Patents

Literature

39results about How to "High effective gas content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing gas-based directly reduced iron by utilizing non-catalytic conversion of coke-oven gas, and system thereof

ActiveCN103525965AAvoid inactivationGuaranteed uptimeShaft furnaceProcess efficiency improvementWater vaporEngineering

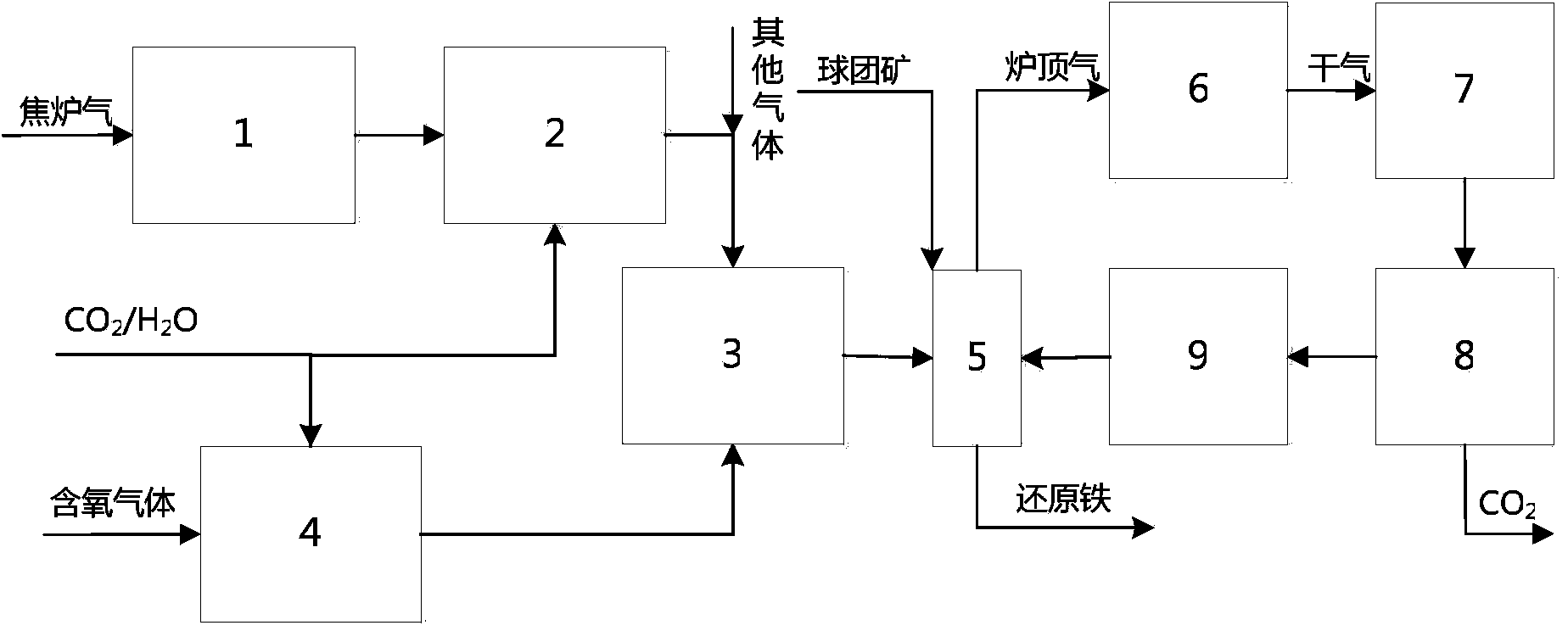

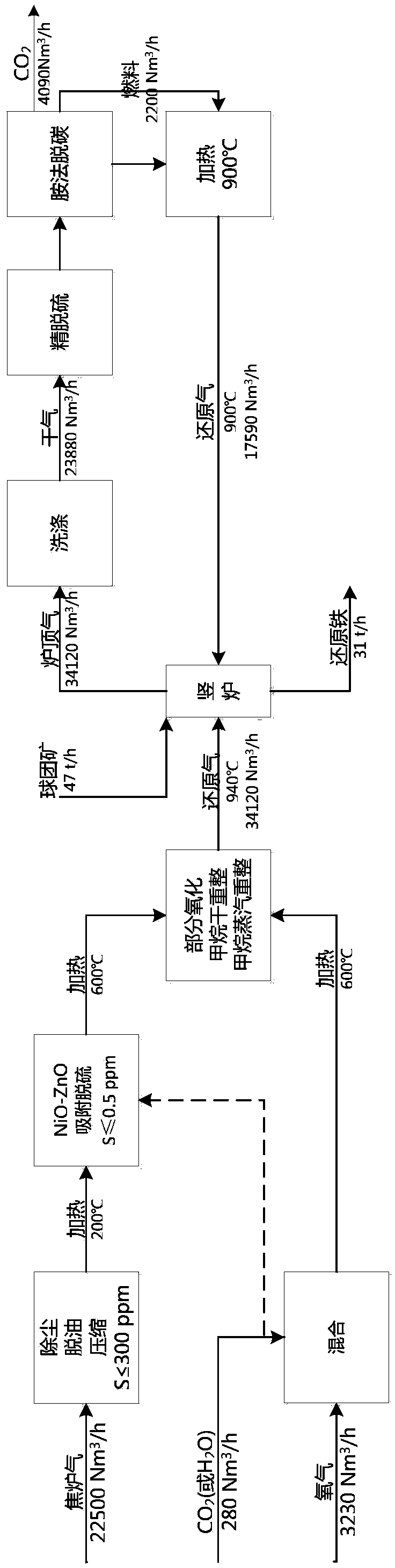

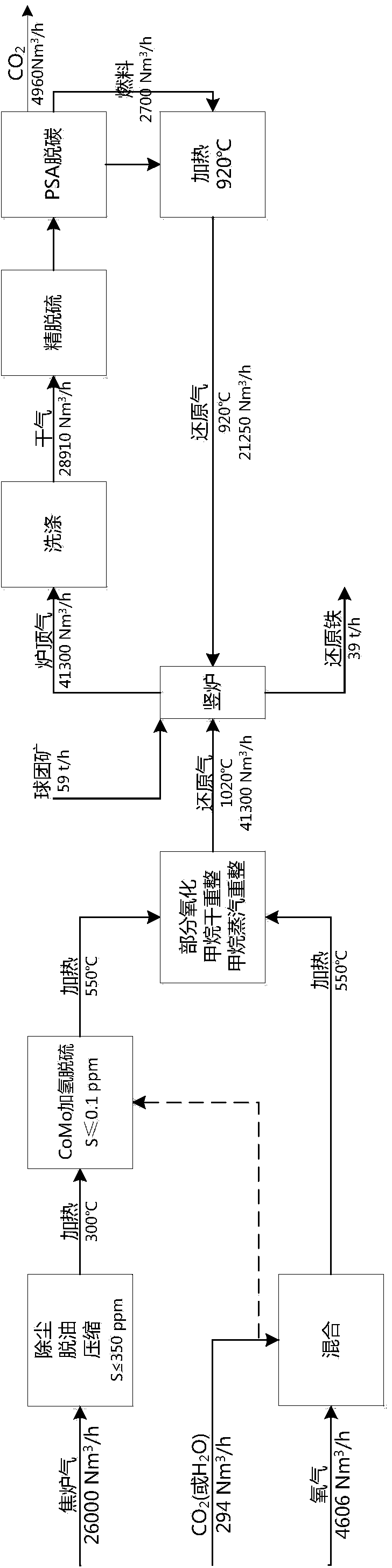

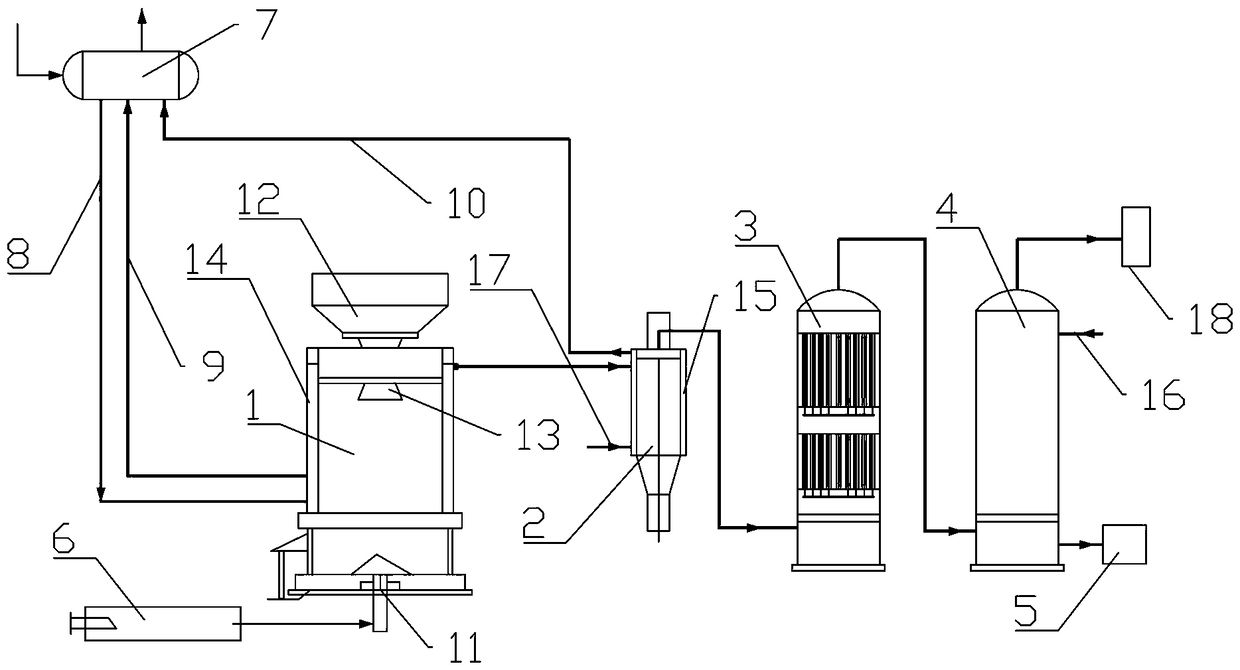

The invention relates to a method for producing gas-based directly reduced iron by utilizing the non-catalytic conversion of a coke-oven gas, and a system thereof. The method comprises the following steps: mixing the coke-oven gas obtained after routine purification and fine desulfurization treatment with a mixed gas comprising one or above two of a converter gas, a blast furnace gas and a purified tail gas to form a raw material gas mixture, and partially combusting the raw material gas mixture and an oxygen-containing gas at a converter burner outlet at a controlled flame temperature of 1100-2300DEG C for the conversion of hydrocarbons in the coke-oven gas and carbon dioxide or water vapor to generate a synthetic gas containing H2 and CO; and allowing the synthetic gas containing H2 and CO to enter a shaft furnace and reduce iron oxide in order to produce reduced iron, and cooling, washing, decarburizing, desulphurizing and purifying a reduced tail gas discharged from a shaft furnace to obtain a purified tail gas. The invention also provides a system for producing the gas-based directly reduced iron by utilizing the non-catalytic conversion of the coke-oven gas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

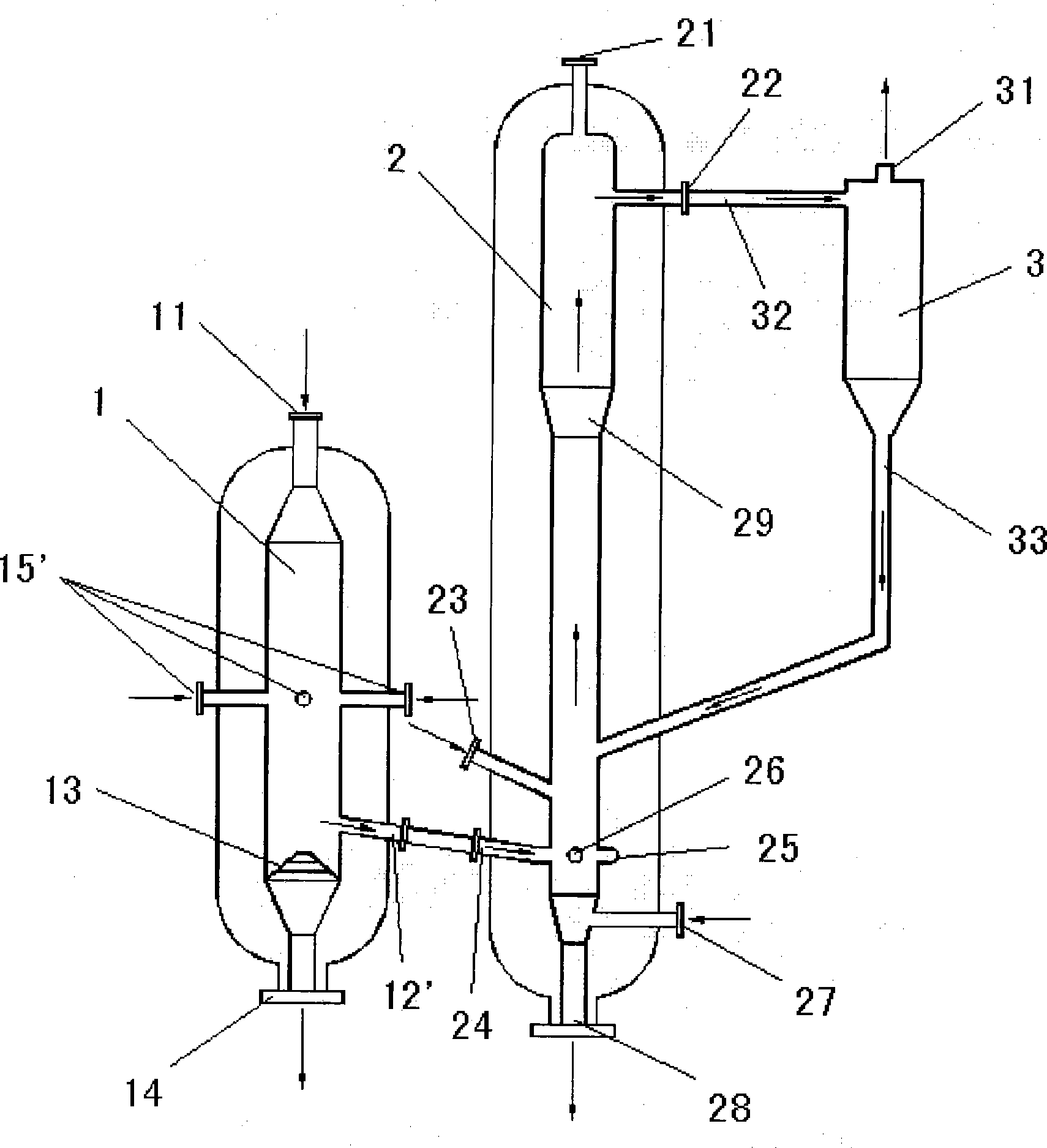

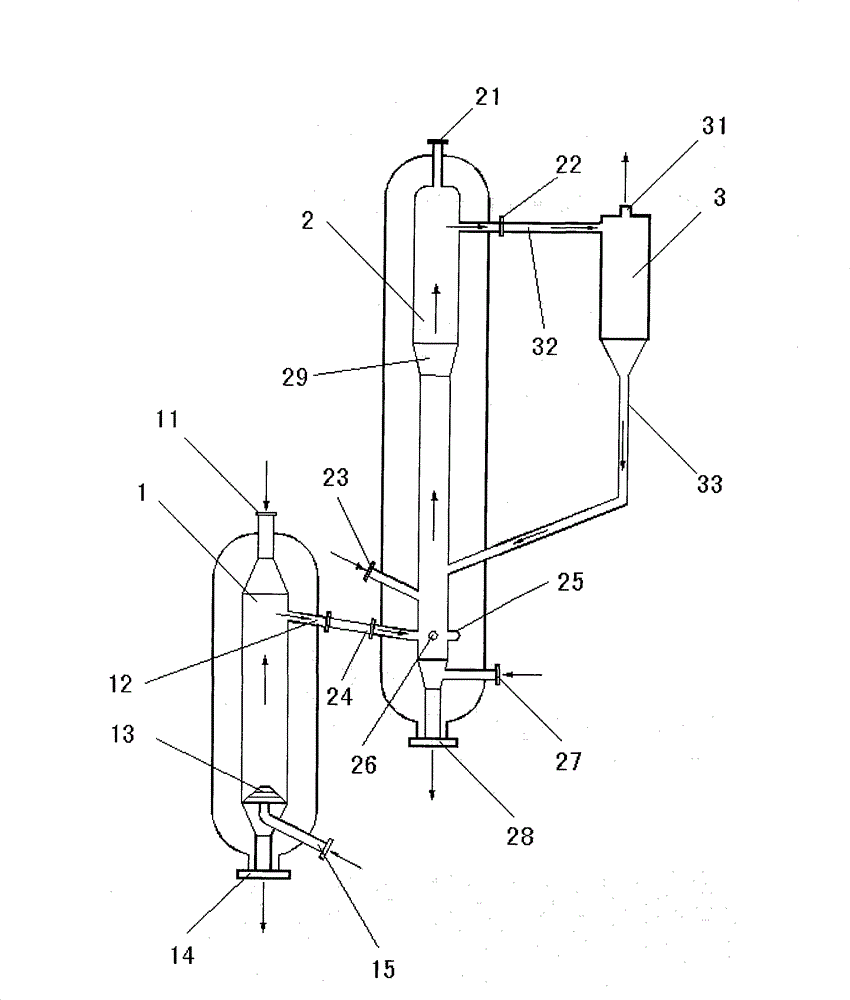

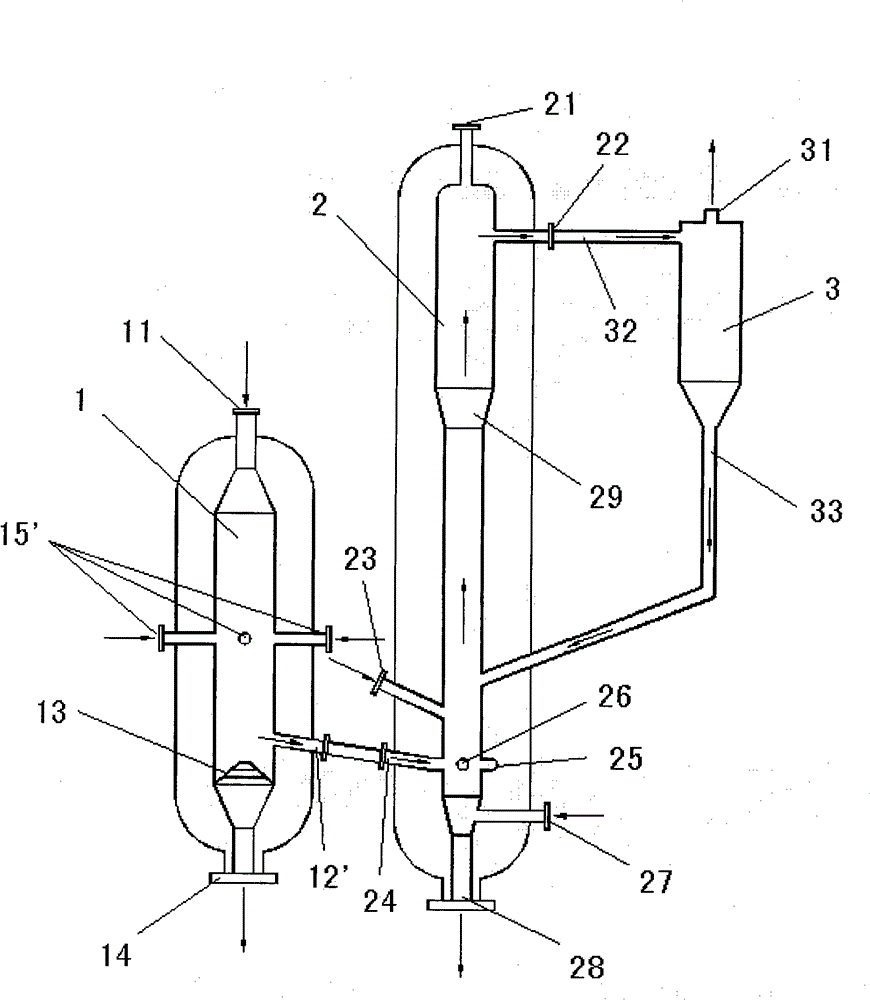

Fixed bed-fluidized bed serially connected gasification method and apparatus

ActiveCN101440308AReduce tar contentEmission reductionCombined combustion mitigationCombustible gas productionFluidized bed gasifierFluidized bed

