Patents

Literature

84results about How to "Reduce CO2" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

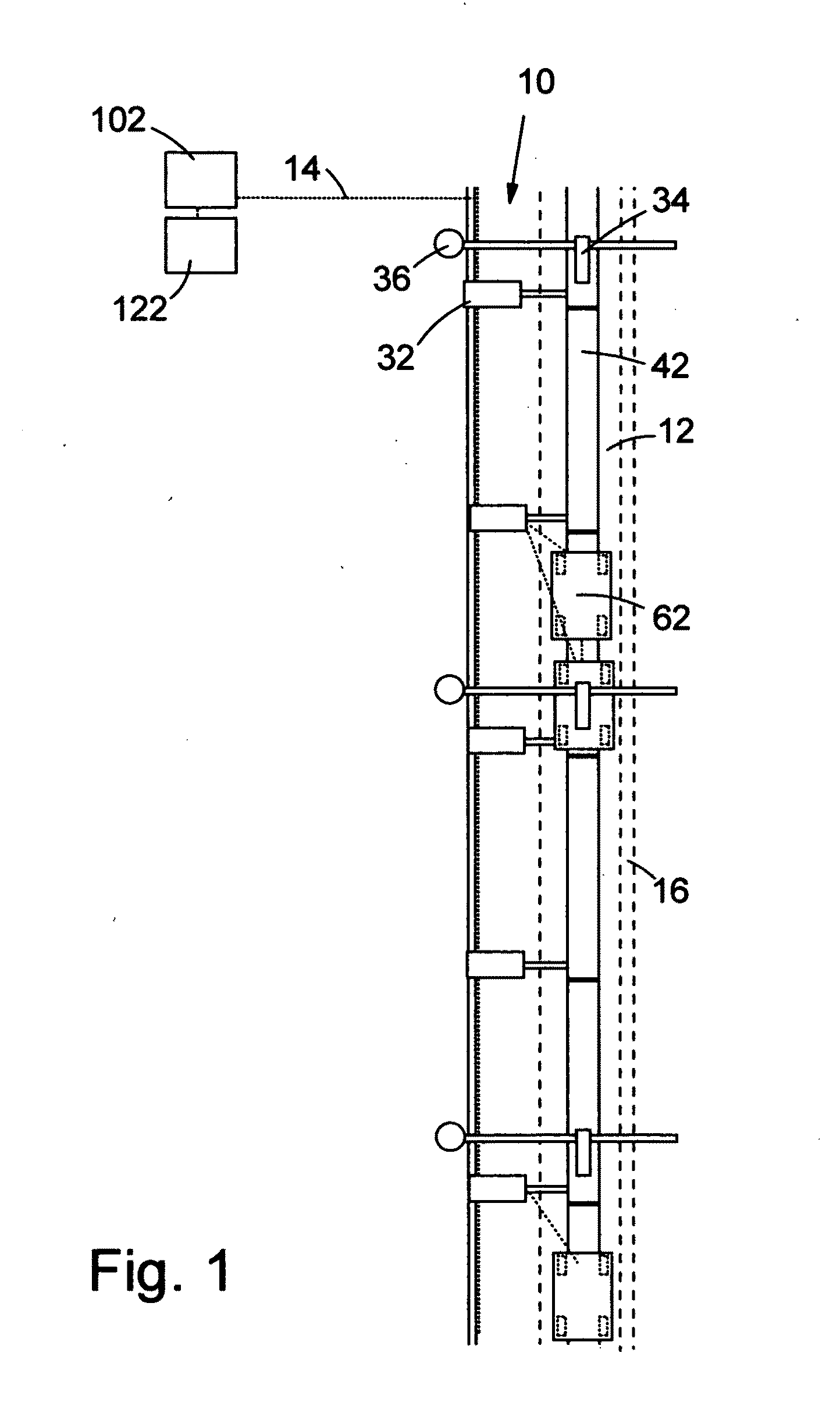

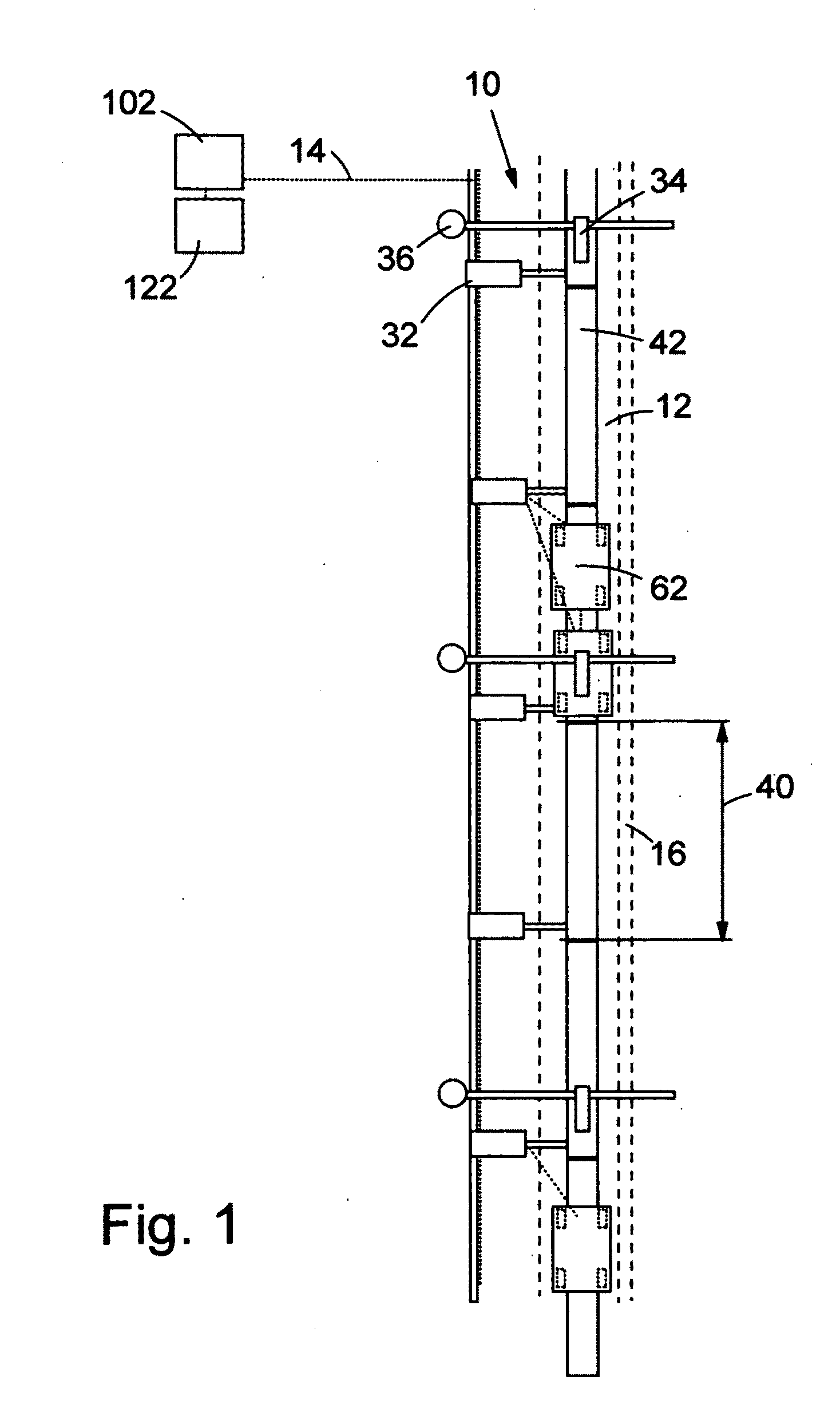

Vehicle operated on electric highway

InactiveUS20110106349A1Shorter headwayReduce the possibilityRail devicesDigital data processing detailsAutomotive engineeringOn board

The vehicle operated in an electric highway system has an electric motor, at least one energy storage device, an on-board power pick up device, at least one coupler, at least one power meter, at least one on-board computer, an on-board part of a lateral location sensor, an on-board lateral position control mechanism, a longitudinal distance / speed sensor, and a longitudinal position control mechanism, and at least one communication device. The vehicle is able to operate and couple together with other vehicles automatically in the electrified lane of the electric highway system.

Owner:SAKITA MASAMI

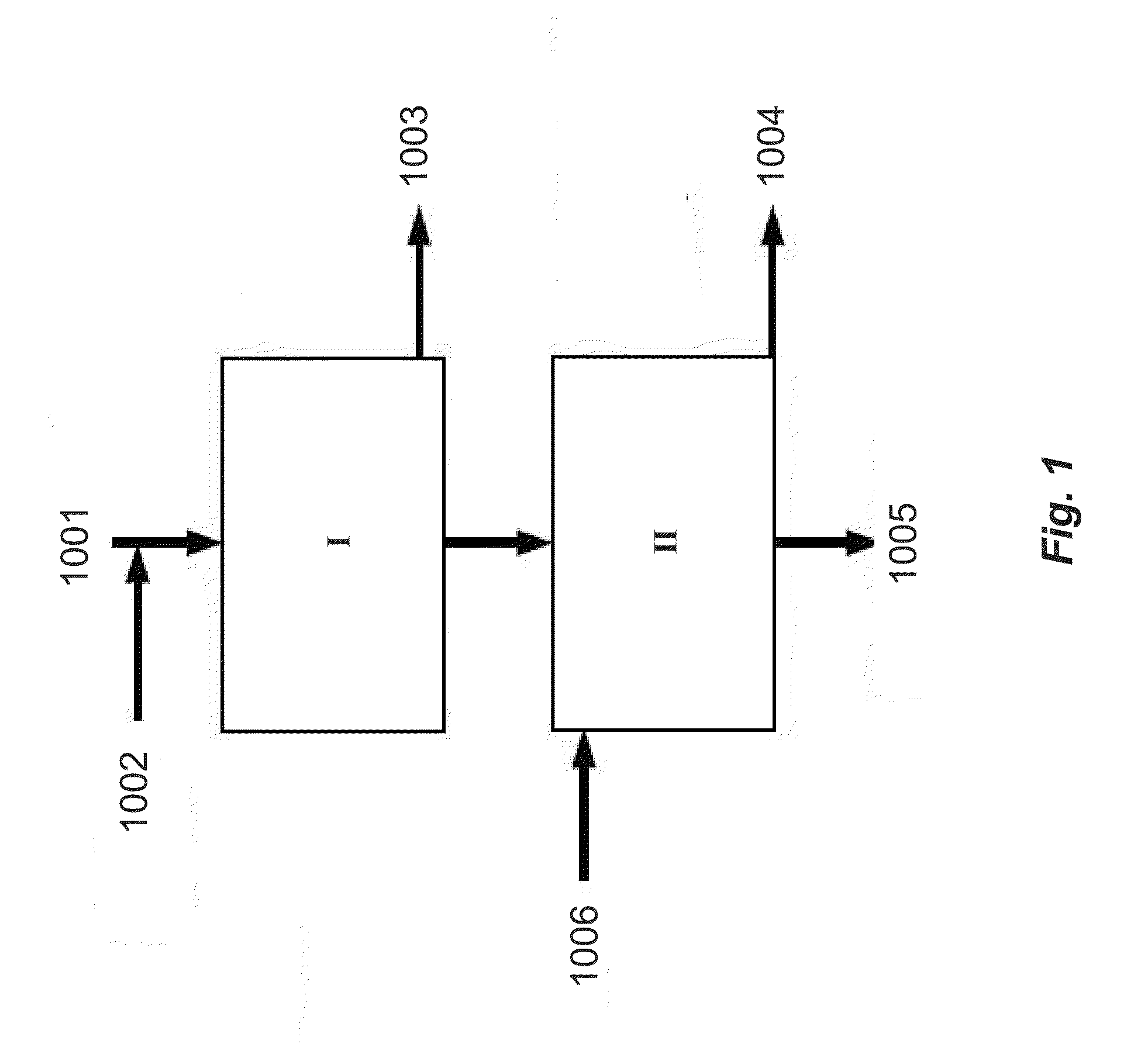

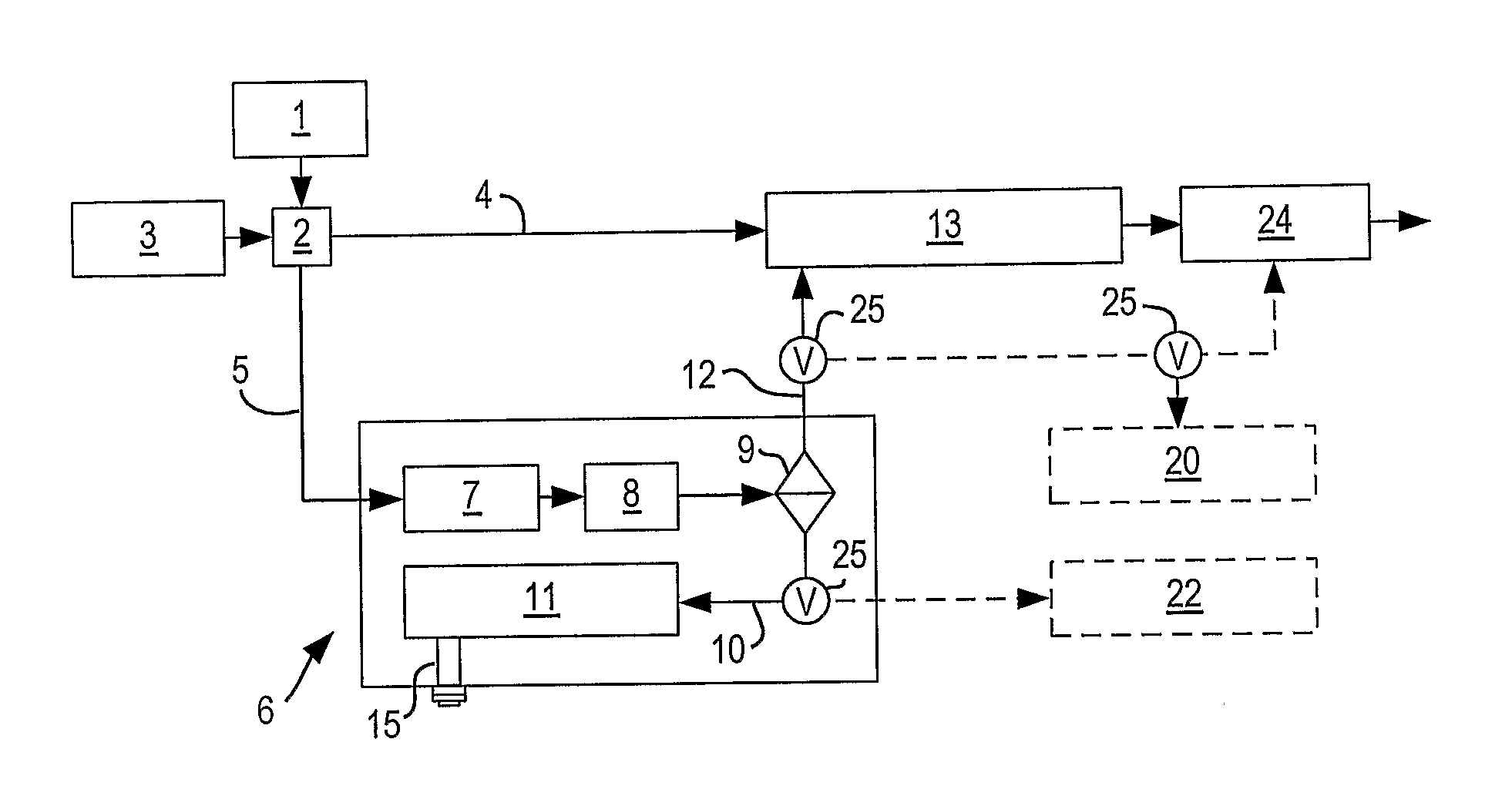

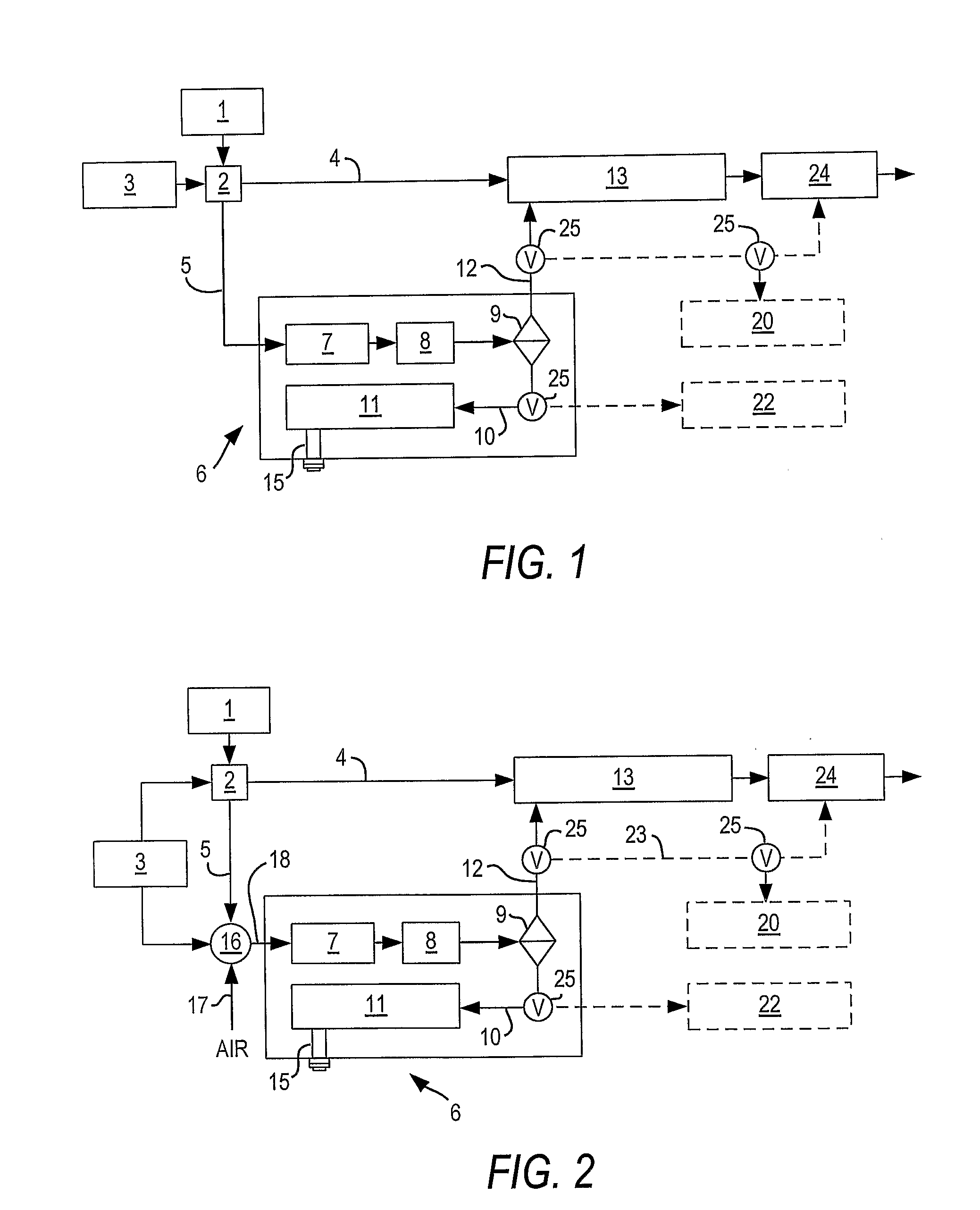

System and method for carbon dioxide capture and sequestration from relatively high concentration co2 mixtures

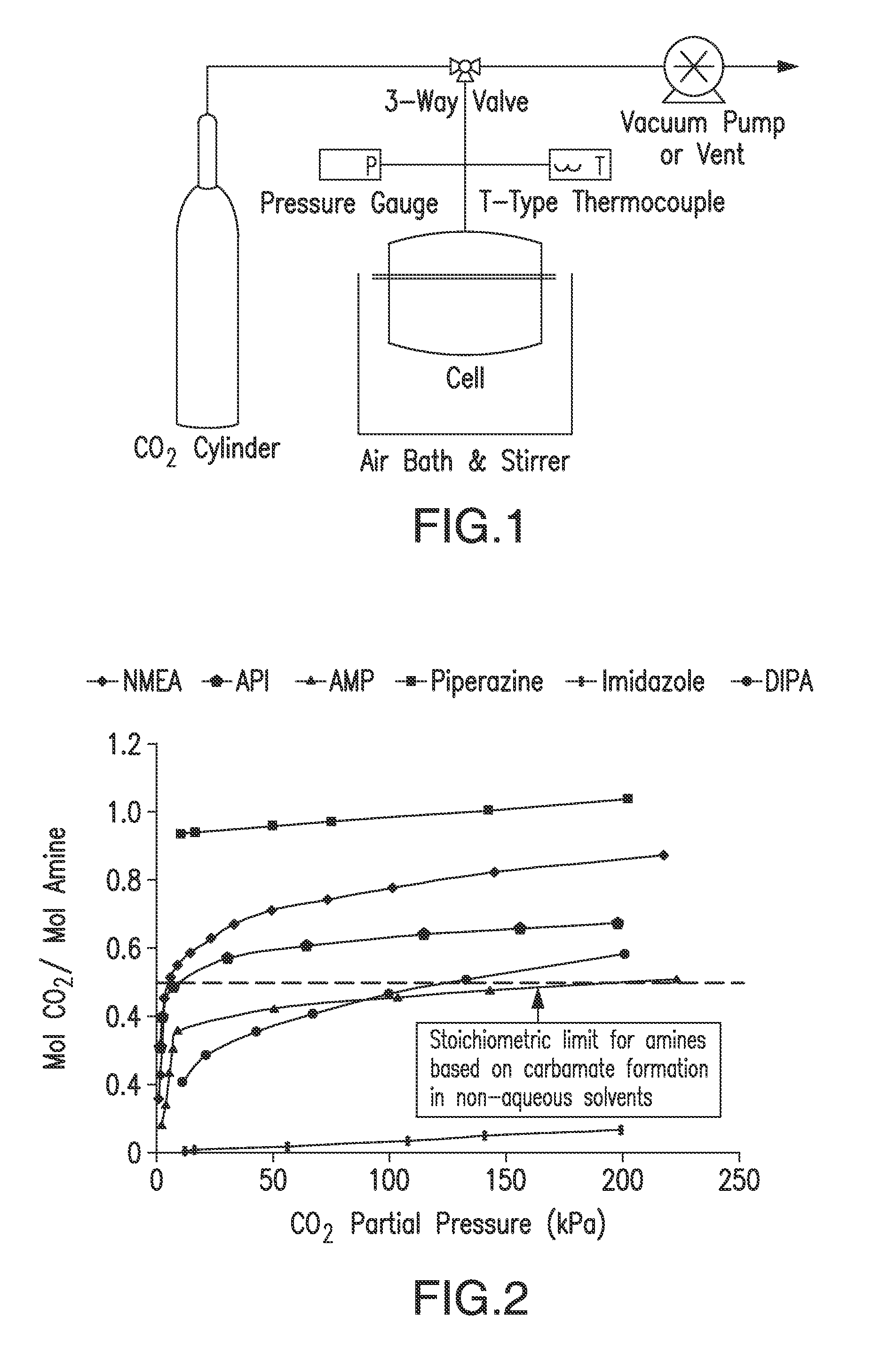

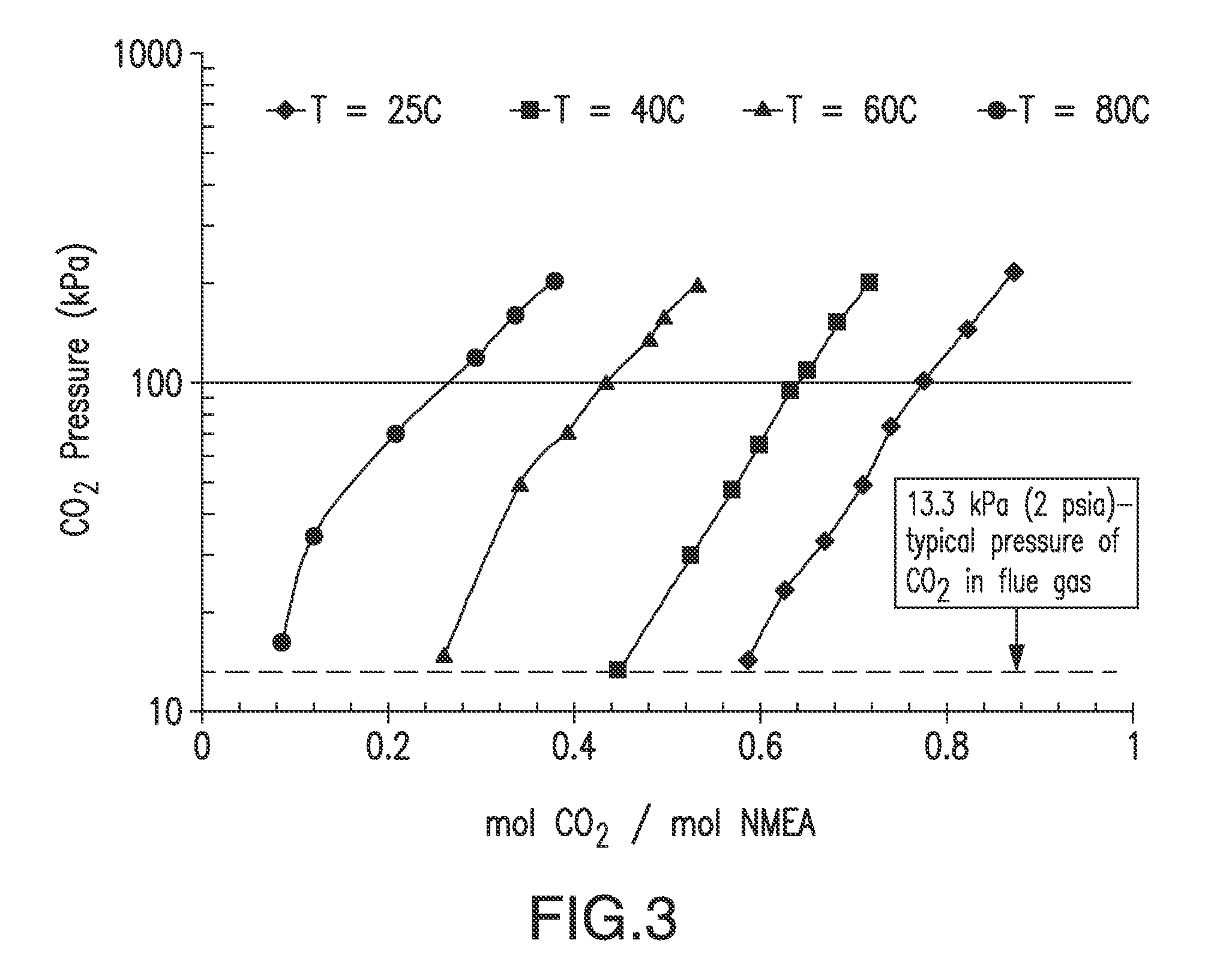

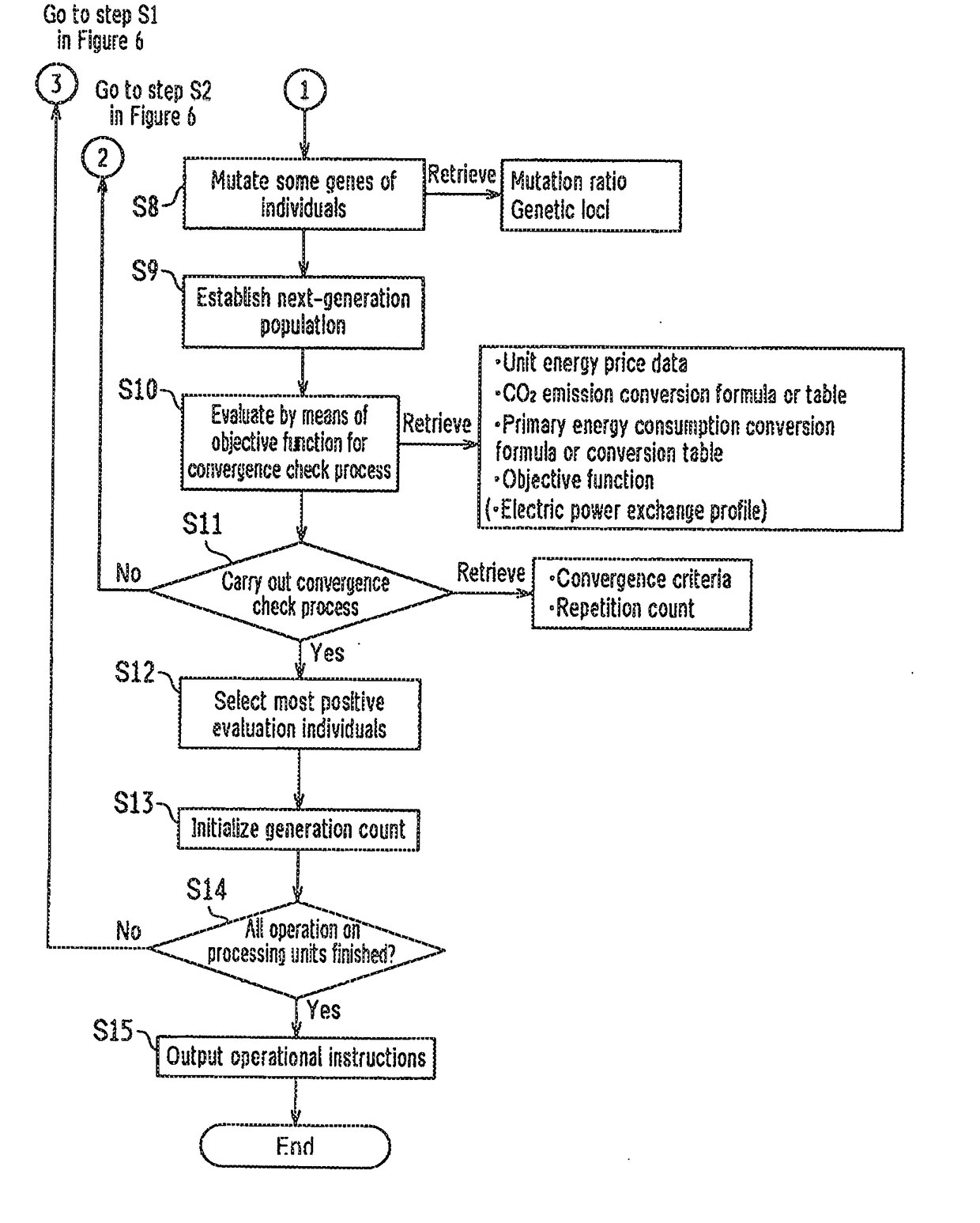

ActiveUS20130312606A1Reduce CO2Efficient captureGas treatmentIsotope separationHigh concentrationPorous substrate

A system and method of reducing the net carbon dioxide footprint of an industrial process that generates power from the combustion of hydrocarbon fuels in which ambient air is admixed with up to 50% by volume of an effluent gas from the power generator of the industrial process, in order to substantially increase the CO2 concentration in the air prior to treatment. The treatment comprises adsorbing CO2 from the admixed ambient air utilizing a cooled, porous substrate-supported amine adsorbent, wherein the porous substrate initially contacts the mixed ambient air containing condensed water in its pores, which act as an intrinsic coolant with respect to the exothermic heat generated by the adsorption process. In addition, prior to regenerating the supported adsorbent, air pressure is substantially reduced in the sealed regeneration chamber and the low pressure chamber is placed in fluid connection with a higher pressure regeneration chamber containing steam and carbon dioxide, to preheat the sorbent to be regenerated and to quickly cool the regenerated sorbent prior to use for further CO2 adsorption.

