Method for emission reduction of CO2 and yield increase of methyl alcohol and acetic acid by means of CO2 emission reduction integrated unit adopted in coal-to-methanol and coal-to-acetic acid processes

A coal-to-methanol and combined device technology, applied in chemical instruments and methods, carbon monoxide reaction to prepare carboxylic acid, and combustible gas, can solve the problems of polluting the environment, aggravating the greenhouse effect, and large combustion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

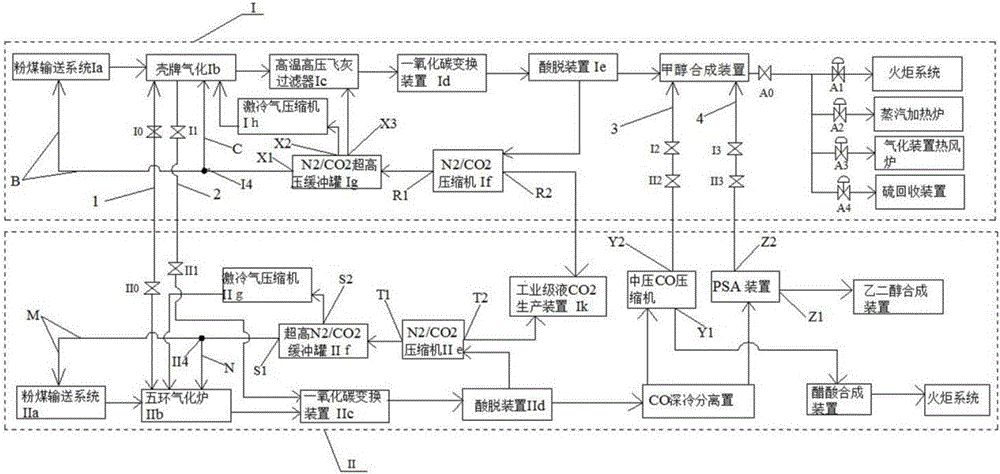

[0035] CO emission reduction in coal-to-methanol and coal-to-acetic acid processes 2 combined devices, such as figure 1 Shown: The device includes coal-to-methanol plant I, coal-to-acetic acid plant II, CO 2 Connect the pipe network 1, and the gas delivery pipeline connecting the coal-to-methanol unit and the coal-to-acetic acid unit, the gas delivery pipeline includes crude gas delivery pipeline 2, hydrogen H 2 Gas delivery pipeline 4 and carbon monoxide CO gas delivery pipeline 3.

[0036] Wherein, the coal-to-methanol unit I includes a pulverized coal delivery system Ia, a Shell gasifier Ib, a high-temperature and high-pressure fly ash filter Ic, a CO conversion unit Id, an acid removal unit Ie, a methanol synthesis unit, a flare system, and steam heating Furnace, gasification unit hot blast stove, sulfur recovery unit, N 2 / CO 2 Compressor If, super high pressure N 2 / CO 2 Buffer tank Ig, chilled gas compressor Ih and industrial grade liquid CO 2 Production device I...

Embodiment 2

[0042] Using coal to methanol and coal to acetic acid to reduce CO emissions 2 Combined plant emission reduction CO 2 And the method for increasing production of methanol and acetic acid comprises the following steps:

[0043] (1) Start the coal-to-methanol unit Ⅰ. After the start-up, the pulverized coal enters the pulverized coal delivery system Ⅰa under the action of the carrier gas nitrogen, and utilizes the pressure difference between the pulverized coal delivery system Ⅰa and the Shell gasifier Ⅰb to 11.20kg The amount of coal input per second is to put coal powder into the Shell gasifier, and at the same time, feed oxygen into the Shell gasifier at a rate of 10.67kg / s with a mass flow rate until the oxygen load is 58%. The mass ratio of the reaction gasifier is 1-1.05, and then the reaction is carried out in the gasifier at a pressure of 0.5-0.8MPa and a temperature of 1400-1600°C; when the pressure in the reaction gasifier is 3.0-4.0MPa, the gasifier When the oxygen l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com