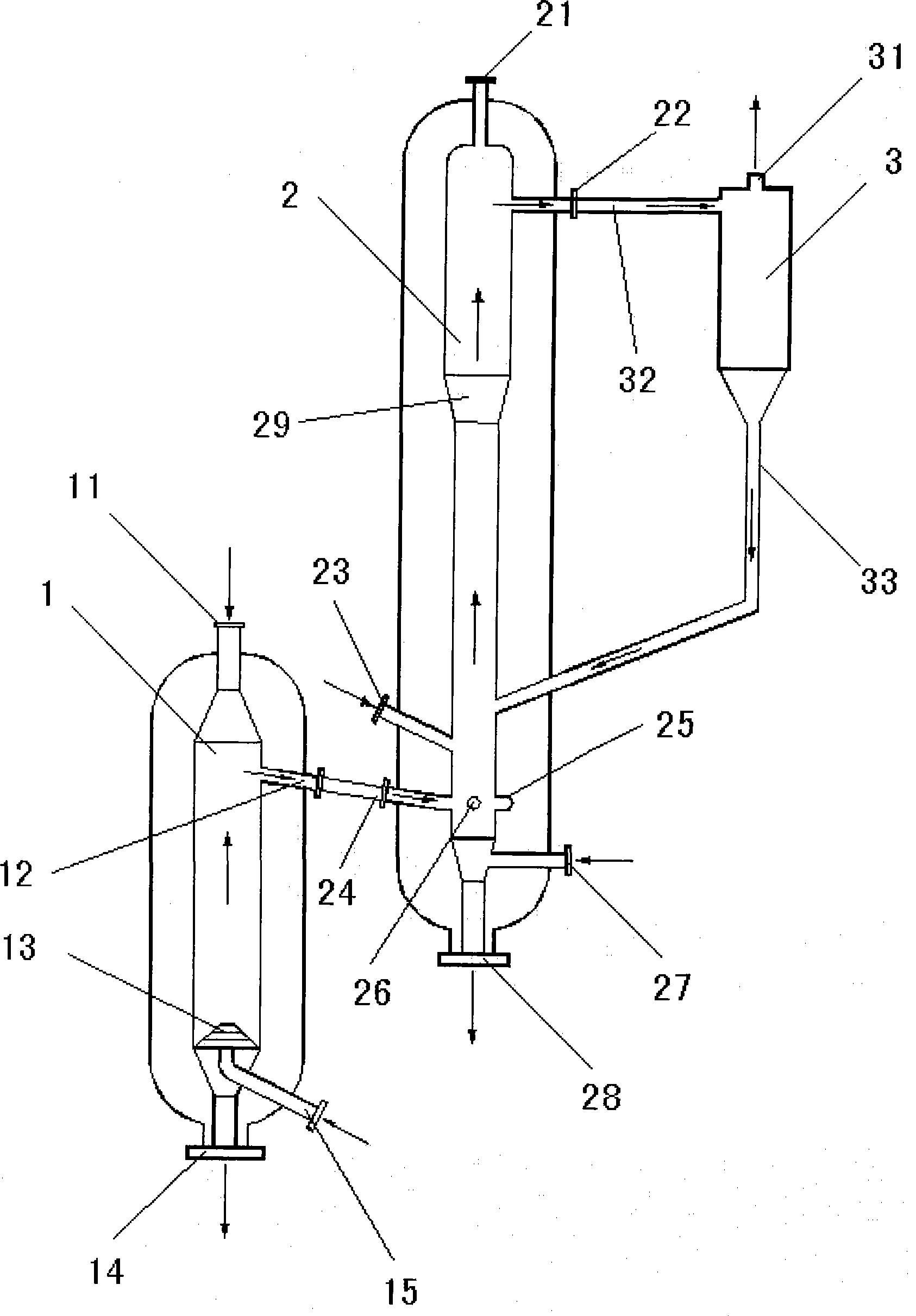

The invention relates to a method and a device for gasification, in particular to the method and the device for serial gasification of a fixed bed and a fluidized bed, wherein the method comprises the following steps: 1) feeding a gasification raw material with the particle size of between 13 and 50 millimeters and a gasification agent to a fixed bed gasifier to perform gasification reaction so as to generate coal gas and ash content, discharging the ash content from an ash discharging opening of the fixed bed, and introducing the coal gas to the lower part of a dense phase zone of a fluidized bed gasifier; 2) feeding a thin particle shapeed coal gasification raw material with the particle size of between 0.5 and 8 millimeters and the gasification agent into a fluidized bed gasifier to perform gasification reaction with the vertically raising coal gas so as to generate the coal and the ash content, discharging the ash content from the ash discharging opening of the fluidized bed, and introducing the coal gas into a cyclone separator; and 3) performing gas-solid separation on the coal gas in the cyclone separator, outputting the coal gas from a coal gas outlet of the cyclone separator, and sending back solid particles carried by the coal gas to the fluidized bed gasifier through a dipleg of the cyclone separator to perform the gasification reaction continuously. The method and the device have quite important significance on improving the economic benefit and reducing the sewage treatment cost for the medium and small-sized coal chemical enterprises in China.

Owner:CCTEG CHINA COAL RES INST

Method for two-stage coal gasification on composite external heat fixed bed and gas furnace

InactiveCN102146301AHigh economic valueReduce manufacturing costEnergy inputCombustible gas productionFixed bedProcess engineering

The invention discloses a method for two-stage coal gasification on a composite externally heated fixed bed and a gas furnace. In the method, by using more than two kinds of external heat for the dry distillation of raw material coal in a dry distillation stage of a two-stage gas furnace, the coal gas in a gasification stage and the coal gas in the dry distillation stage can be utilized efficiently by adopting different simple purification measures respectively, gas generation is performed by a continuous gas generation method and a circulating gas generation method, chemical synthetic raw material gases meeting different component requirements can be produced by using different oxidizers and gasifying agents, and at the same time, tar with high economic value is extract from a raw material soft coal. The method and the gas furnace have the advantages of small investment, simple operation, environmental friendliness, high comprehensive coal gasification efficiency and low gas generation cost, and are suitable for constructing or reconstructing fixed bed gas generation furnaces which operates widely at present.

Owner:王子国

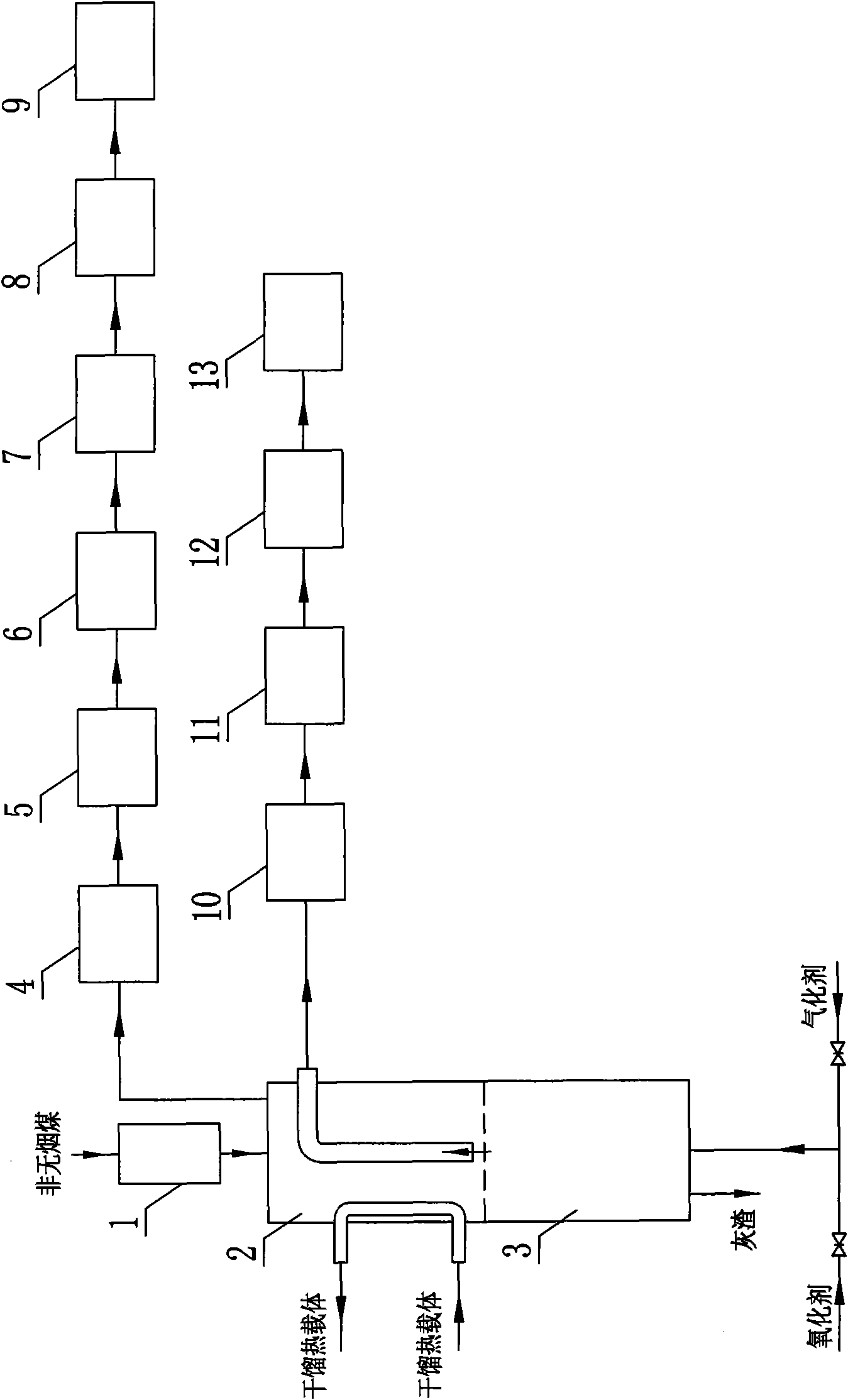

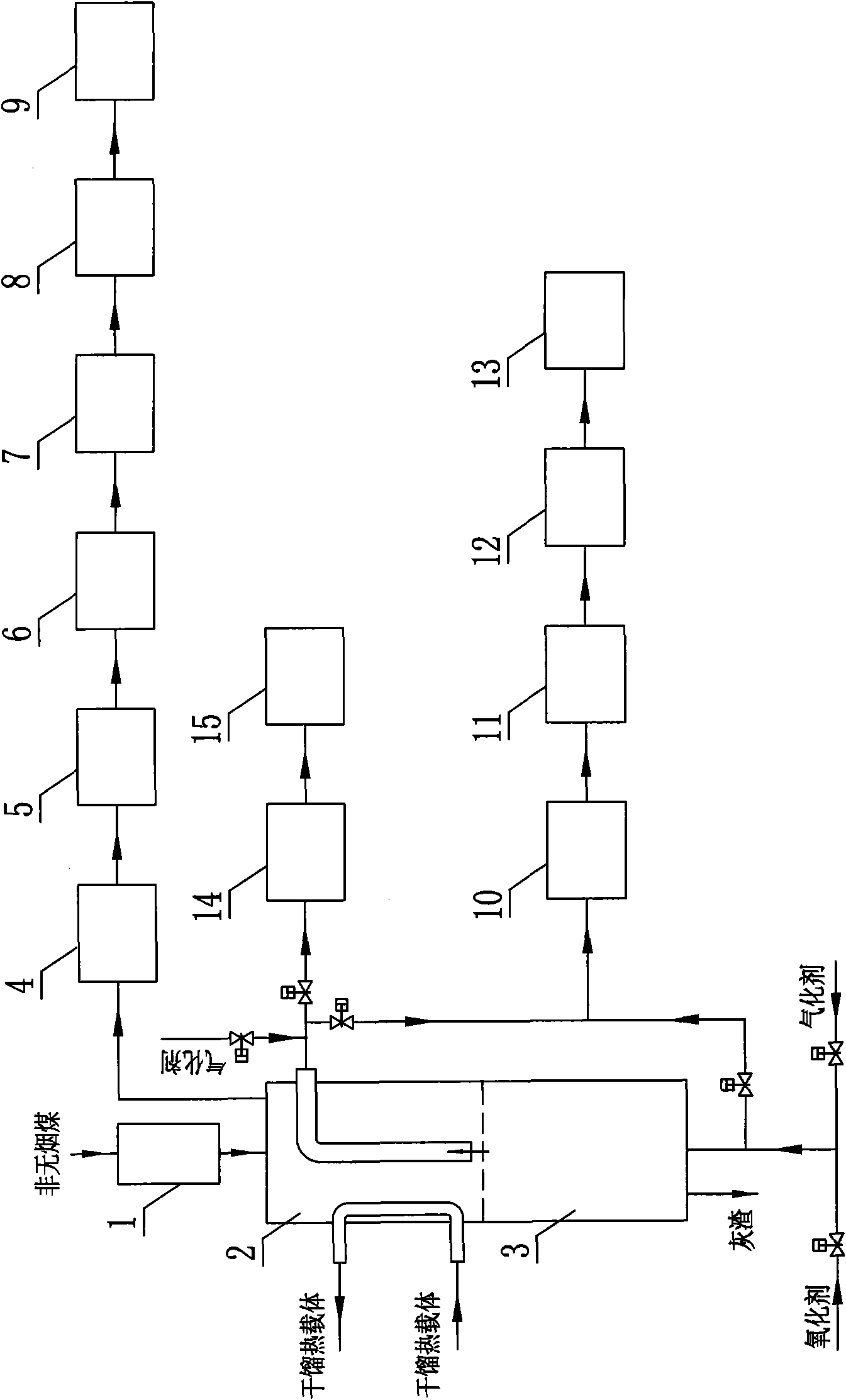

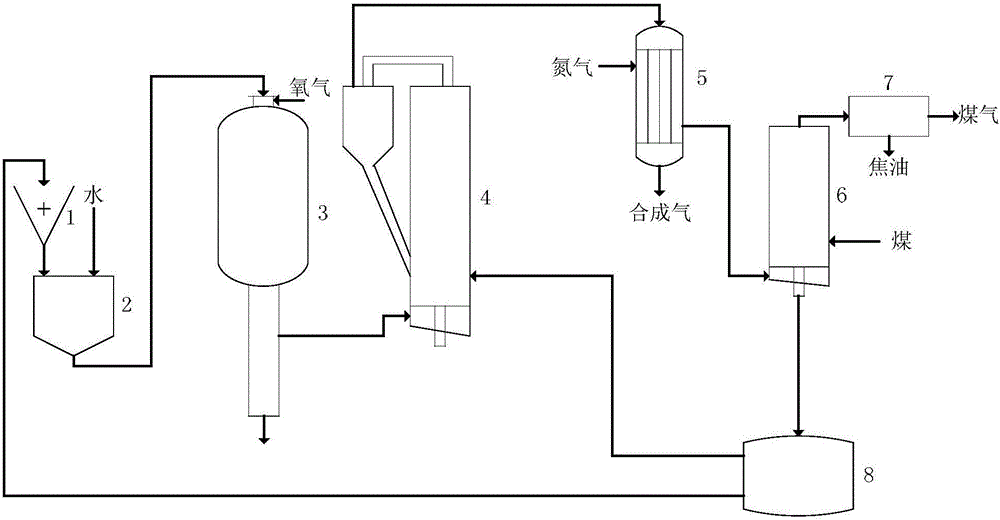

Coupling technology adopting lignite-gasification gas production and dry distillation upgrading

InactiveCN105505467AReduce total usageImprove utilization efficiencyDirect heating destructive distillationEnergy inputSyngasGas composition

The invention provides a coupling technology adopting lignite-gasification gas production and dry distillation upgrading. A coal gasification device and a coal-produced semi-coke dry distillation device are connected in series for use, high-temperature synthesis gas produced from coal after gasification in a gasification furnace directly enters a dry distillation furnace, is taken as a dry distillation heat-carrying gas and is sufficiently contacted with the coal in the dry distillation furnace, H2O and CO2 in the synthesis gas are contacted with a hot carbon material for further reaction, effective gas composition in the synthesis gas is increased, and a semi-coke product, coal tar and dry distillation gas are obtained through pyrolysis and dry distillation upgrading of the coal. The semi-coke product is collected from the bottom of the dry distillation furnace, a mixture of the coal tar, the dry distillation gas and the synthesis gas is collected from the top of the dry distillation furnace, and a coal tar product and a synthesis gas product are obtained through cooling separation. Compared with a simple lignite-gasification gas production technology, the effective gas composition of the produced synthesis gas is higher, the CO2 emission proportion of a traditional coal gasification technology can be reduced, the heat of the whole technological procedure is sufficiently utilized, additional heat input is not required for semi-coke production through dry distillation of the coal, and the energy utilization efficiency is high.