Owner:GLOBAL THERMOSTAT OPERATIONS LLC

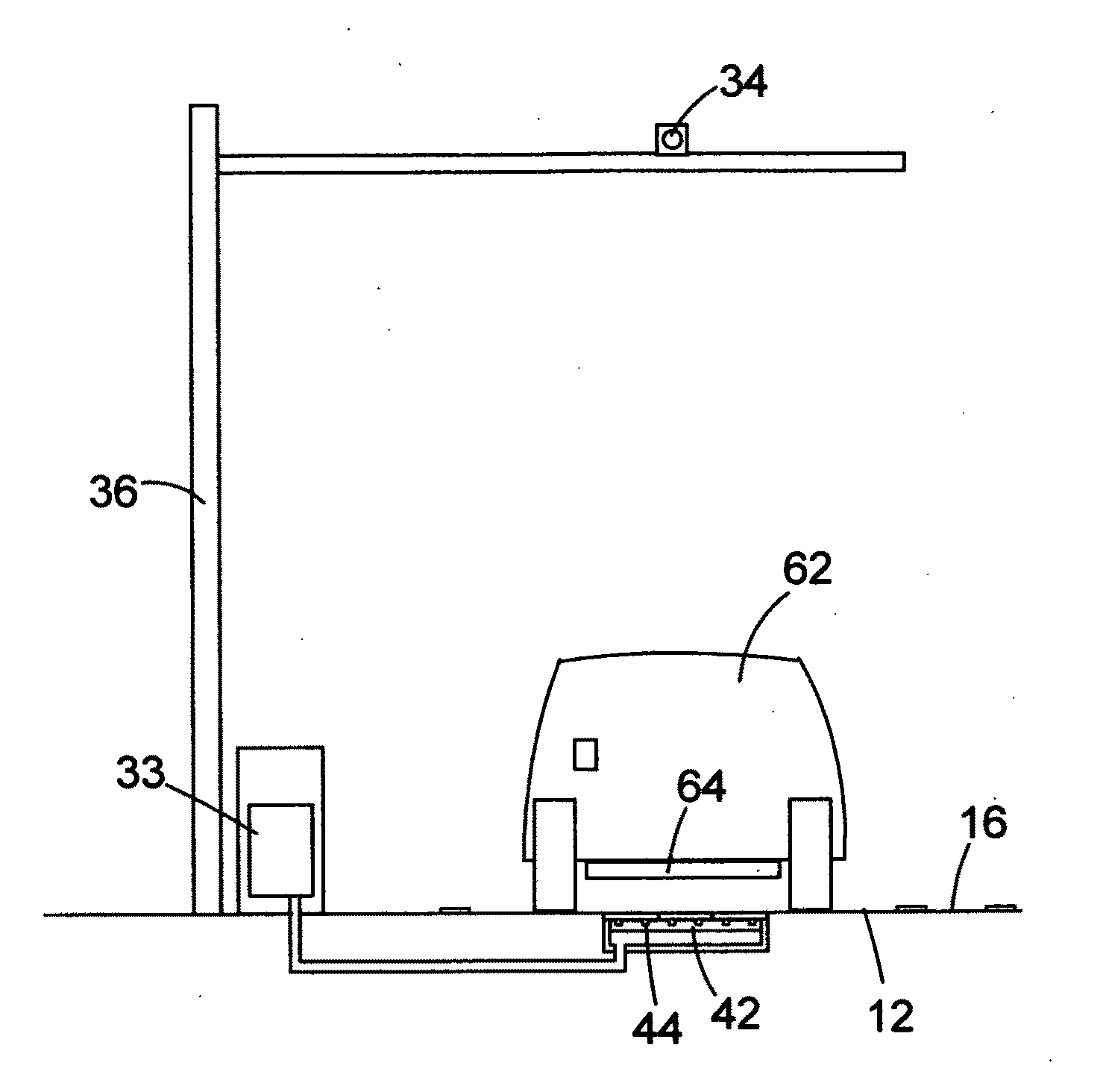

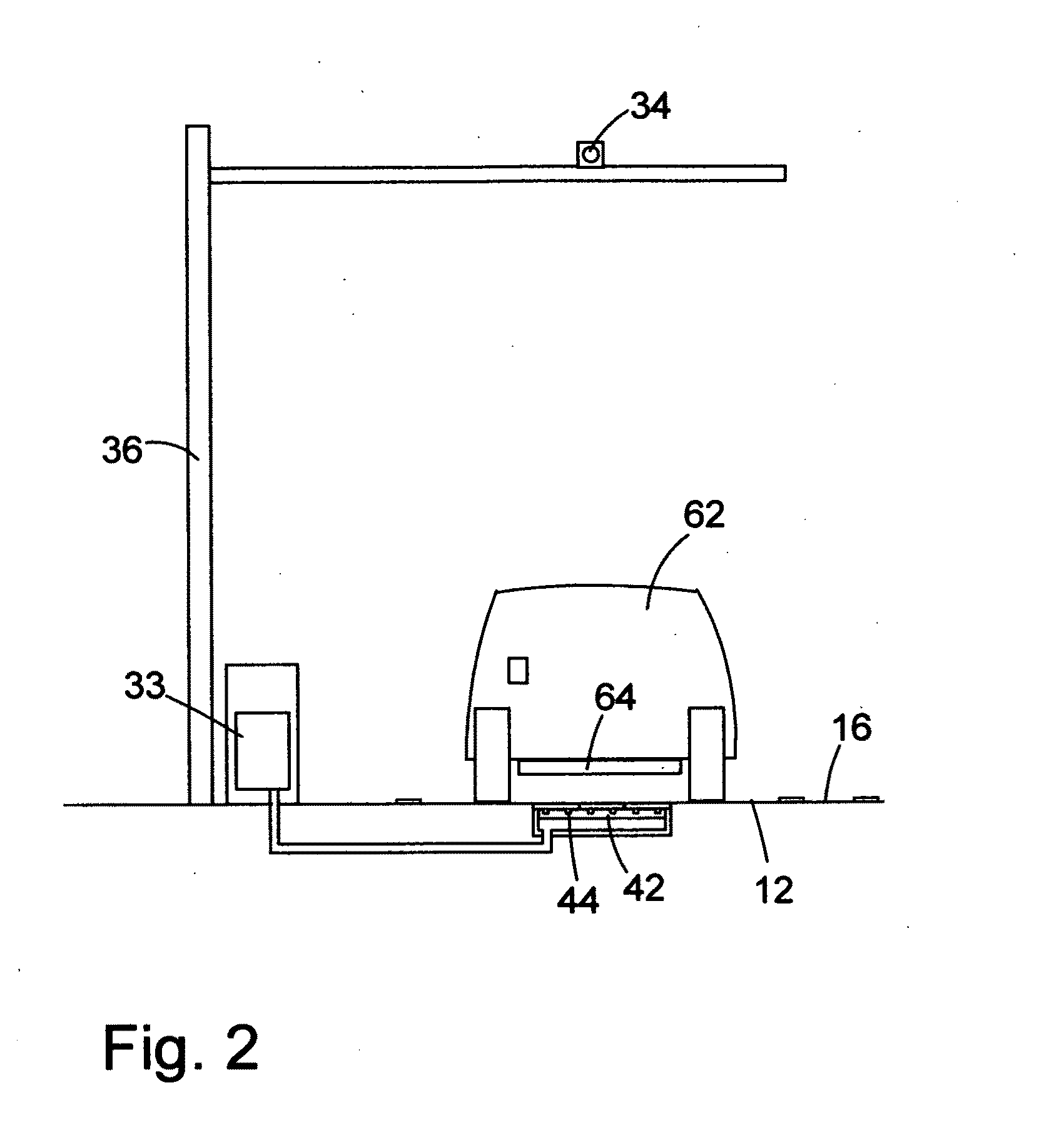

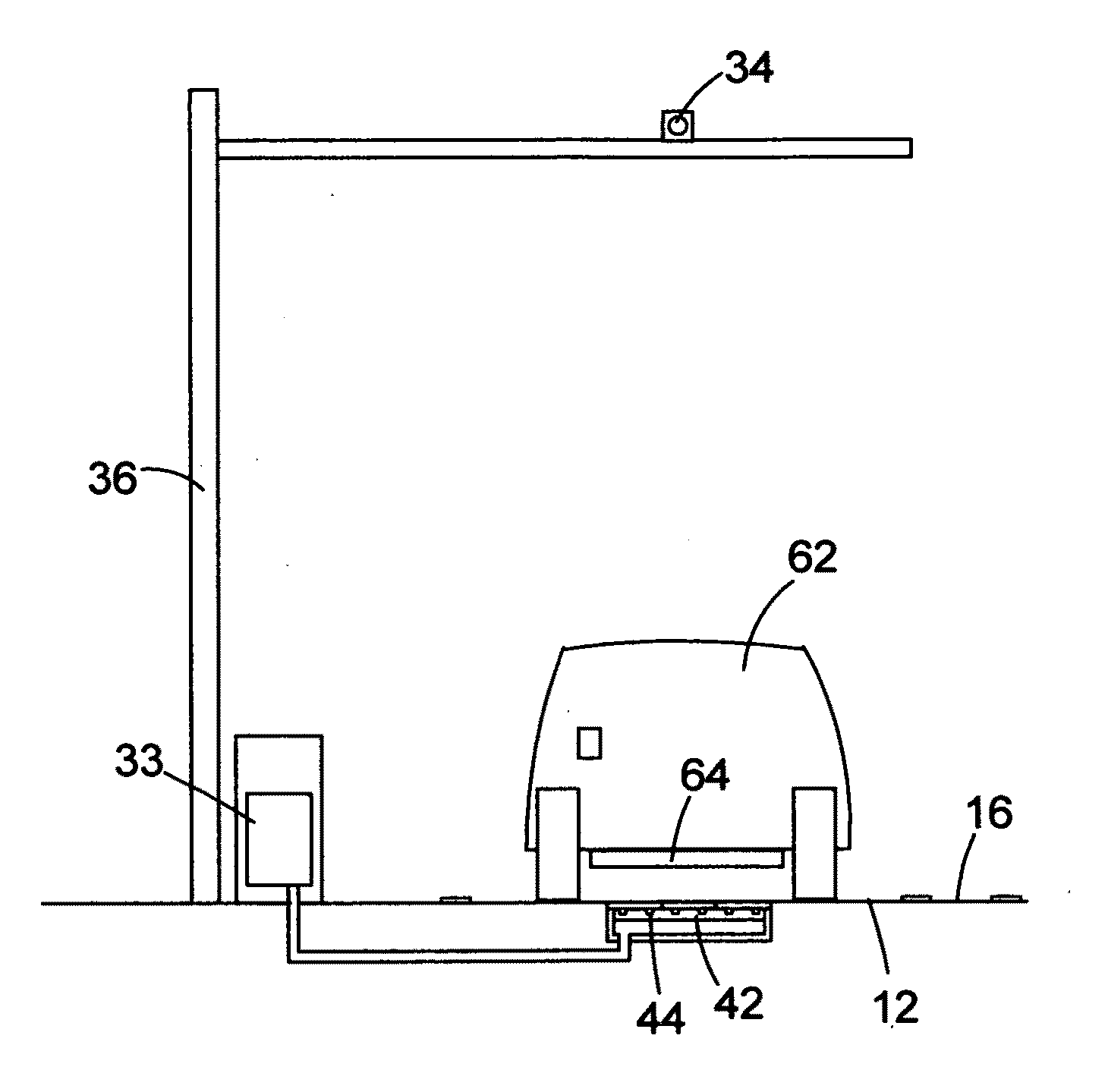

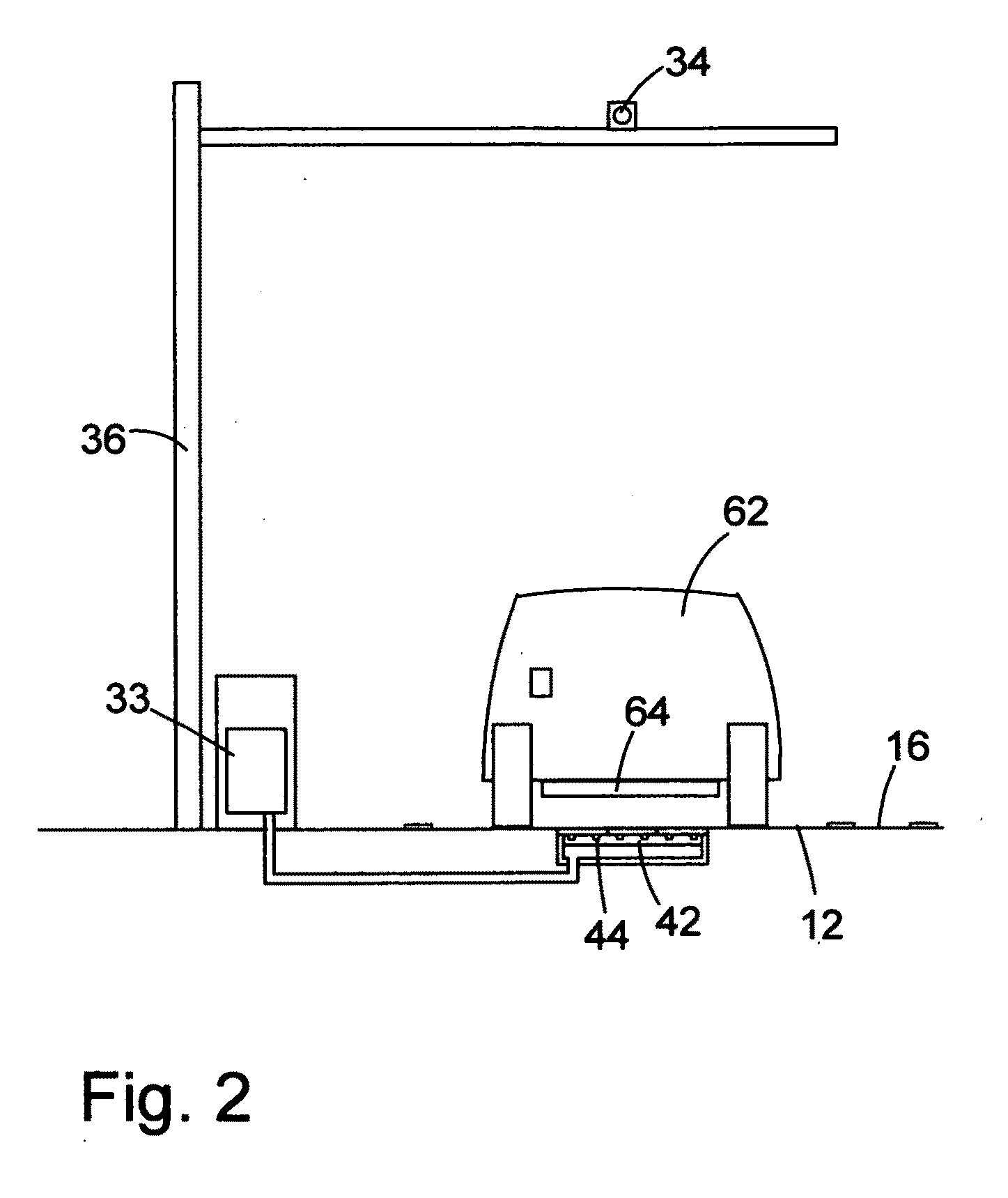

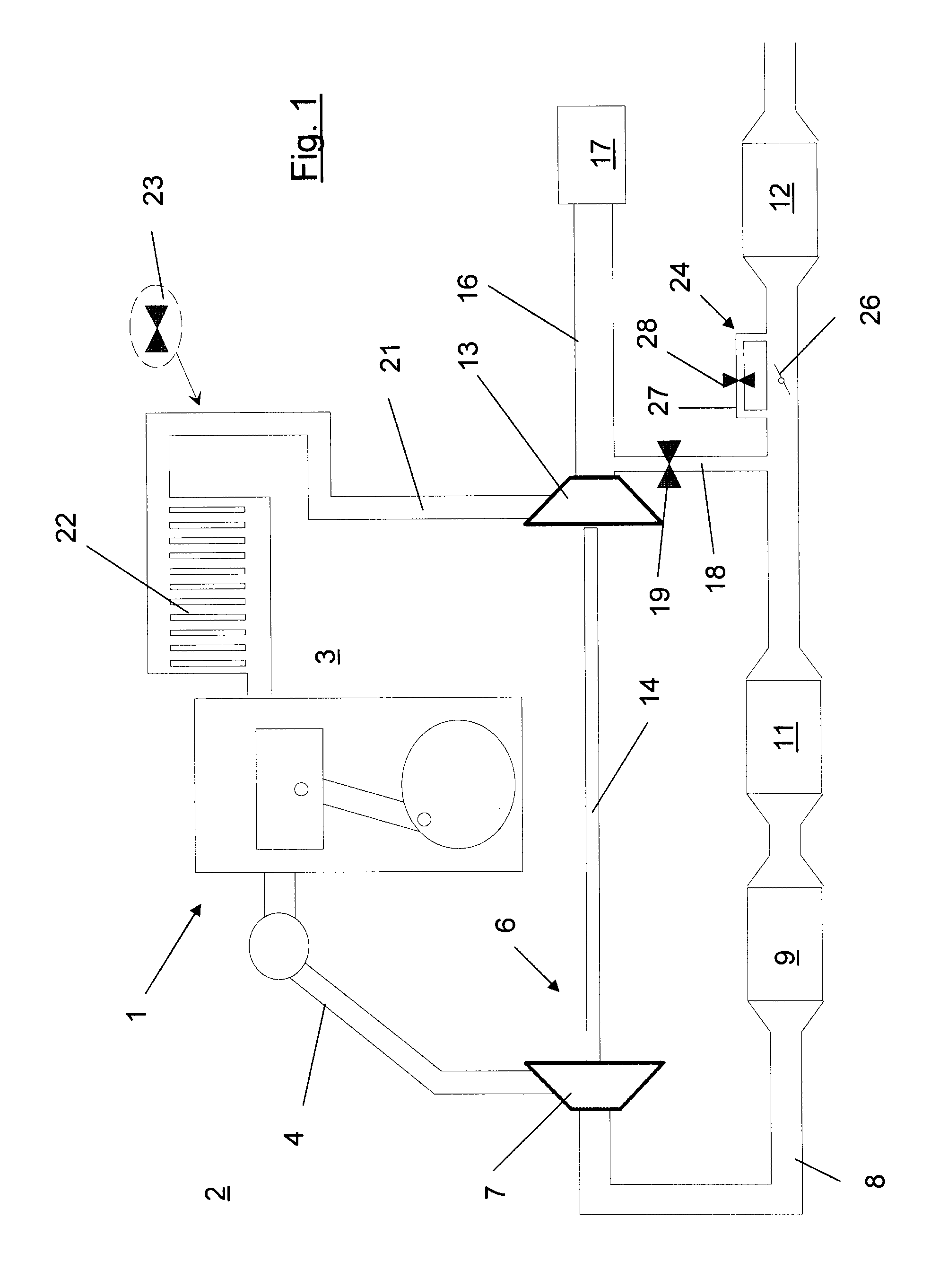

Electric highway system

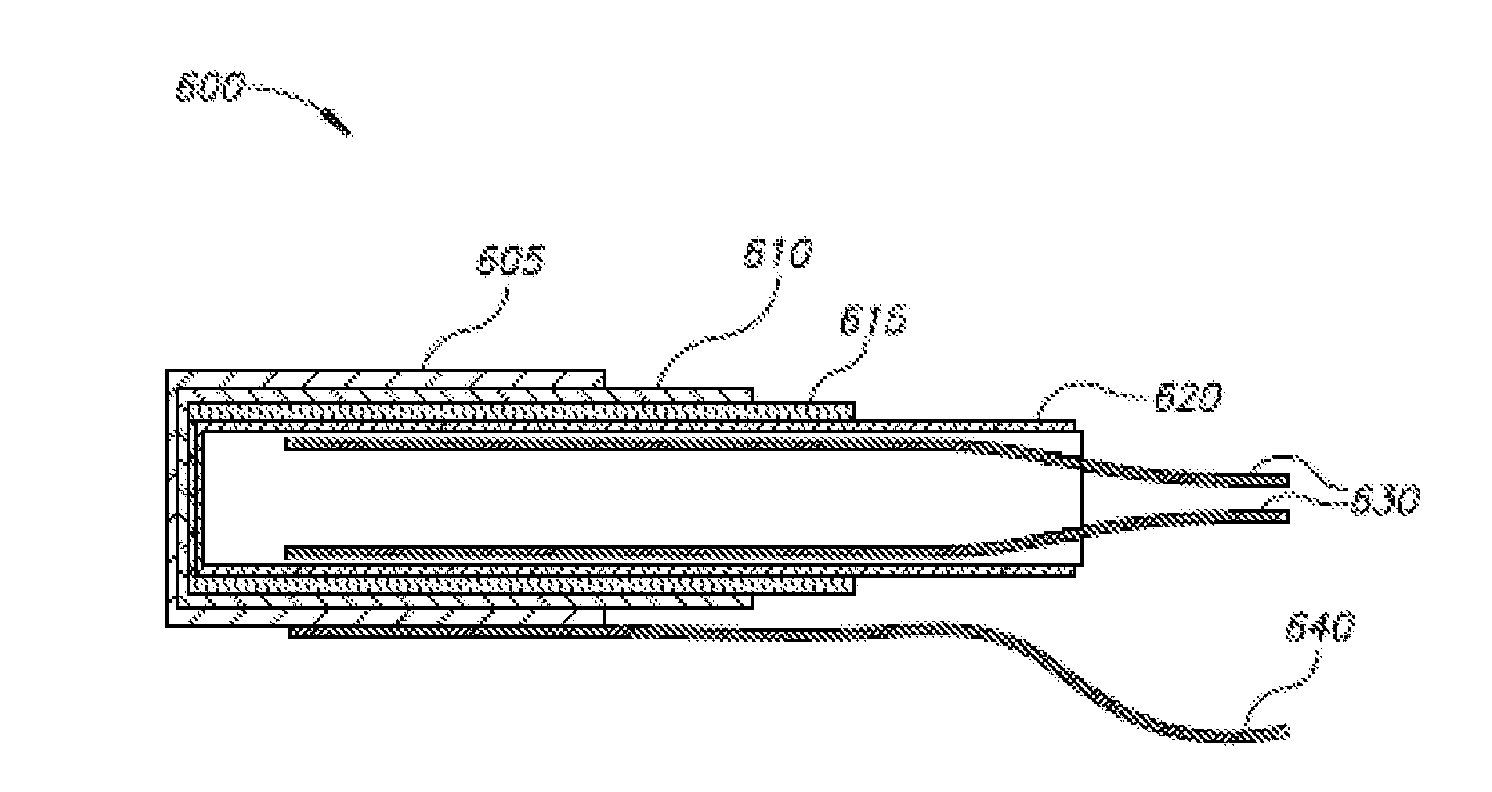

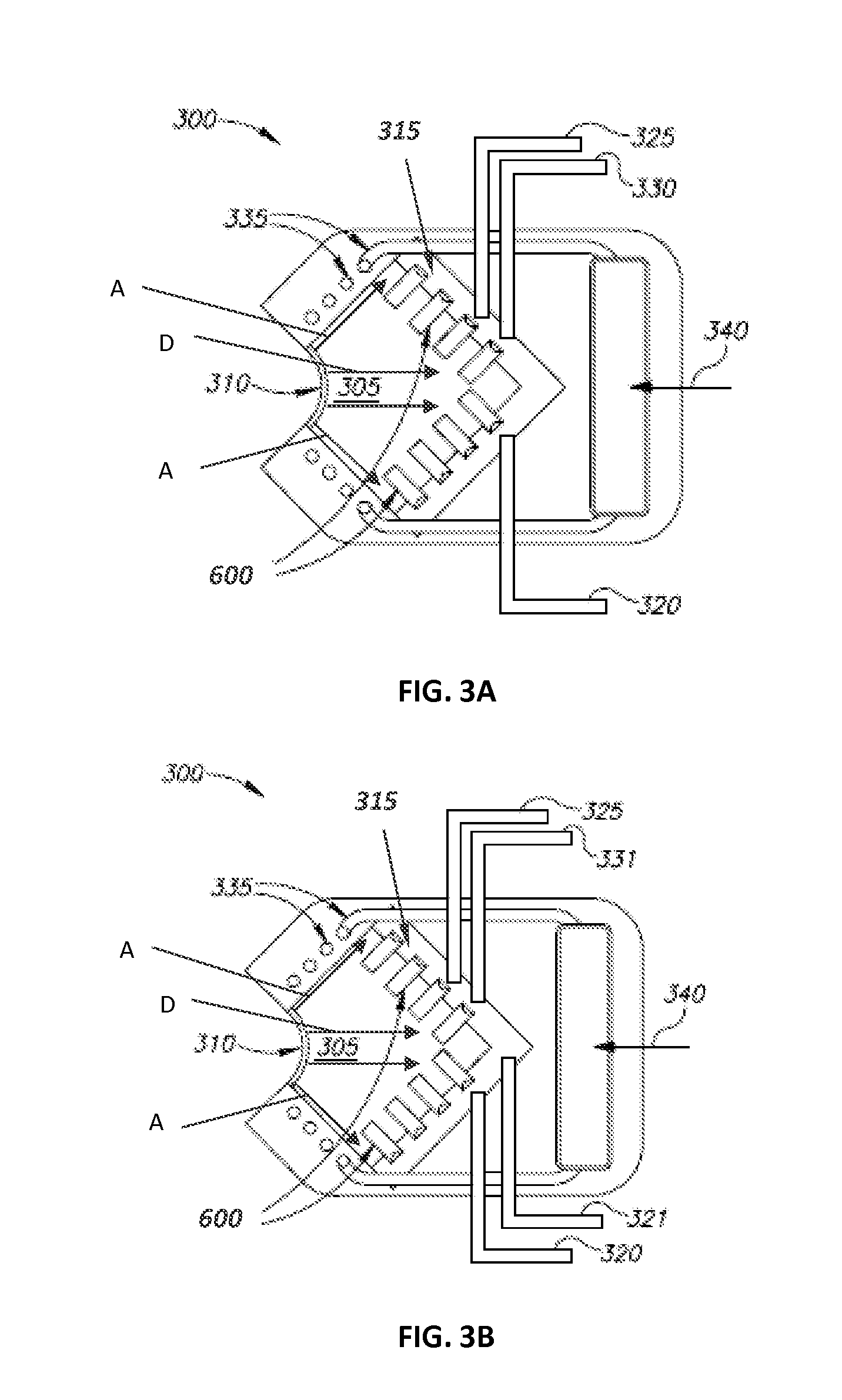

InactiveUS20110094840A1Easy to detectPromote repairAnalogue computers for vehiclesRail devicesHighway systemElectrical conductor

The electric highway includes at least one electrified lane that may be separated from other non-electrified lanes by a non-elevated strip of dividers, a roadside subsystem that includes a system operation monitoring center that monitors system operation; a plurality of roadside conductor assemblies, each of which includes at least one roadside conductor laid within a coaxial pipe made of a non-magnet field shielding material, and its / their housing in the traffic lane; a roadside part of an on-board part of a lateral location sensor; a plurality of roadside controller each of which includes a power supply assembly, at least one communication device housed in a roadside box, and a plurality of roadside posts with a camera affixed to it. The electric highway system is monitored continuously at the system operation monitoring center.

