Crucible cover for large size sapphire single crystal growth furnace

A sapphire and growth furnace technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as atomic vacancies cannot be eliminated, adverse effects on crystal quality, etc., achieve obvious social and economic benefits, and reasonable temperature field distribution , the effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

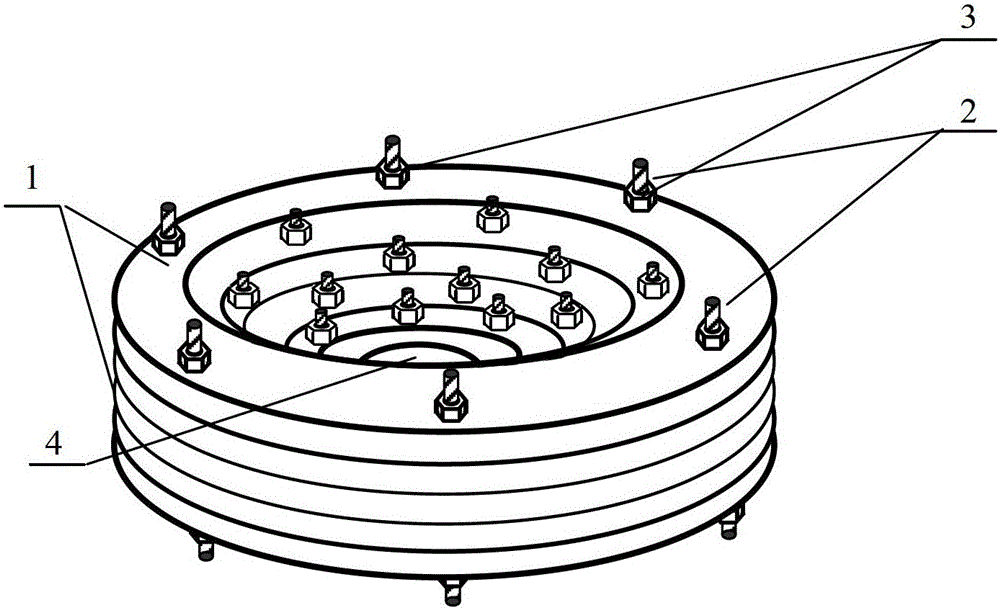

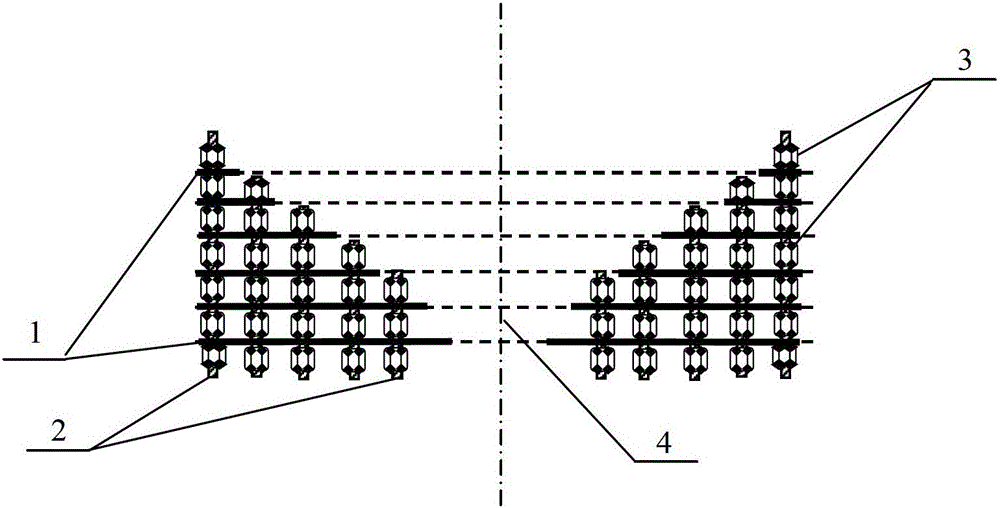

[0024] combine Figure 1-2 , In this embodiment, the crucible cover is made of a circular multilayer molybdenum sheet 1, and the multilayer molybdenum sheet 1 has a circular central hole 4, and the diameter of the central hole gradually decreases from top to bottom. One room of multilayer molybdenum sheets is connected and fixed by molybdenum bolts 2 and matching molybdenum nuts 3 , and one room of multilayer molybdenum sheets is separated by molybdenum nuts 3 . The outer diameter of the molybdenum sheet is 320mm, the inner diameter of the uppermost molybdenum sheet is 260mm, and the inner diameter of each layer of molybdenum sheets is 16mm smaller than that of the previous layer; the thickness of the top two layers of molybdenum sheets is 2mm, and the thickness of the bottom two layers of molybdenum sheets is 4mm. The thickness of the middle 4 laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com