Fixed bed-fluidized bed serially connected gasification method and apparatus

A fluidized-bed gasifier and fluidized-bed technology are applied in the production of combustible gas, petroleum industry, combined combustion mitigation, etc., and can solve the problems affecting the continuous stability of biomass gasification production, affecting the use of gas, and high tar content , to achieve the effects of low cost, increased calorific value, and increased effective gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

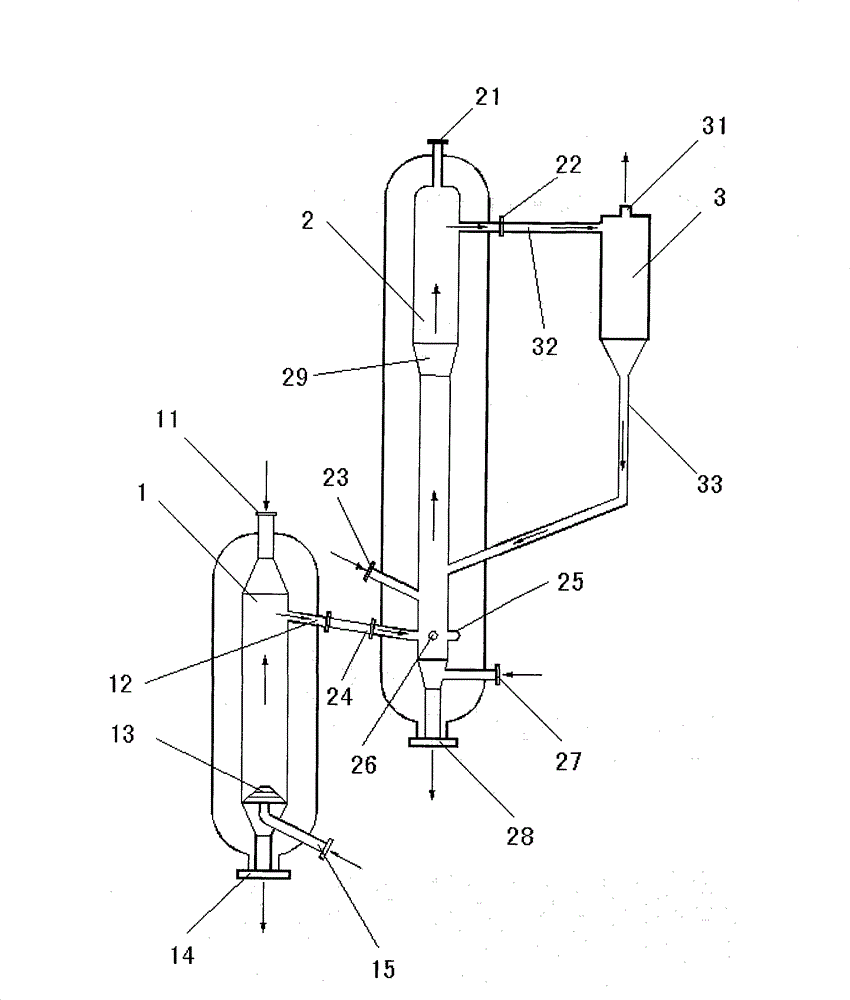

[0018] Such as figure 1 As shown, the present invention includes a fixed bed gasifier 1 , a fluidized bed gasifier 2 and a cyclone separator 3 .

[0019] The fixed-bed gasifier 1 in this embodiment is a gas upward gasifier. A fixed-bed material inlet 11 is arranged on the top of the fixed-bed gasifier 1. A fixed-bed gas outlet 12 is arranged on the upper part of the fixed-bed gasifier 1. A conventional rotary grate 13 is provided at the lower part of the bed gasifier 1 , and a fixed bed ash outlet 14 is provided at the bottom of the fixed bed gasifier 1 . A fixed bed gasification agent inlet 15 is arranged above the fixed bed ash outlet 14 and below the rotary grate 13, and the rotary grate 13 can evenly distribute the gasification agent.

[0020] The top of the fluidized bed gasifier 2 is provided with a manhole 21 for maintenance, the upper part of the fluidized bed gasifier 2 is provided with a fluidized bed gas outlet 22, and the lower part of the fluidized bed gasifier 2...