Owner:SAKITA MASAMI

Chemical recycling of pla by hydrolysis

ActiveUS20120142958A1Simple processImprove impactOrganic compound preparationPlastic recyclingSolventHydrolysis

Owner:FUTERRO SA

Chemical recycling of pla by alcoholysis

ActiveUS20120029228A1Simple processImprove impactPreparation from carboxylic acid halideOrganic compound preparationSolventPolymer

Owner:FUTERRO SA

Method for on board decarbonization of hydrocarbon fuels in a vehicle

ActiveUS20100175639A1Significant positive effectRaise the ratioHydrogenInternal combustion piston enginesHydrogenInternal combustion engine

A method and apparatus for the reduction of carbon dioxide emissions by the on-hoard treatment of a portion or all of the hydrocarbon fuel used to power an internal combustion engine mounted in a conventional transportation vehicle, utilize known decarbonization technology to break the fuel's hydrogen-carbon bond. The compounds are then cooled and separated into (1) elemental carbon powder that is stored on-board for later recovery and industrial use, and (2) hydrogen, or a hydrogen-rich gas stream, that is burned as a fuel in the ICE and / or diverted to other on-board energy related applications.

Owner:SAUDI ARABIAN OIL CO

N-Functionalized Imidazole-Containing Systems and Methods of Use

Owner:UNIVERSITY OF ALABAMA

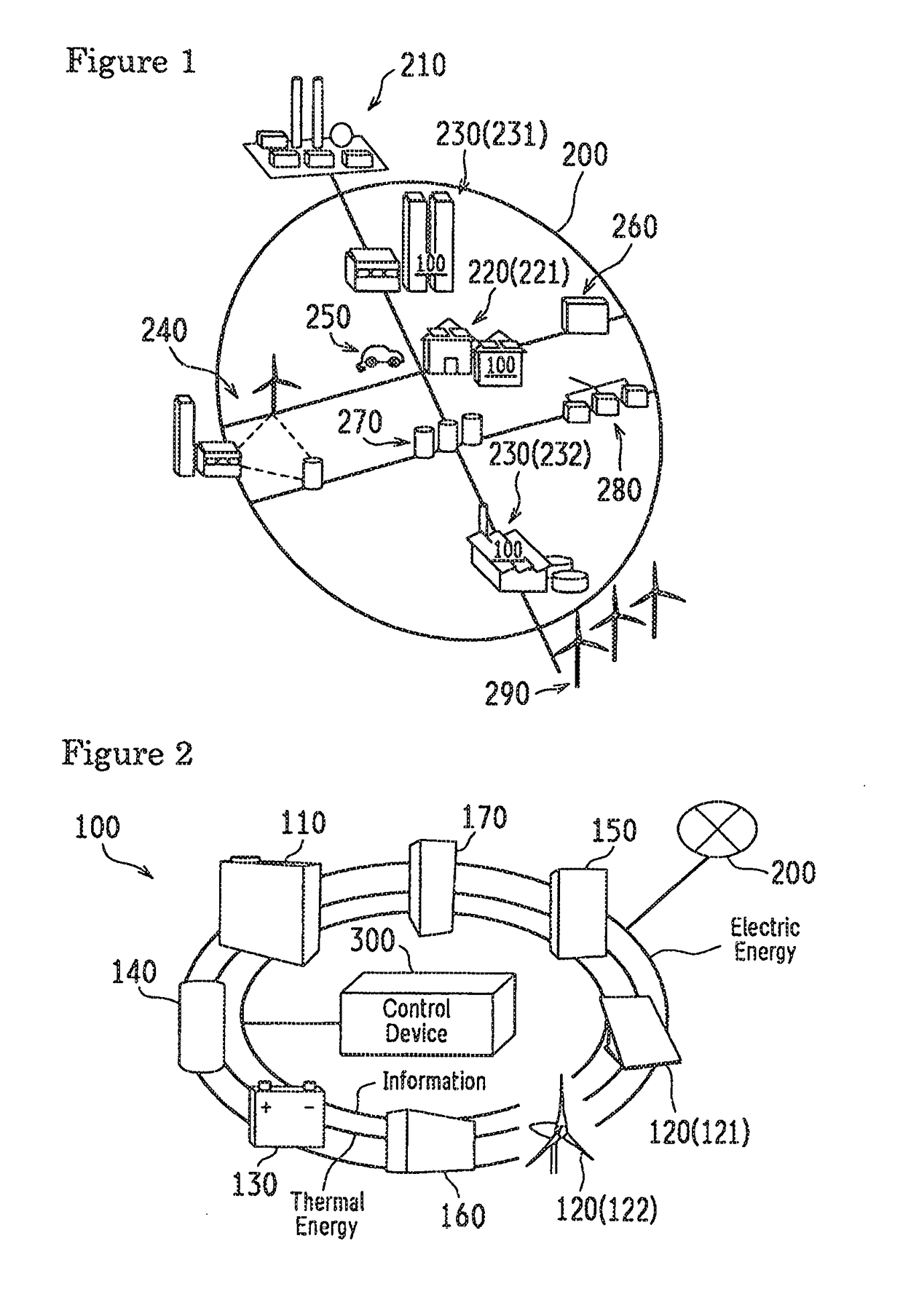

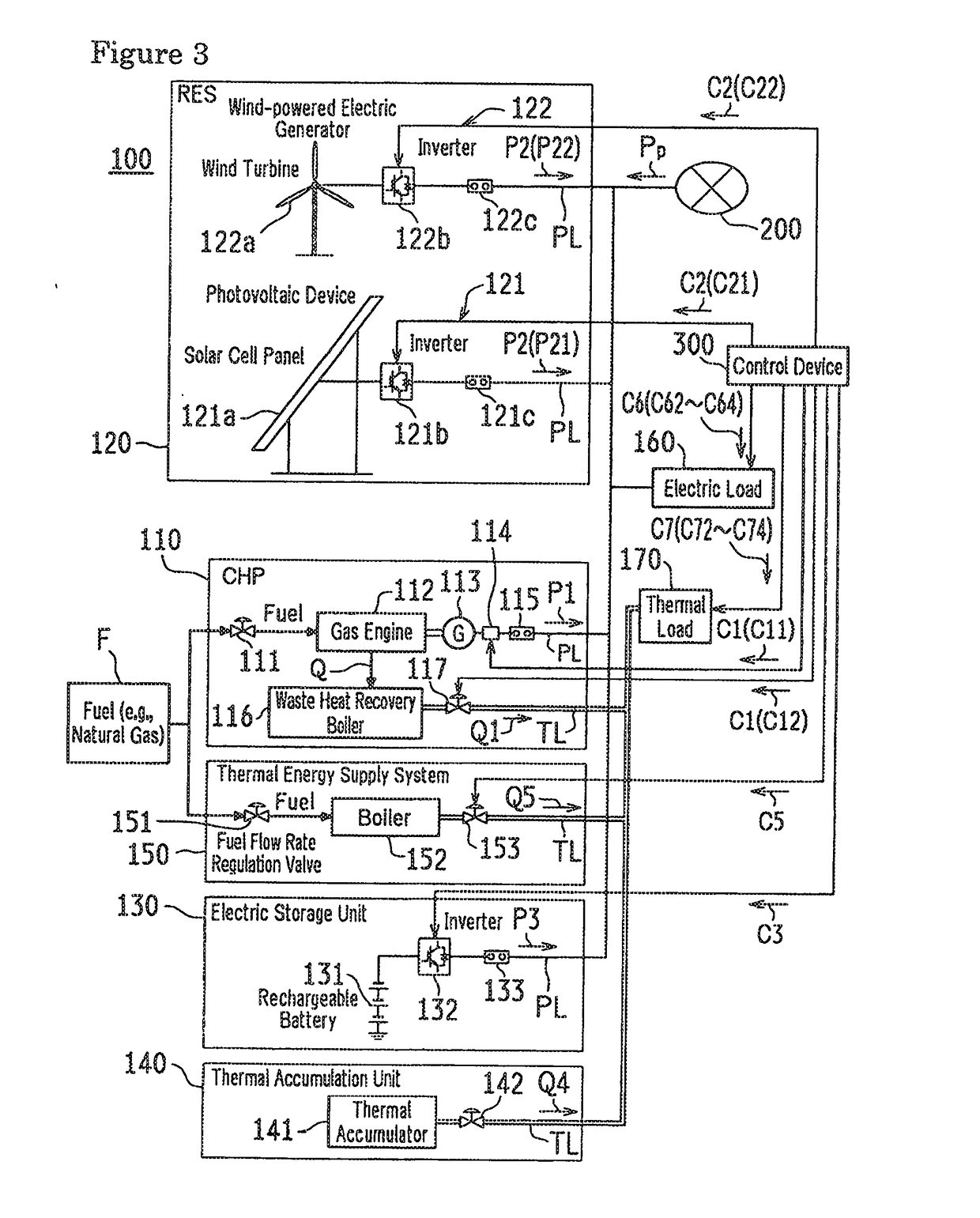

Control device for optimizing local energy network

ActiveUS20180322591A1Emission reductionReduce energy consumption costsData processing applicationsPower network operation systems integrationEnergy balancingThermal energy

Disclosed is a control device capable of reducing CO2 emission and primary energy consumption, as well as energy supply cost, to lowest possible levels in optimal energy management. In repeatedly generating two or more energy balance candidates for each unit time for the outputs of the electric power grid and thermal accumulation unit based on combinations of varied values of the output ratios of a CHP, an RES, a thermal energy supply system, and an electrical storage unit and the consumption ratios of electric and thermal loads until the convergence of the evaluation values of the two or more candidates reaches a convergence criterion.

Owner:ENEL PRODUZIONE +1

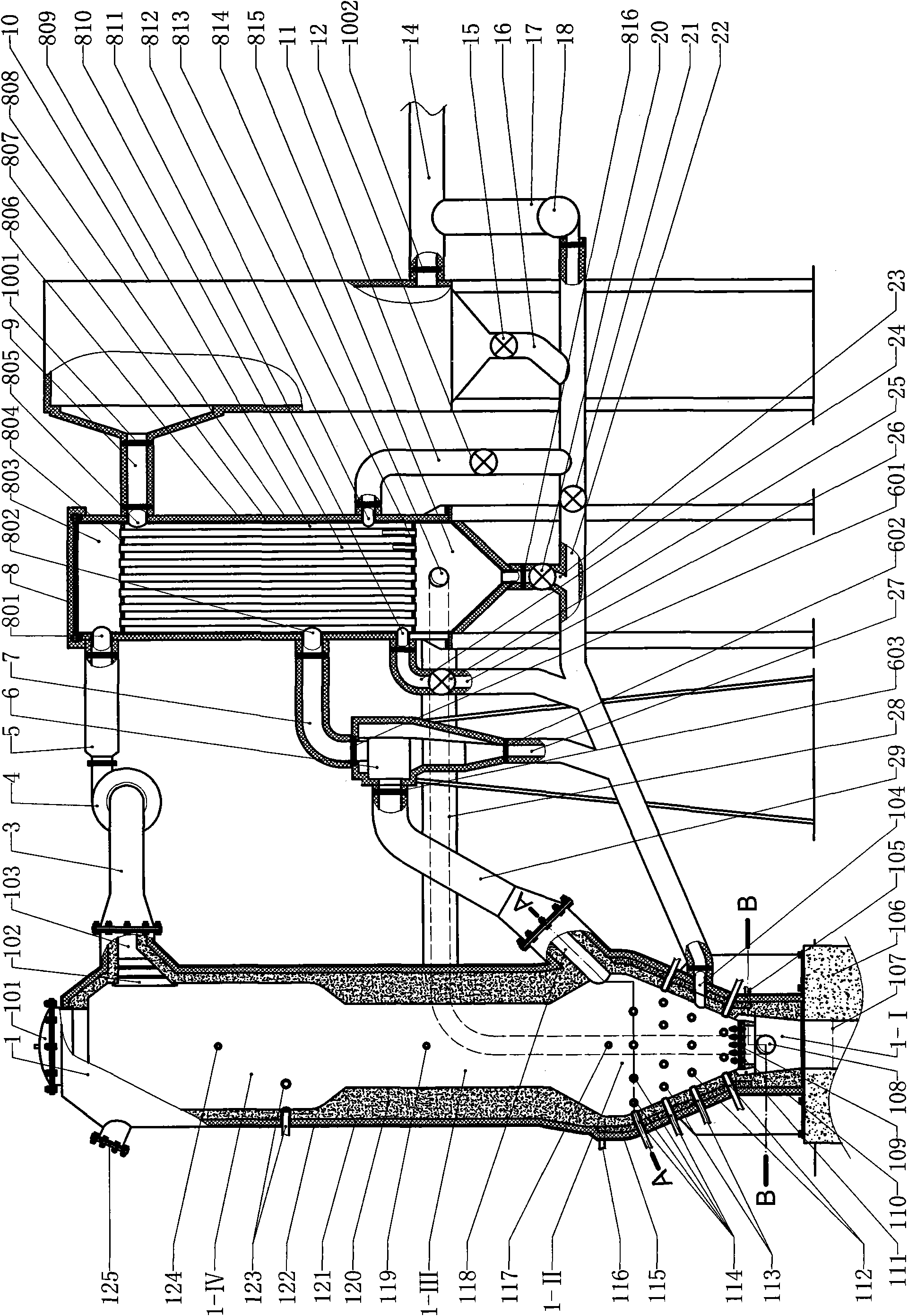

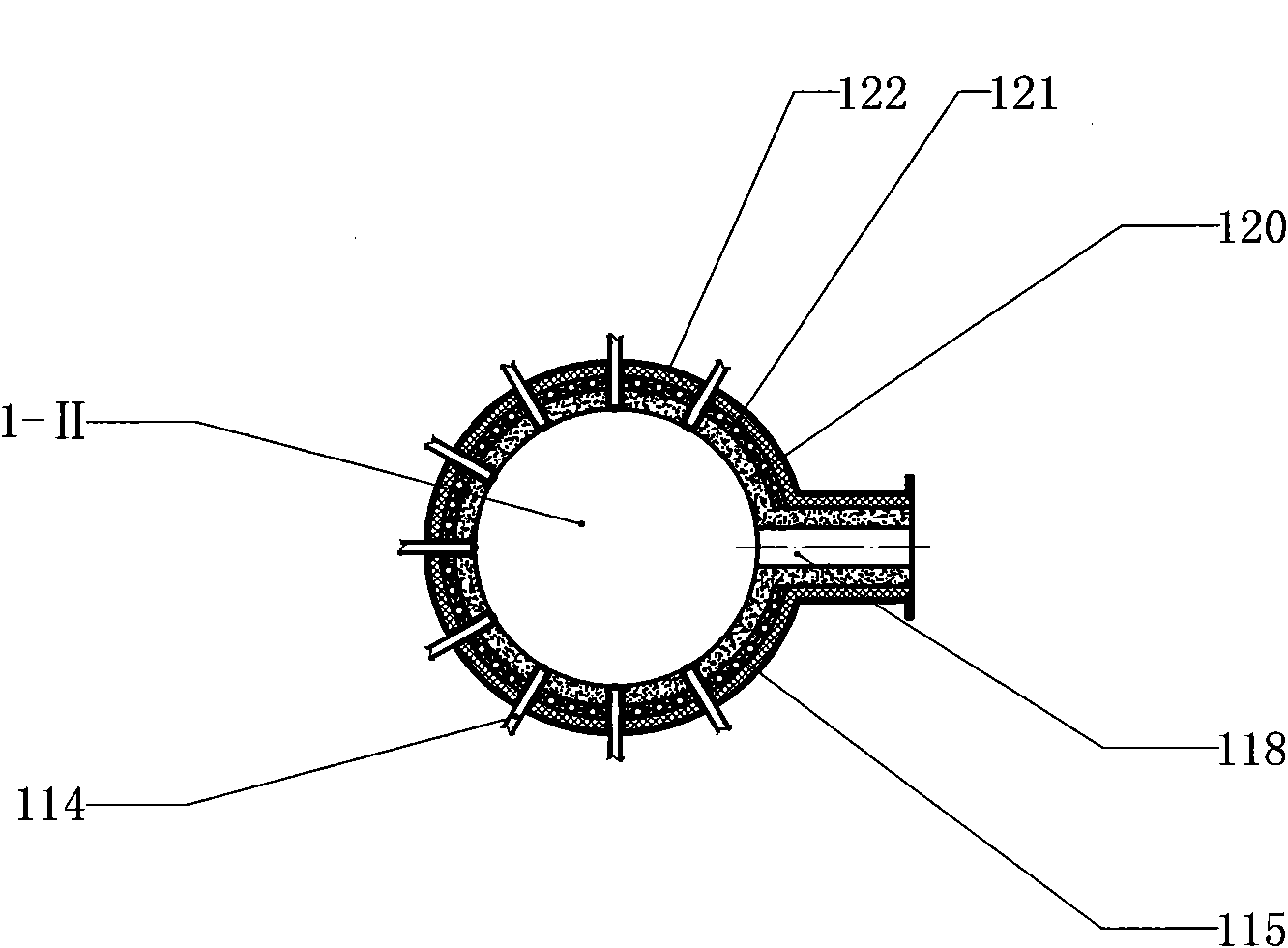

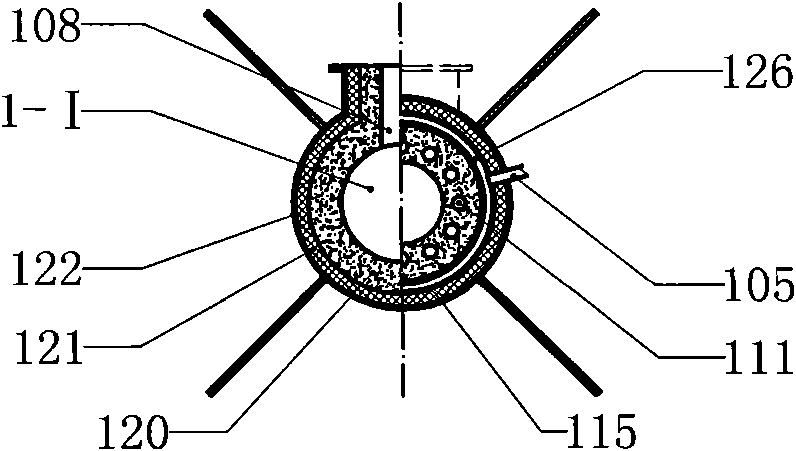

Method and equipment for gasifying coal by using plasma

InactiveCN101781584AIncrease gasification rateReduce coal consumptionGranular/pulverulent flues gasificationChemical reactionWater vapor

The invention provides method and equipment for gasifying coal, relating to a coal chemical industry technique and gasification furnace equipment. The invention is characterized in that a fluidized bed gasification furnace is designed into a three-section working mode, the upper section is a suspended preheating section, the middle section is a turbulent flow pyrolyzing section, the lower section is a bubbled gasifying section, a plasma torch is arranged at the bubbled gasifying section, and water vapor is heated to be greater than 4000 DEG C in the plasma torch, is decomposed into active chemicals H., O., H2., HO., O2. and then is directly sprayed to carbon coke of the bubbled gasifying section for chemical reaction to generate synthesis gas of CO and H2 and release heat; and pyrolysis gas, the water vapor and fluidized gas in the furnace are mixed, are discharged out of the furnace through an outlet of the suspended preheating section and then return the bubbled gasifying section of the gasification furnace through a fluidized air pipe and a fluidized fan, and soot, gaseous tar, CmHn and CH4 in the pyrolysis gas react with the water vapor to generate the synthesis gas of the CO and the H2. Compared with the conventional coal gasification technique, the invention reduces the consumption of coal resources and the discharge of greenhouse gases.