Owner:CHINA TIANCHEN ENG +1

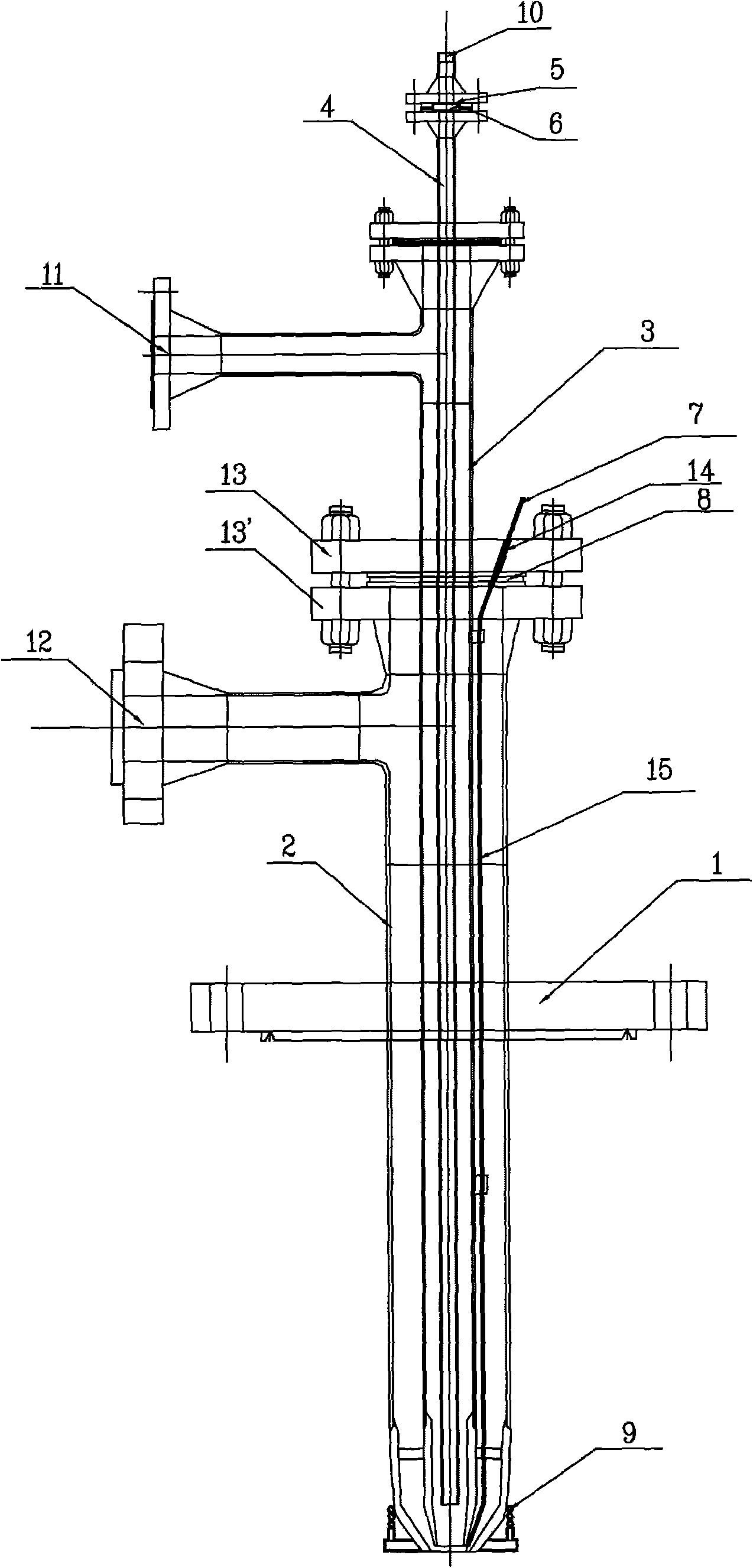

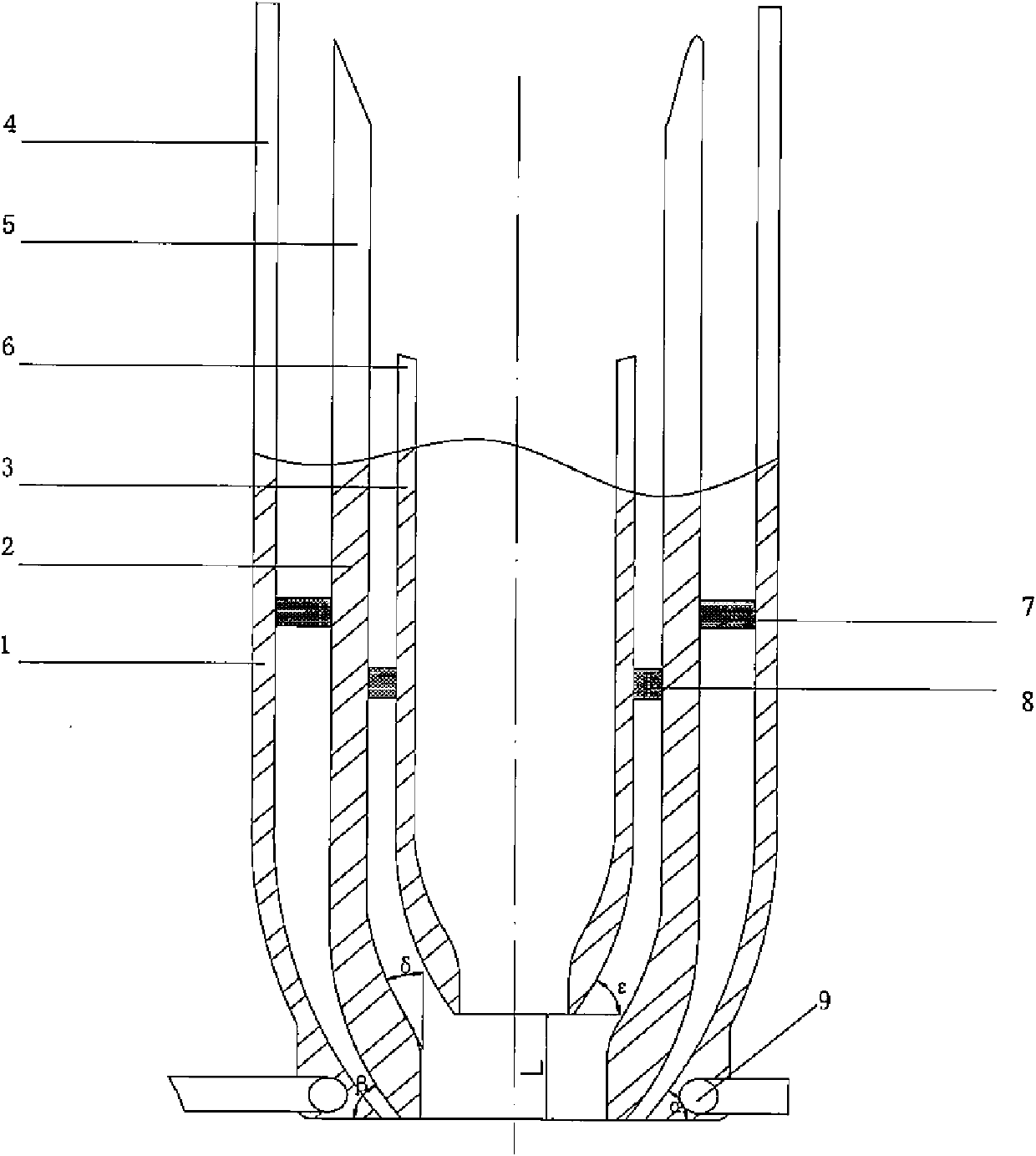

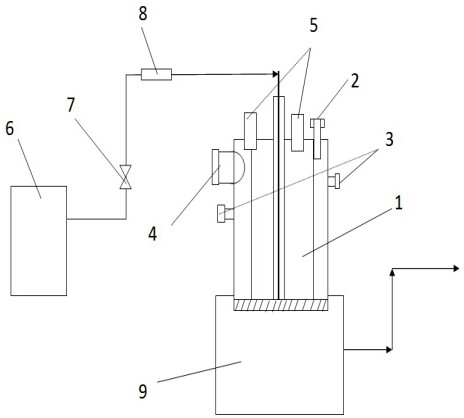

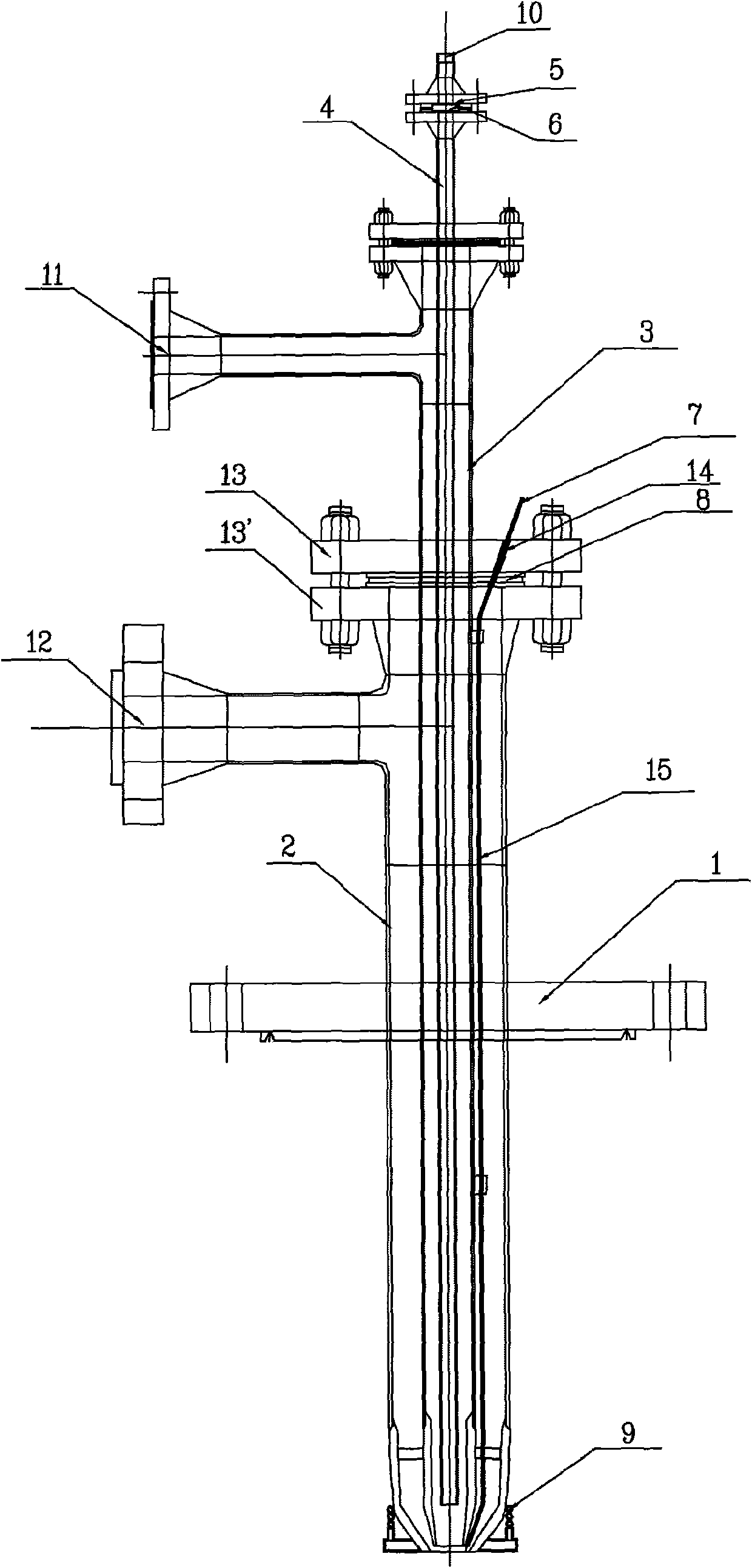

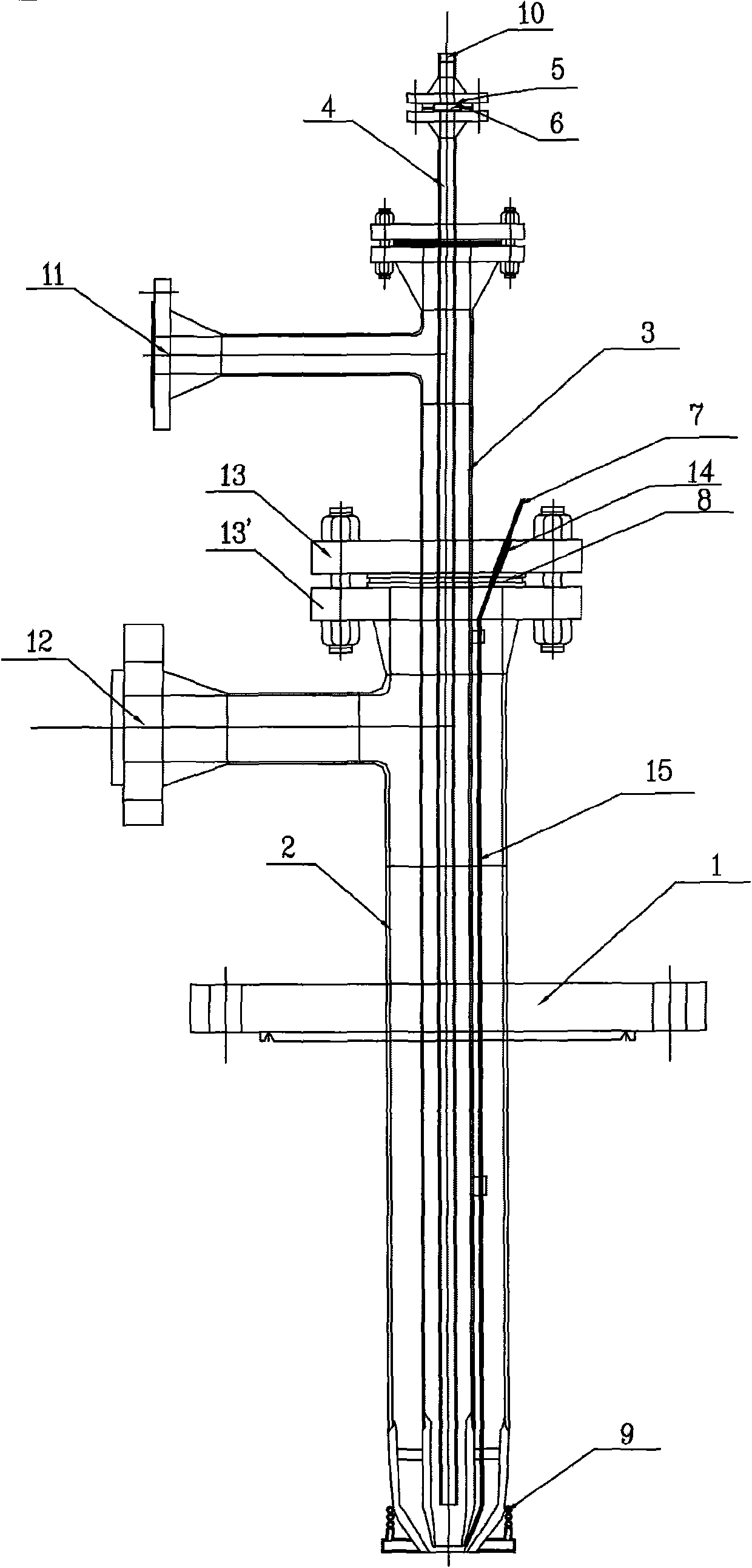

Start-up compound burner for water-coal-slurry or coal dust gasification furnace

InactiveCN101650031AAdjust the size of the annulusHigh media speedCombined combustion mitigationGaseous fuel burnerCoal dustProduct gas

The invention provides a start-up compound burner for a water-coal-slurry or coal dust pressure gasification furnace. The start-up compound burner comprises a fuel gas passage pipe and a combustion-supporting gas passage pipe which are coaxially sheathed with each other and respectively arranged inside and outside, and ignition electrodes, wherein the fuel gas passage pipe is connected with the combustion-supporting gas passage pipe through two flanges, the two flanges are sealed by a gasket, the size of an annular space between a flow passage at the front end of the combustion-supporting gaspassage pipe and the fuel gas passage pipe is adjusted by the thickness of the gasket, and the ignition electrodes are arranged outside the combustion-supporting gas passage pipe and extended to the front ends of the fuel gas passage pipe and the combustion-supporting gas passage pipe. The start-up compound burner has the advantages of compact structure and space saving. The burning of various fuel gases can be realized by adjusting the fuel gas passage. During the actual operation, the burner can automatically ignite and keep temperature rise stable. Besides, the invention can also lower thework intensity of on-site personnel, and can perform continuous operations of baker and chemical industrial feeding without being dismantled after the installation in cold conditions.

Owner:YANKUANG GRP CO LTD +1

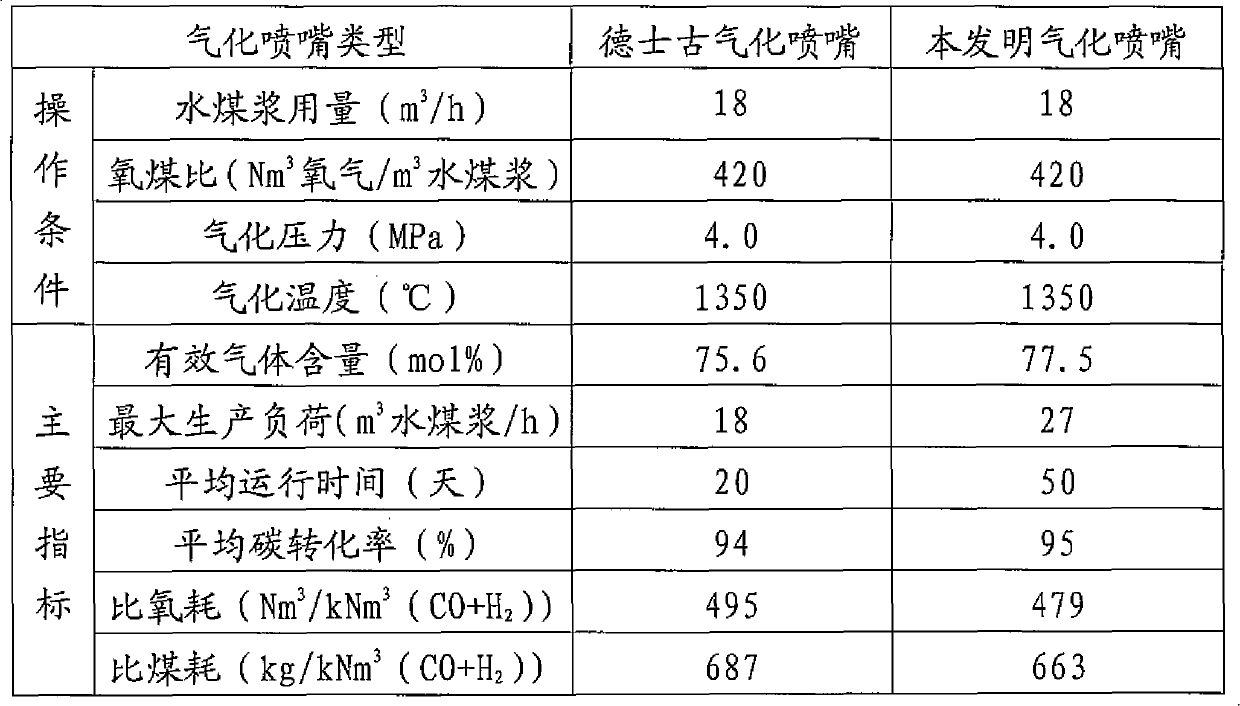

A gasification nozzle

InactiveCN102260533AImprove premix atomization effectWell mixedLiquid spraying apparatusGranular/pulverulent flues gasificationEpoxyCoal water

A gasification nozzle, which comprises a central oxygen nozzle, a coal-water slurry nozzle and an epoxy nozzle that are concentrically arranged from the inside to the outside, wherein the end section of the central oxygen nozzle is relative to the inner diameter of the end section of the coal-water slurry nozzle. The shrinkage is 20mm-100mm; the inclination angle of the epoxy nozzle is 20°-50°; the inclination angle of the outer side of the coal-water slurry nozzle is 30°-70°, and the inclination angle of the inner side is 30°-80°; the center The outside inclination angle of the oxygen nozzle is 30°-70°; a first locator is arranged in the epoxy channel, and a second locator is arranged in the coal-water slurry channel, and the top of the first locator is in the shape of a swirl sheet, so The included angle between the top and the feeding direction of oxygen is 20°-60°. When the gasification nozzle of the invention is used for gasification, the gasification effect of the coal-water slurry is better, the maximum production load of the gasification nozzle is increased, and the service life of the gasification nozzle is longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