Embodiment 2

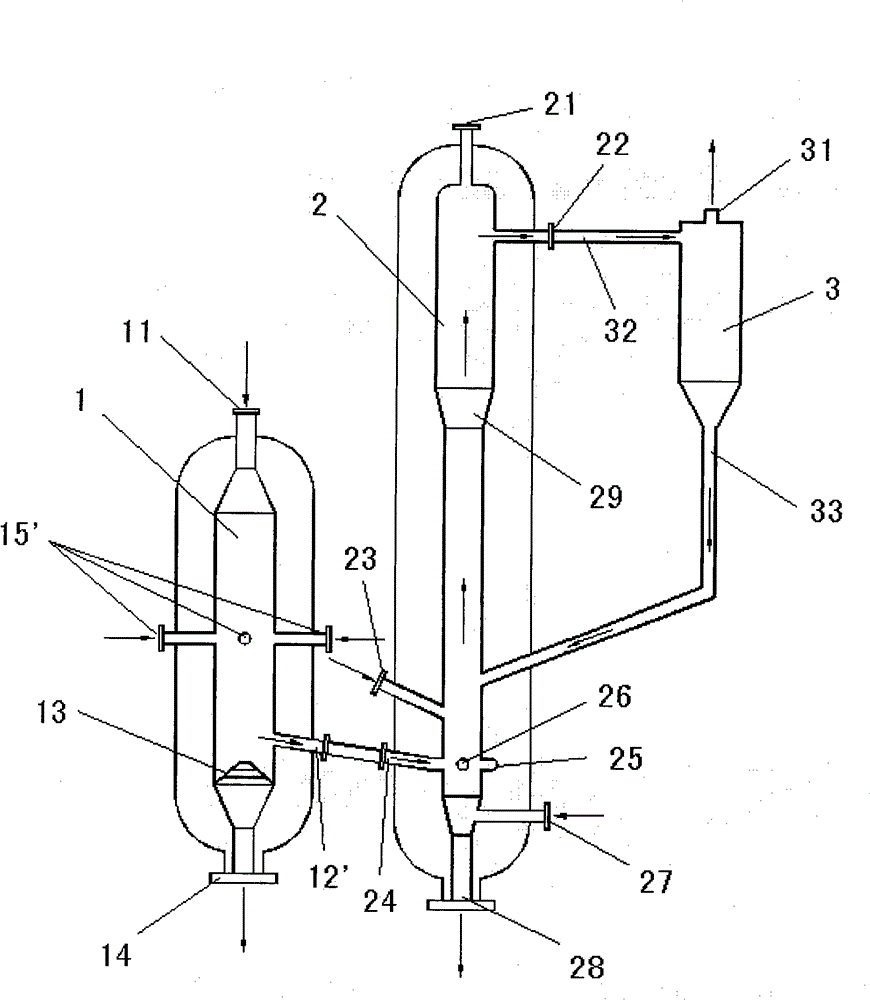

[0024] Such as figure 2 As shown, the fixed-bed gasifier 1 in this embodiment is a gas down-flow gasifier, and this embodiment is basically the same as Embodiment 1, the difference is that the fixed-bed gasification agent inlet 15' is set at the fixed-bed In the middle of the gasifier 1, instead of the lower part, the number of fixed bed gasification agent inlets 15' is 2 to 4; the fixed bed gas outlet 12' is set at the lower part of the fixed bed gasifier 1, located Above grate 13.

Embodiment 3

[0026] Such as figure 1 As shown, taking the device structure of Example 1 as an example, the fixed-bed fluidized-bed serial gasification method of the present invention is described, which includes the following steps:

[0027]1) The biomass gasification raw material with a particle size of 13-50 mm is fed downward into the fixed bed gasifier 1 in normal operation from the fixed bed material inlet 11 at the top of the fixed bed gasifier 1, and the superheated steam and air The mixed gas is sent upwards from the fixed bed gasification agent inlet 15 at the lower part of the fixed bed gasifier 1, and is evenly distributed into the fixed bed gasifier 1 through the rotary grate 13, so that the bulk gasification raw material and gasification agent are in a fixed state. The pyrolysis and gasification reaction is carried out by countercurrent contact in the bed gasifier 1 to produce tar-rich gas and ash. The ash is discharged from the fixed bed ash outlet 14, and the gas passes thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com