Owner:周开根

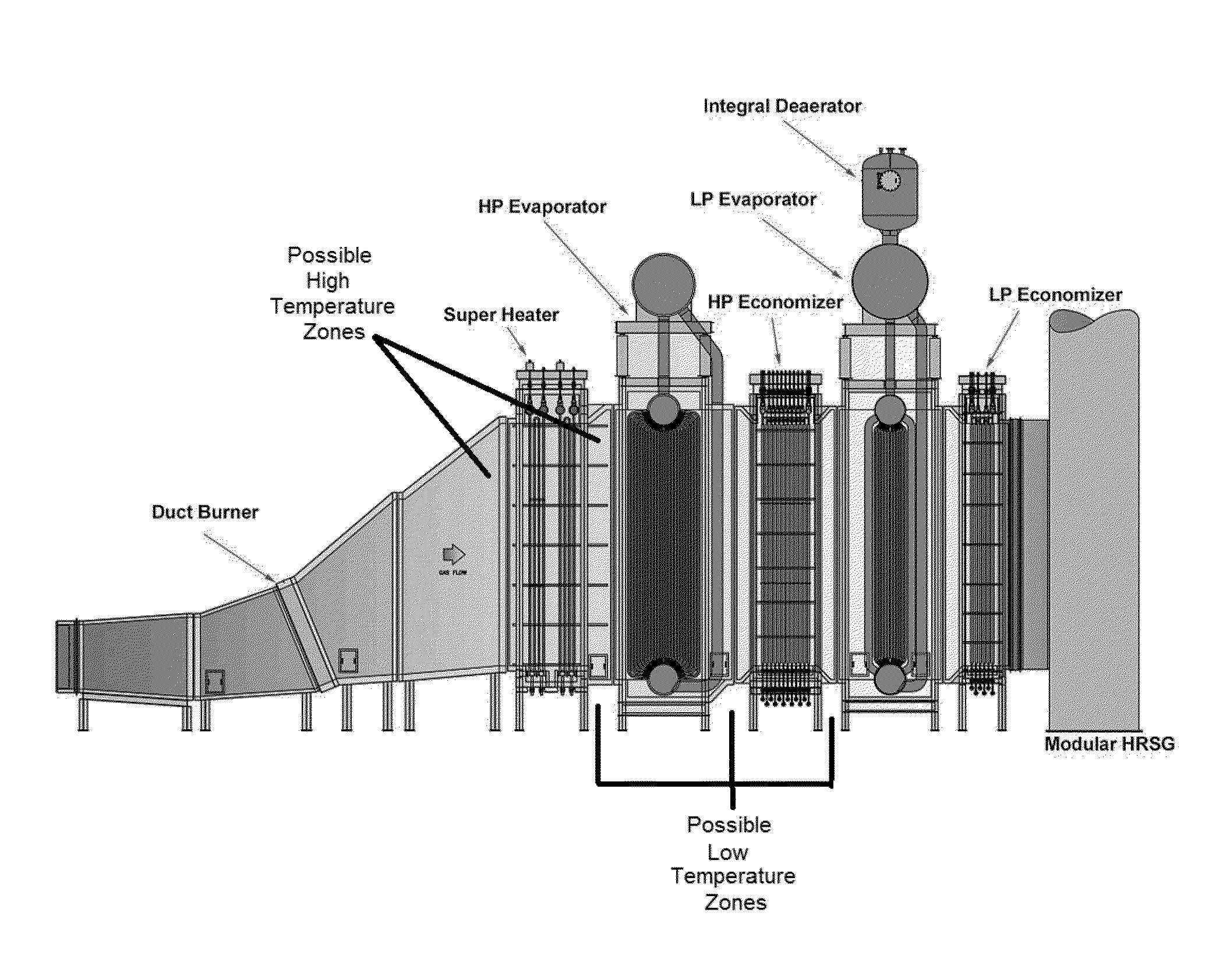

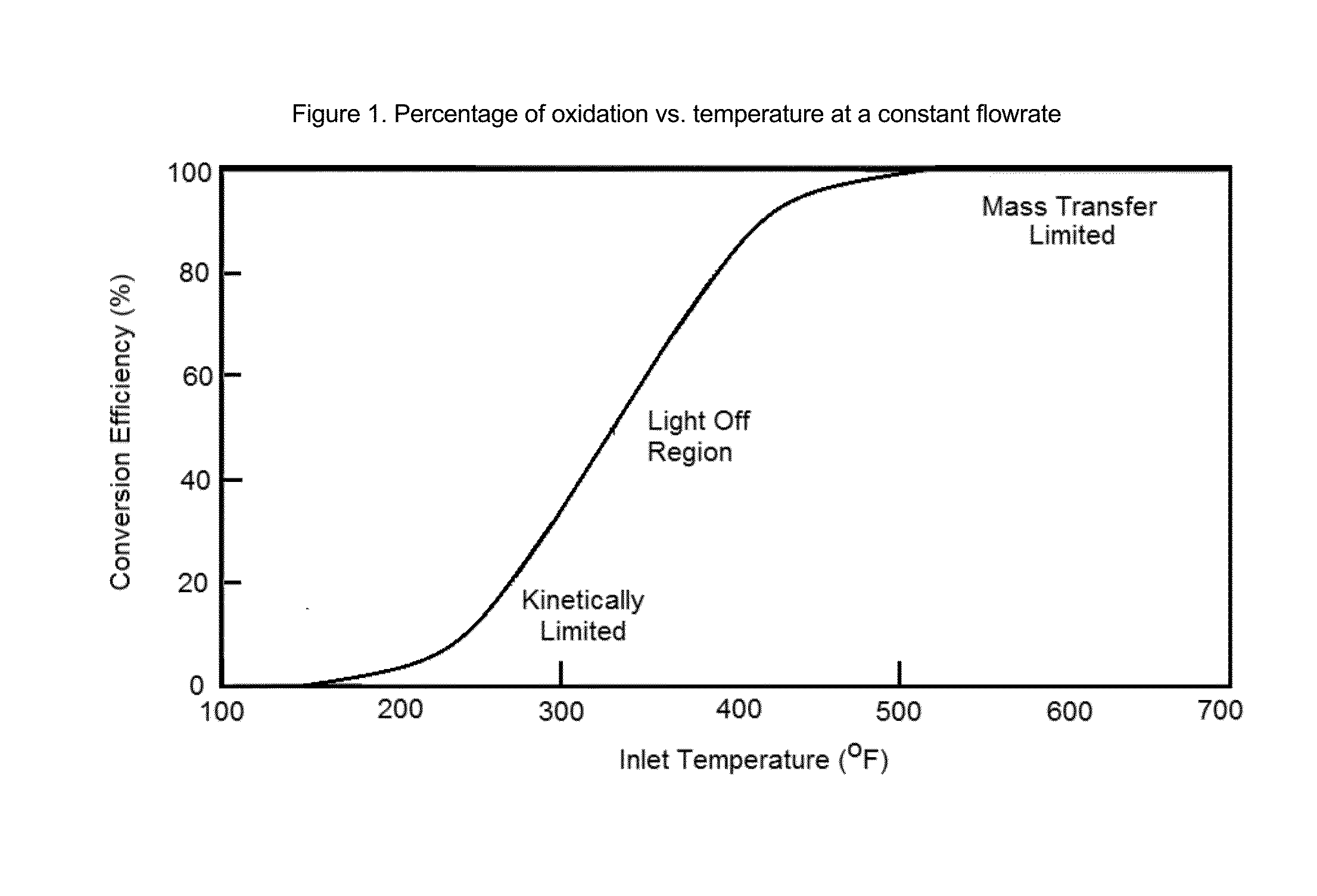

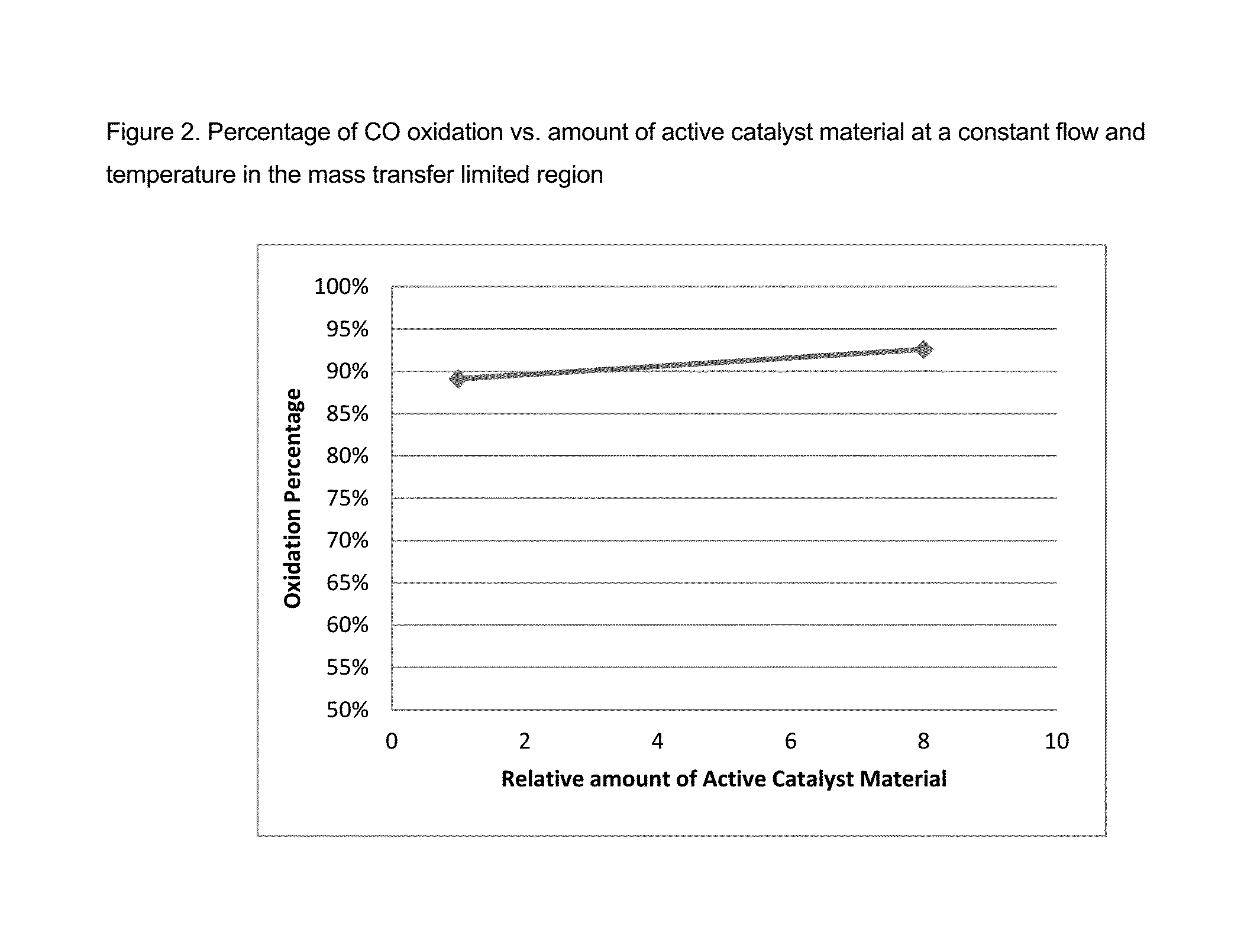

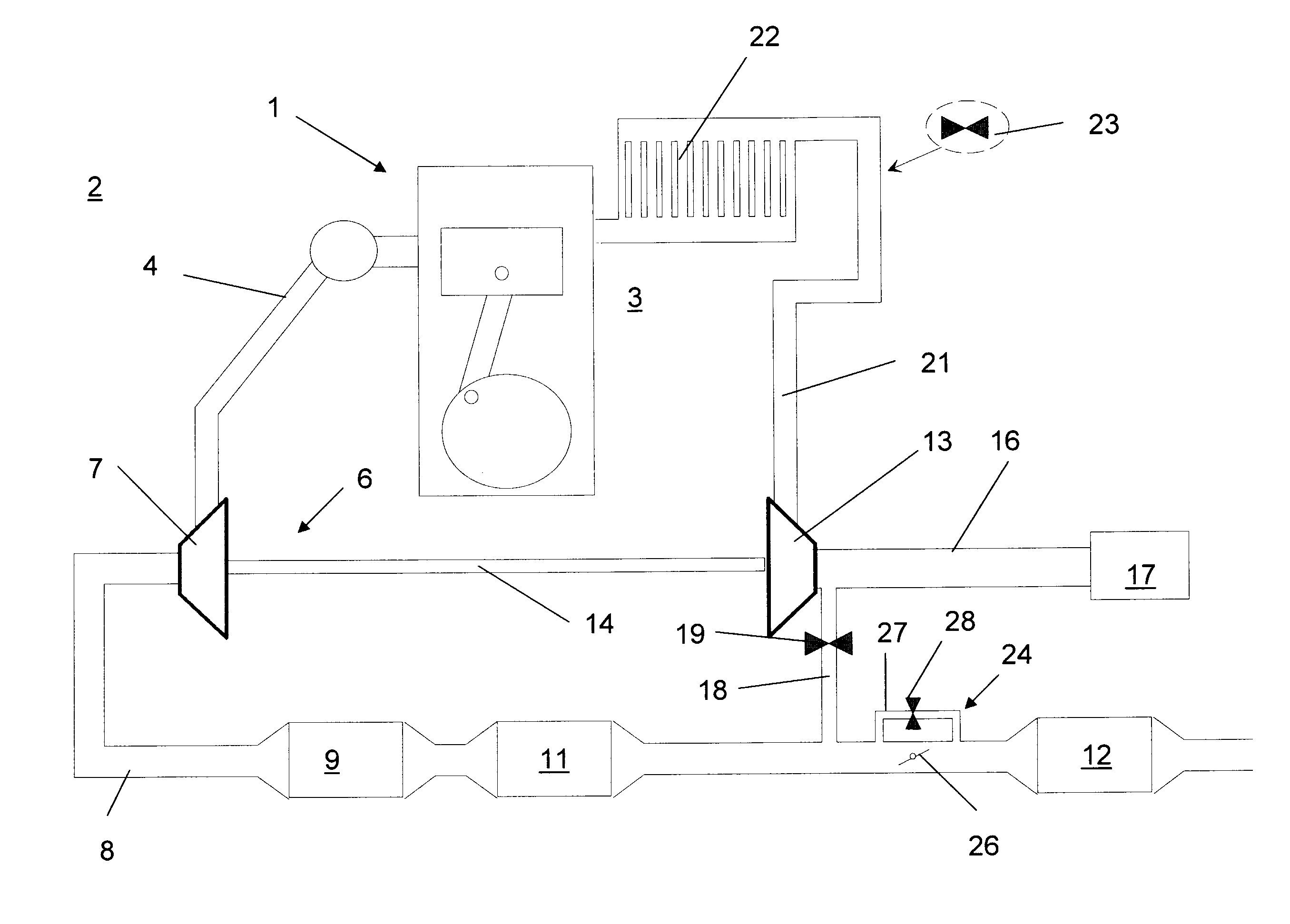

Exhaust system for power generating apparatus

InactiveUS20160245139A1Emission reductionReduce CO2Steam generation heating methodsExhaust apparatusExhaust gasExhaust fumes

An exhaust system for a power generating apparatus comprising a heat source for combusting a fuel in air to produce power, which exhaust system being adapted to receive a flowing exhaust gas and comprising a catalyst system for treating the exhaust gas, which catalyst system comprising a first oxidation catalyst and a second catalyst, wherein the first oxidation catalyst is positioned downstream from the heat source so that the flowing exhaust gas contacts the first oxidation catalyst before the second catalyst.

Owner:JOHNSON MATTHEY PLC

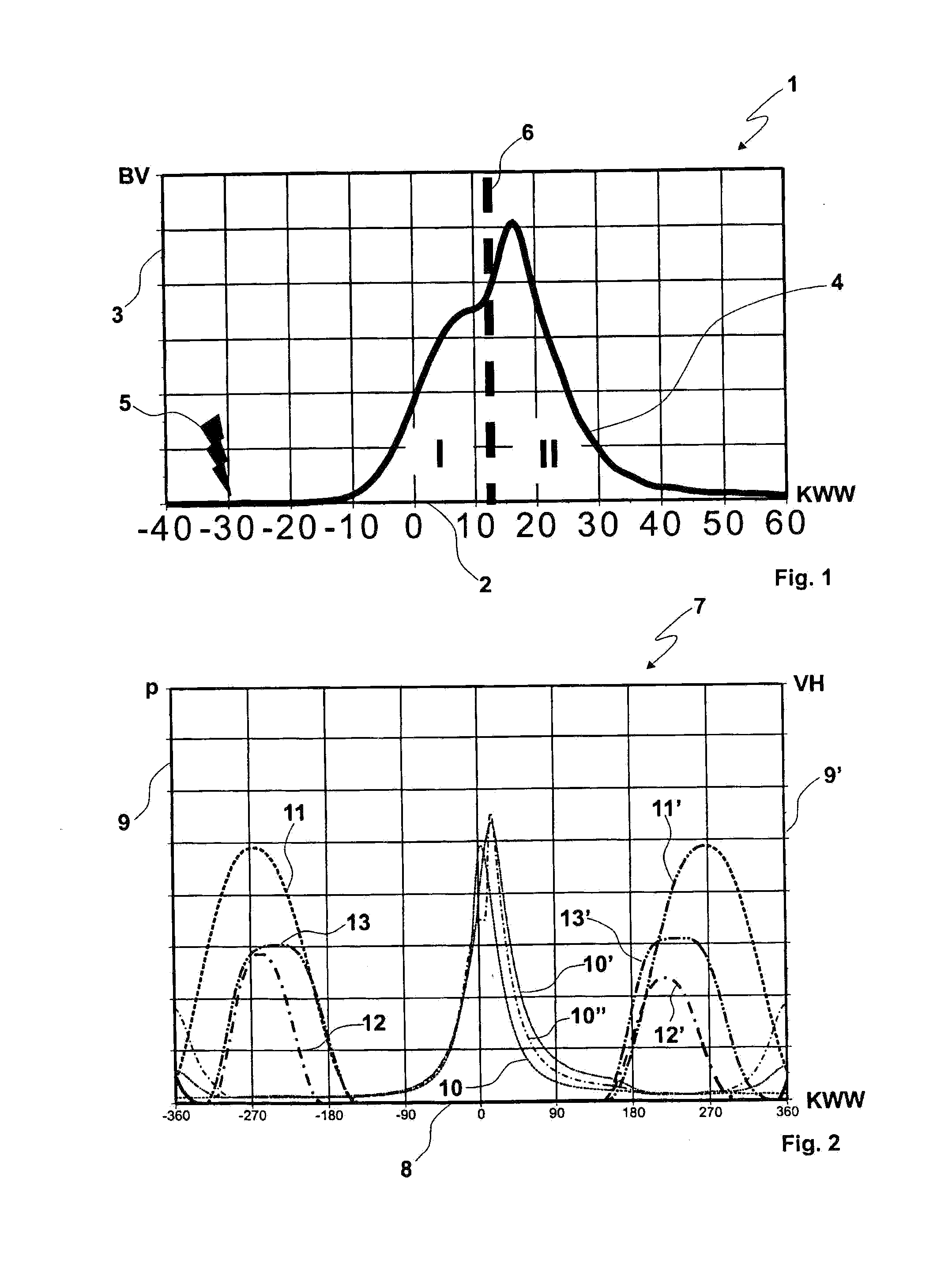

Control method for temporarily increasing the exhaust gas temperature

InactiveUS20090151333A1Raise exhaust gas temperatureReduce CO2Electrical controlNon-fuel substance addition to fuelExhaust fumesPost injection

The invention relates to a control method for increasing the exhaust gas temperature of an internal combustion engine, which has at least one exhaust gas aftertreatment device in its exhaust tract, and which has an exhaust gas recirculation system, to which a regulating system is assigned. In order to increase the temperature of the exhaust gas and avoid engine oil dilution due to retarded post-injections, the regulating system increases the exhaust gas back-pressure while maintaining an exhaust gas recirculation rate, and increases a fuel injection quantity into the combustion chamber during the main injection.

Owner:FORD GLOBAL TECH LLC

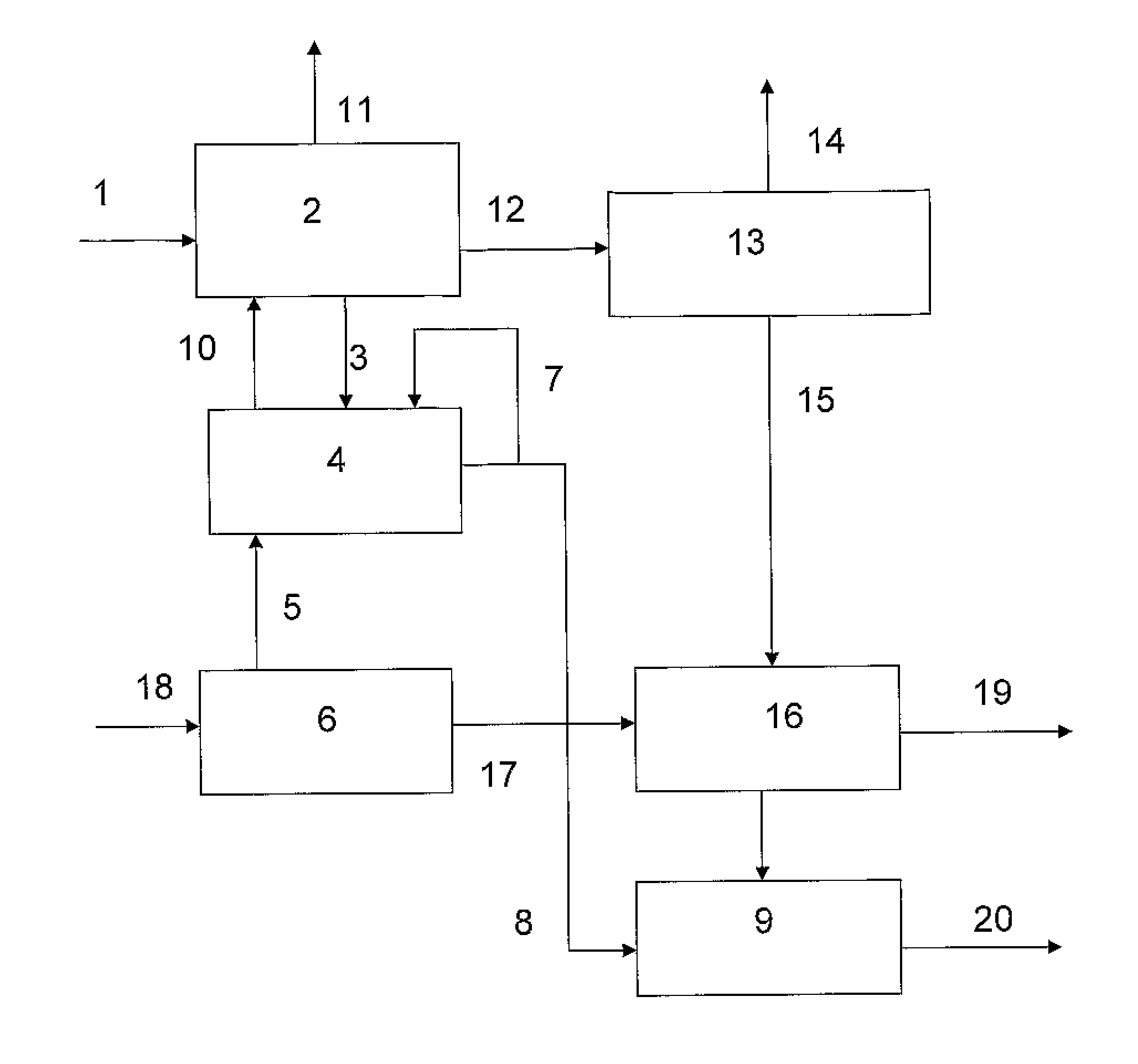

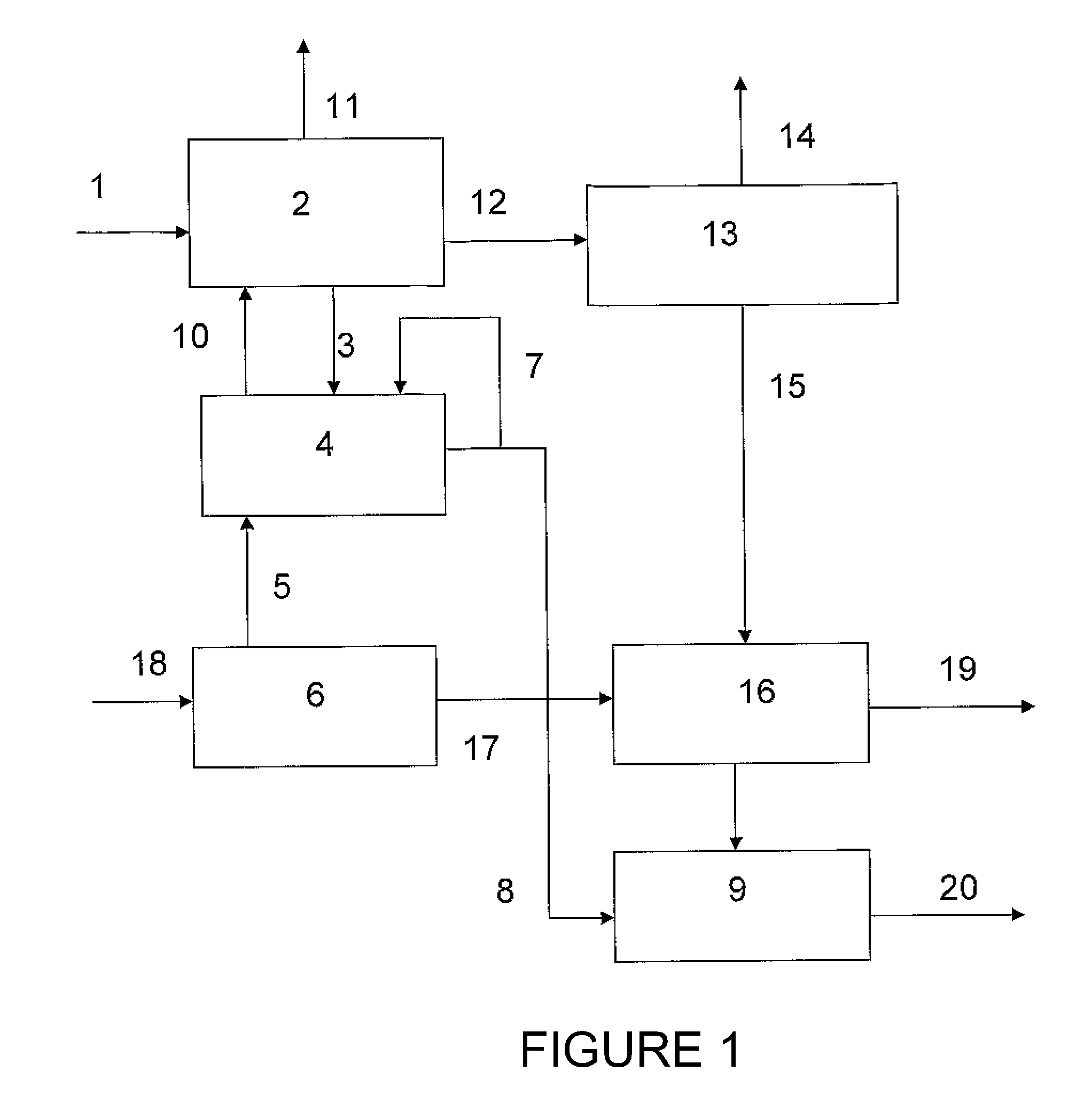

Integrated process for the manufacture of olefins and intermediates for the productions of ammonia and urea

ActiveUS20110250119A1Improve energy efficiencyReduce carbon dioxide emissionsUrea derivatives preparationCatalytic crackingSteam reformingAmmonia production

An integrated process for the manufacture of olefins and intermediates for the production of ammonia and urea, comprising an FCC reactor, a regenerator, a steam reforming unit, an air-separation unit, an ammonia production unit and a urea production unit, is described. This process makes it possible to minimize CO2 emissions to atmosphere, make use of heavy feedstocks of low added value (AR) for the production of light olefins, in addition to making maximum use of all the flows involved, thus increasing the energy efficiency achieved, all at the same time.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

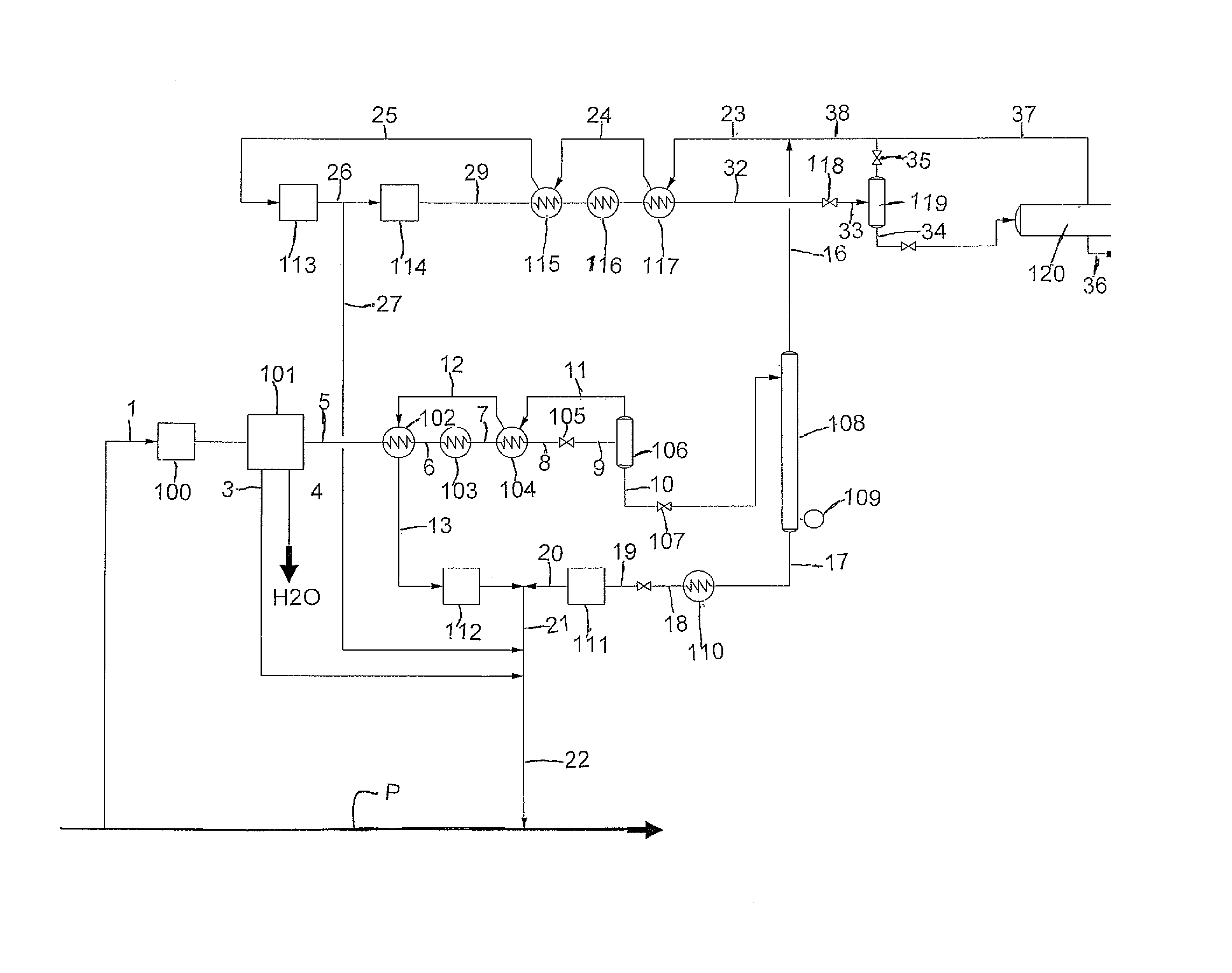

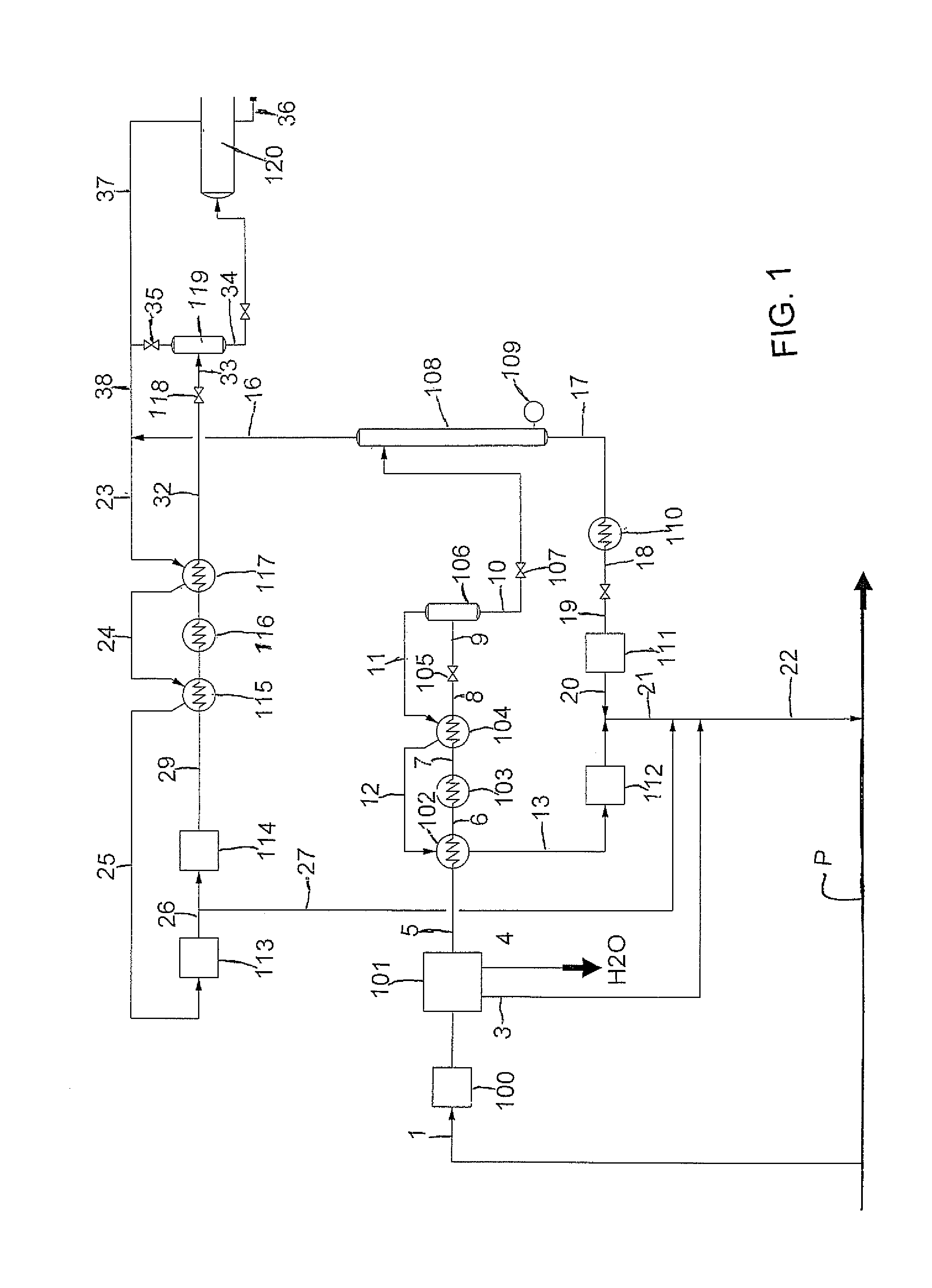

Simplified LNG Process

ActiveUS20130180282A1Small scaleSimple processSolidificationLiquefactionWater vaporProcess engineering

A simplified method for production of a commercial supply liquefied natural gas (LNG) supplied in a pressurized vessel includes taking a supply of natural gas including contaminants from a stranded well or from a pipe line and extracting from the supply gas water vapor and CO2 in a fixed bed absorption system. In a first stage the supply gas is separated into first and second streams where the first stream contains all the cold energy available from the feed stream and sufficient of the contaminants are removed to meet a product specification for the composition of the LNG supply. In a second stage the first stream is liquefied by the available cool energy for commercial pressurized supply container The second stream contains natural gas which is as much as 75% of the feed stream together with substantially all the contaminants and is used as a natural gas supply.