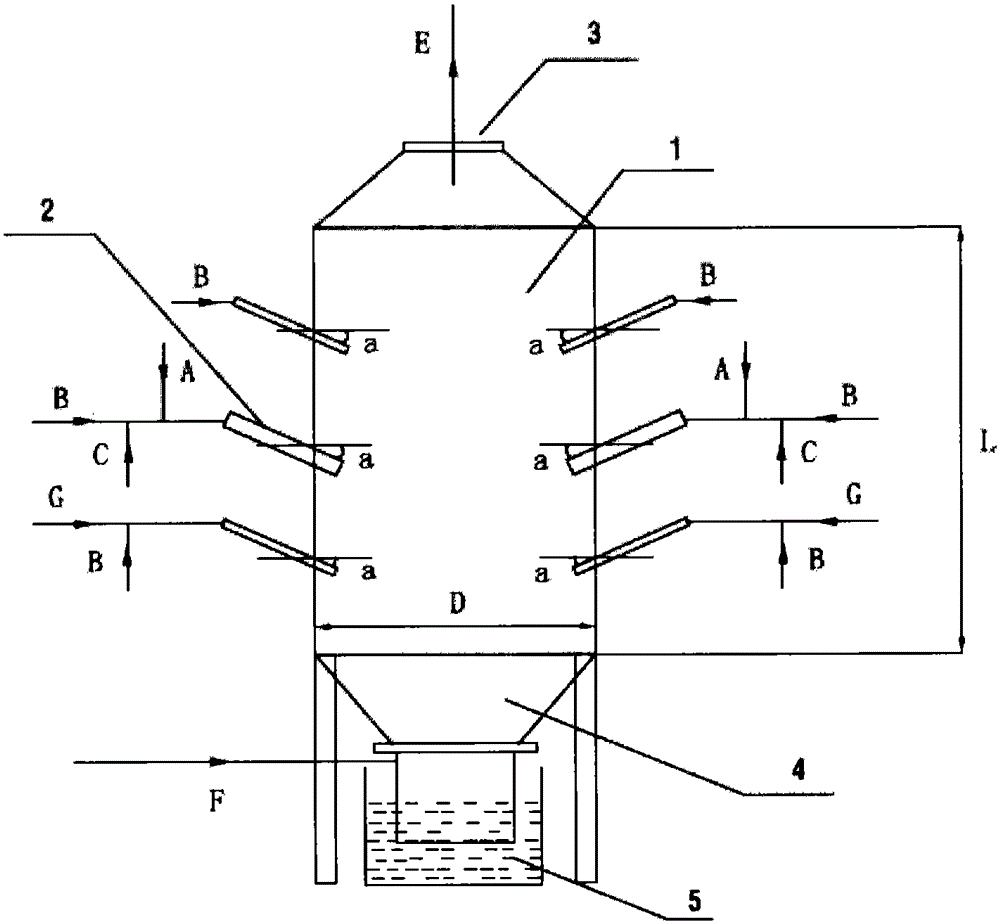

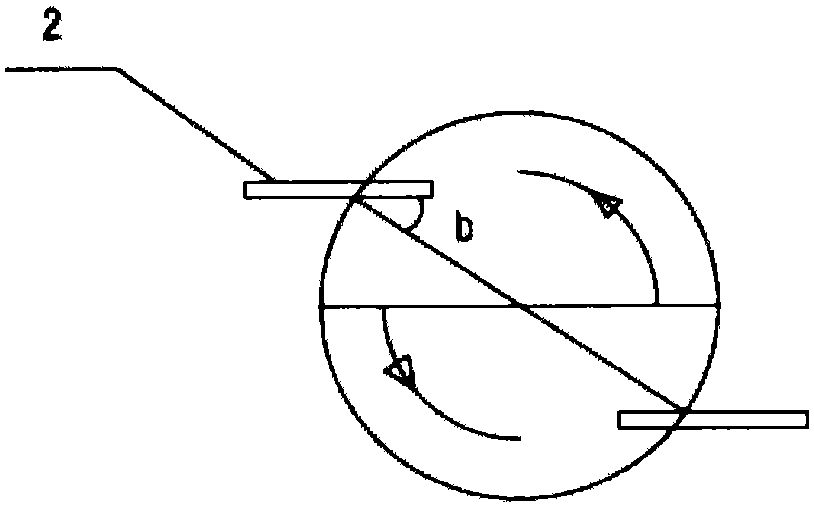

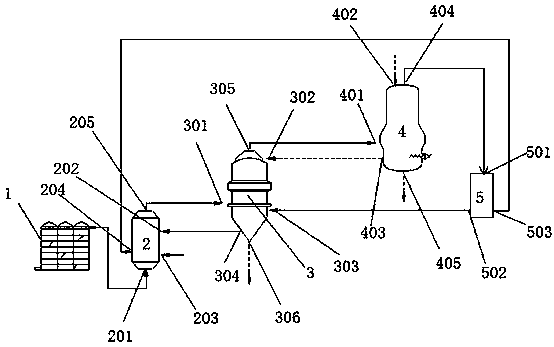

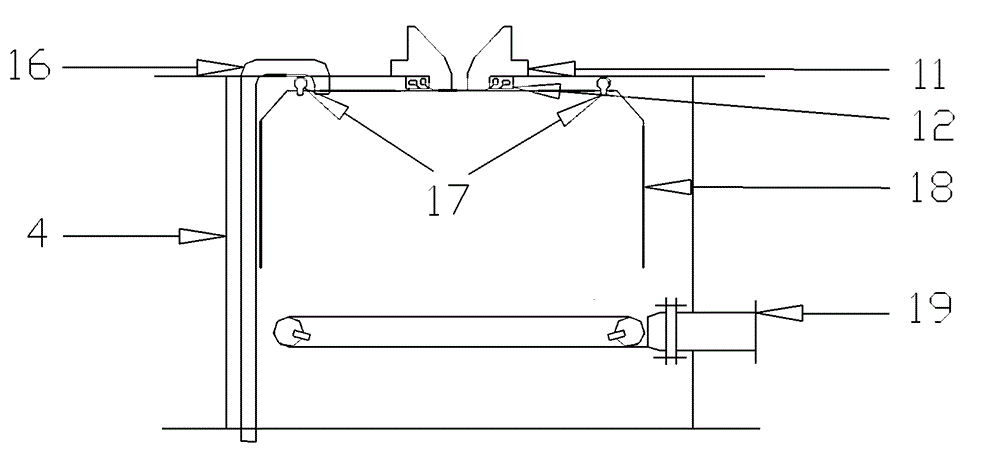

Swirl-flow type gasification furnace and swirl-flow type gasification process

InactiveCN105038860AGood technical effectIncrease gasification strengthCombined combustion mitigationGranular/pulverulent flues gasificationSlagRetention time

The invention discloses a swirl-flow type gasification furnace and swirl-flow type gasification process. The swirl-flow type gasification furnace comprises a furnace body (1), a feeding spray gun (2), a hot coal gas outlet (3) located at the top part of the furnace body, and a slag-melting chamber (4) located at the bottom part of the furnace body. According to the invention, the feeding spray gun used for entering the gasification furnace adopts tangent feeding, and the spray gun slopes down with a certain angle, so gasification raw materials are gasified in a swirl-flow form in the furnace; relative speeds of gas and solid phases are enhanced; retention time is prolonged; and gasification intensity and carbon transformation rate of the gasification furnace are improved; meanwhile, multi-layer spray-gun feeding is adopted, so classified supply of a gasifying agent is realized; reaction of the gasification raw materials and the gasifying agent in the gasification furnace is more fully; and gasification efficiency is higher.

Owner:北京柯林斯达科技发展有限公司

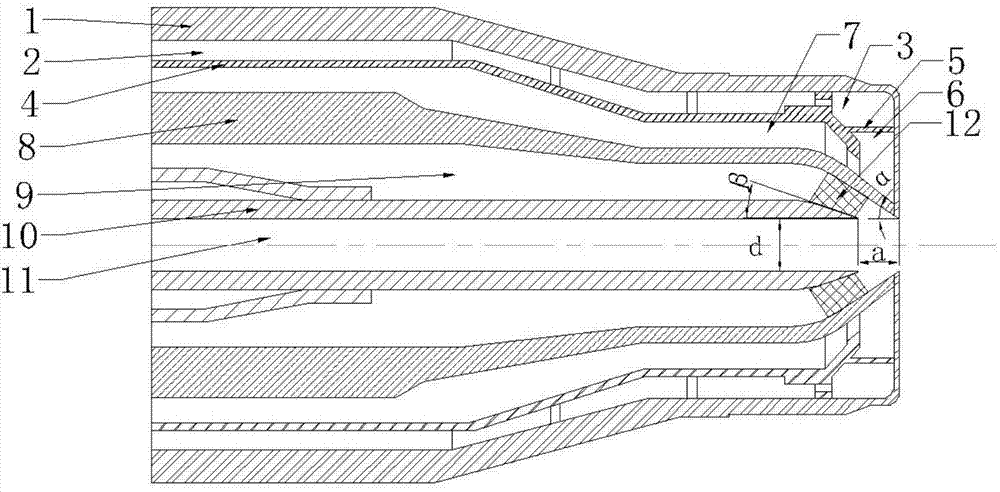

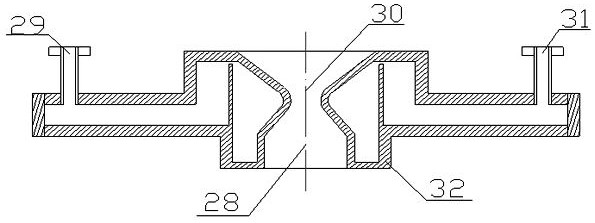

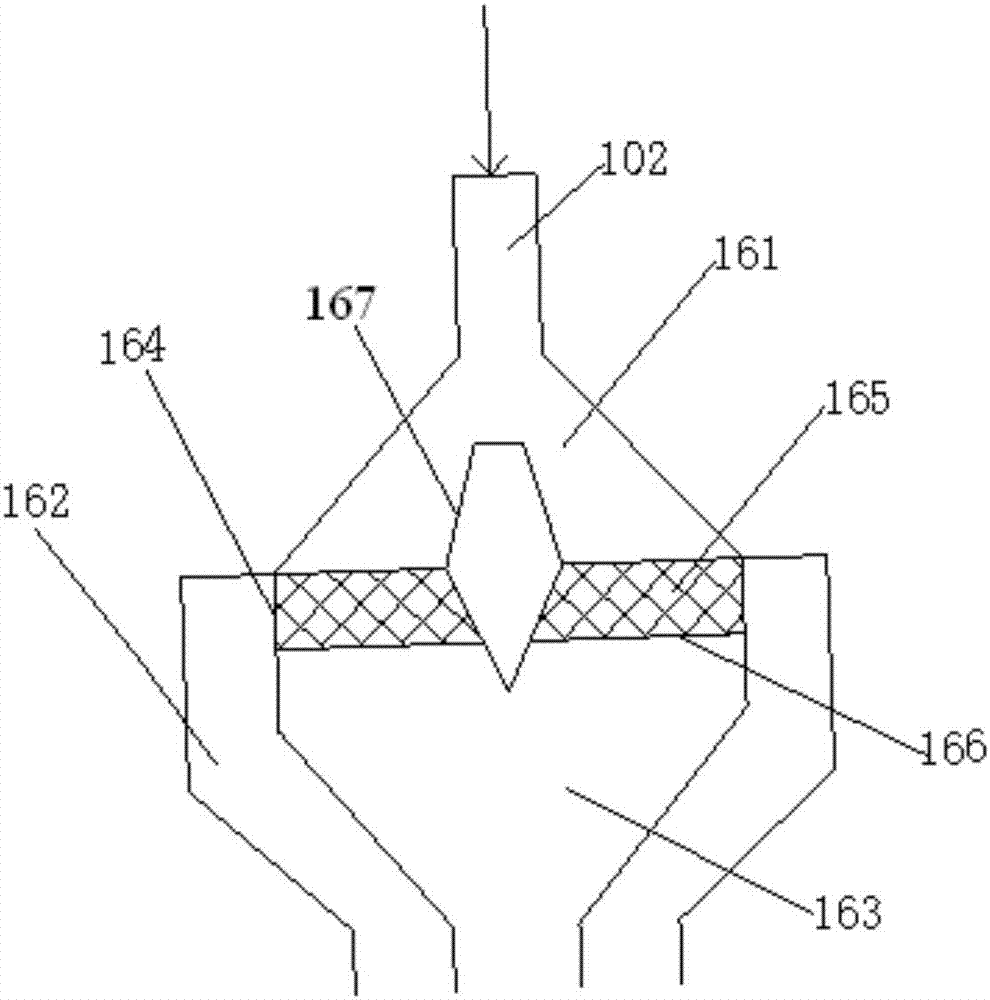

Nozzle for increasing carbon conversion rate of pulverized coal entrained-bed gasifier

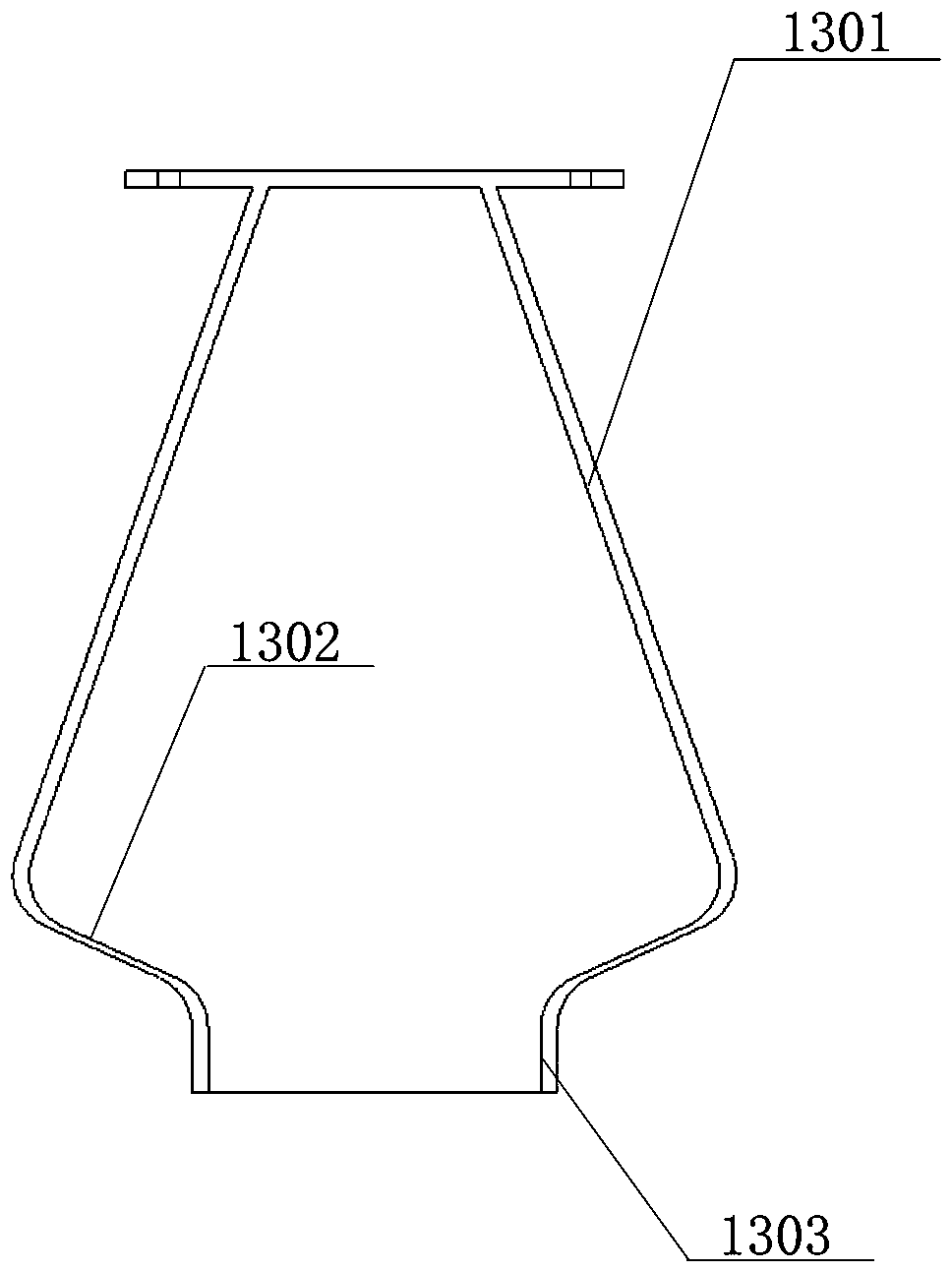

InactiveCN103937554AIncrease tangential speedHigh effective gas contentCombined combustion mitigationGranular/pulverulent flues gasificationCycloneEngineering

The invention relates to a nozzle for increasing carbon conversion rate of a pulverized coal entrained-bed gasifier. The nozzle comprises outer water-cooled sleeves, an inner water-cooled sleeves, outer ring spray heads and inner ring spray heads which are coaxial from the outside and inside, wherein a cooling water leading-out channel is arranged between the outer water-cooled sleeves and the inner water-cooled sleeves, a cooling water introduction channel is arranged between the inner water-cooled sleeves and the outer ring spray heads, an outer ring channel is arranged between the outer ring spray heads and the inner ring spray heads, the inner ring spray heads form an inner ring channel, a front end water-cooled chamber is arranged at an outlet of the cooling water leading-out channel and an outlet of the outer ring channel is provided with a plurality of cyclones symmetrically. According the invention, the flow field in the gasifier is changed by designing the gasifier nozzle to enhance the mixing of pulverized coal and air flow, thereby prolonging the residence time of the particles and ultimately improving the carbon conversion rate in pulverized coal.

Owner:HUANENG CLEAN ENERGY RES INST

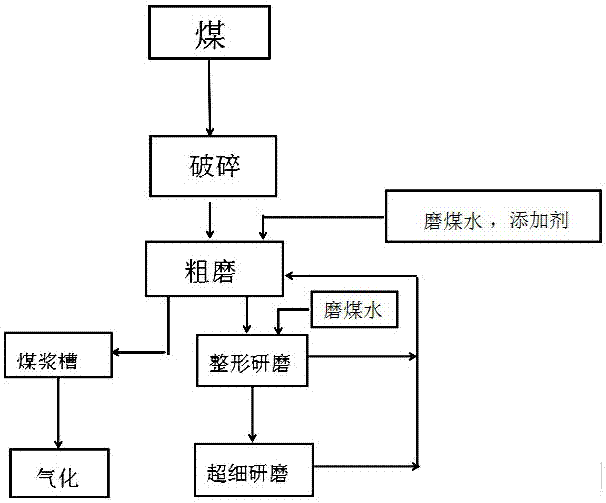

Coal slurry concentration increasing and industrial wastewater treating process and device

ActiveCN107312580AImprove liquidityReduce apparent viscosityLiquid carbonaceous fuelsGrain treatmentsIndustrial effluentEnergy consumption

The invention discloses a coal slurry concentration increasing and industrial wastewater treating process and device. The process comprises the following steps: (1) crushing coal, and then adding water and a dispersant for coarse grinding till the particle size is 50 microns or below, thus obtaining slurry 1; (2) performing shaping grinding on 25 to 35 weight percent of slurry 1 till the particle size is 20 to 30 microns, thus obtaining slurry 2, and pumping the residual slurry 1 serving as a water coal slurry product into a water coal slurry storage tank for gasification; (3) performing ultrafine grinding on 15 to 25 weight percent of the slurry 2 till the particle size is 5 to 10 microns, thus obtaining slurry 3, and conveying the residual slurry 2 and the newly obtained slurry 3 into the coarse grinding stage for coarse grinding, wherein after the coarse grinding in the step (1) and the steps (2) and (3) are repeatedly performed for multiple times, the aim of effectively increasing the concentration of the slurry 1 is fulfilled. In the concentration increasing process, used water can be replaced with industrial wastewater. According to the coal slurry concentration increasing and industrial wastewater treating process disclosed by the invention, the concentration of the coal slurry can be increased by at least 3 percent; the gasification energy consumption can be substantially reduced; the coal slurry concentration increasing and industrial wastewater treating process has the characteristics of safety, reliability, convenience in improvement and obvious economical benefits.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

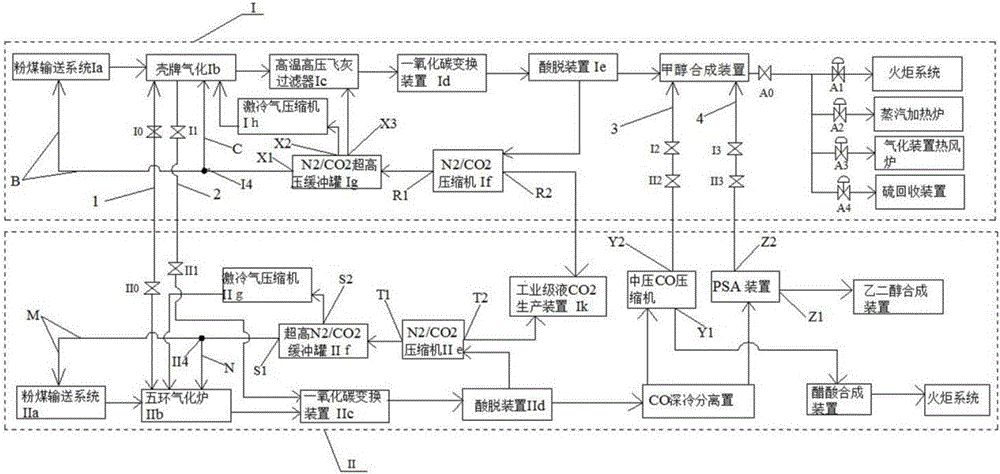

Method for emission reduction of CO2 and yield increase of methyl alcohol and acetic acid by means of CO2 emission reduction integrated unit adopted in coal-to-methanol and coal-to-acetic acid processes

InactiveCN106083524AReduce contentReduce CO2Organic compound preparationHydroxy compound preparationAcetic acidSocial benefits

The invention discloses a method for emission reduction of CO2 and yield increase of methyl alcohol and acetic acid by means of a CO2 emission reduction integrated unit adopted in coal-to-methanol and coal-to-acetic acid processes. The integrated unit comprises a coal-to-methanol device and a coal-to-acetic acid device, a CO2 connection pipe network connected with the coal-to-methanol device and the coal-to-acetic acid device, and a gas delivery pipeline connected with the coal-to-methanol device and the coal-to-acetic acid device. The method comprises the steps of starting the coal-to-methanol device firstly; opening the CO2 connection pipe network and starting the coal-to-acetic acid device after the coal-to-methanol device runs for a certain period of time, wherein qualified gas generated during operation of the coal-to-acetic acid device is used for preparing acetic acid, and unqualified gas enters a methanol synthesis device through the gas delivery pipeline to be recycled. The byproduct CO2 generated from methanol preparation is recycled to the coal-to-methanol device and the coal-to-acetic acid device, CO2 emission is reduced greatly, useful gas generated in the coal-to-acetic acid process is used for preparing methanol and acetic acid, the yield of methanol and acetic acid is increased, and economic and social benefits are remarkable.

