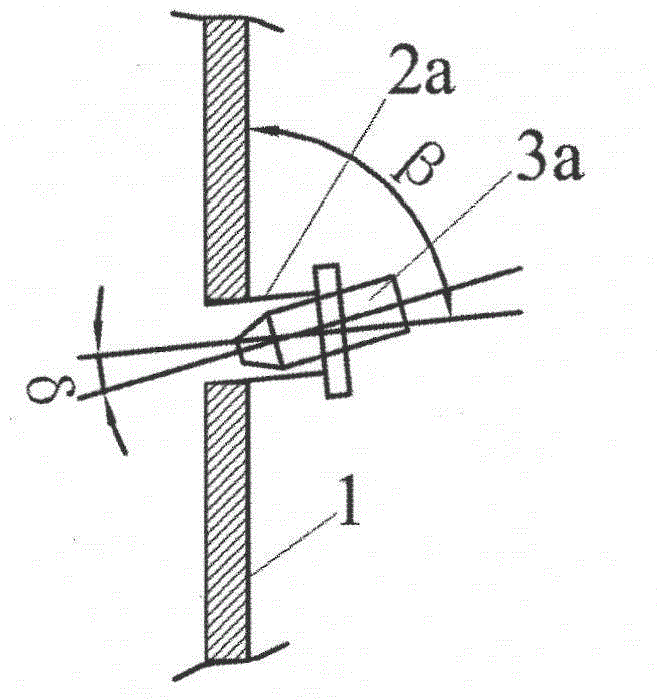

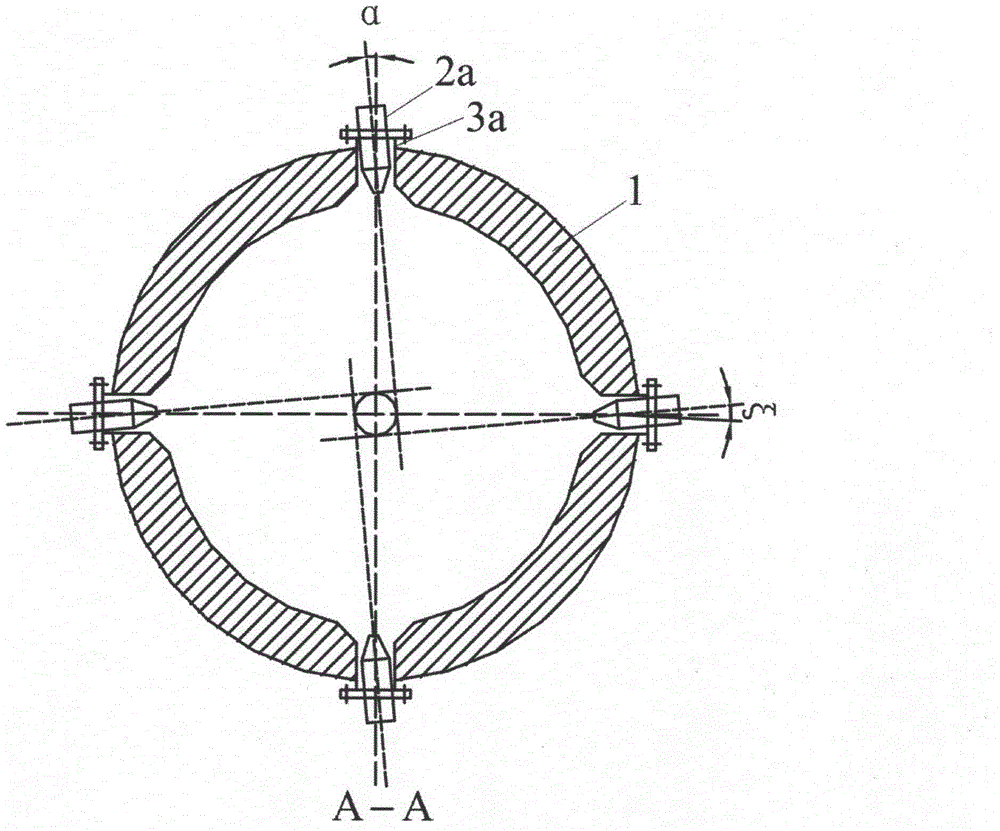

[0052] A two-stage entrained dry coal gasification furnace with a daily coal processing capacity of 3,000 tons. The gasification pressure is 4.0 MPa. The inner wall is a water-cooled wall structure. Four small tangential circles are arranged on the side of gasification chamber 1 in the upper section of the gasification furnace. The side process burner 3a has a tangent angle of 4.5°, and the gasification chamber 4 in the lower section of the gasifier is provided with two opposed process burners 3b. Let the inner diameter of the main body of gasification chamber 1 in the upper part of the gasifier be D 1 , the main size parameters of the gasifier are shown in Table 1:

[0053] Table 1 Main dimension parameters of gasifier

[0054] parameters

value

parameters

value

Inner diameter of synthesis gas outlet 5

0.32D 1 (m)

α

4.5(°)

Inner diameter of side process burner chamber 2a

0.4D 1 (m)

ξ

0(°)

Distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com