Owner:9052151 CANADA

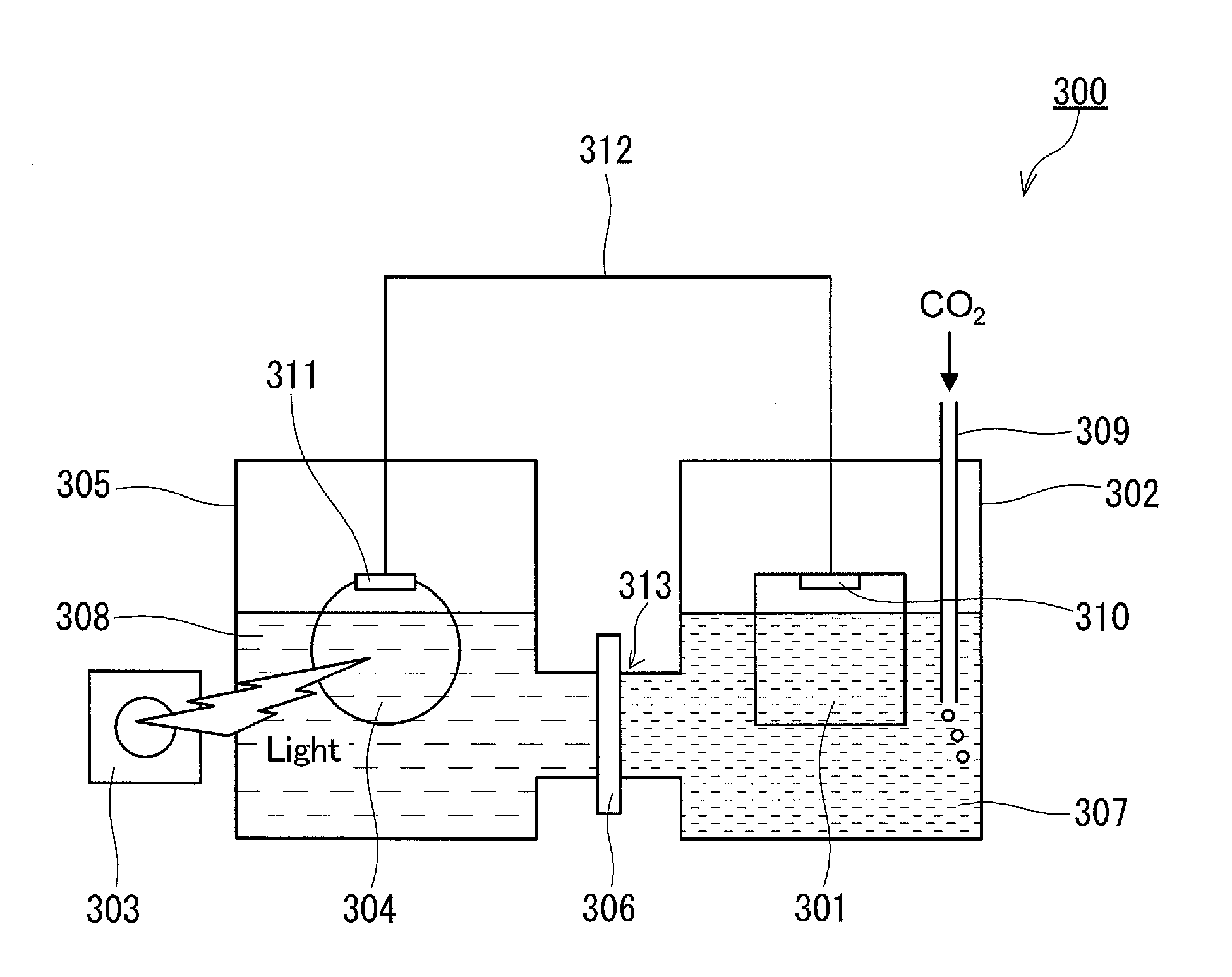

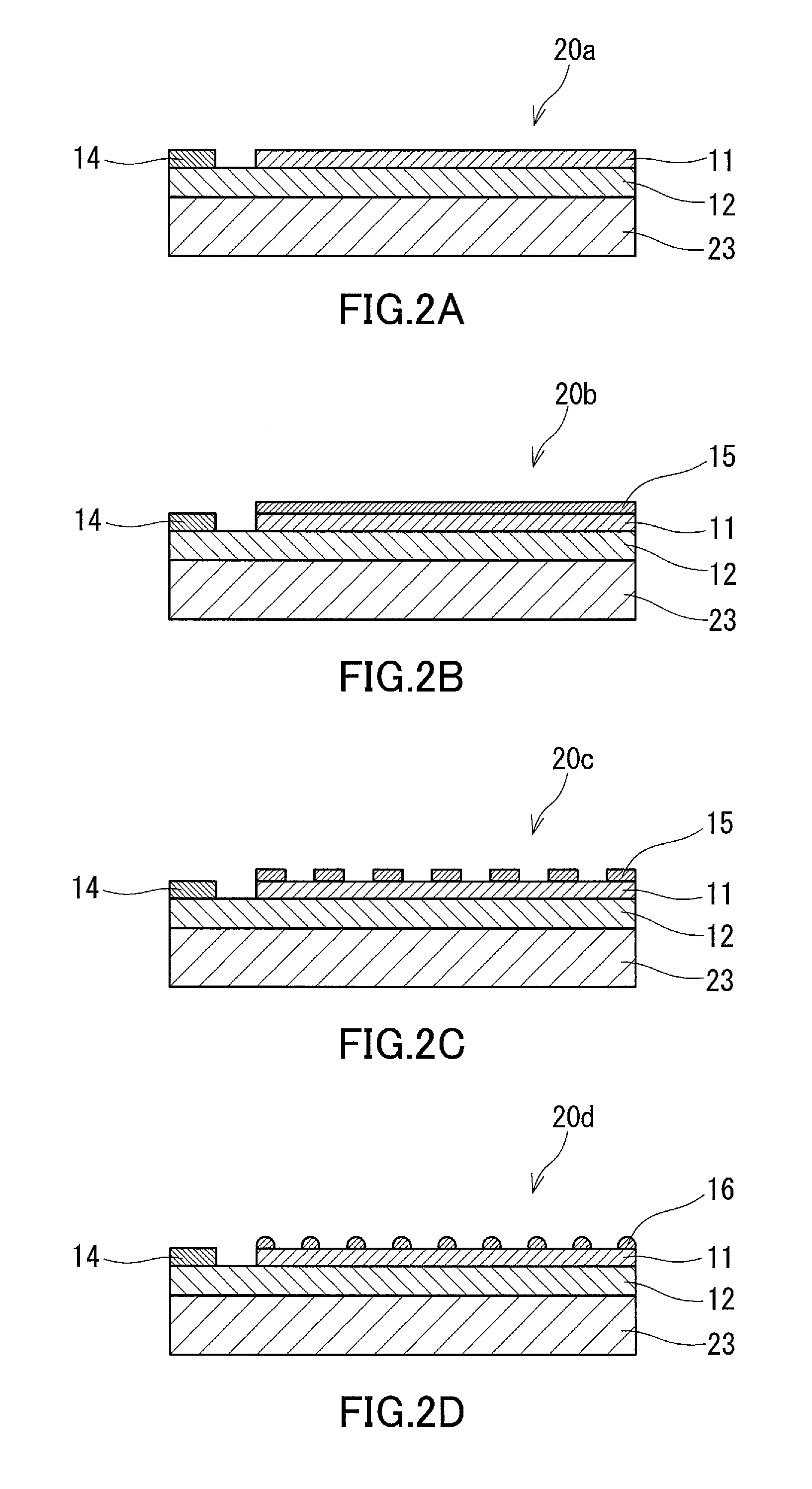

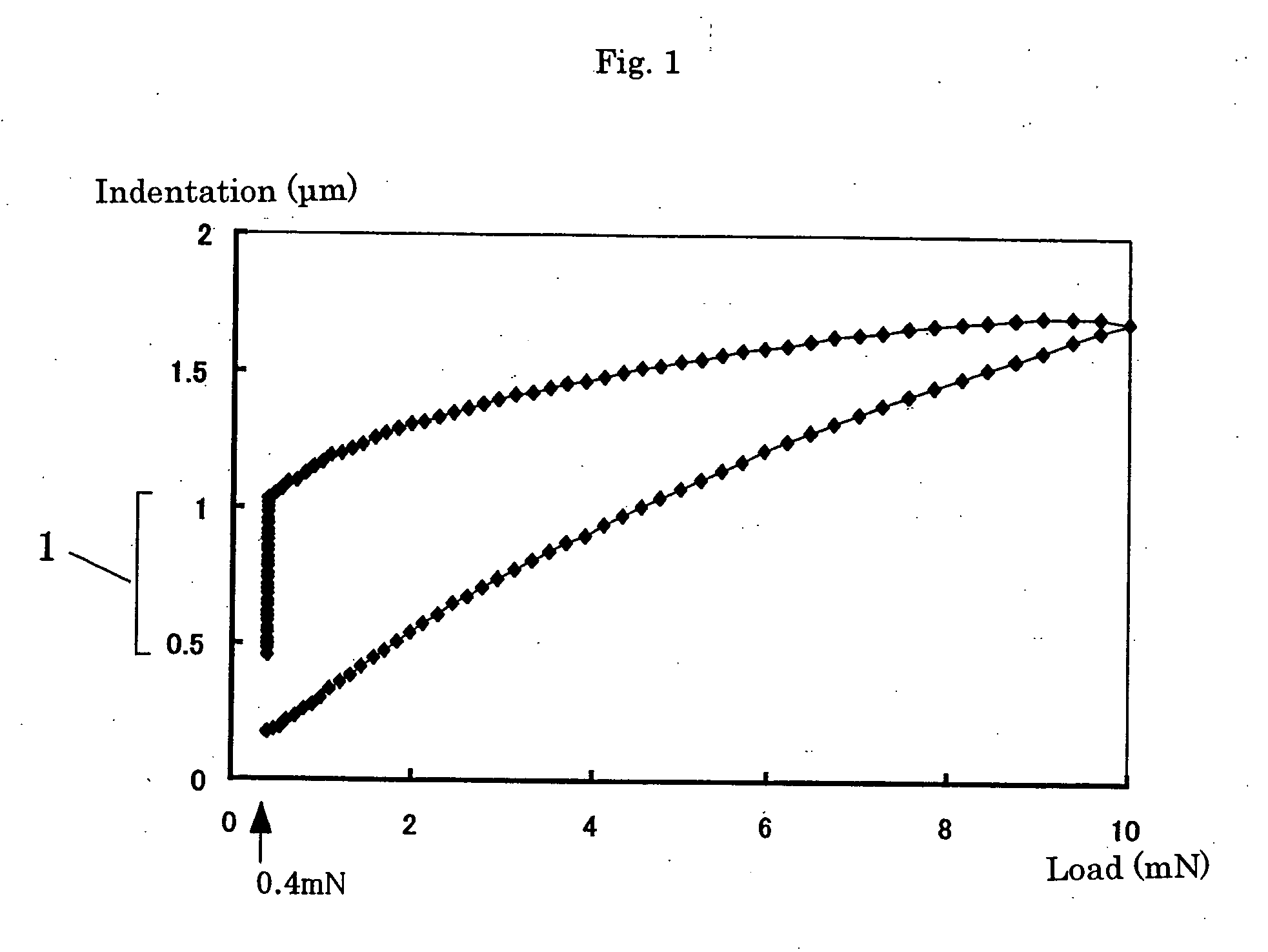

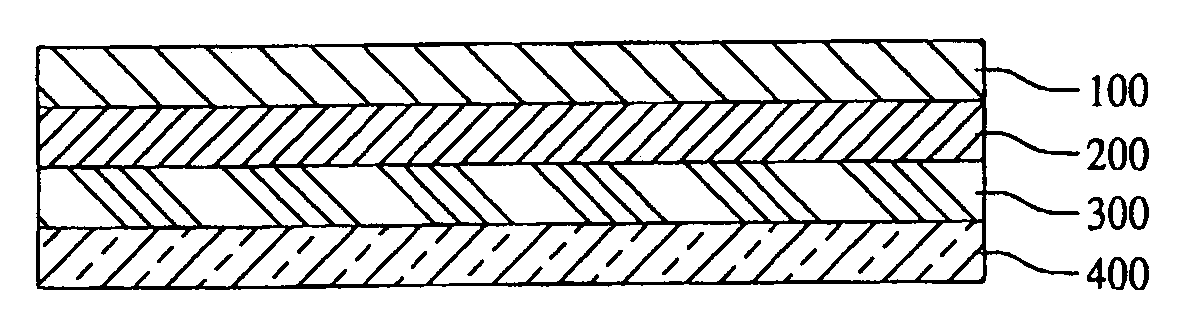

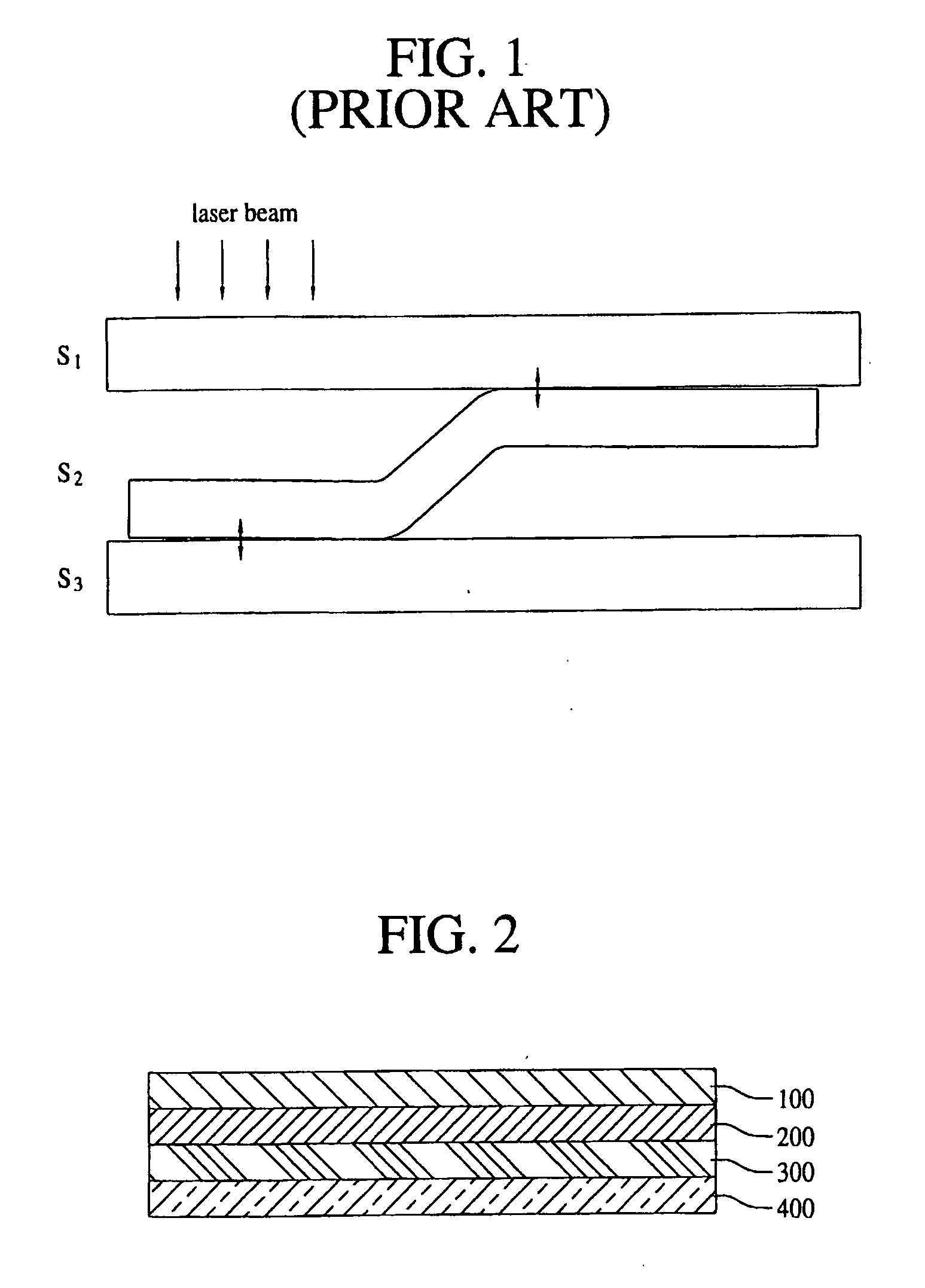

Carbon dioxide reduction device and method for reducing carbon dioxide

InactiveUS20150218719A1Improve efficiencyReduce CO2CellsPhotography auxillary processesProtonElectrolyte

A device for reducing CO2 by light, including: a cathode chamber holding a first electrolyte solution that contains CO2; an anode chamber holding a second electrolyte solution; a proton conducting membrane disposed in a connecting portion between these chambers; a cathode electrode; and an anode electrode. The cathode electrode has a CO2 reduction reaction region composed of a metal or a metal compound, and the anode electrode has a photochemical reaction region composed of nitride semiconductors. The photochemical reaction region of the anode electrode has a multilayer structure of a GaN layer and an AlxGa1-xN layer containing Mg (0<x≦0.25). The content of Mg in the AlxGa1-xN layer is 1×1015 or more and 1×1019 or less in terms of the number of Mg atom per cm3. The anode electrode is disposed in such a manner that the AlxGa1-xN layer can be exposed to light.

Owner:PANASONIC CORP

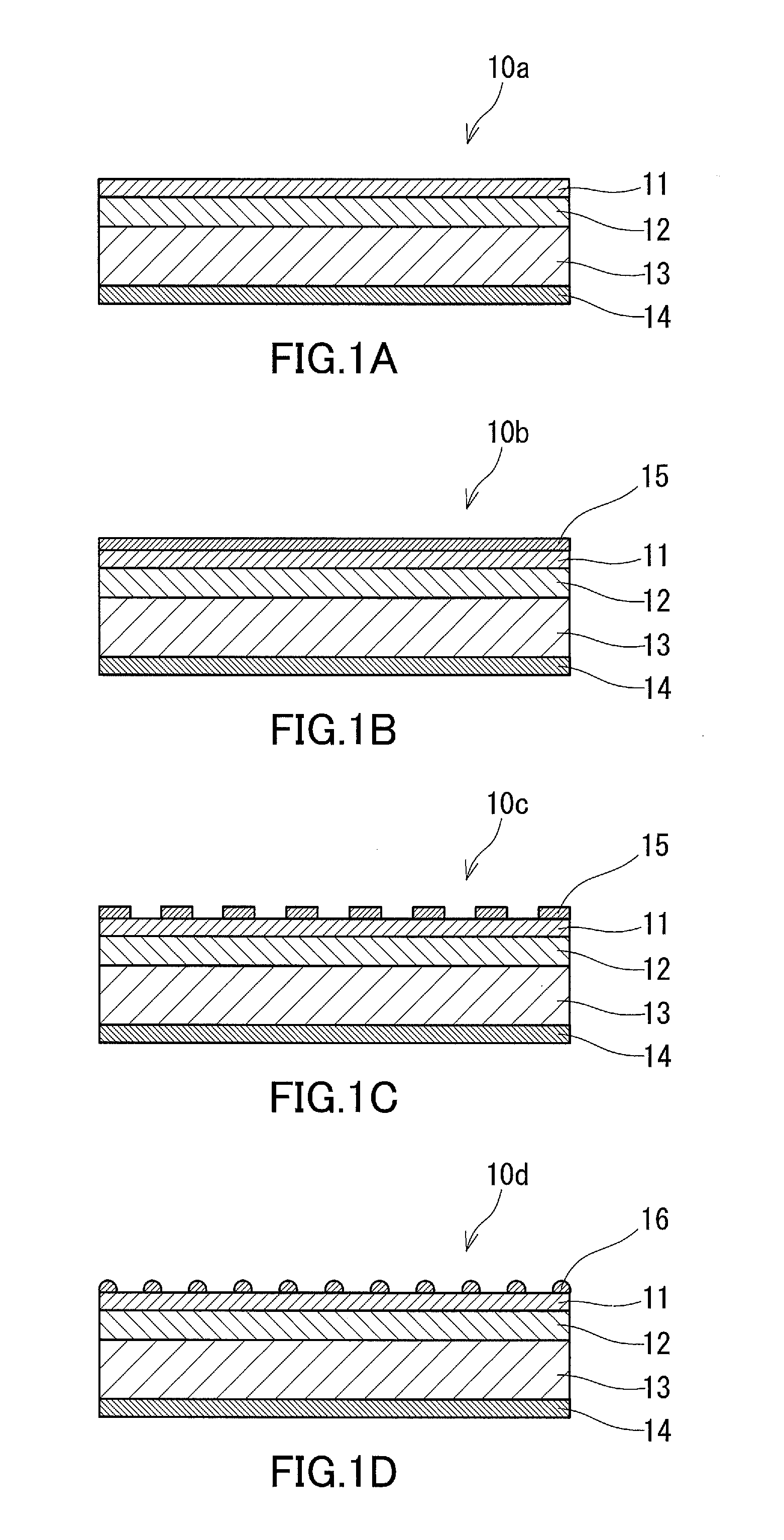

Coating compositions and method of forming coating film

InactiveUS20050142297A1Shorten heating timeSave spaceSynthetic resin layered productsPretreated surfacesPolyolAlcohol

The present invention provides a thermosetting and photocurable coating composition comprising: (A) at least one compound selected from the group consisting of radical-polymerizable unsaturated monomers, resins containing radical-polymerizable unsaturated groups, and resins containing radical-polymerizable unsaturated groups and thermosetting functional groups; (B) a hydroxyl-containing polyester resin produced by esterifying a polybasic acid (a) and a polyhydric alcohol (b), wherein an alicyclic polybasic acid (a1) and / or an alicyclic polyhydric alcohol (b1) are included in a ratio of 20% or more based on the total weight of polybasic acid (a) and polyhydric alcohol (b); (C) a crosslinking agent; and (D) a photopolymerization initiator; and a method of forming a coating film using the coating composition.