Owner:HENAN LONGYU COAL CHEM

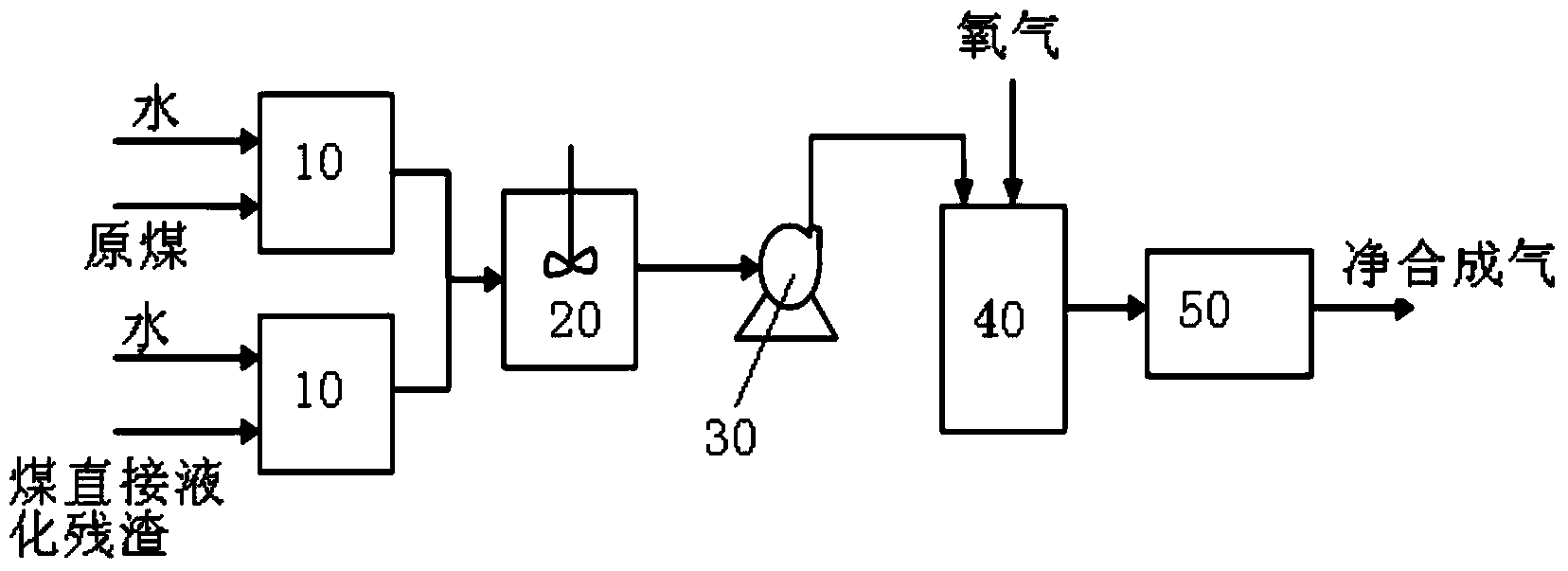

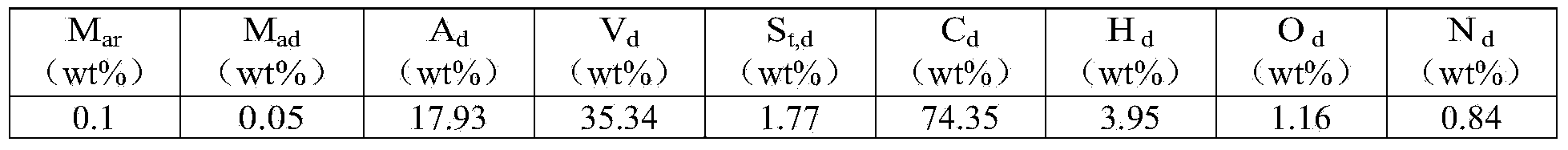

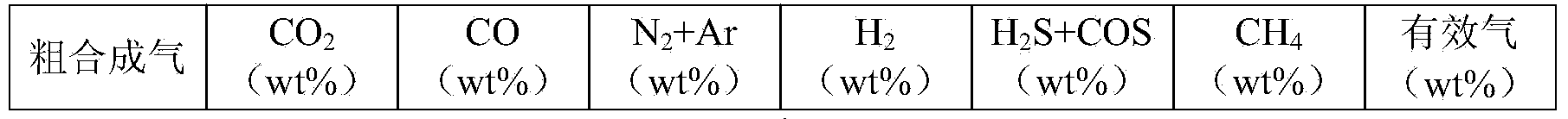

Method of producing rough synthesis gas by taking direct coal liquefaction residue as raw material

ActiveCN103923703AFull and efficient useNo pollution in the processGranular/pulverulent flues gasificationAdditive ingredientCatalytic effect

The invention discloses a method of producing rough synthesis gas by taking direct coal liquefaction residue as a raw material. The method comprises the following steps of: S1, preparing the direct coal liquefaction residue into coal-water slurry; S2, mixing the coal-water slurry with an oxygen gas to carry out gasification reaction to obtain rough synthesis gas. The method disclosed by the invention realizes sufficient and efficient utilization of the direct coal liquefaction residue, so that sulfur with higher content in the direct coal liquefaction residue is converted into H2S in a gasification process and recycled in a follow-up rough synthesis gas purifying process, and therefore, an efficient utilization process is pollution-free on environment, high in product additional value, simple in treatment process, and free of bad influences on equipment operation; meanwhile, a heat value of the direct coal liquefaction residue is high and Fe-series catalysts needed for liquidation of coals enriched in the direct coal liquefaction residue have catalytic effect on the coal gasification process, so that content of active gas ingredients in the finally obtained rough synthesis gas is higher.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

System and method for producing sponge iron by gas-based shaft furnace

The invention relates to a system and method for producing sponge iron in a gas-based shaft furnace. The system includes: a heating furnace, a gas reforming and carburizing device, a shaft furnace reducing device and a furnace top gas purification device; the invention combines reforming and carburizing Combined, while realizing gas conversion, high-carburized sponge iron is obtained, which has good economic benefits and low cost. Compared with the traditional shaft furnace process, the cooling of the shaft furnace is omitted, the carbon precipitation effect is greatly reduced, and the reduction gas intake is solved. Air clogging problem.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

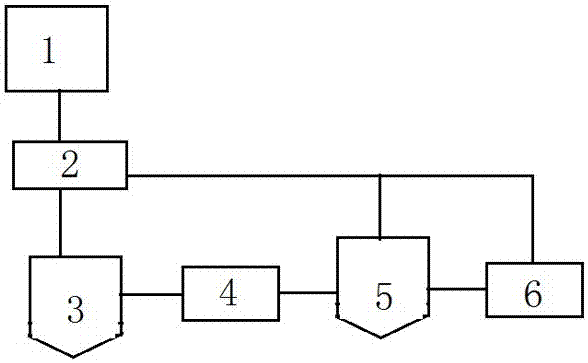

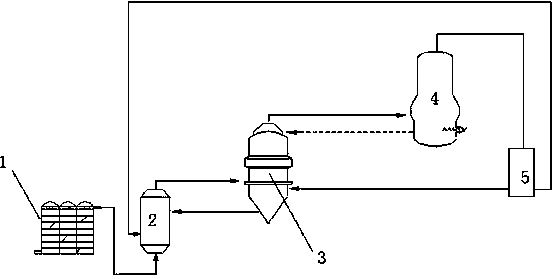

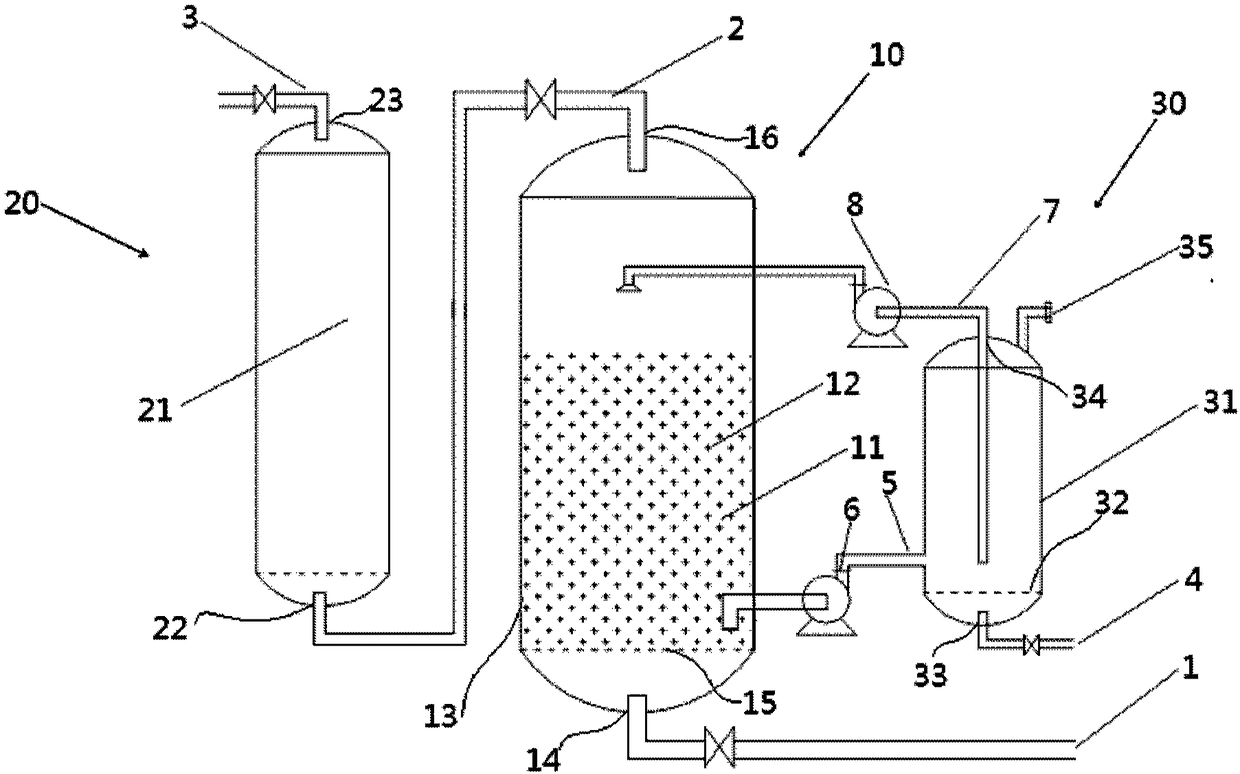

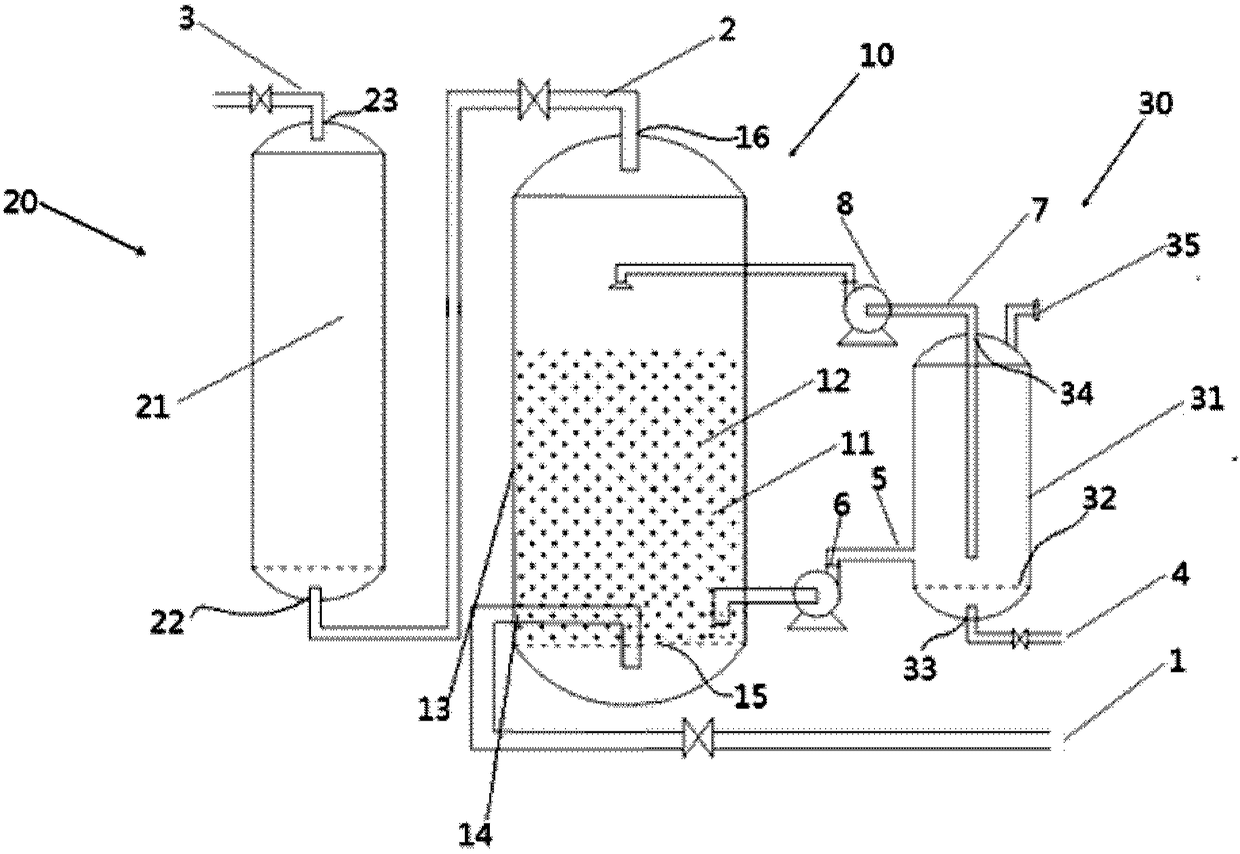

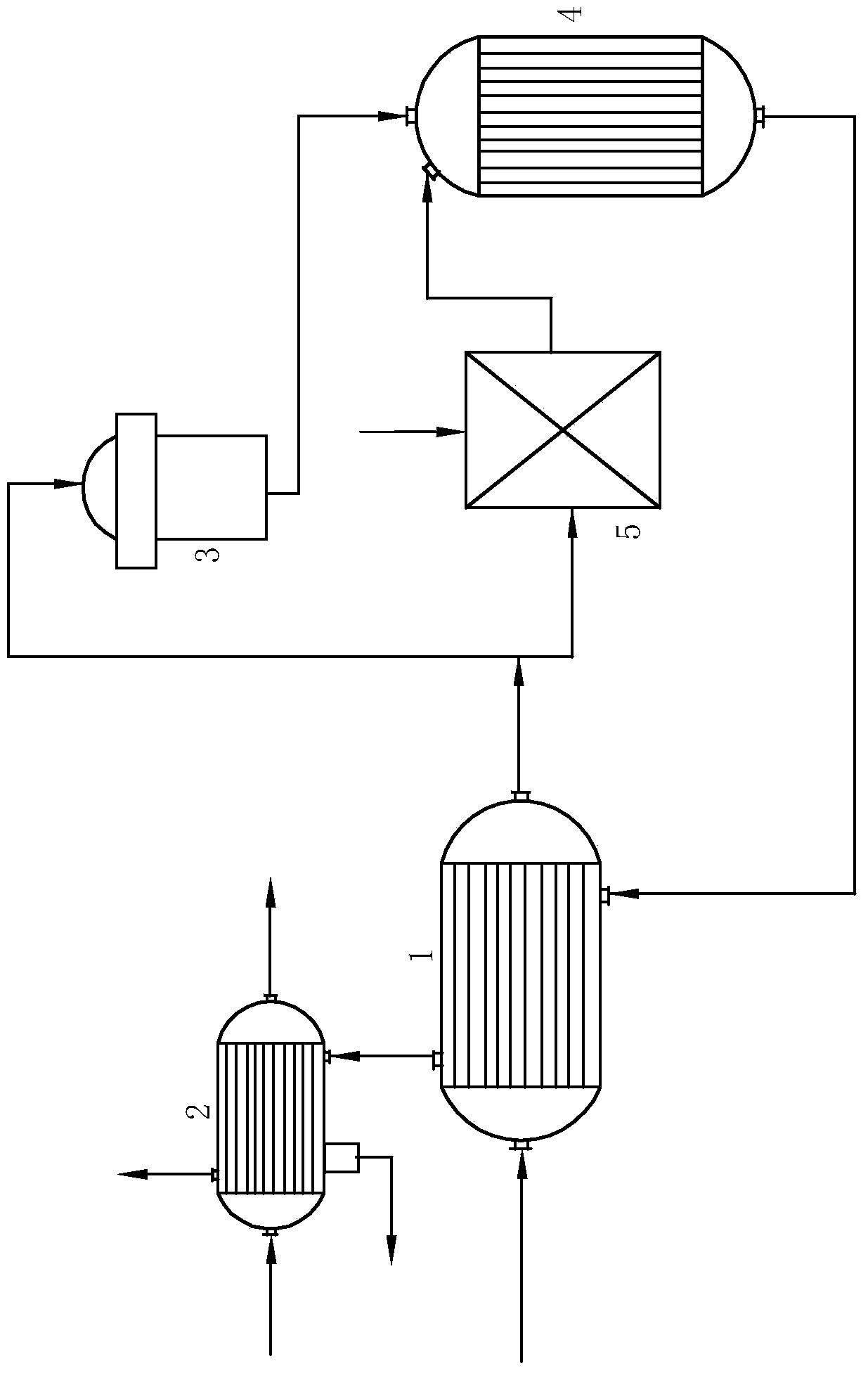

Recycling system and method for gas waste heat of coal water slurry gasification

InactiveCN105779018ANo generationEasy to operateEnergy inputGasification processes detailsCoal waterFluidized bed

The invention provides a recycling system for gas waste heat of coal water slurry gasification and a recycling method for the gas waste heat of the coal water slurry gasification by using the system. The recycling system comprises a coal water slurry gasifier (3), a fluidized bed gasification device (4), a gas heat exchanger (5) and a fluidized bed pyrolyzer (6); the gas outlet of the coal water slurry gasifier (3) is communicated with the gas inlet of the fluidized bed gasification device (4); the gas outlet of the fluidized bed gasification device (4) is communicated with the gas inlet of the gas heat exchanger (5); the nitrogen outlet of the gas heat exchanger (5) is communicated with the gas inlet of the fluidized bed pyrolyzer (6). The gas waste heat recycling and purifying process, based on fluidized bed gasification, provided by the invention combines the technical advantages of the fluidized bed gasification, and is simple in integrated system equipment, easy to operate, high in thermal efficiency and free of pollution.

