A gasification nozzle

A nozzle and nozzle technology, applied in granular/powder fuel gasification, injection device, liquid injection device, etc., can solve the problems of high volatile content, inability to obtain gasification effect, short service life, etc., to improve the effective gas content, improve the effect of premix atomization, improve the effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

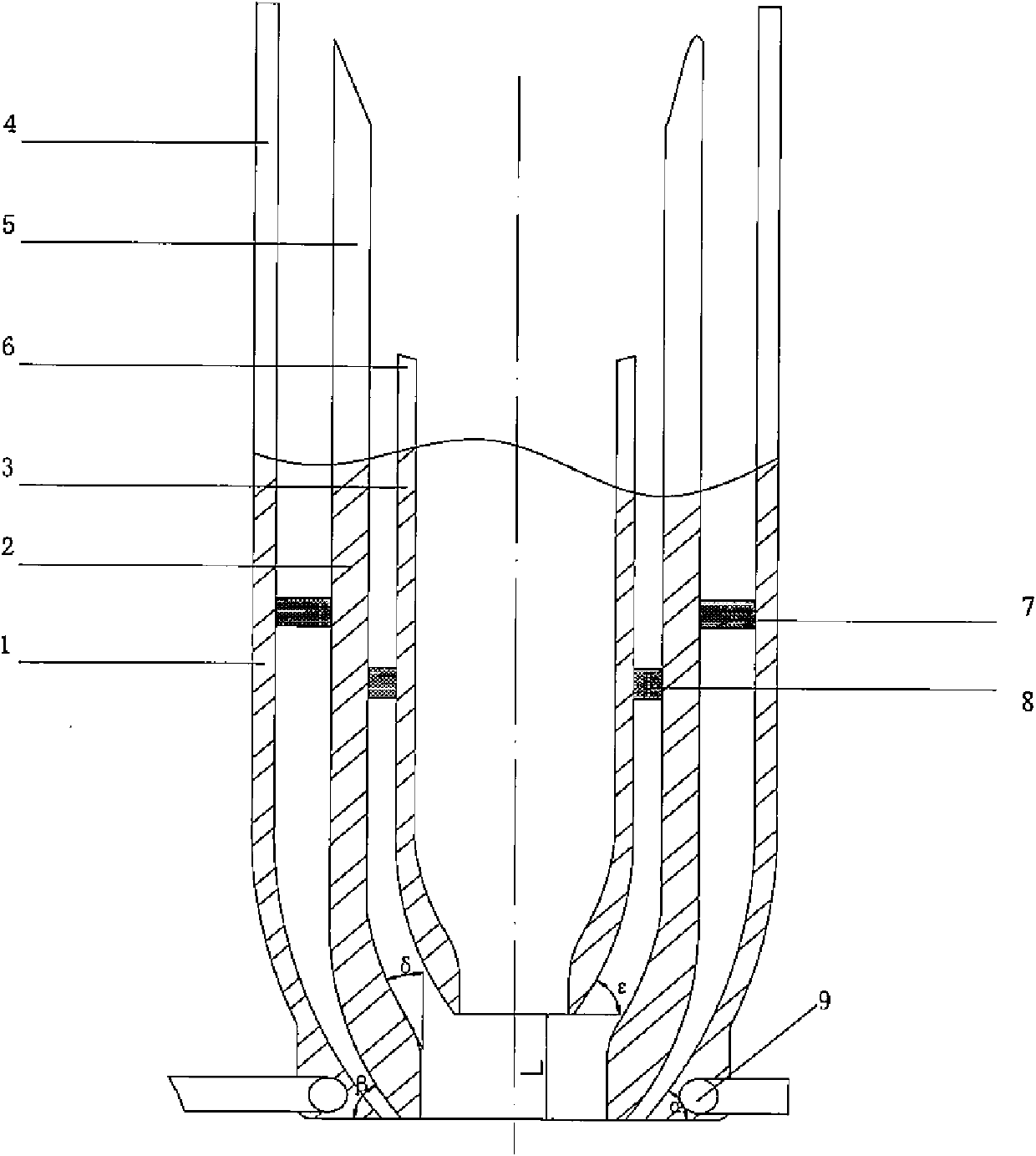

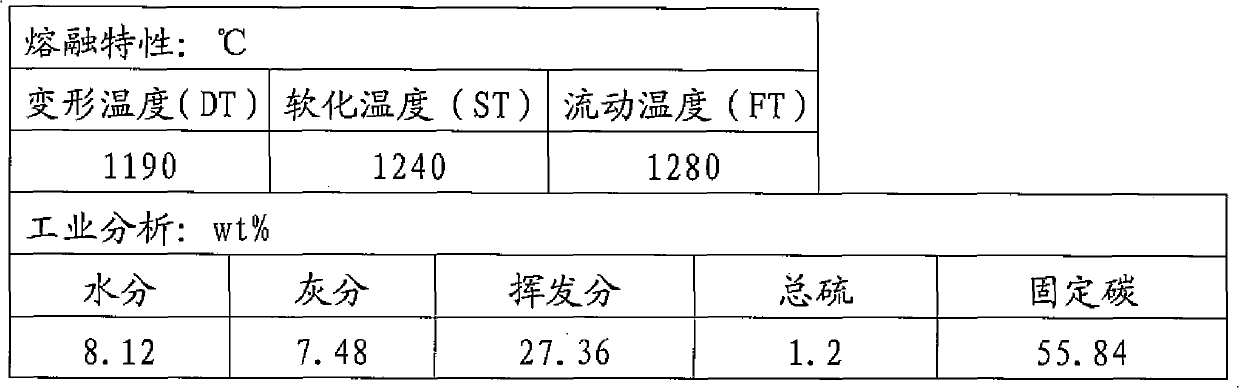

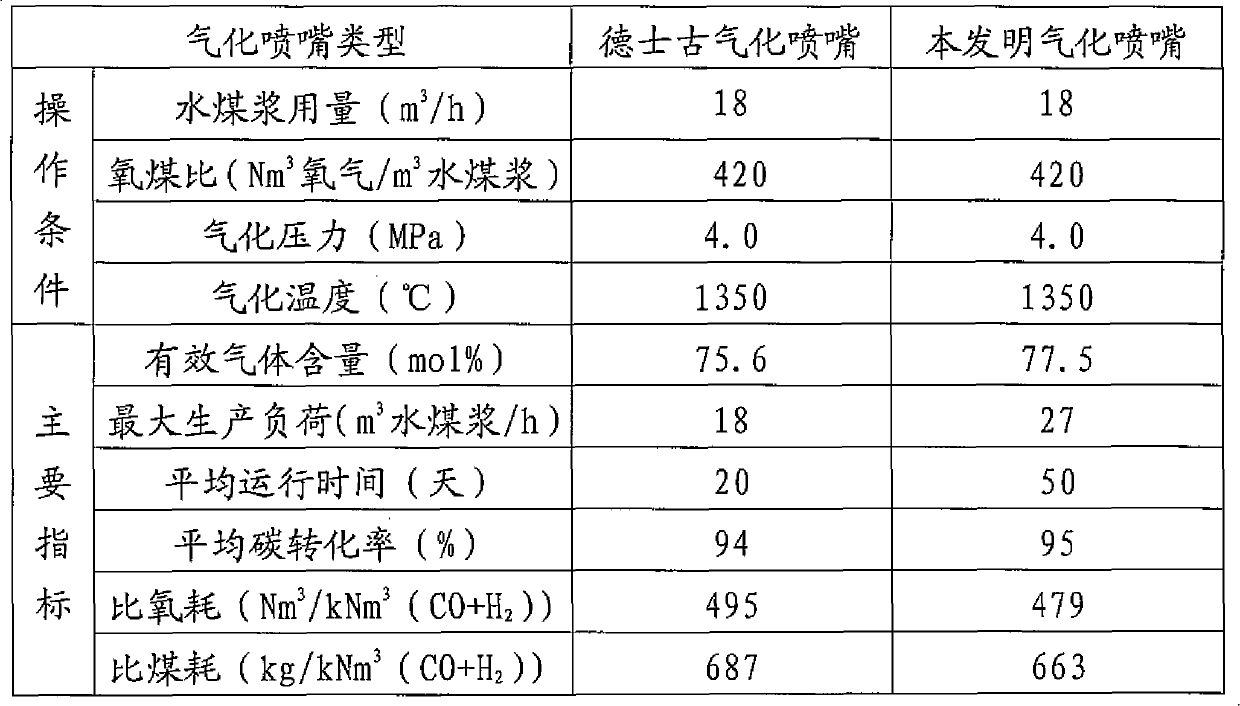

[0035] respectively will be as figure 1The shown gasification nozzle of the present invention and the Texaco three-channel gasification nozzle imported from Shougang Company are set in the same coal-water slurry gasification furnace, and lignite produced in the Ningdong area of Ningxia with a calorific value of about 20kJ / kg is used. As raw coal for gasification, it is pulverized into pulverized coal less than 10mm, and together with process water (accounting for 43wt% of the total weight of the coal-water slurry) and commercially available compound type coal-water slurry additive NDF (accounting for the total weight of the coal-water slurry 1wt%) into a ball mill to be ground into a certain particle size distribution with a mass percentage of 56wt% and a viscosity of 1100mPa·s coal-water slurry, which is introduced into the coal-water slurry gasifier through the above two gasification nozzles under the same operating conditions production of syngas. The physical property d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com