Owner:KANSAI PAINT CO LTD

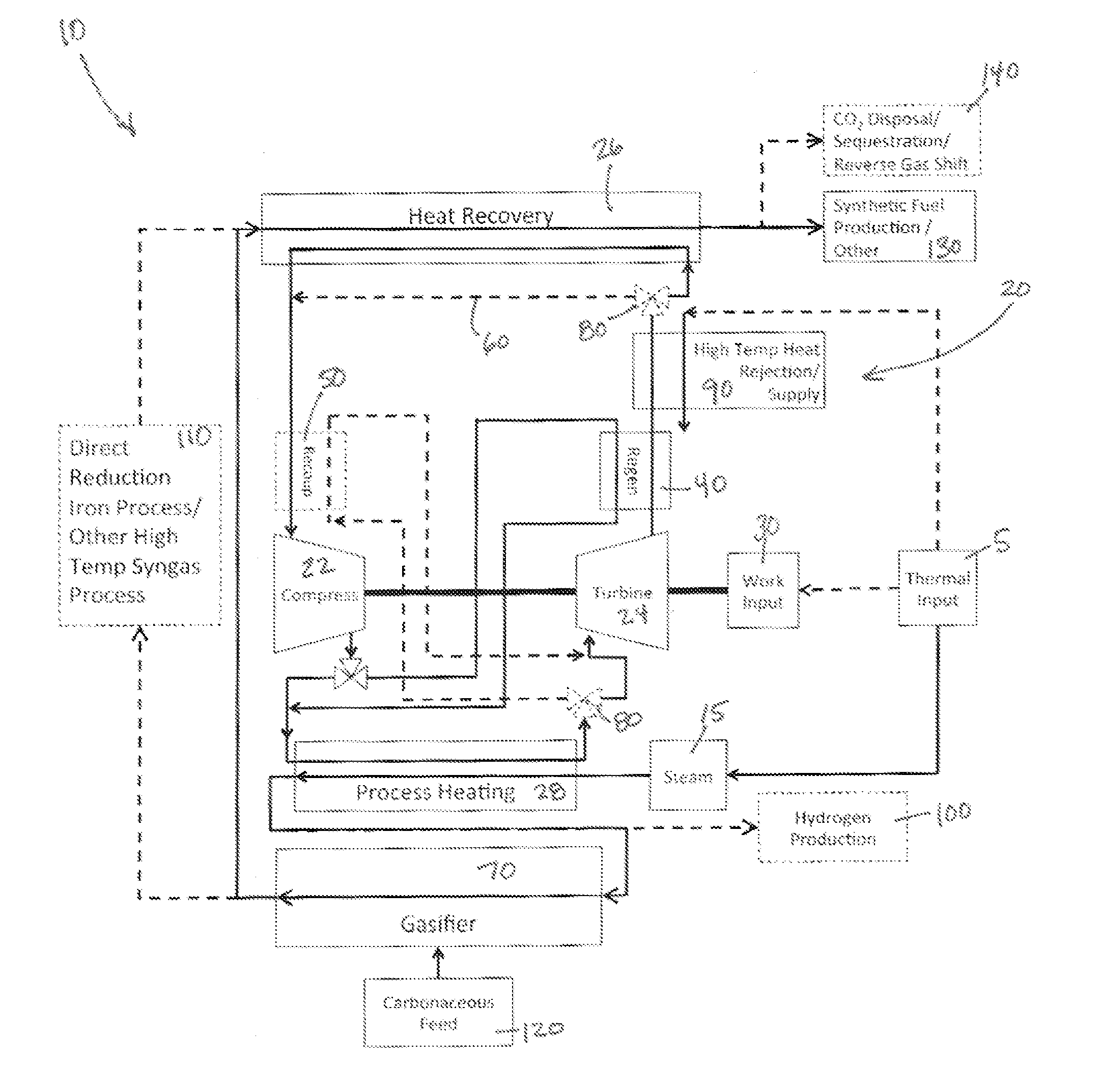

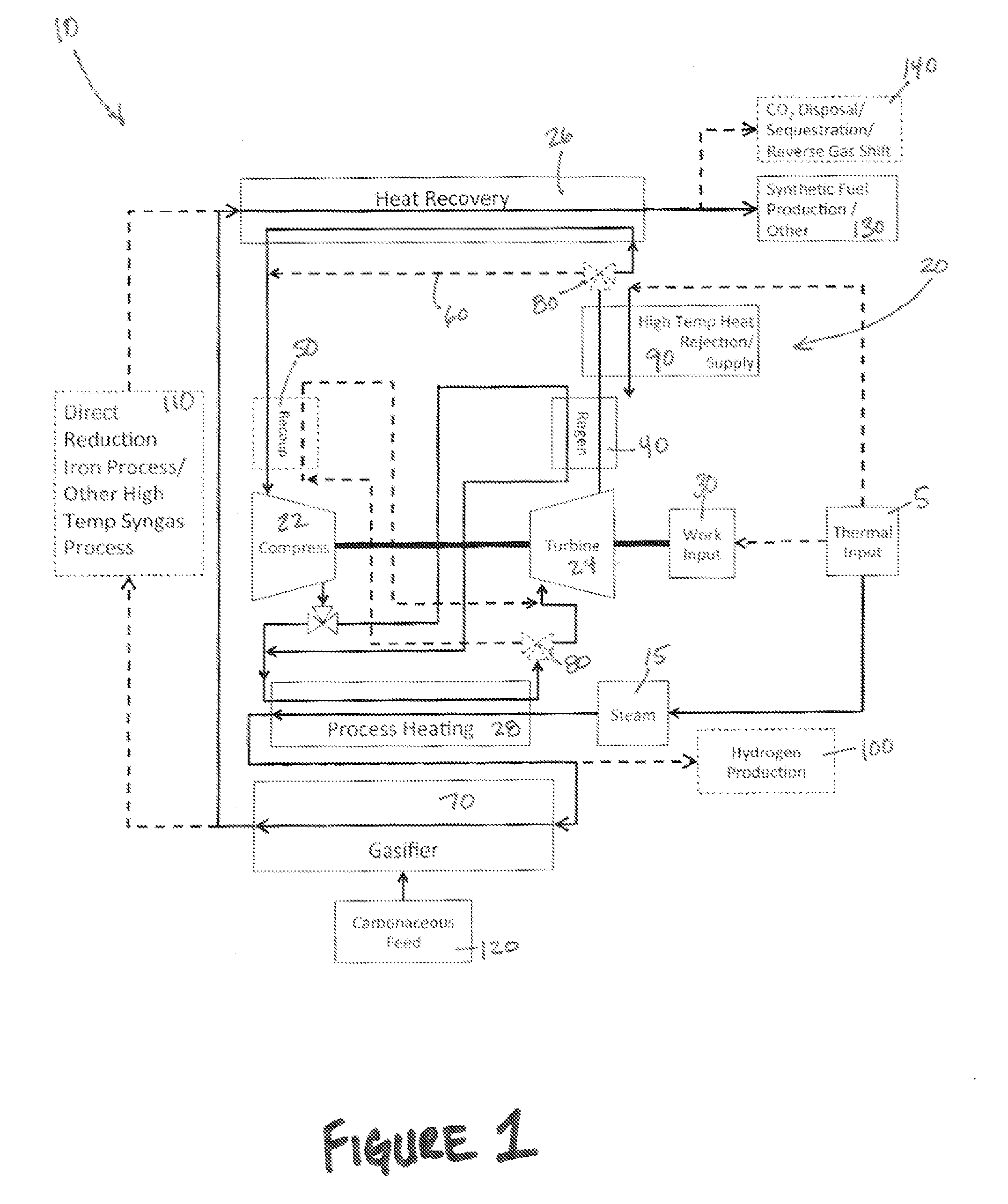

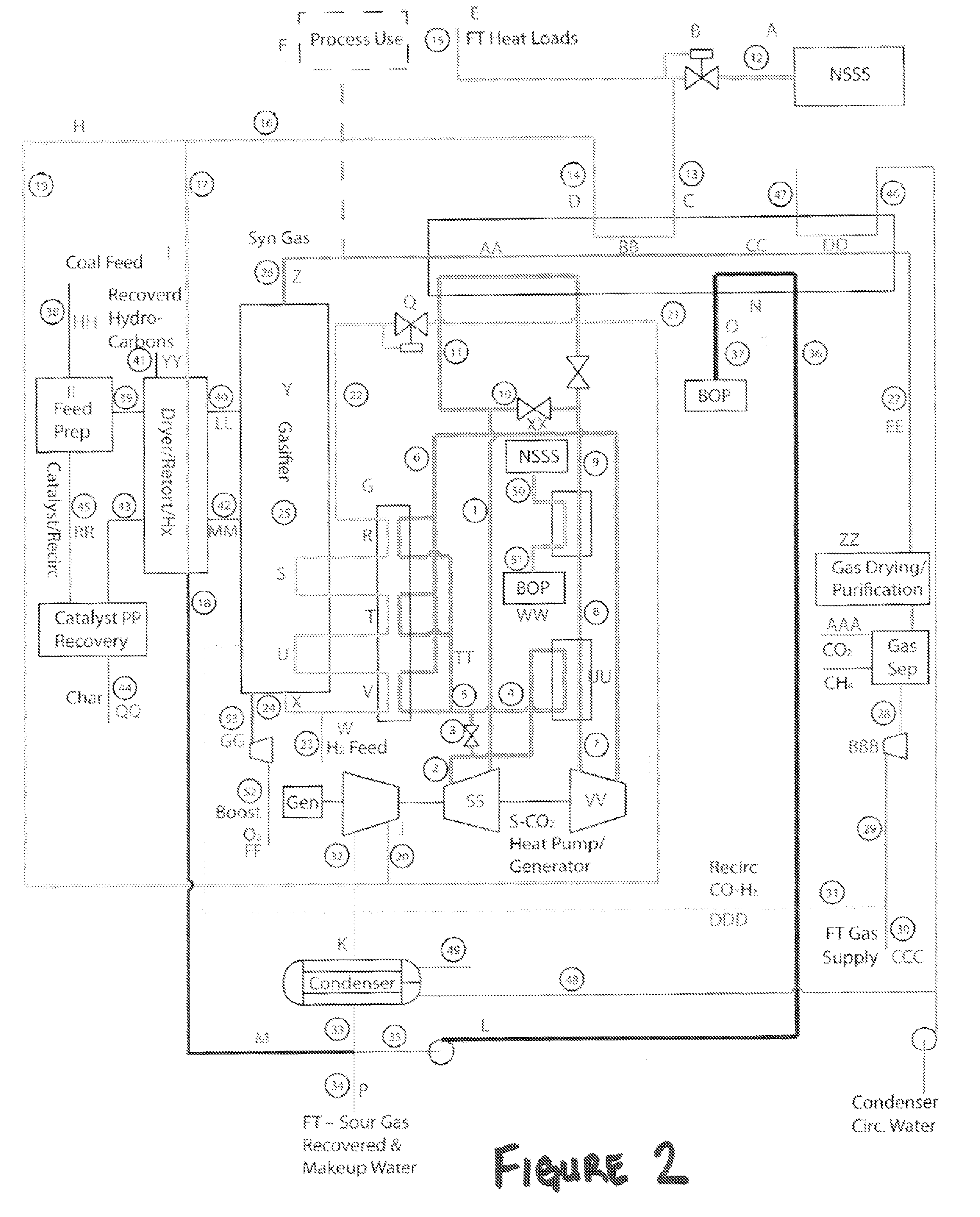

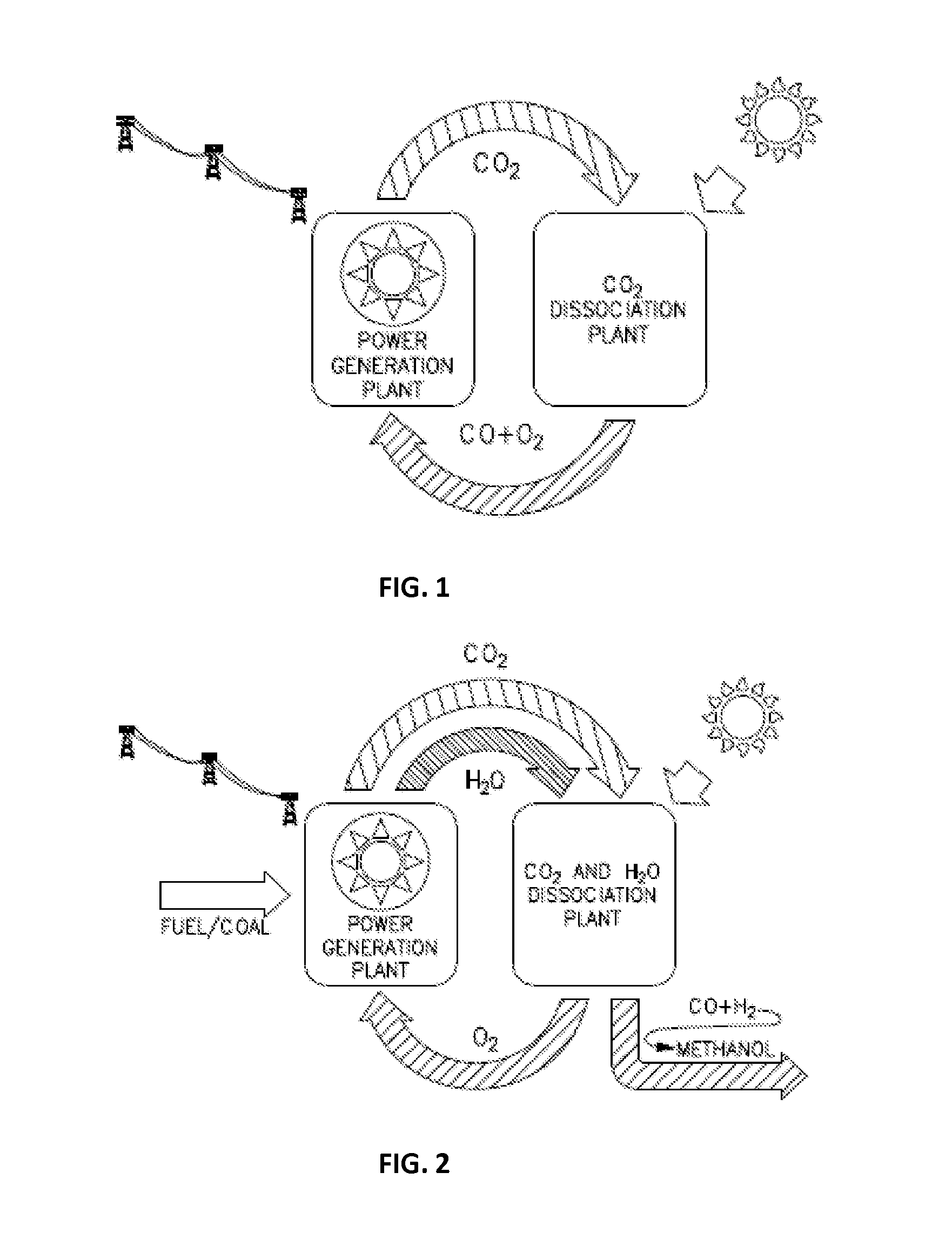

Nuclear powered facility that generates consumable fuels

InactiveUS20120039430A1Reduce emissionReduce CO2 emissionSteam generation heating methodsHeat recovery systemsProcess engineeringProduct gas

The present invention includes a system and method of producing consumable fuels generally including a thermal input device, a gasifier, a heat pump, and a product gas heat recovery device. Optionally, the system and method of the present invention includes a nuclear steam supply device as a thermal input. Optionally, the nuclear steam supply device includes a sodium fast reactor having a core outlet temperature of less than about 650° C.

Owner:ABEL CAL R

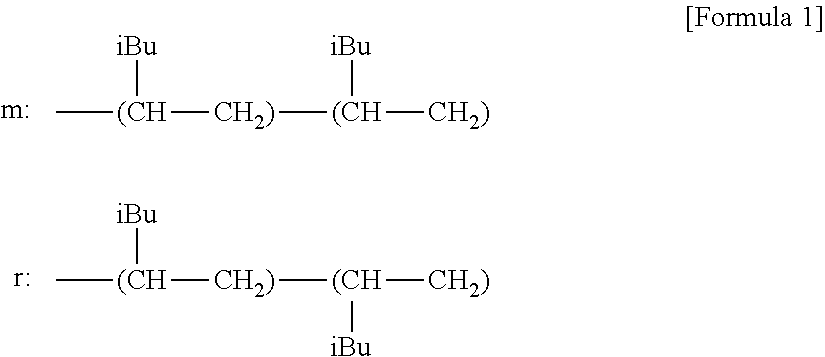

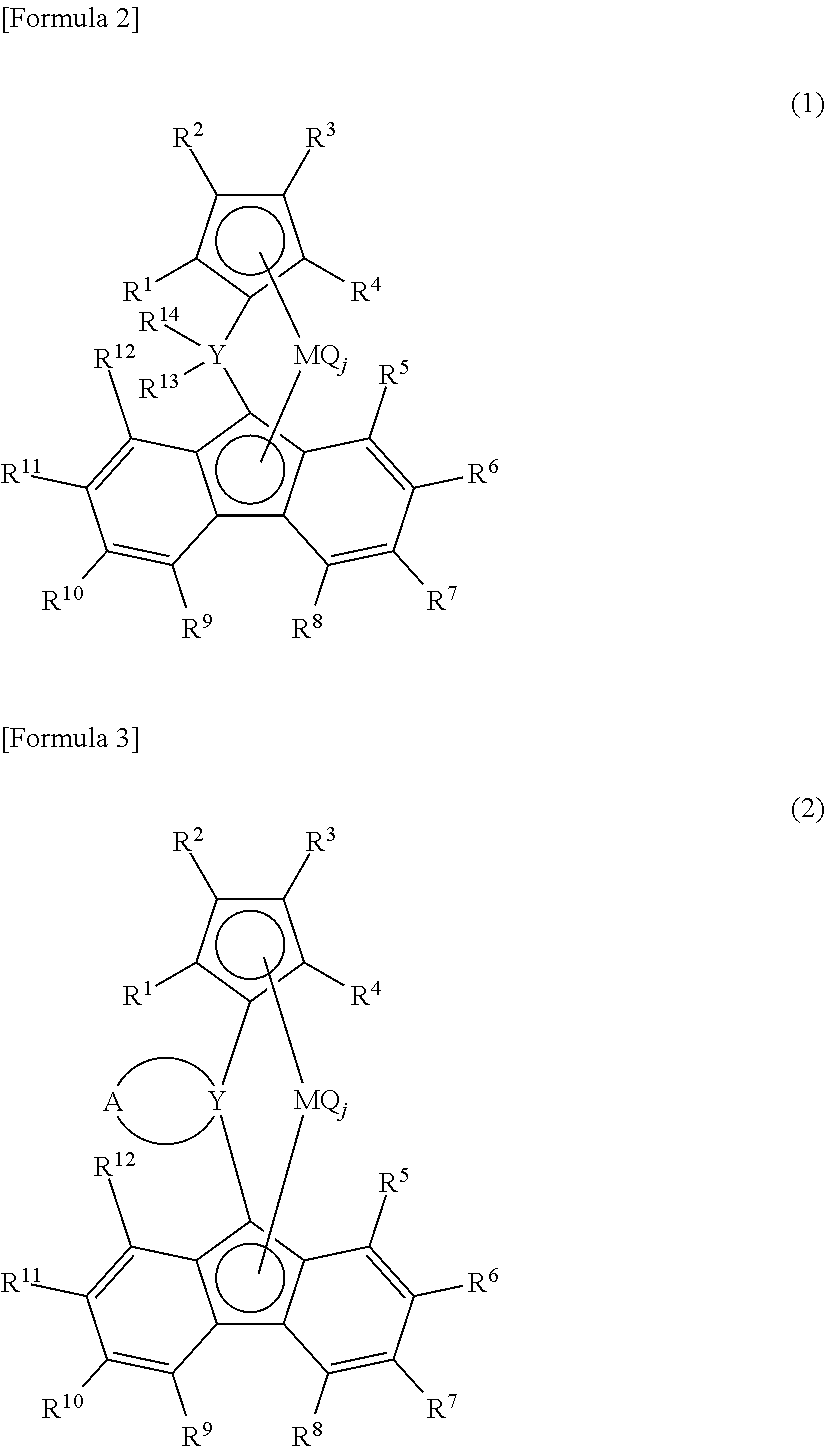

4-methyl-1-pentene polymer, resin composition containing 4-methyl-1-pentene polymer, masterbatch thereof, and formed product thereof

ActiveUS20110165416A1Excellent mold releasabilityExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsMasterbatchSolvent

[Object] To provide a resin composition with excellent mold releasability and blocking resistance.[Solution] A resin composition containing a 4-methyl-1-pentene polymer includes 0.01 to 10 parts by mass of a 4-methyl-1-pentene polymer (B) per 100 parts by mass of at least one resin (A) selected from the group consisting of thermoplastic resins and thermosetting resins, wherein the 4-methyl-1-pentene polymer (B) has (B1) an intrinsic viscosity [η] of 0.01 or more but less than 0.50 dl / g measured at 135° C. in a decalin solvent.

Owner:MITSUI CHEM INC

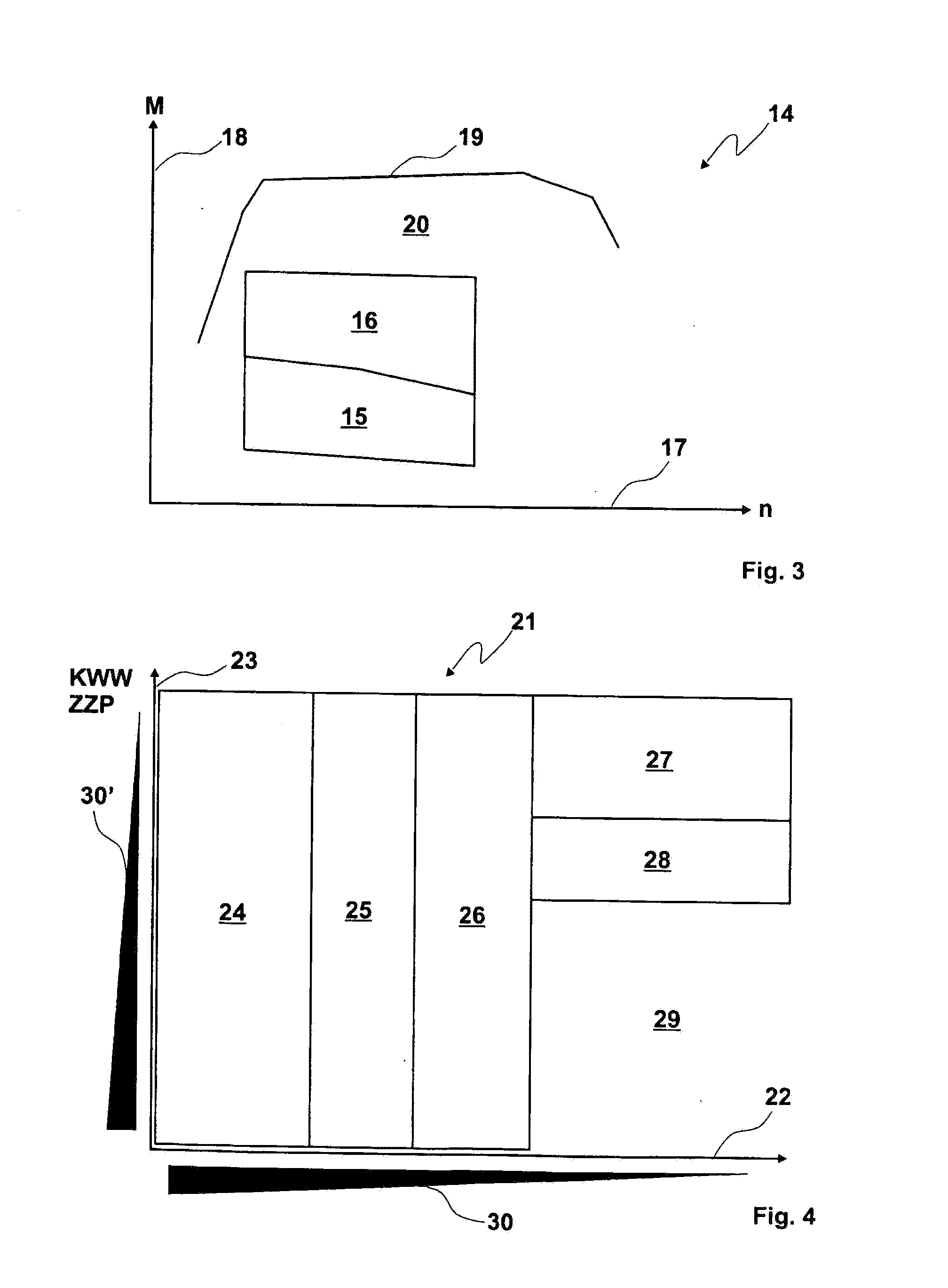

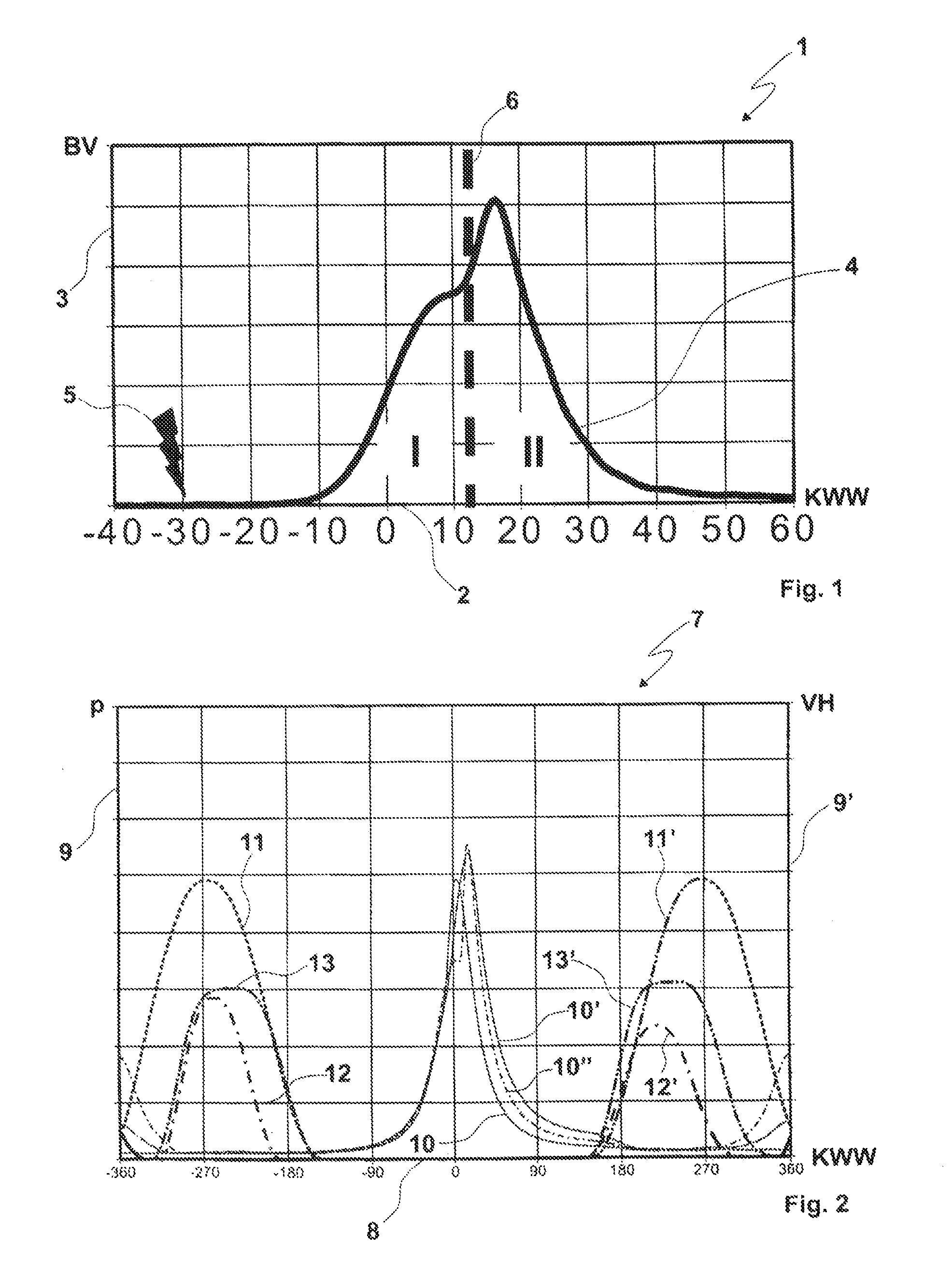

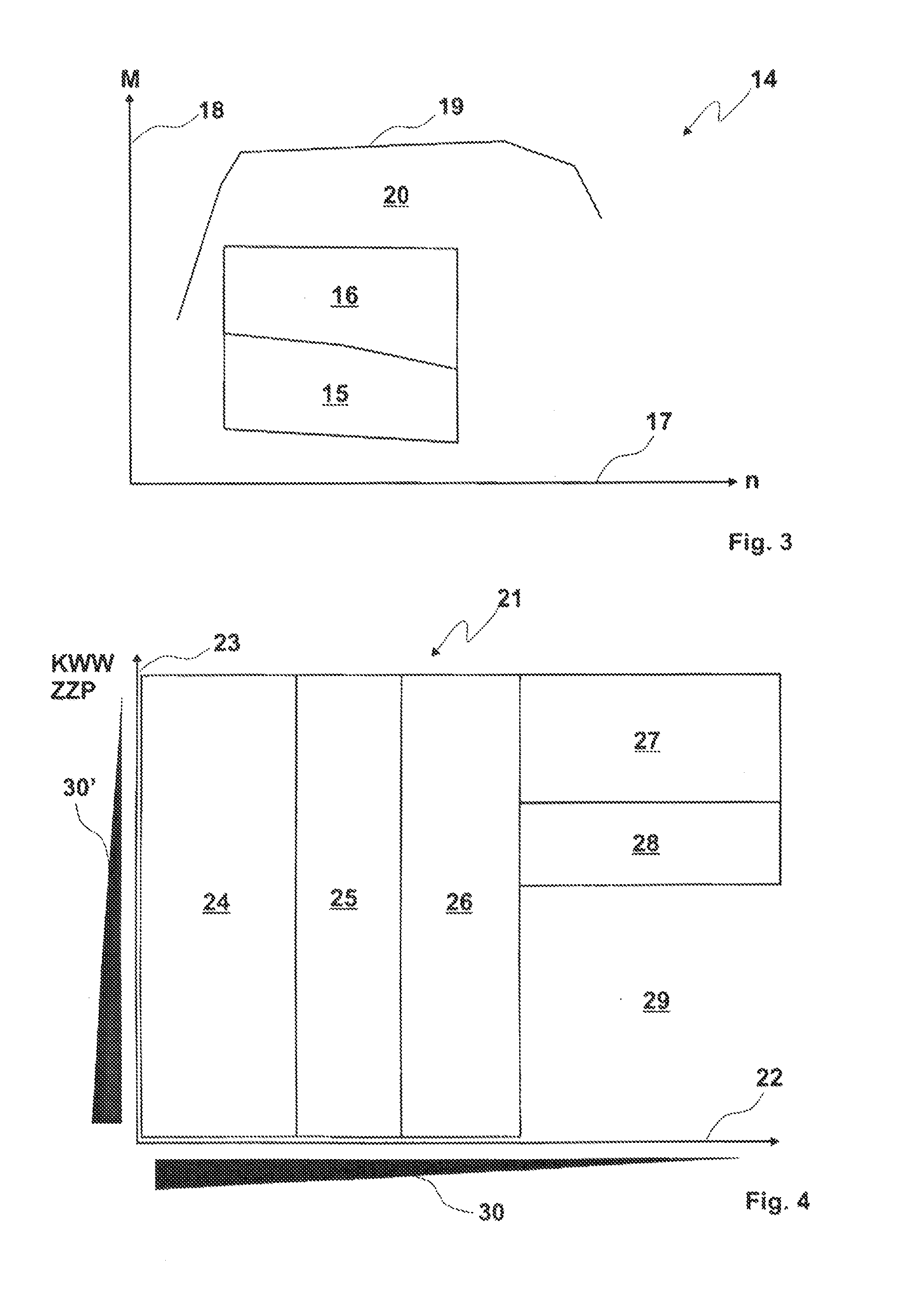

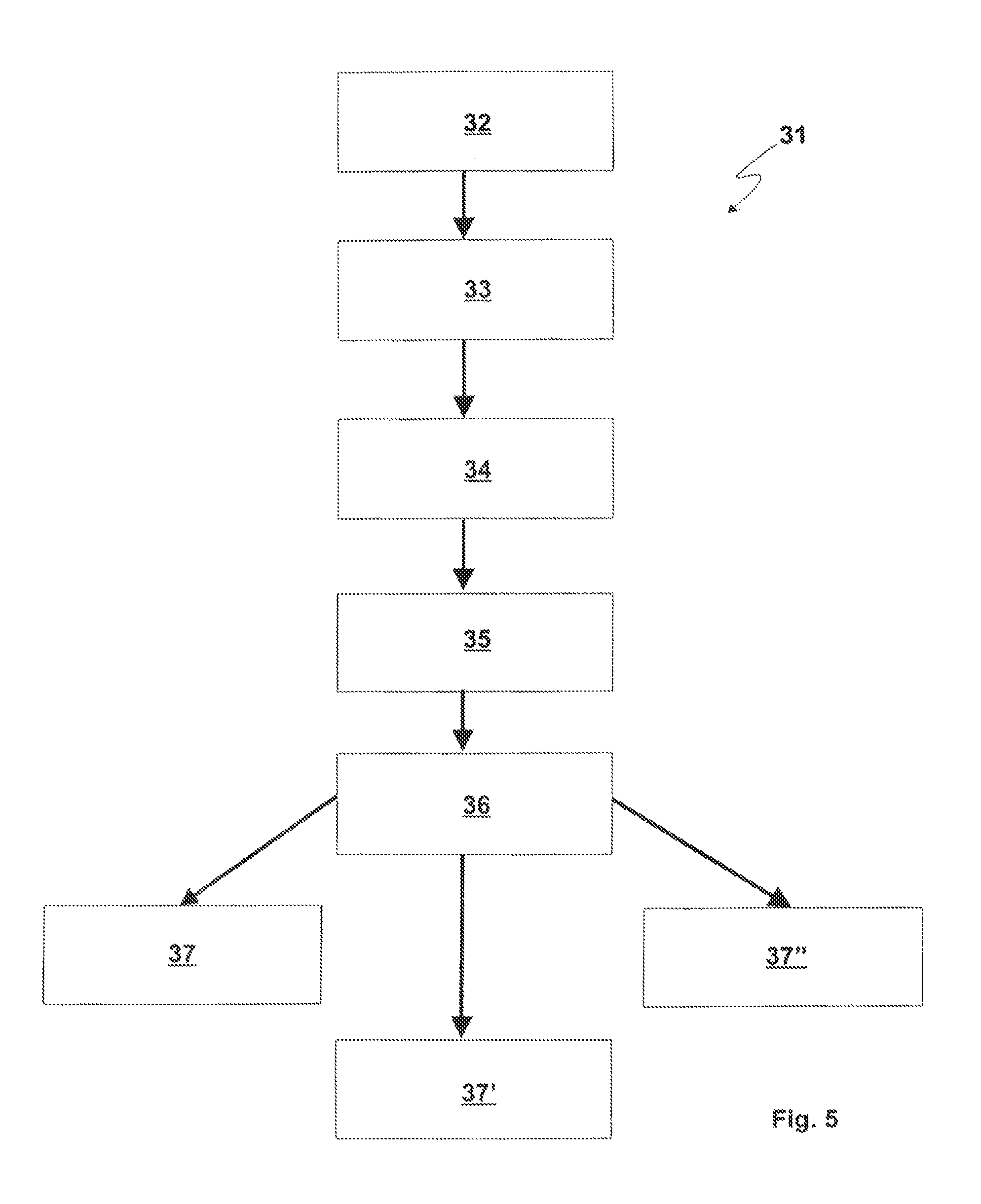

METHOD OF OPERATING AN INTERNAL COMBUSTION ENGINE WITH DIRECT FUEL INJECTION AND LOW NOx EMISSIONS

InactiveUS20130297183A1Ensure stable implementationReduce CO2Electrical controlNon-fuel substance addition to fuelExternal combustion engineGasoline