Owner:SHENWU TECH GRP CO LTD

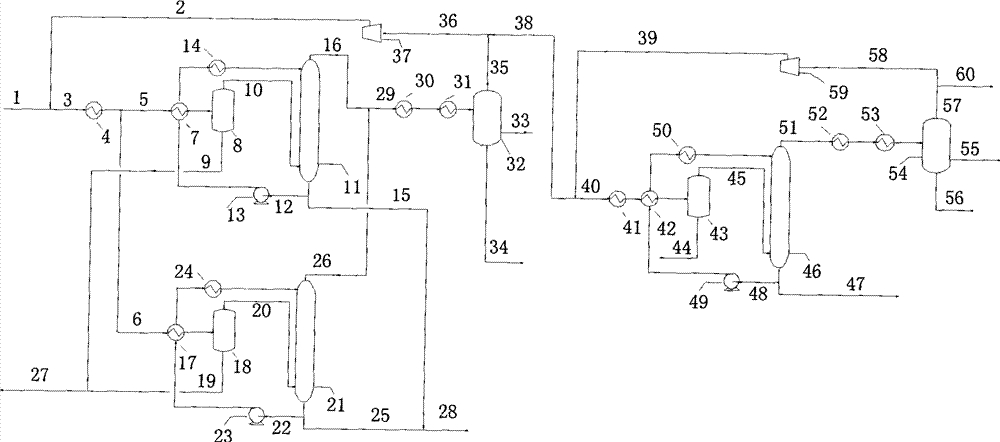

Technique for producing oil products by fischer-tropsch synthesis

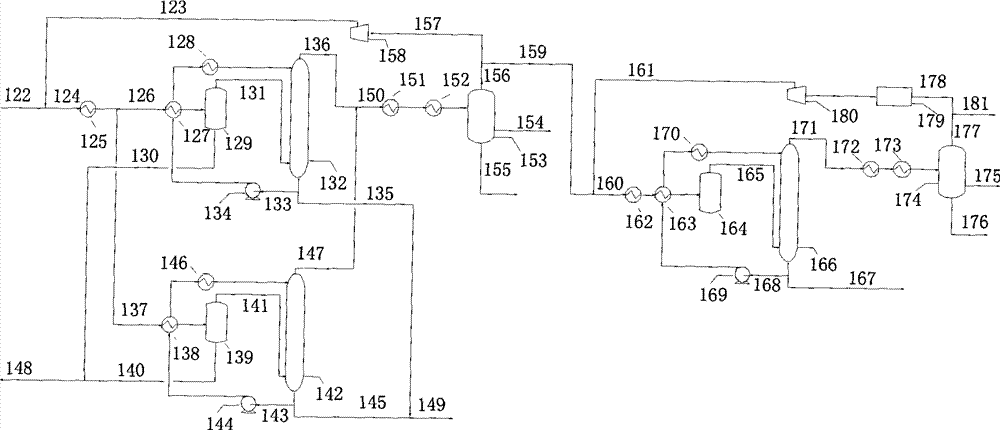

ActiveCN101381616BFlexible product planReduce the numberLiquid hydrocarbon mixture recoveryHydrogenFuel gas

The invention relates to a technological method for preparing oil products by the Fischer-Tropsch synthesis. In the technological method, a FT synthesis process comprises a first-stage FT synthesis process and a second-stage FT synthesis process; in particular, the technological method comprises the following steps: (1) synthesis gases are subjected to FT synthesis reaction in a first-stage synthesis reactor; (2) a part of tail gases from the first-stage synthesis reactor are circularly returned to an entrance of the first-stage synthesis reactor, and another part of the tail gases enter a second-stage synthesis reactor for the further FT synthesis reaction; (3) a part of tail gases from the second-stage synthesis reactor are circularly returned to an entrance of the second-stage synthesis reactor, and another part of the tail gases are used for reclaiming low-carbon hydrocarbons and hydrogen gases and then are used as fuel gases; and (4) by utilizing the recovered hydrogen gases, thehydrocarbon products in the first-stage synthesis reactor and the second-stage synthesis reactor and the hydrocarbon products which are obtained by separating and recovering the tail gases are subjected to hydrogenation and purification and then are fractionated to generate various oil products. Compared with prior art, the technological method has the characteristics of economy, flexibility, lowcost and the like.

Owner:YANKUANG ENERGY R&D CO LTD

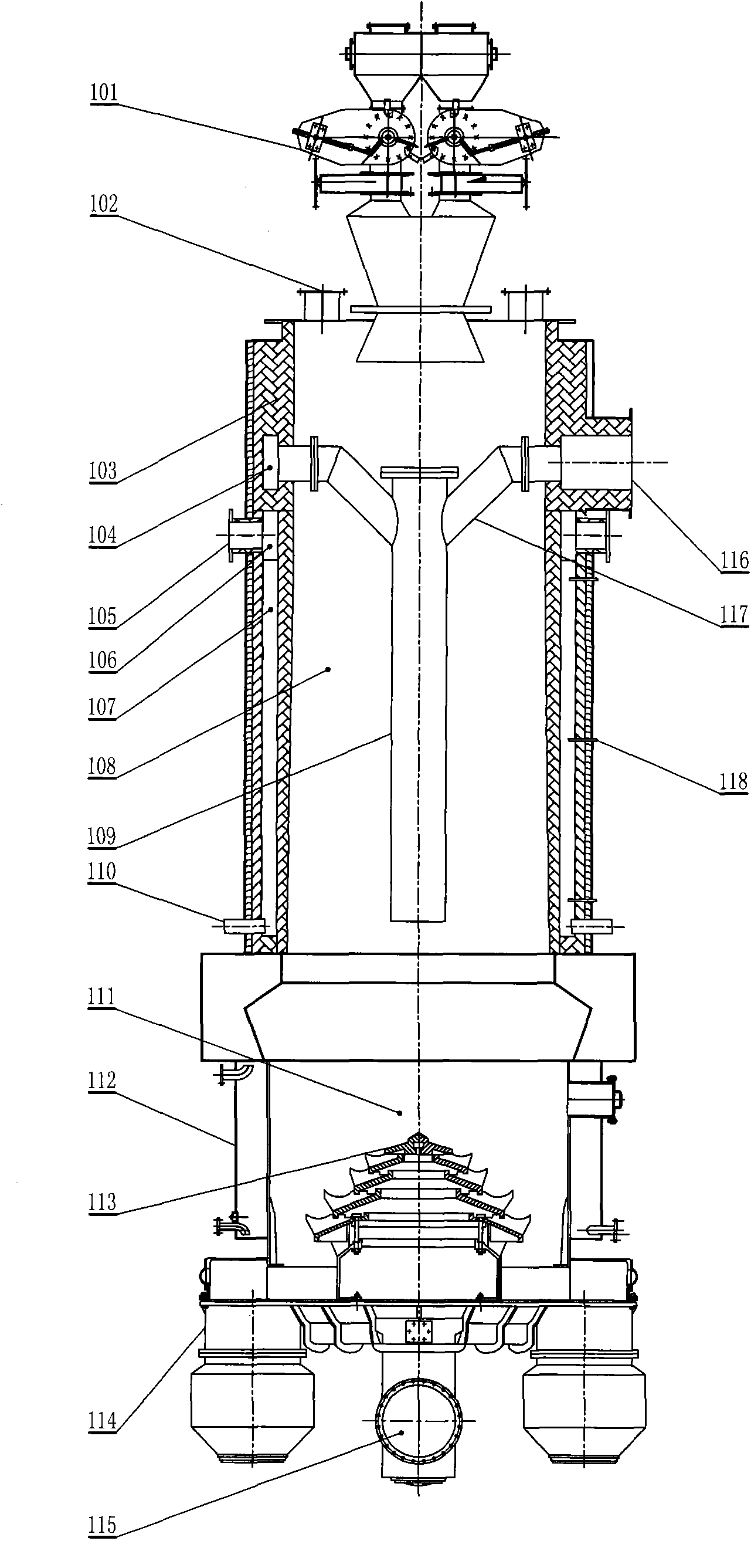

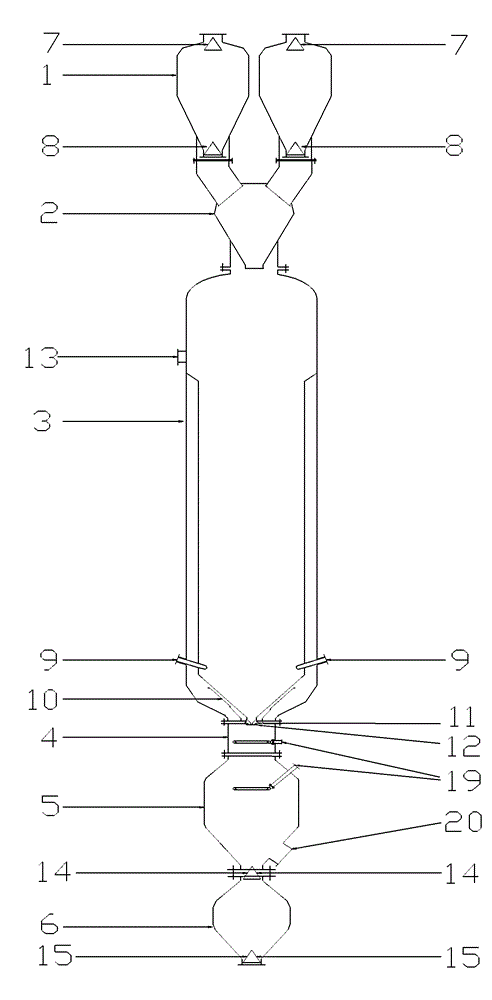

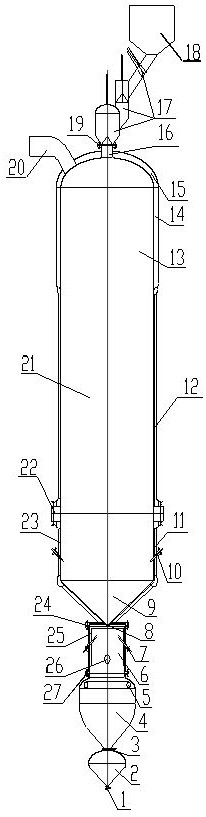

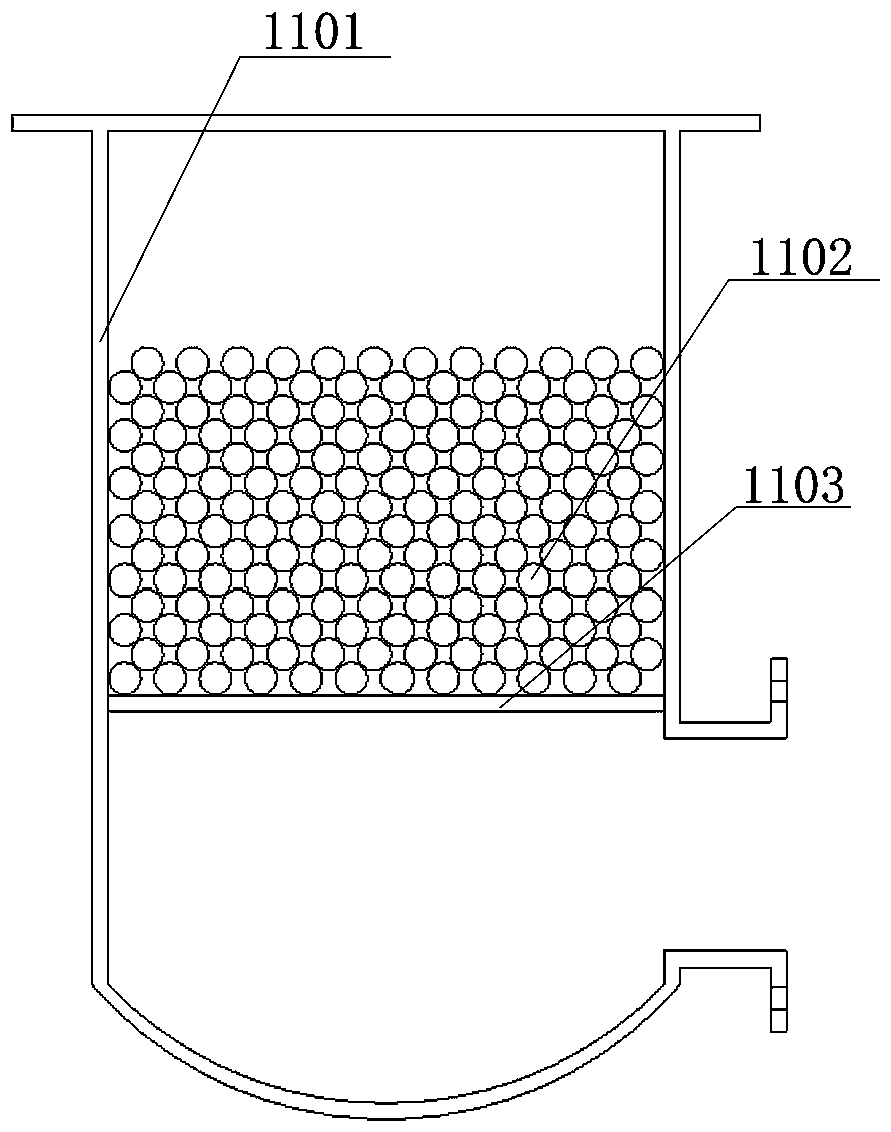

Slag gasifier for pressurized fixed bed

InactiveCN103436296BImprove carbon conversionImprove conversion rateCombustible gas productionSolid fuelEngineering

The invention relates to a slag gasifier for a pressurized fixed bed. The slag gasifier comprises a coal lock for intermittently taking coal from a bunker and feeding the coal into a pressurized gasifier container, a transition bin enabling the coal in the coal lock to be fed in the pressurized gasifier container conveniently, the pressurized gasifier container for combusting and gasifying carbon-containing solid fuels at a certain temperature and with certain pressure by virtue of a gasifying agent from a nozzle, a connection pup joint for gasifying operations of slagging, chilling, evacuation and the like, a chilling chamber for chilling and cooling molten slag and a slag lock for storing vitric slag particles and discharging the vitric slag particles to the outside by a cone valve. An operation method of the slag gasifier comprises the steps of adjusting the temperature of a raw gas outlet, gasifying carbon-containing solid fuels, adjusting the gasifying load of the gasifier, controlling the operation pressure of the gasifier, controlling the pressure difference between the connection pup joint and the gasifier, slag discharge of a slag discharging port and slag support operations, chilling and cooling molten slag, controlling water quantity of the chilling chamber to remove heat of the molten slag, storing slag particles and discharging the slag particles to the outside.

Owner:SHANGHAI ZEMAG MINDAC MACHINERY EQUIP

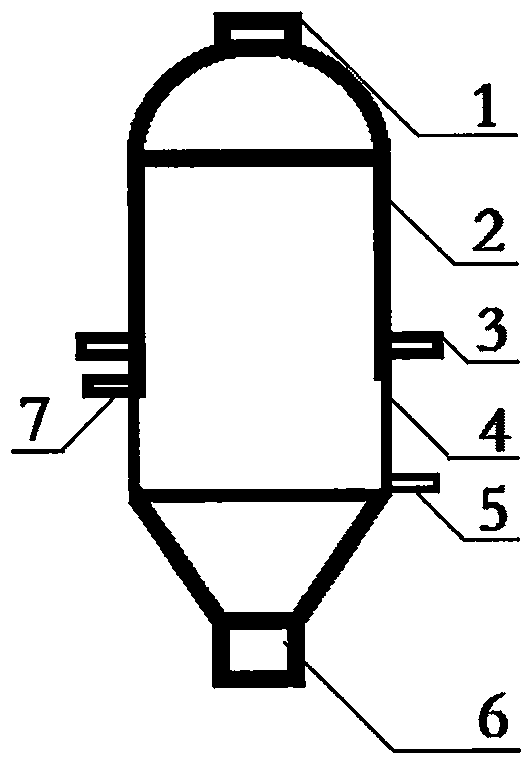

Mesomorphic substance internal cold shock gasification furnace

PendingCN109370657AImprove gasification efficiencyImprove high temperature thermal blocking efficiencyGranular/pulverulent flues gasificationChemical industryHazardous substance

The invention discloses a mesomorphic substance internal cold shock gasification furnace, and relates to the technical field of coal chemical industries and environments. The mesomorphic substance internal cold shock gasification furnace comprises a vertical cylindrical gasification chamber 2, more than two multi-nozzles 3 and the like, the vertical cylindrical gasification chamber 2 is provided with a high-temperature gas outlet 1, a water cold shock device 5 and a slag-water outlet 6, organic matters in combustible gas, carbon-containing solids and carbon and organic matters in carbon-containing liquid such as oil tar can be simultaneously transformed into synthesis gas, toxic and harmful substances such as dioxin, landfill leachate and heavy metal in the synthesis gas are subjected to high-temperature heat blocking, and coal, urban garbage and organic solid wastes are used in a recycled and clean manner. The gasification furnace can be used for various devices such as low-temperature coal gasification furnaces, coal pyrolysis furnaces, organic solid waste pyrolysis furnaces, rubbish pyrolysis gasification furnaces and coke-oven gas chemical industry devices to perform technicaltransformation of use and deep disposal of coal gas, coke-oven gas, pyrolysis gas, coke powder, pyrolysis residues and toxic and harmful substances, and can be used for newly built devices for organicsolid waste recycling, efficient use of coal, cleaning gasification, IGCC (integrated gasification combined cycle) power generation, urban central heating and the like.

Owner:邰学林

Slag gasification reaction furnace for preparing carbon monoxide, and gas preparation method thereof

PendingCN111635783ARaise the pyrolysis gasification reaction temperatureHigh gasification temperatureChemical industryGasification processes detailsWater jacketMolten slag

The invention relates to a slag gasification reaction furnace for preparing carbon monoxide, and a gas preparation method thereof, belongs to the fields of coal chemical industry, coke (containing semi-coke) gasification, fuel gas and the like, and relates to chemical engineering, a chemical process, chemical machinery, an instrument and an automation technology. The slag gasification reaction furnace comprises a gasification furnace body, a slag hole, a combustion short section, a chilling chamber and an automatic coke adding machine, wherein the gasification furnace body comprises a shell, an upper barrel, a hearth inlet, a coal gas outlet, lining refractory bricks, a water jacket, a gasifying agent nozzle, a water cooling coil pipe, a slag pool, a furnace cover and a large connecting flange. According to the invention, due to the adoption of slag gasification and liquid deslagging, the gasification temperature is high, the carbon conversion rate is improved, the effective gas content is high, the operation energy consumption is low, the cost is low, the methane content is low, the raw coal application is wide, the investment is saved, the equipment is completely domesticated, the maintenance is convenient, the operation is simple and feasible, the requirements of safety, environmental protection and energy conservation are met, and the pure oxygen continuous gasification technology is upgraded.

Owner:江西昌昱实业有限公司

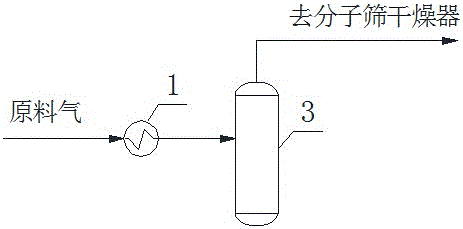

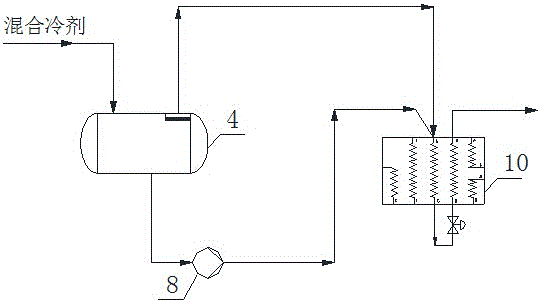

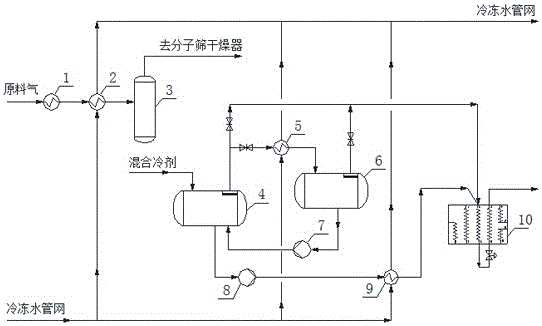

System for improving LNG yield of methane cryogenic separation

InactiveCN106679332ASimple processEasy to operateSolidificationLiquefactionMolecular sieveOperant conditioning

The invention provides a system for improving the LNG yield of methane cryogenic separation. According to the system, cold water at 5-10 DEG C of a chilled water pipe network is mainly used for inputting cooling capacity to a raw gas compression system and a mixed refrigerant circulation system for methane cryogenic separation. The purposes of optimizing the operation conditions of a methane rectifying column and improving separation efficiency are realized by lowering the temperature of raw methane gas and mixed refrigerants, and therefore the content of formaldehyde in column top gas is reduced, and the LNG yield is improved. Particularly, a chilled water heat exchanger is added before the raw gas enters a molecular sieve, and two chilled water heat exchangers are added correspondingly before a gas phase pipeline and a liquid phase pipeline of a refrigerant compressor outlet separation tank enter a cold box. The system improves the LNG yield of methane cryogenic separation, effectively increases the output of LNG, brings considerable economic benefits for enterprises, and is simple in process, convenient to operate and low in daily maintenance cost.