In an operating method for an internal combustion engine with direct fuel injection including a plurality of combustion chambers, in particular a direct-injection gasoline engine for a motor vehicle, wherein the operating method comprises low-NOx combustion (NAV) and uses a plurality of partial operating modes, wherein, in a NAV partial operating mode, water is injected into the respective combustion chamber, and, during said NAV partial operating mode, at an ignition point (ZZP), a largely homogeneous, lean fuel / exhaust gas / air mixture having a combustion air ratio of λ≧1 is spark ignited by means of an ignition device so as to initiate flame front combustion (FFV) with a transition to a controlled auto-ignition (RZV). The injection of water permits the NAV partial operating mode to be stably implemented even at high engine loads and speeds.

Owner:DAIMLER AG

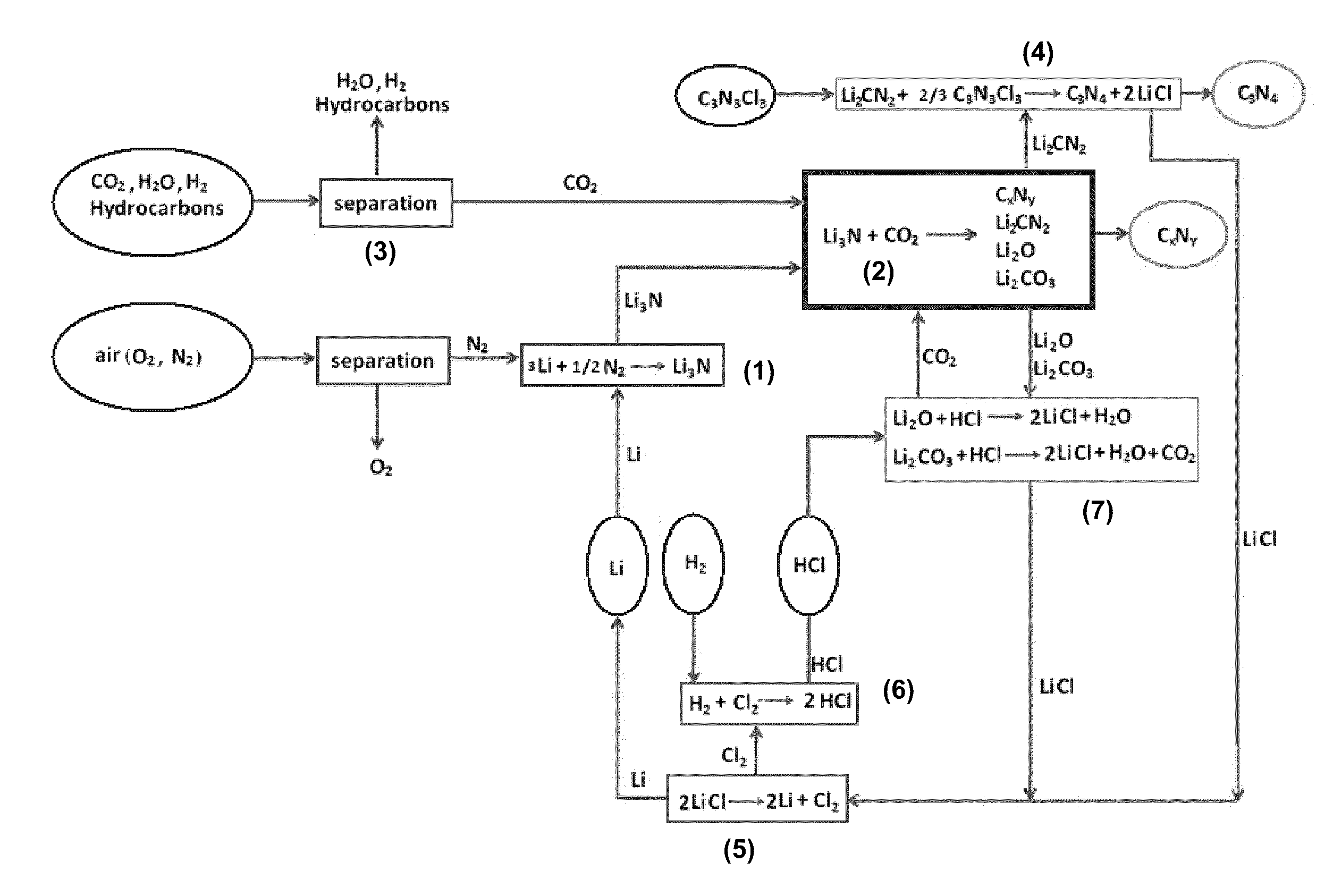

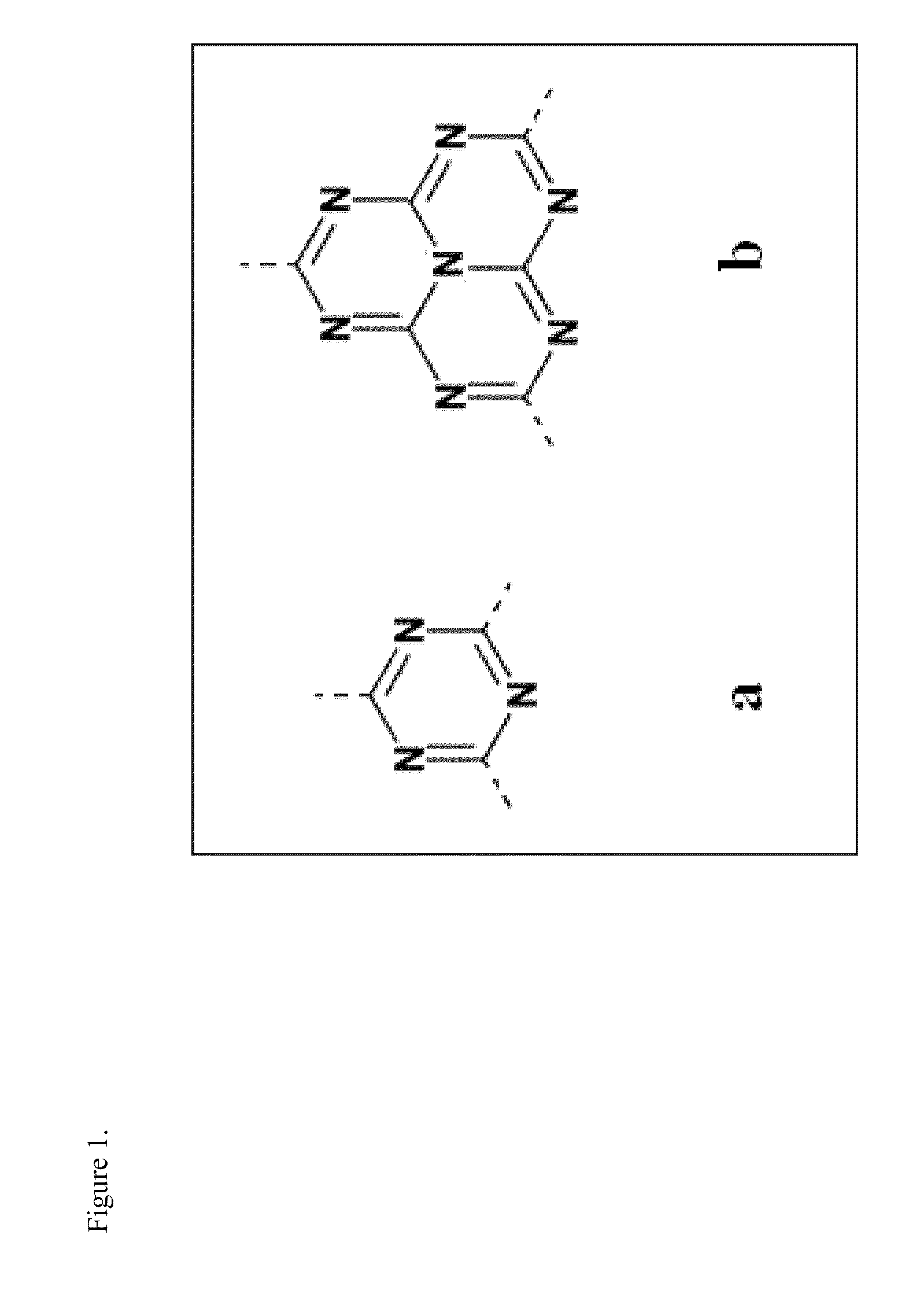

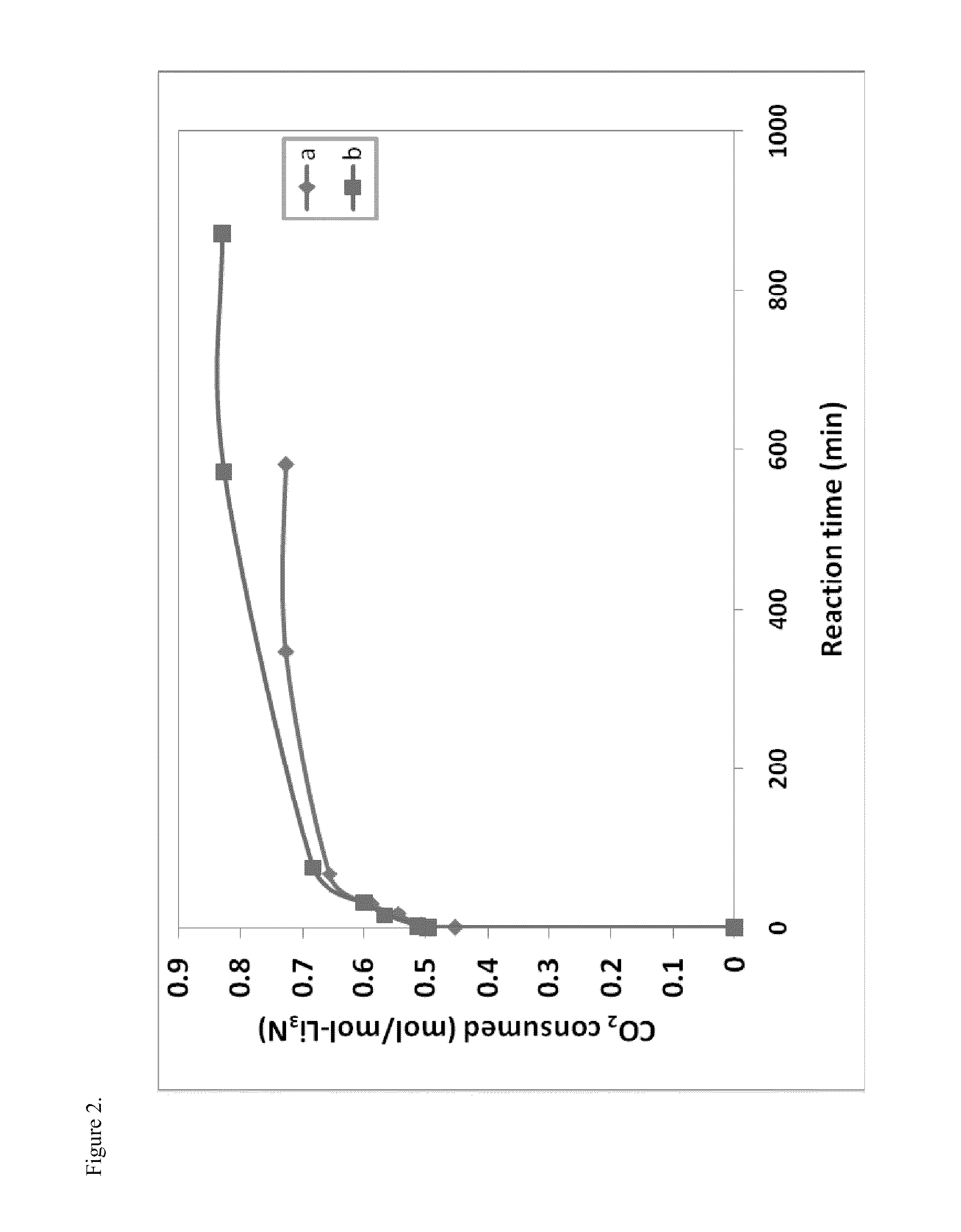

Synthesis of carbon nitrides from carbon dioxide

Provided are methods of converting carbon dioxide to carbon nitrides. In a first reaction, carbon dioxide may be reacted with metal nitrides, such as Li3N, to form carbon nitrides in a fast and exothermic reaction. Also provided are methods of using product metal cyanamides from the first reaction to subsequently generate additional carbon nitrides.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

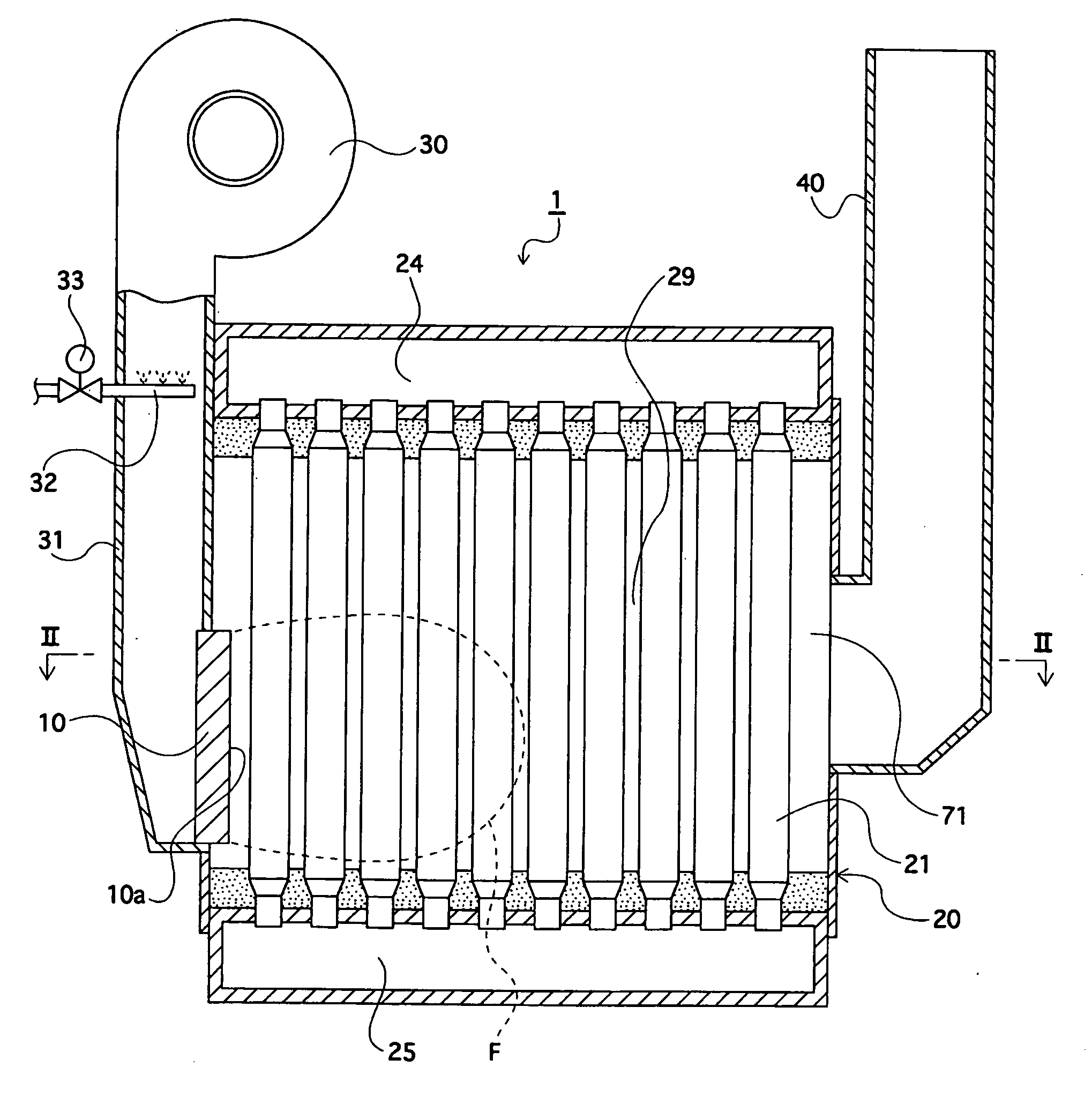

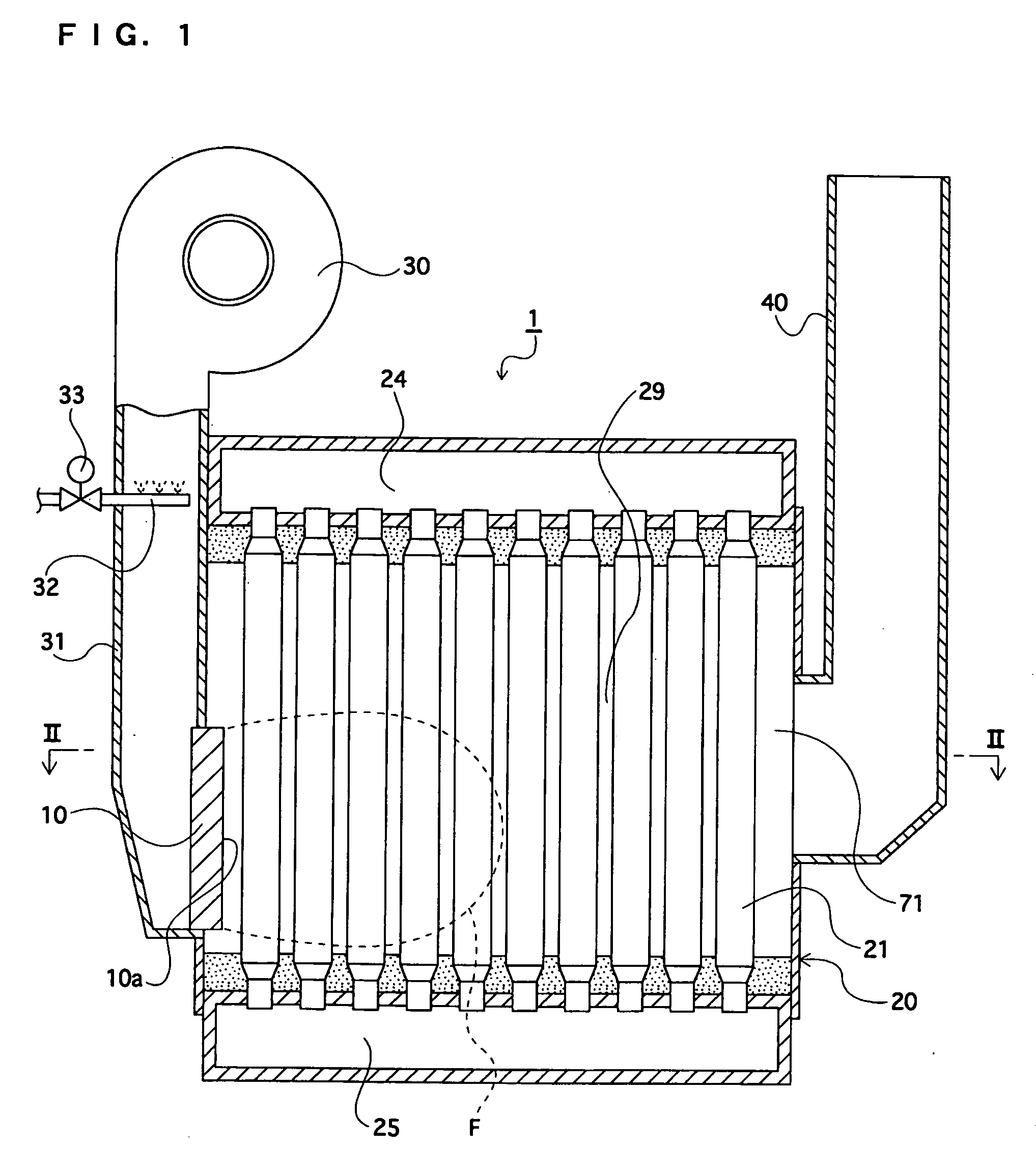

Boiler and low-NOx combustion method

ActiveUS20060177784A1Reduction in OReduce NOxBoiler water tubesStaged combustionCombustion chamberProcess engineering

To provide a boiler capable of realizing a reduction in O2, a reduction in NOx, and a reduction in CO. The present invention provides a boiler including: a premixed gas burner, and water tubes in close proximity to the premixed gas burner, characterized in that the premixed gas burner ejects a premixed gas toward the water tubes at a predetermined angle; and the boiler further includes a fuel supply portion capable of supplying at least one of a gas fuel and a premixed gas provided at a position on a downstream side of and spaced apart by a predetermined distance from the premixed gas burner.

Owner:MIURA COMPANY LIMITED

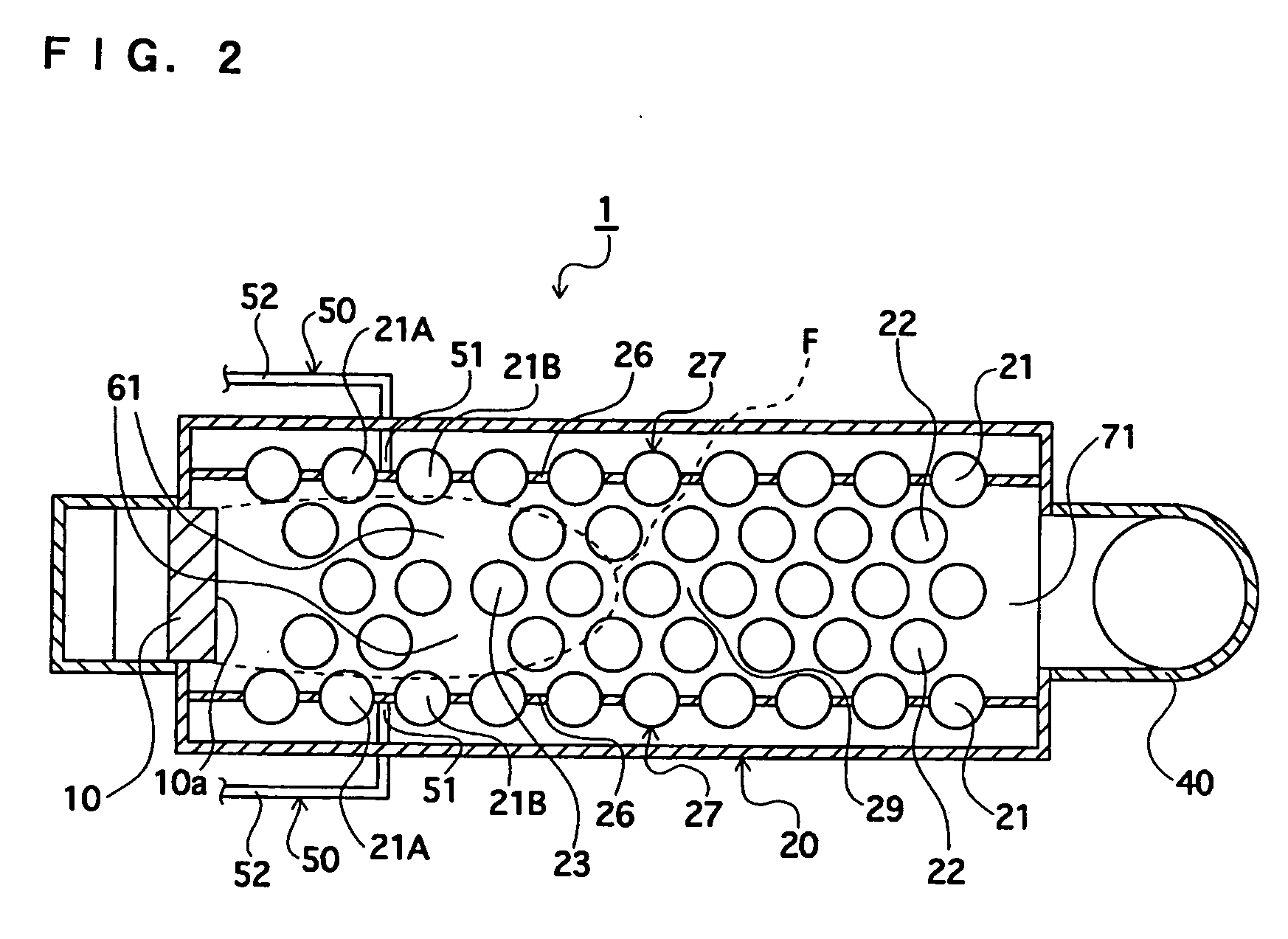

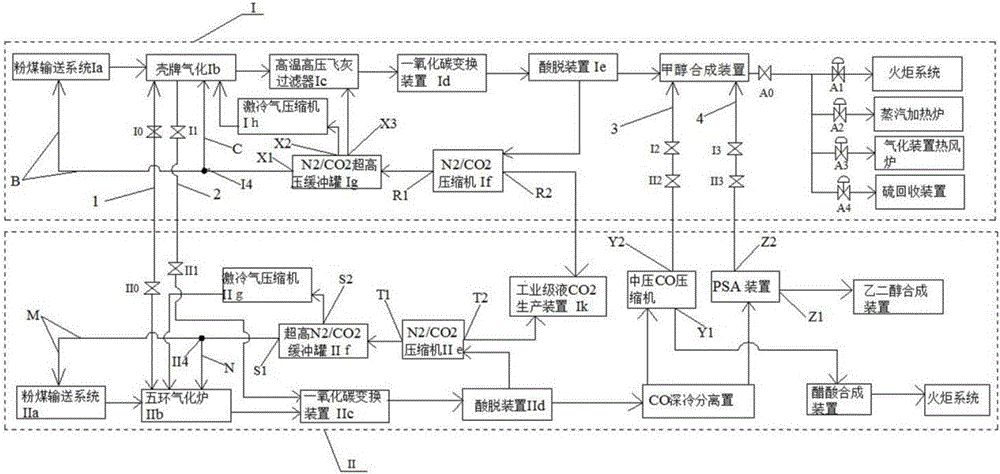

Method for emission reduction of CO2 and yield increase of methyl alcohol and acetic acid by means of CO2 emission reduction integrated unit adopted in coal-to-methanol and coal-to-acetic acid processes

InactiveCN106083524AReduce contentReduce CO2Organic compound preparationHydroxy compound preparationAcetic acidSocial benefits

The invention discloses a method for emission reduction of CO2 and yield increase of methyl alcohol and acetic acid by means of a CO2 emission reduction integrated unit adopted in coal-to-methanol and coal-to-acetic acid processes. The integrated unit comprises a coal-to-methanol device and a coal-to-acetic acid device, a CO2 connection pipe network connected with the coal-to-methanol device and the coal-to-acetic acid device, and a gas delivery pipeline connected with the coal-to-methanol device and the coal-to-acetic acid device. The method comprises the steps of starting the coal-to-methanol device firstly; opening the CO2 connection pipe network and starting the coal-to-acetic acid device after the coal-to-methanol device runs for a certain period of time, wherein qualified gas generated during operation of the coal-to-acetic acid device is used for preparing acetic acid, and unqualified gas enters a methanol synthesis device through the gas delivery pipeline to be recycled. The byproduct CO2 generated from methanol preparation is recycled to the coal-to-methanol device and the coal-to-acetic acid device, CO2 emission is reduced greatly, useful gas generated in the coal-to-acetic acid process is used for preparing methanol and acetic acid, the yield of methanol and acetic acid is increased, and economic and social benefits are remarkable.