Owner:查都(海南)科技有限公司

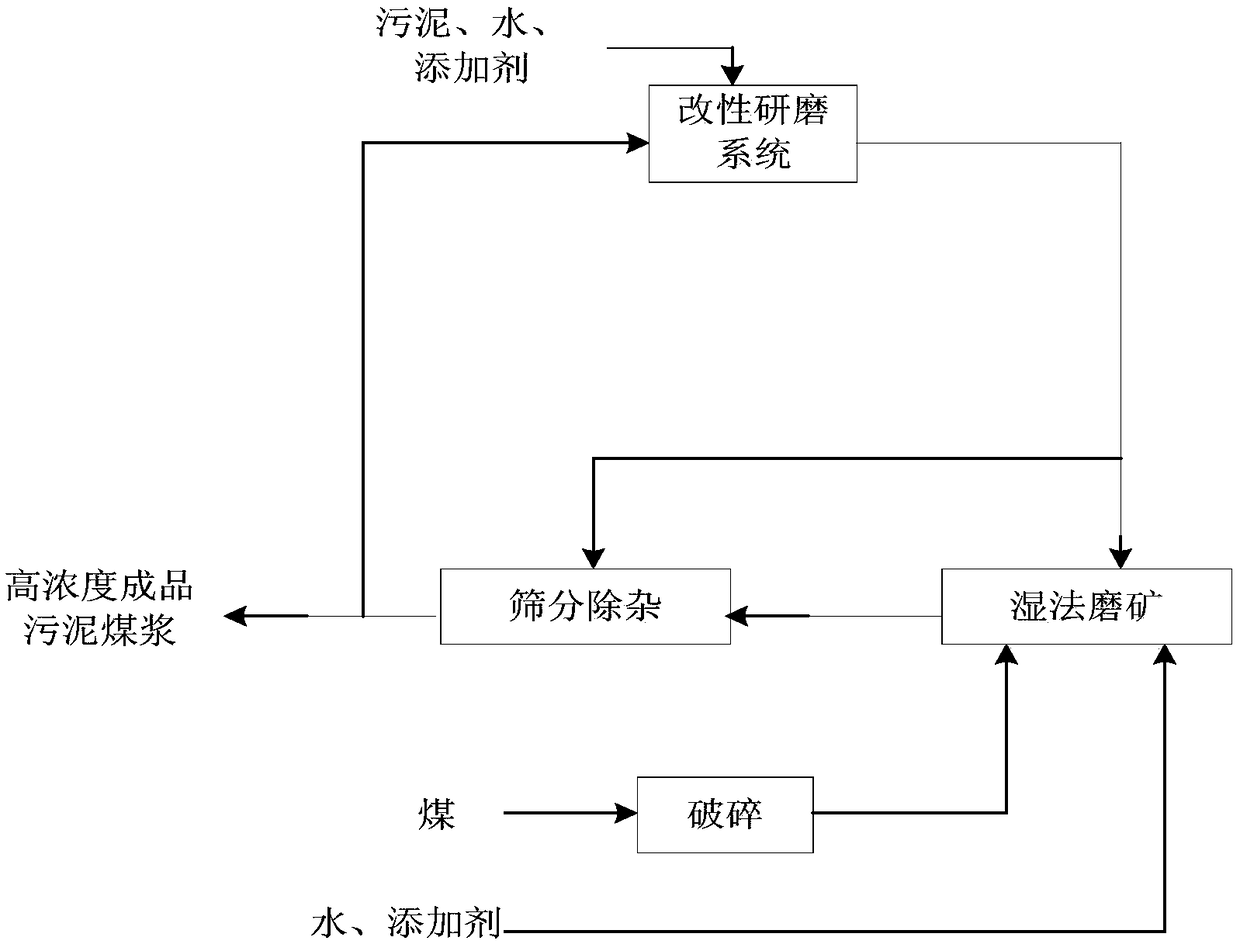

High-concentration sludge coal slurry, preparation method and application thereof

ActiveCN108949267AImprove liquidityPromote atomizationGasification processes detailsLiquid carbonaceous fuelsCoal waterHigh concentration

The invention provides high-concentration sludge coal slurry, a preparation method and an application thereof. The mass concentration of the high-concentration sludge coal slurry is 64%-68%, the masspercent of sludge is 1%-30%, the mass percent of coal powder is 30%-68%, and the proportion between the dry base content of particles with the granularity being less than or equal to 75mum in the sludge coal slurry and the total base content of the sludge coal slurry is more than or equal to 30%. The high-concentration sludge coal slurry, the preparation method and the application provided by theinvention have the beneficial effects that the mass concentration of the coal water slurry is at least increased by 3-6 percent points, the fluidity, stability and atomizing property of the coal slurry are respectively greatly improved, the sludge treating cost is reduced, the heat value of the sludge is also effectively utilized, the process flow is simple, the operability is strong, the energy consumption is low, the production requirements for long-period safety and continuity are met, and the high-concentration sludge coal slurry can meet the requirements of gasification and burning of thecoal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

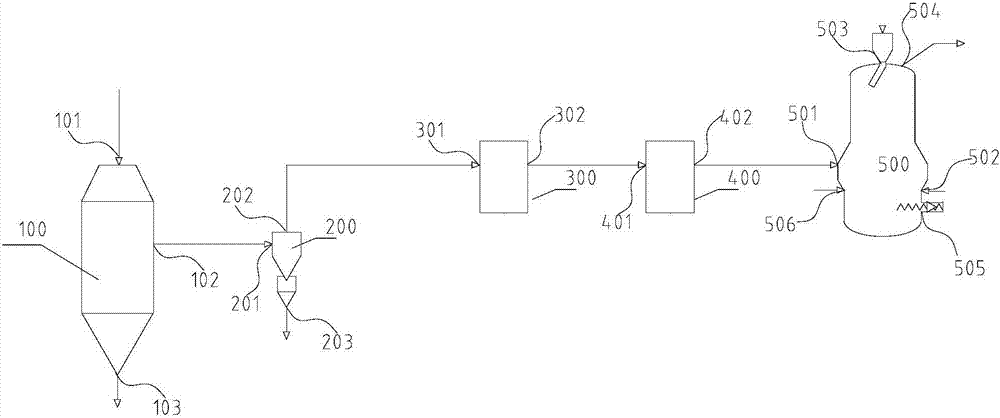

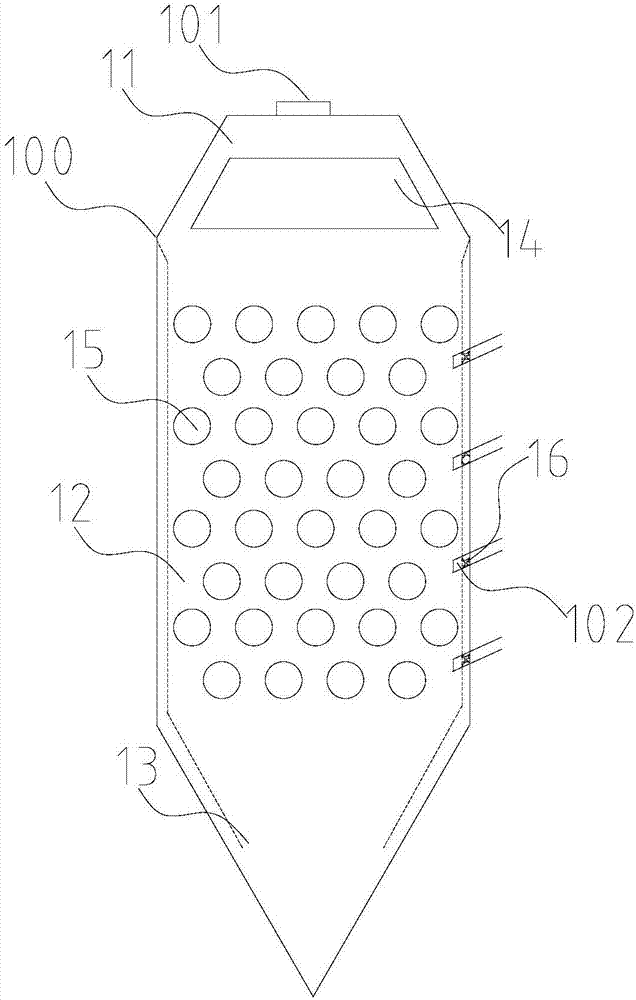

System and method for treating low-rank coal

PendingCN107216894ASimple processHigh effective gas contentShaft furnaceSpecial form destructive distillationDecarburizationProcess engineering

The invention discloses a system and method for processing low-rank coal. The system includes: a fast pyrolysis device with a pyrolysis gas outlet, and a particle dust removal unit is arranged at the pyrolysis gas outlet; a dust collector with a pyrolysis gas outlet. Gas inlet, dust particle outlet and dedusted gas outlet; desulfurization and decarbonization device, with dedusted gas inlet and purified gas outlet; heating device, with purified gas inlet and heated gas outlet; gas-based shaft furnace, gas-based vertical The furnace has a reducing gas inlet, a cooling gas inlet, an oxidized pellet inlet, a furnace top gas outlet, a reduced pellet outlet and a heat exchanged gas outlet, and the reducing gas inlet is connected with the heated gas outlet. The system can effectively use the pyrolysis gas obtained from the pyrolysis of low-rank coal as reducing gas for the gas-based shaft furnace, and at the same time by-produce semi-coke, which significantly improves resource utilization and reduces CO2 emissions, and the process is short and water-intensive. Low consumption and low investment.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

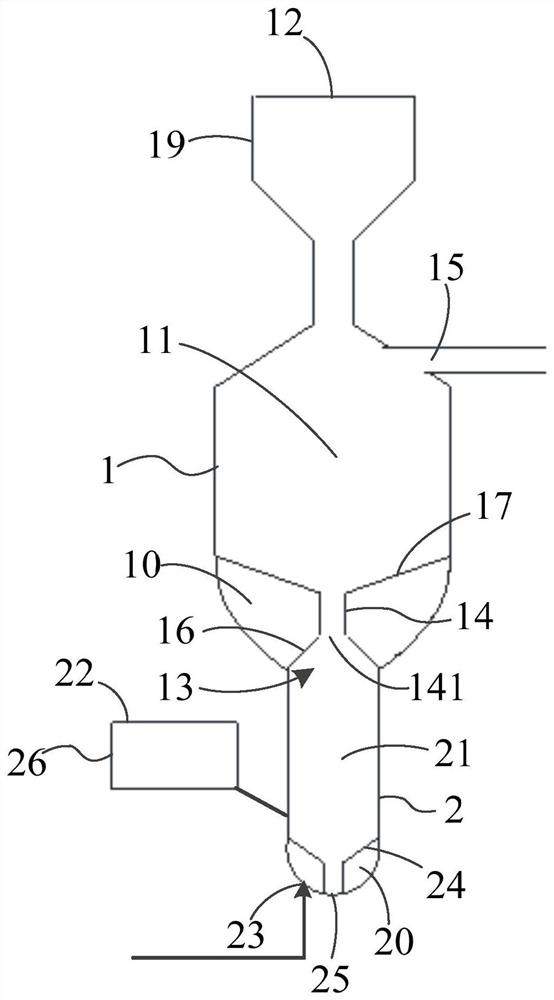

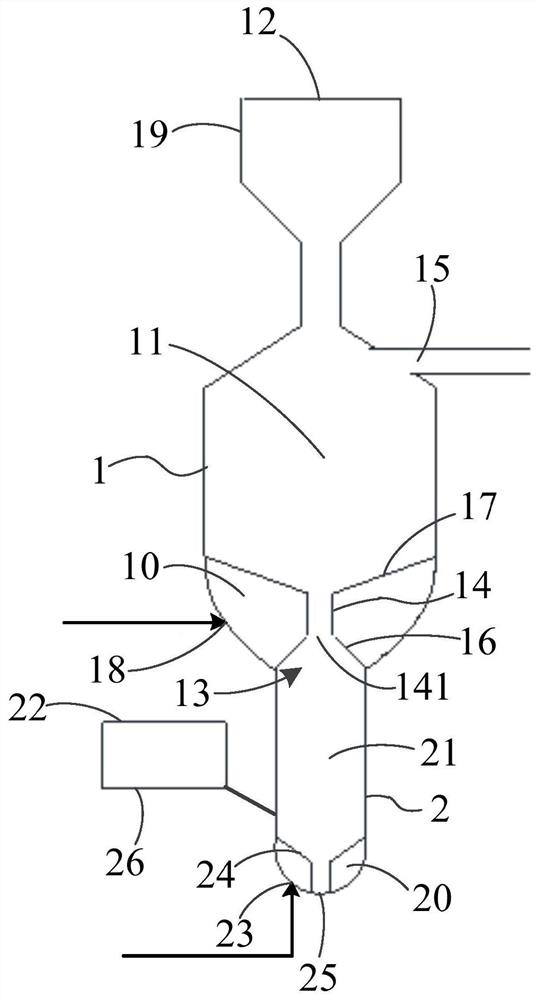

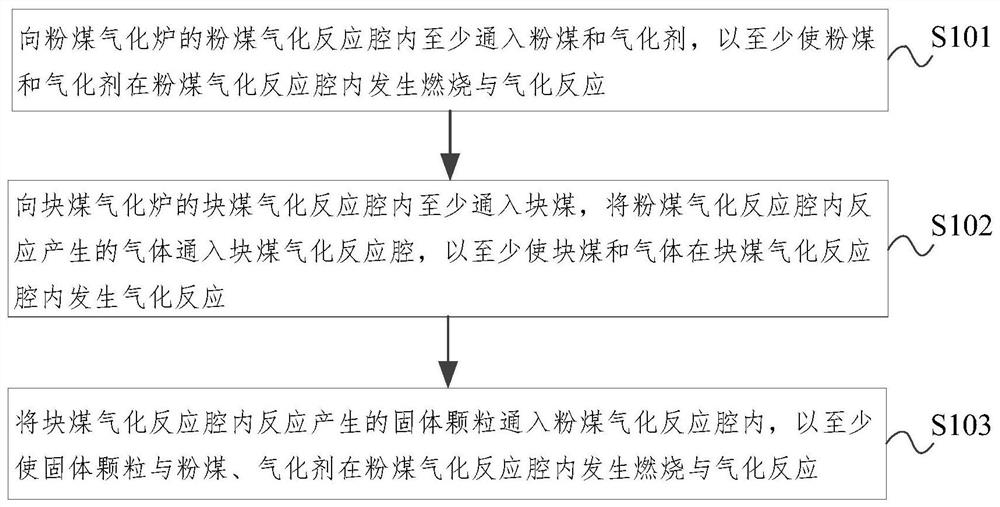

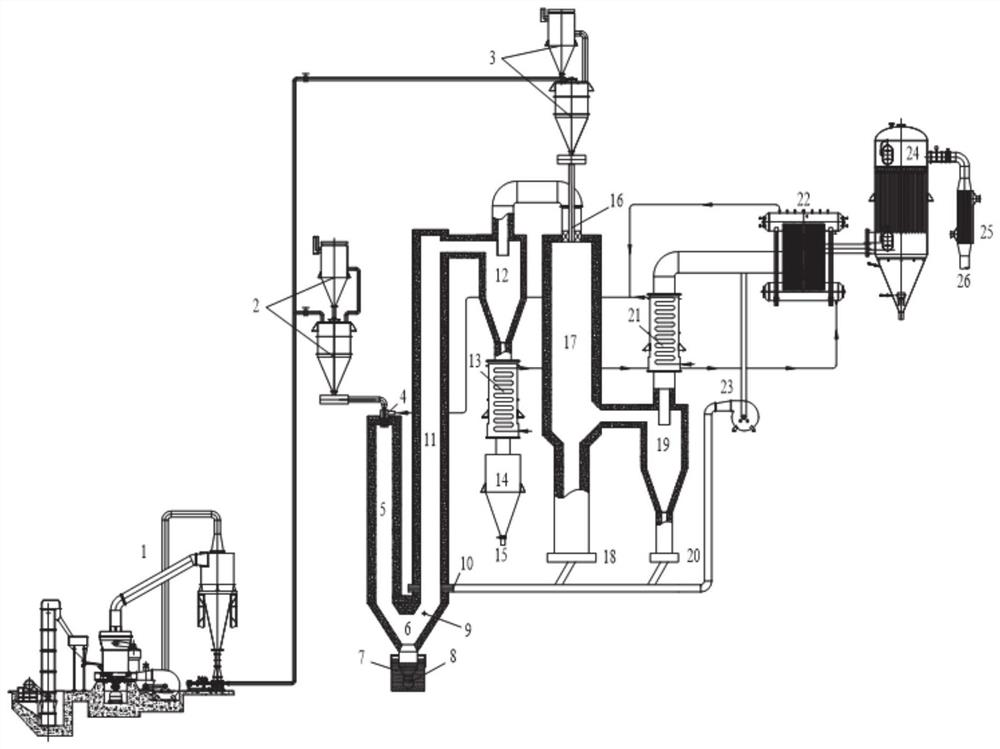

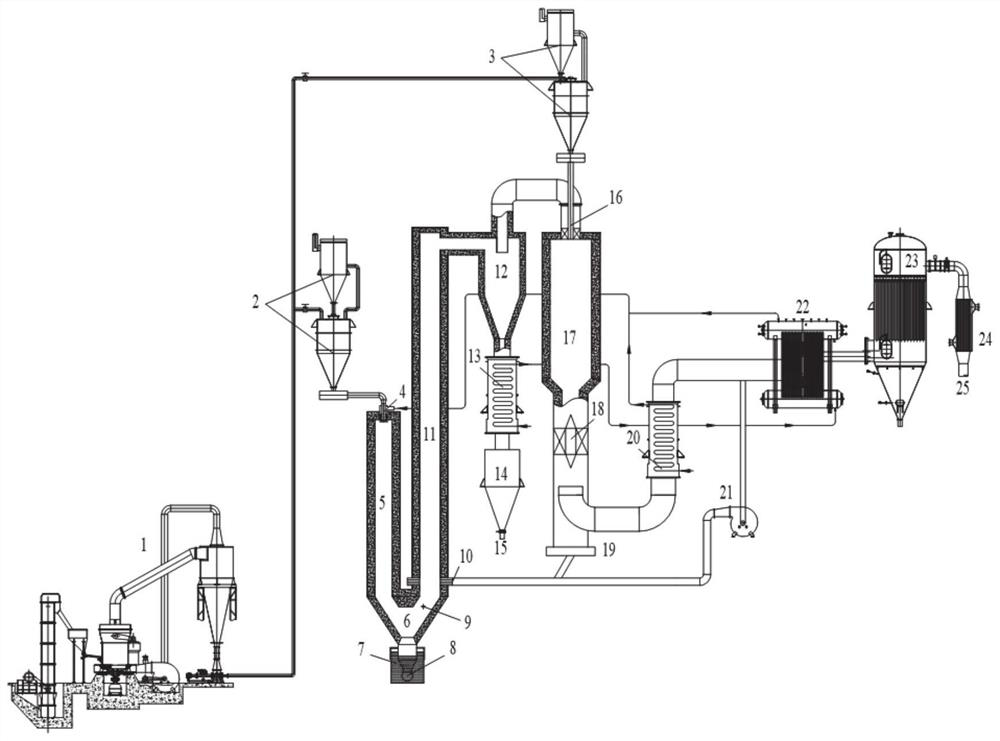

Coupling gasification system and method of pulverized coal and lump coal

ActiveCN112029538BRealization of gasificationAvoid accumulationGasification processes detailsGranular/pulverulent flues gasificationThermodynamicsCombustion

The disclosure relates to a coupled gasification system and method for pulverized coal and lump coal, the system includes a lump coal gasifier and a pulverized coal gasifier; the pulverized coal gasifier has a pulverized coal gasification reaction chamber, a pulverized coal inlet, and a gasification agent inlet The lump coal gasification furnace has a lump coal gasification reaction chamber, a lump coal inlet, a gas inlet, a slagging port and a crude gas gas outlet; the gas inlet is connected with the pulverized coal gasification reaction chamber, so that the gas generated by the reaction in the pulverized coal gasification reaction chamber It enters the lump coal gasification reaction chamber from the gas inlet, and reacts with the lump coal gasification; the slag outlet is connected with the pulverized coal gasification reaction chamber, so that the solid particles produced by the reaction in the lump coal gasification reaction chamber enter from the slag outlet to the Combustion and gasification reactions occur in the pulverized coal gasification reaction chamber, thereby realizing the simultaneous gasification of pulverized coal and lump coal, so as to balance the uneven supply and demand of pulverized coal and lump coal, and improve the utilization rate and conversion rate of coal.

Owner:ENN SCI & TECH DEV

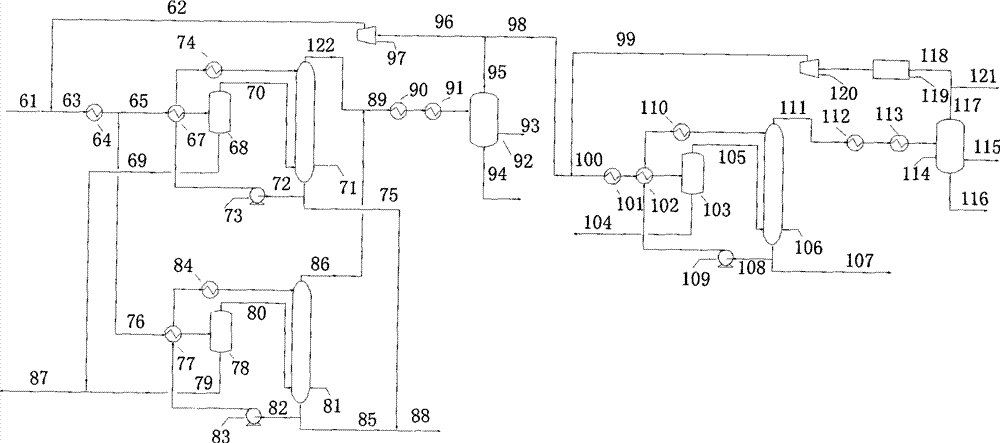

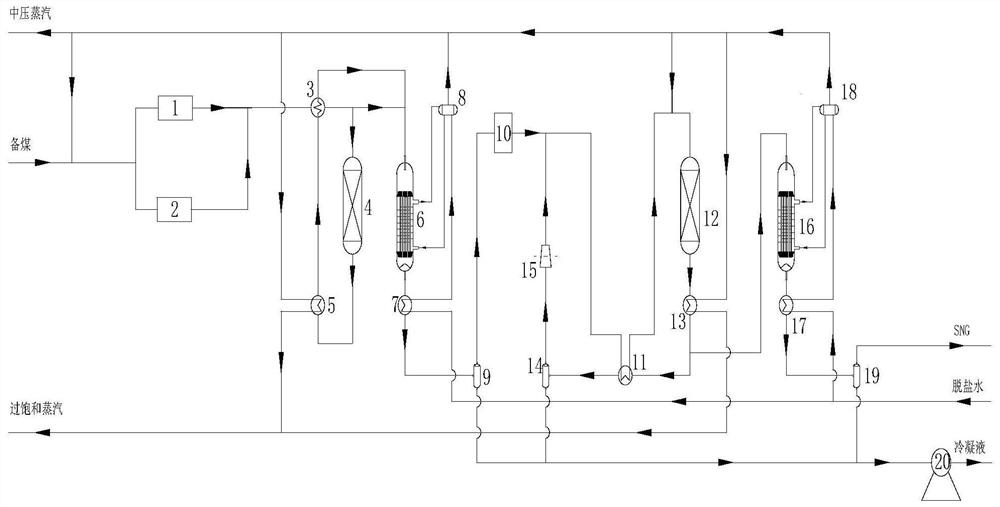

A sulfur-resistant methanation system and method for coal-to-natural gas

ActiveCN111718760BRealize comprehensive utilizationReduce trafficProductsReagentsSyngasThermodynamics

The invention discloses a sulfur-resistant methanation system and method for coal-based natural gas, which belongs to the technical field of coal-based natural gas; firstly, a coal gasification process combining crushed coal gasification and pulverized coal gasification is adopted, and an adiabatic reactor and a homogeneous temperature reactor are used in conjunction with each other. The combined sulfur-resistant methanation process performs methane synthesis on the crude gas to increase the effective content of methane in the synthesis gas and reduce the reaction load of the subsequent section, and then remove the sulfide and carbon dioxide in the raw gas through a conventional purification process, and finally through adiabatic The deep methanation process combining the reactor and the uniform temperature reactor produces qualified natural gas for civil use; this process system realizes the comprehensive utilization of raw coal, effectively reduces the production load of the methanation process, and reduces the size of the reactor and pipeline equipment , improve the unit production capacity, and make full use of the strong exothermic characteristics of the methanation reaction to produce medium-pressure steam and high-quality supersaturated steam, rationally utilize the heat in the process system, reduce energy consumption, and increase production efficiency.

Owner:HUANENG CLEAN ENERGY RES INST

Device for optimizing combustion flow field of pulverized coal gasification furnace

PendingCN113493704ASafe and stable operationAvoid overheatingGasification processes detailsGranular/pulverulent flues gasificationSyngasThermodynamics

The invention relates to a device for optimizing a combustion flow field of a pulverized coal gasification furnace, which is beneficial to stable combustion and promotes the gasification process. The device for optimizing the combustion flow field of the pulverized coal gasification furnace comprises a pulverized coal main burner, an ignition burner, an oxygen system, a pulverized coal system, a cooling water system, the gasification furnace, a gas storage tank, a gas adjusting device and a flow measuring device, and an oxygen feeding system, a pulverized coal feeding system and the cooling water system are arranged on a pulverized coal burner body. An ignition device is arranged at the upper part of the pulverized coal burner body, the center of the pulverized coal burner body is an optimizing device air inlet channel and is used for adjusting burner atomization and optimizing the combustion flow field, the burner center air inlet is supplied by a storage tank, and a measuring device and an adjusting device are arranged on the combustion flow field optimizing device. And the lower part of the pulverized coal burner body is provided with a pulverized coal gasification furnace, and synthesis gas generated by combustion reaction is sent out of a boundary area. In the operation stage of the gasification furnace, the combustion flow field is improved by adjusting the central gas flow of the burner, so that the conversion rate of coal is increased.

Owner:新疆中能万源化工有限公司

System and method for catalytic purification and treatment of coal chemical raw synthesis gas

ActiveCN105838449BReduce the amount of solutionAchieving directional reorientationCombustible gas catalytic treatmentGasification processes detailsSyngasSorbent

The invention discloses a system and a method for catalytic purification treatment on a coal chemical industry crude synthesis gas. The system comprises a molten salt catalysis reaction device and a secondary purification device, wherein the molten salt catalysis reaction device is filled with molten salt; the secondary purification device is filled with an adsorbent. When the system is used, the crude synthesis gas is fed into the molten salt catalysis reaction device; fine coal powder, semi-coke granules, tar and phenolic substances in the crude synthesis gas sufficiently contact the molten salt under the viscous capturing action of the molten salt, and are subjected to catalytic cracking, gasification and reforming reaction under the action of gasses such as H2, CO, CO2 and H2O(g) in the crude synthesis gas, and then the crude synthesis gas can be purified; the crude synthesis gas purified in the molten salt catalysis reaction device is fed into the secondary purification device, and the molten salt carried by the crude synthesis gas can be desorbed through the absorbent in the secondary purification device.

Owner:TAIYUAN UNIV OF TECH

Treatment method of cycle tail gas in Fischer-Tropsch synthetic oil process

ActiveCN105018162BSimple processIncrease profitHydrogenChemical industryPlasma generatorHigh pressure

The invention relates to a Fischer-Tropsch synthetic oil process circulation tail gas treatment method. The method is characterized in comprising the following steps: circulation tail gas is subjected to heat exchange with synthesis gas from a combined catalysis and reforming reactor through a first heat exchanger, and is divided into two streams; a first stream of the circulation tail gas enters a plasma generator; a second stream of the circulation tail gas enters a gas mixer and is mixed with a certain proportion of high-pressure steam, such that water content in the raw gas is adjusted; mixed gas from the mixer and plasma gas from the plasma generator are respectively injected into the combined catalysis and reforming reactor from a top inlet of the combined catalysis and reforming reactor; the gases are mixed, and the mixed gas enters a catalytic reaction part and is subjected to a combined catalysis and reforming reaction; synthetic gas from the combined catalysis and reforming reactor is subjected to heat recovery, and a liquid phase is separated, such that the gas can be recycled as circulation tail gas.

Owner:SINOPEC NINGBO ENG +2

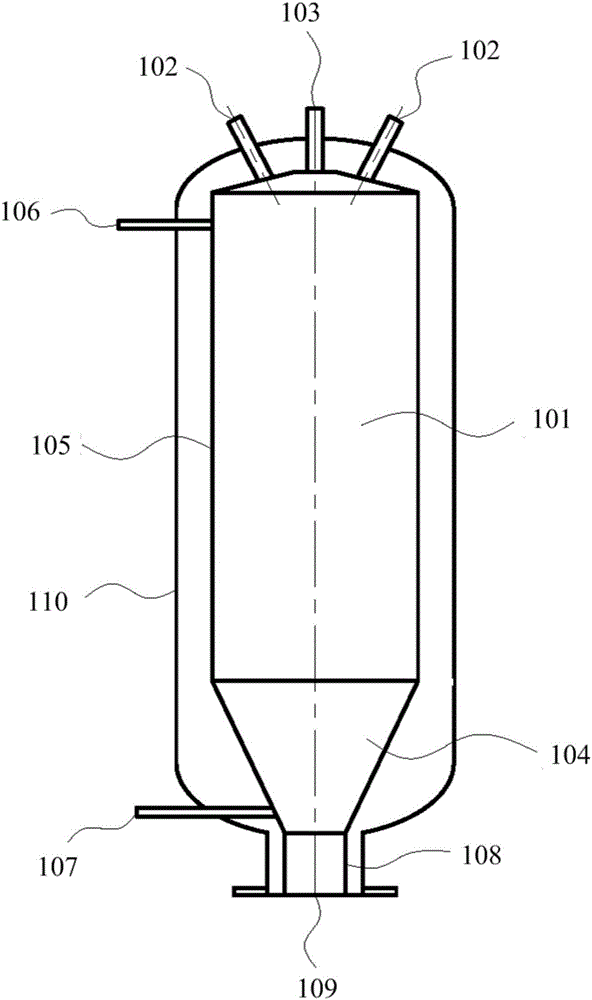

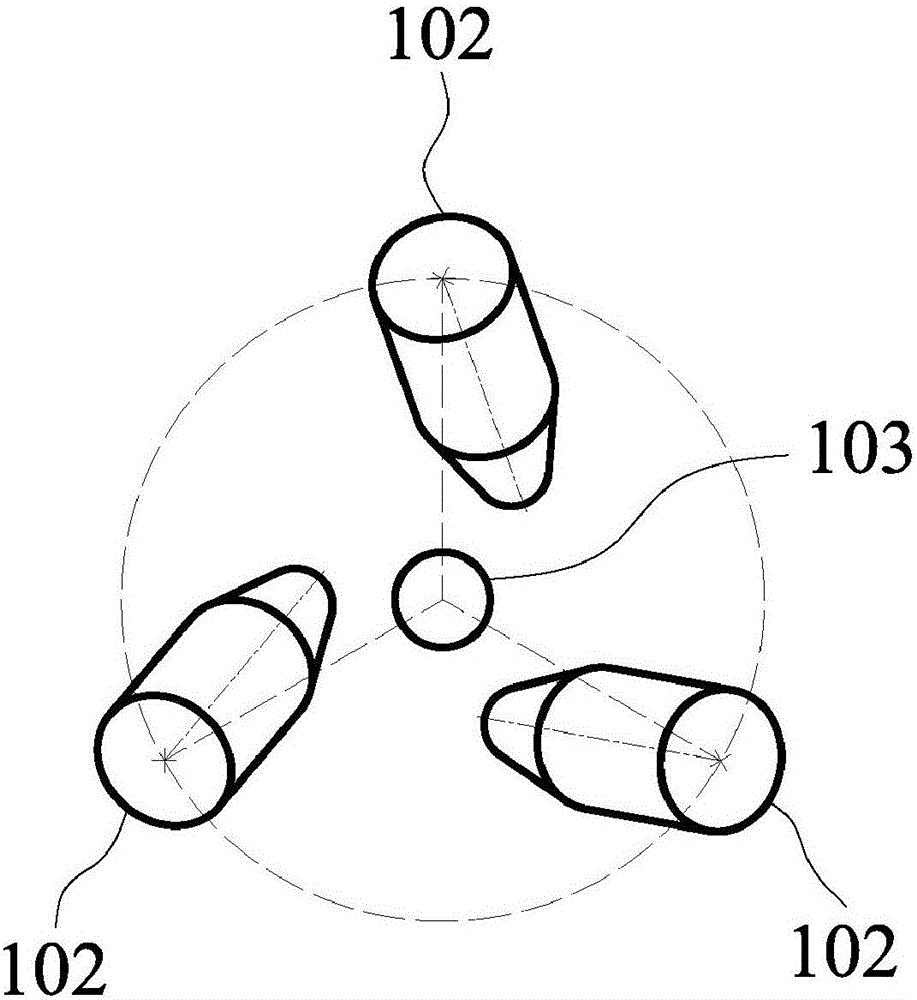

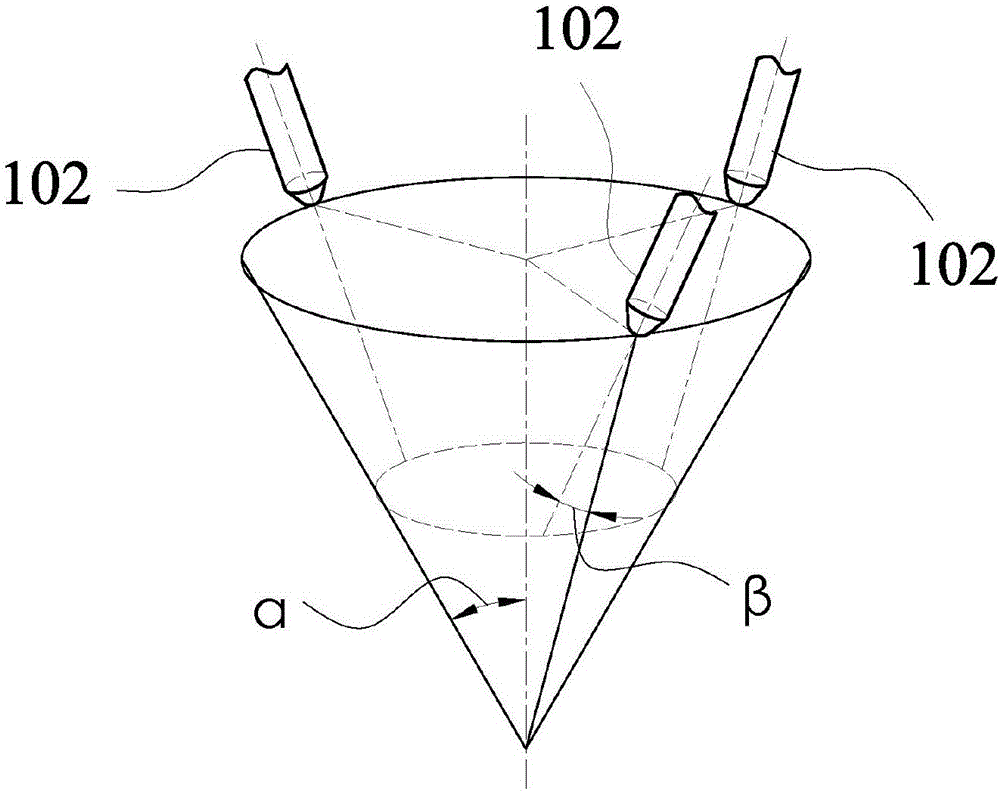

Coal gasifier

ActiveCN106244244AWell mixedExtended stayGasification processes detailsGasification apparatus detailsRetention timeProcess engineering

The invention provides a coal gasifier which comprises a gasification chamber, N process burners and an ignition burner. The ignition burner is arranged in the center of the top of the gasification chamber; the N process burners are arranged on the top of the gasification chamber and arranged at the periphery of the ignition burners in a surrounding mode, wherein N>=3; the projection straight lines of the center lines of the process burners at the outlet center points of the corresponding process burners and the projection straight lines of the center lines of the process burners on the plane determined by the axis of the gasification chamber are a generation line of a same cone, and the included angles of the center lines of the process burners and the corresponding projection straight lines are beta, wherein beta is larger than 0 degree. According to the coal gasifier, dry coal powder and a gasification agent are uniformly mixed in the gasification chamber, the retention time of the dry coal powder particles in the gasification chamber is long, therefore, effective gas components in synthetic gas are increased, the unsymmetric burning phenomenon is avoided, and the carbon conversion rate is high.

Owner:KEDA MAS CLEAN ENERGY +1

Fixed bed-fluidized bed serially connected gasification method and apparatus

ActiveCN101440308BReduce tar contentEmission reductionCombined combustion mitigationCombustible gas productionFluidized bed gasifierFluidized bed

Owner:CCTEG CHINA COAL RES INST

System and method for co-producing coal gas and powdery active coke

ActiveCN112226241AHigh effective gas contentHigh calorific valueEnergy inputGasification processes detailsThermodynamicsCarbonization

The invention relates to a system and a method for co-producing coal gas and powdery active coke. The system comprises a gasification activation furnace, a coke breeze separator, a carbonization furnace and a carbonized semicoke separator, the gasification activation furnace is of a U-shaped structure with the bottom communicated, the gasification furnace and the activation furnace are arranged onthe two sides respectively, the top of the activation furnace is connected with the coke breeze separator, the top of the coke breeze separator is connected with the carbonization furnace, and the carbonization furnace is connected with the carbonized semicoke separator; the carbonization furnace is connected with the bottom of the activation furnace. The carbonized semicoke is activating by taking powdered coal air gasified gas as a heat source and a medium to prepare powdered activated coke; meanwhile, the activated coal gas waste heat is used for carrying out pulverized coal carbonizationto prepare carbonized semicoke. Powdery active coke is rapidly prepared by fully utilizing coal gas waste heat, and meanwhile, coal gas with a relatively high calorific value is produced.

Owner:SHANDONG UNIV

A fixed-bed pure oxygen continuous gasification device and process suitable for various coal qualities

ActiveCN105542860BImprove decomposition rateHigh effective gas contentChemical industryGasification processes detailsAdditive ingredientFixed bed

The invention relates to a fixed-bed pure-oxygen continuous gasification device and process adaptable to diversified coals. According to the device and the process, CO2, pure oxygen and superheated steam serve as gasifying agents and subject to a gasification reaction with feed coal in a fixed-bed pure-oxygen continuous gasifier, so as to generate gasified coal gas; the gasified coal gas enters a dust remover so as to remove solid particles from the gasified coal gas, and a water cooler is arranged at the upper part of the efficient dust remover and is used for recovering part of sensible heat from the gasified coal gas; the gasified coal gas subjected to dust removal enters a heat-pipe heat exchanger for heat recovery, and low-pressure steam is a byproduct; and low-temperature gasified coal gas enters a low-pressure coal gas scrubbing tower for final cooling and dust removal, and scrubbed water gas is connected and conveyed to a gas tank. The content of CO and H2 in the gasified coal gas can reach 80% or more, the ratio range of adjustment of CO among ingredients of the coal gas is 40-65%, the ratio range of adjustment of H2 among the ingredients of the coal gas is 5-40%, and the gasified coal gas can serve as raw material gas of a variety of chemical products through being subjected to further deep treatment by processes such as conversion and purification.

Owner:河南顺达新能源科技有限公司

Start-up compound burner for water-coal-slurry or coal dust gasification furnace

InactiveCN101650031BAdjust the size of the annulusHigh media speedCombined combustion mitigationGaseous fuel burnerCoal dustProduct gas

Owner:YANKUANG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com