Owner:HENAN LONGYU COAL CHEM

METHOD OF OPERATING AN INTERNAL COMBUSTION ENGINE WITH LOW NOx COMBUSTION

InactiveUS20130327293A1Reduce nitrogen oxide emissionsReduce fuel consumptionElectrical controlInternal combustion piston enginesCombustion chamberGasoline

An operating mode for an internal combustion engine, in particular a directly injected internal combustion engine featuring a plurality of combustion chambers, in particular for a direct-injection gasoline engine, for example in a motor vehicle, an operating mode having at least in part low-NOx combustion (NAV) and having a plurality of partial operating modes whereby it is switched between a RZV partial operating mode having pure controlled auto-ignition (RZV) and a NAV partial operating mode, whereby in the case of said NAV partial operating mode, at an ignition point (ZZP) a largely homogeneous, lean fuel / exhaust gas / air mixture in the respective combustion chamber having a combustion air ratio of λ≧1 is spark ignited by means of an ignition device, where the flame front combustion (FFV) initiated by the spark-ignition transitions to a controlled auto-ignition (RZV). By combining the NAV partial operating mode with the RZV partial operating mode, the engine load range in which a controlled auto-ignition (RZV) can be performed enlarged, and as a result the fuel consumption and the NOx emissions is reduced in this expanded engine load range too.

Owner:DAIMLER AG

Resin composition and molded article made thereof

A resin composition is described that is excellent in strength, impact resistance, heat resistance and moldability, while further allowing for a reduction in the amount of CO2 needed for its production. The resin composition includes a styrene-based resin (A), an aliphatic polyester (B) and at least one species selected from a compatibilizer (C) and a dicarboxylic anhydride (D), wherein the compatibilizer is preferably at least one species selected from: (C-1) a methyl methacrylate polymer; (C-2) a vinyl-based polymer which an epoxy unit or acid anhydride unit is copolymerized; (C-3) a graft polymer in which a methyl methacrylate unit is grafted to a rubbery polymer; and (C-4) a block copolymer having a polylactide segment and a vinyl-based polymer segment.

Owner:TORAY IND INC

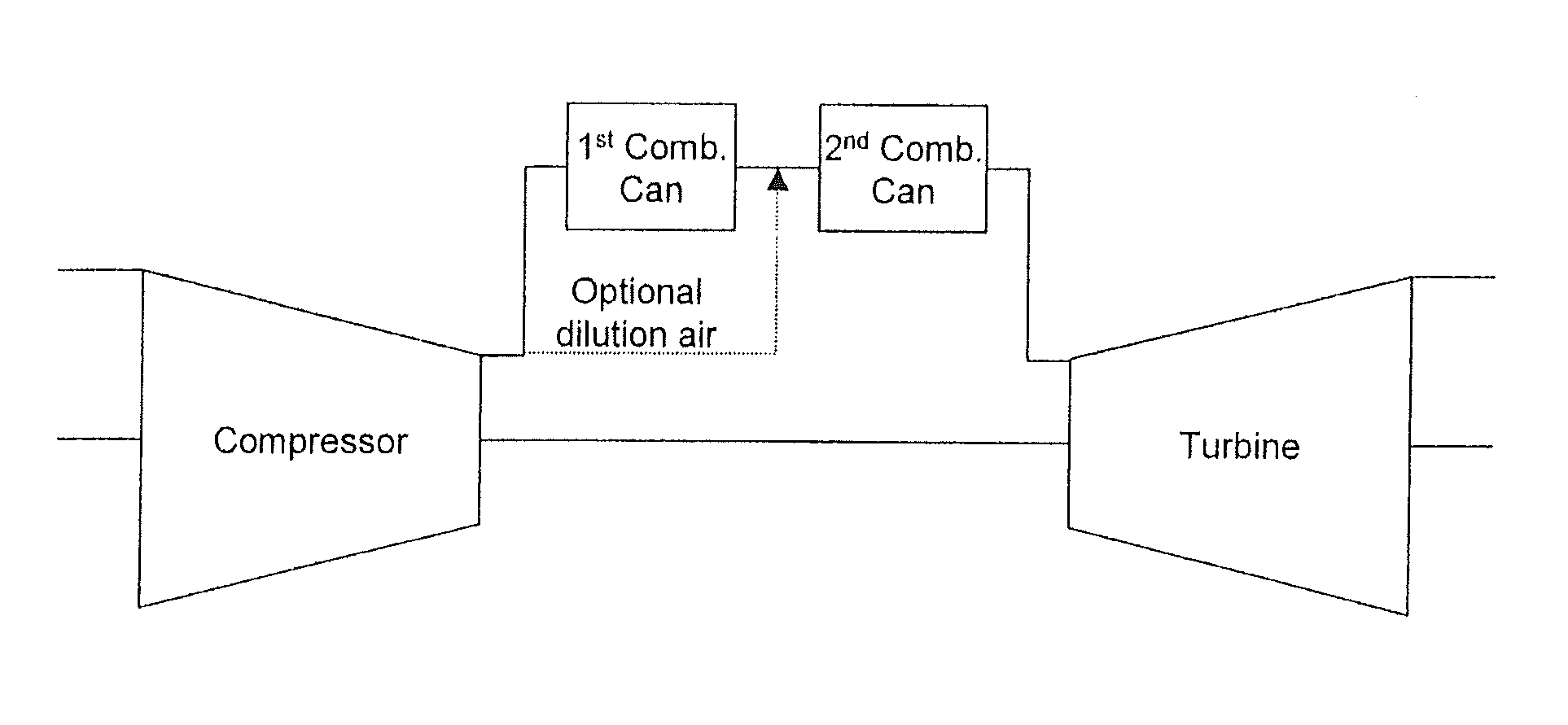

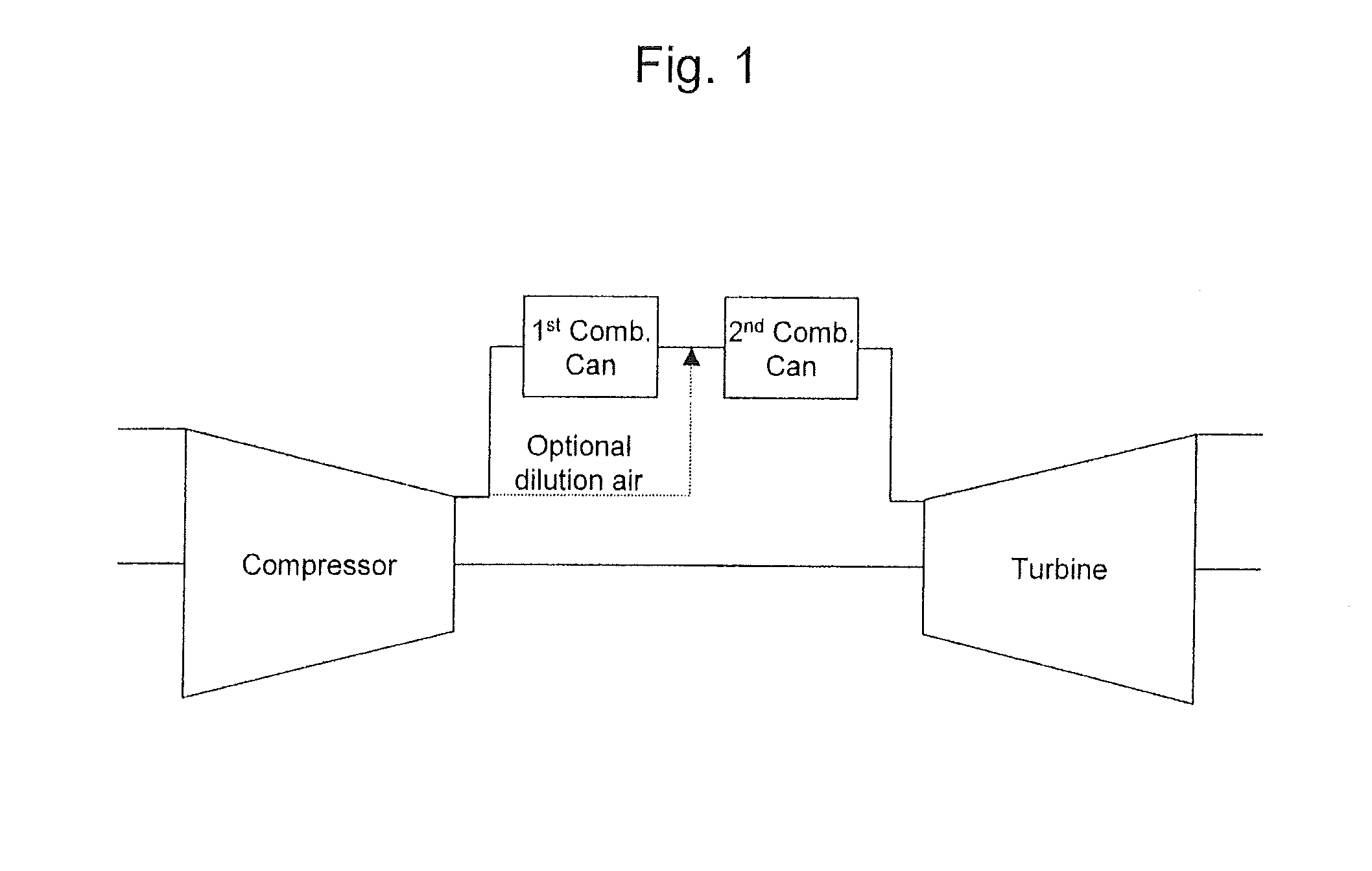

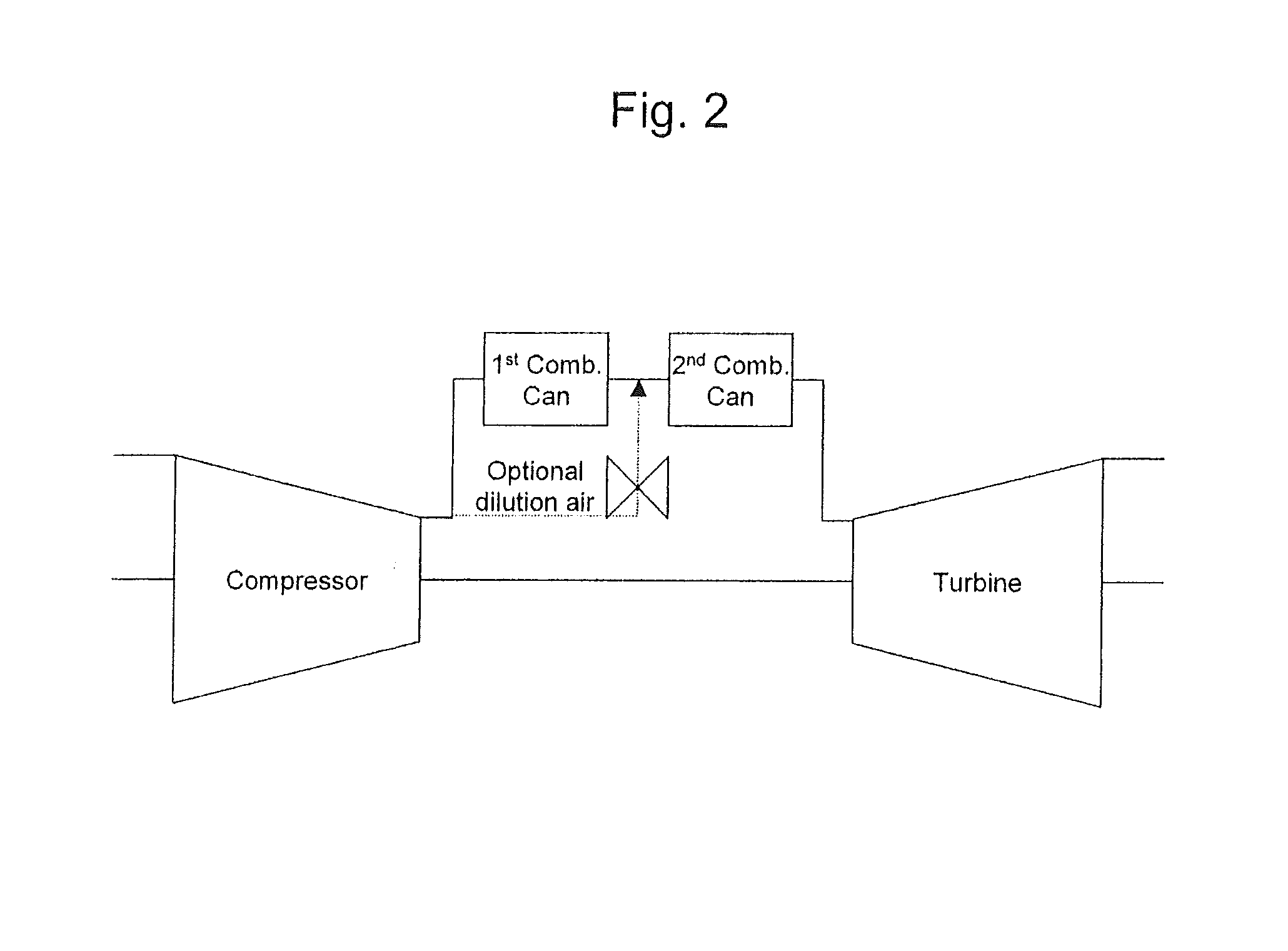

Method for a part load co reduction operation for a sequential gas turbine

ActiveUS20150101341A1Reduce carbon dioxide emissionsReduce CO2Fuel supply regulationContinuous combustion chamberCombustorProduct gas

The invention concerns a method for a part load CO reduction operation and a low-CO emissions operation of a gas turbine with sequential combustion. The gas turbine essentially includes at least one compressor, a first combustor which is connected downstream to the compressor. The hot gases of the first combustor are admitted at least to an intermediate turbine or directly or indirectly to a second combustor. The hot gases of the second combustor are admitted to a further turbine or directly or indirectly to an energy recovery. At least one combustor runs under a caloric combustion path having a can-architecture, and wherein the air ratio (λ) of the combustion at least of the second combustor is kept below a maximum air ratio (λmax).

Owner:ANSALDO ENERGIA SWITZERLAND AG

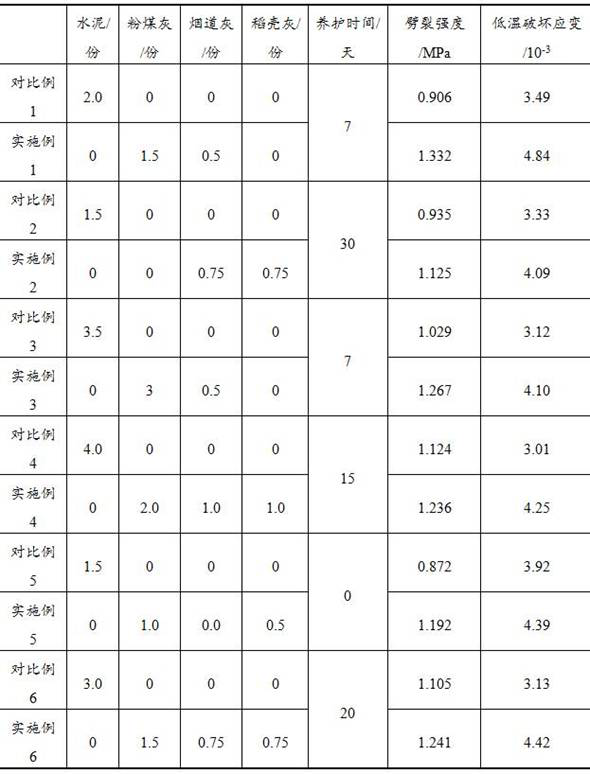

Emulsified asphalt plant-mixed cold recycled asphalt mixture and preparation method thereof

ActiveCN113636786ASolve the reuse problemReduce CO2Solid waste managementBitumen emulsionEnvironmental engineering

The invention belongs to the field of recycling of highway and urban road waste materials, and provides an emulsified asphalt plant-mixed cold-recycled asphalt mixture and a preparation method thereof. The emulsified asphalt plant-mixed cold-recycled asphalt mixture is prepared from, by mass, 10-25 parts of new aggregate, 70-85 parts of old aggregate and 3-6 parts of filler, wherein the total amount of the component A is 100 parts; the component B comprises, by weight, 3.5-5.5 parts of emulsified asphalt, 3.5-5.5 parts of water and 0.5-5 parts of industrial waste residues, and the industrial waste residues are a mixture of two or more of fly ash, flue ash and rice hull ash. Compared with a common cement-emulsified asphalt plant-mixed cold-recycled mixture, the product provided by the invention has the advantages that the final long-term strength and low-temperature damage strain of the emulsified asphalt plant-mixed cold-recycled mixture can be improved by 10-50% and 10-40% respectively by adding a certain proportion of industrial waste residues.

Owner:HUNAN UNIV

Cement produced from industrial solid wastes

ActiveCN109912243AHigh strengthImprove acid and alkali corrosion resistanceCement productionAlkaline waterPolyol

The invention relates to cement produced from industrial solid wastes. The cement is prepared from cement clinker, the industrial solid wastes and a composite alkaline additive. The composite alkalineadditive consists of triethanolamine, polymeric polyol, calcium formate, alkaline water and industrial salt. The obtained cement has the advantages of high compressive strength, acid and alkali corrosion resistance and the like under the conditions of proper raw material specific composition and proper proportion, and the preparation method is simple to operate, easy to industrialize, good in application prospect and suitable for industrial production and application.

Owner:西卓子山草原水泥集团包头三固有限责任公司

Light-emitting polymer composition and organic EL display device using the same

InactiveUS20050095460A1Improve adhesionReduce cohesionDischarge tube luminescnet screensElectroluminescent light sourcesLuminescent polymersDisplay device

A light-emitting polymer composition for a light-emitting layer in an organic EL display device includes at least first and second light-emitting polymers having different interfacial characteristics which lower a cohesion between elements of the first and second light-emitting polymers.

Owner:SAMSUNG DISPLAY CO LTD

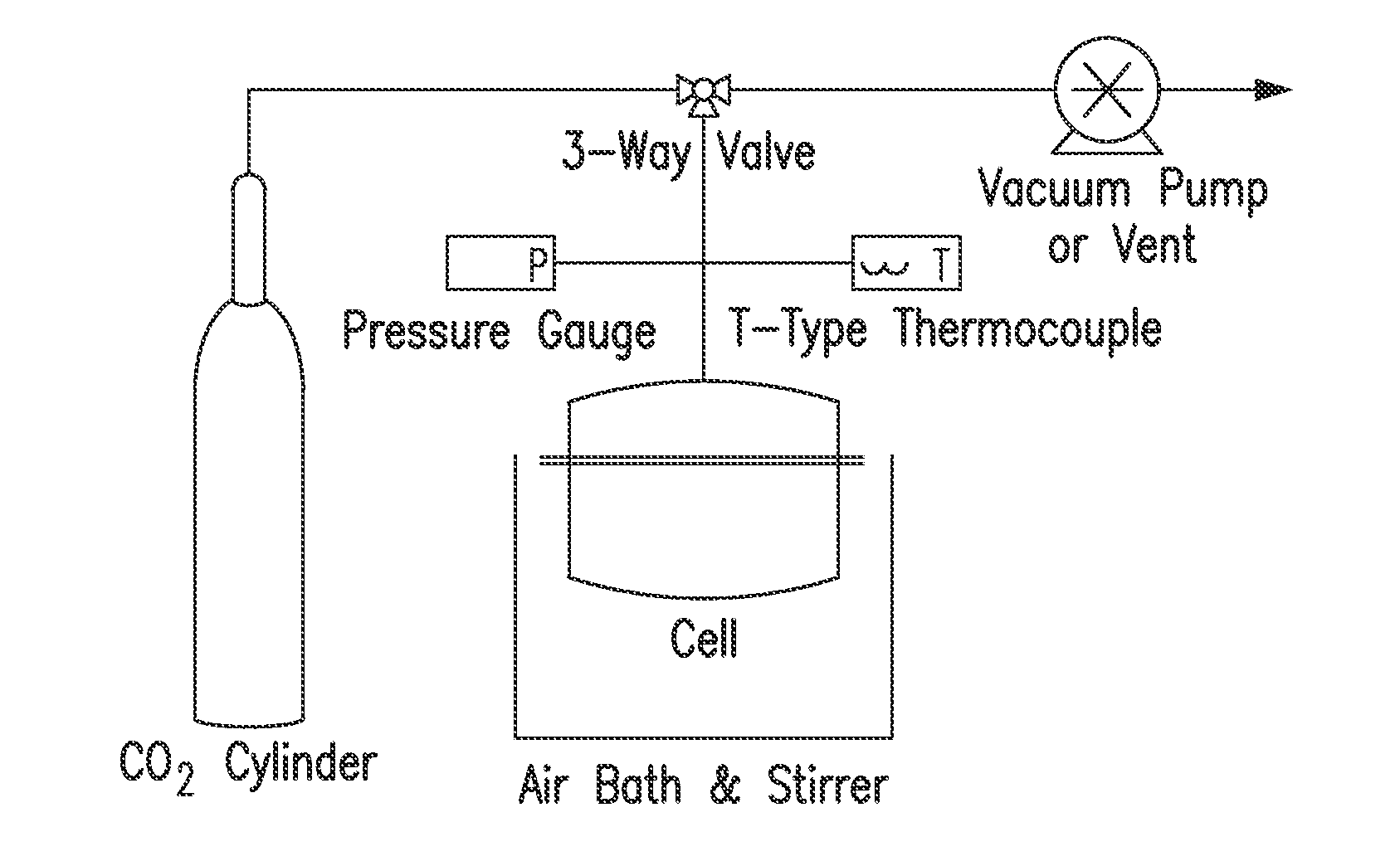

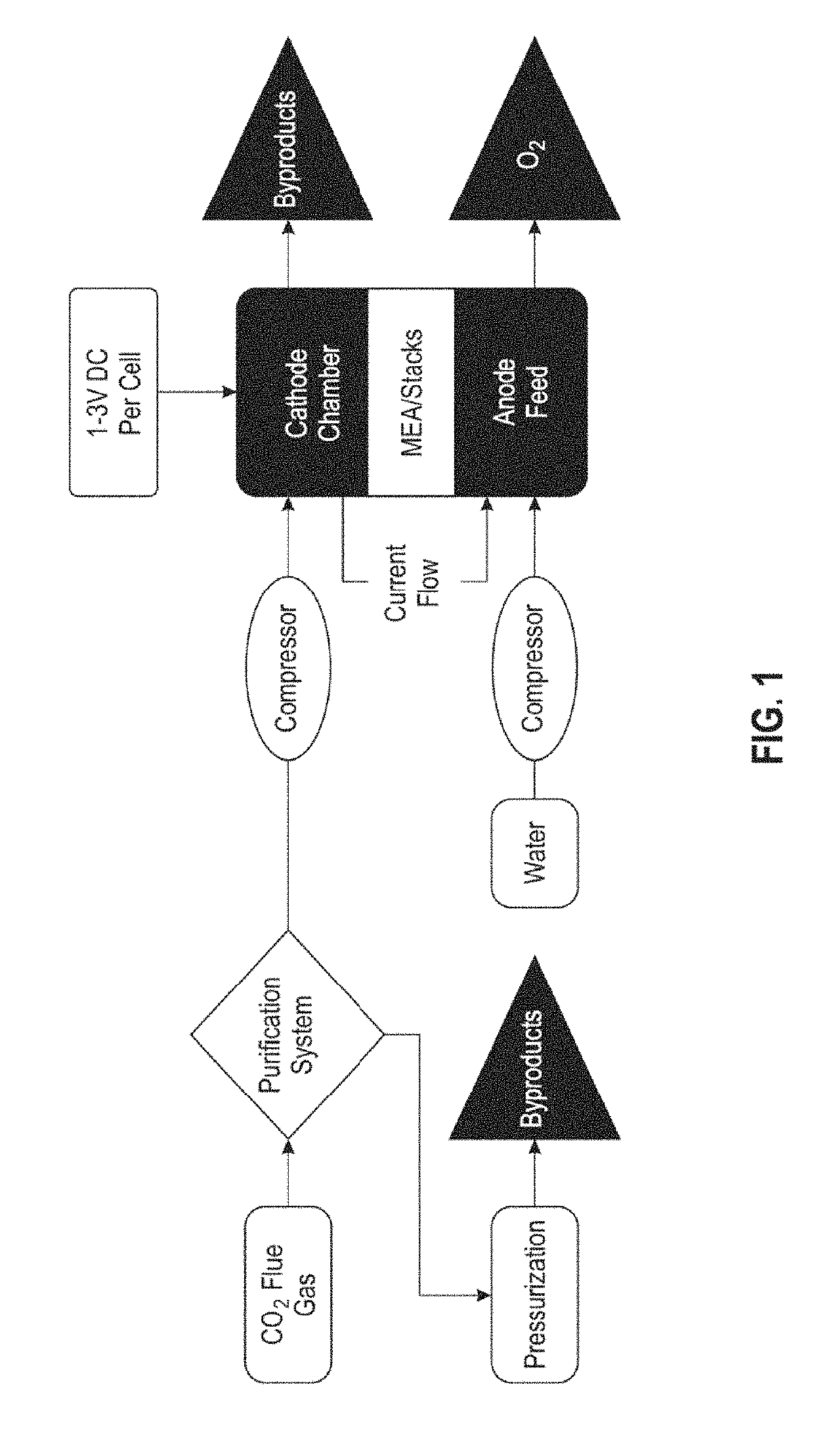

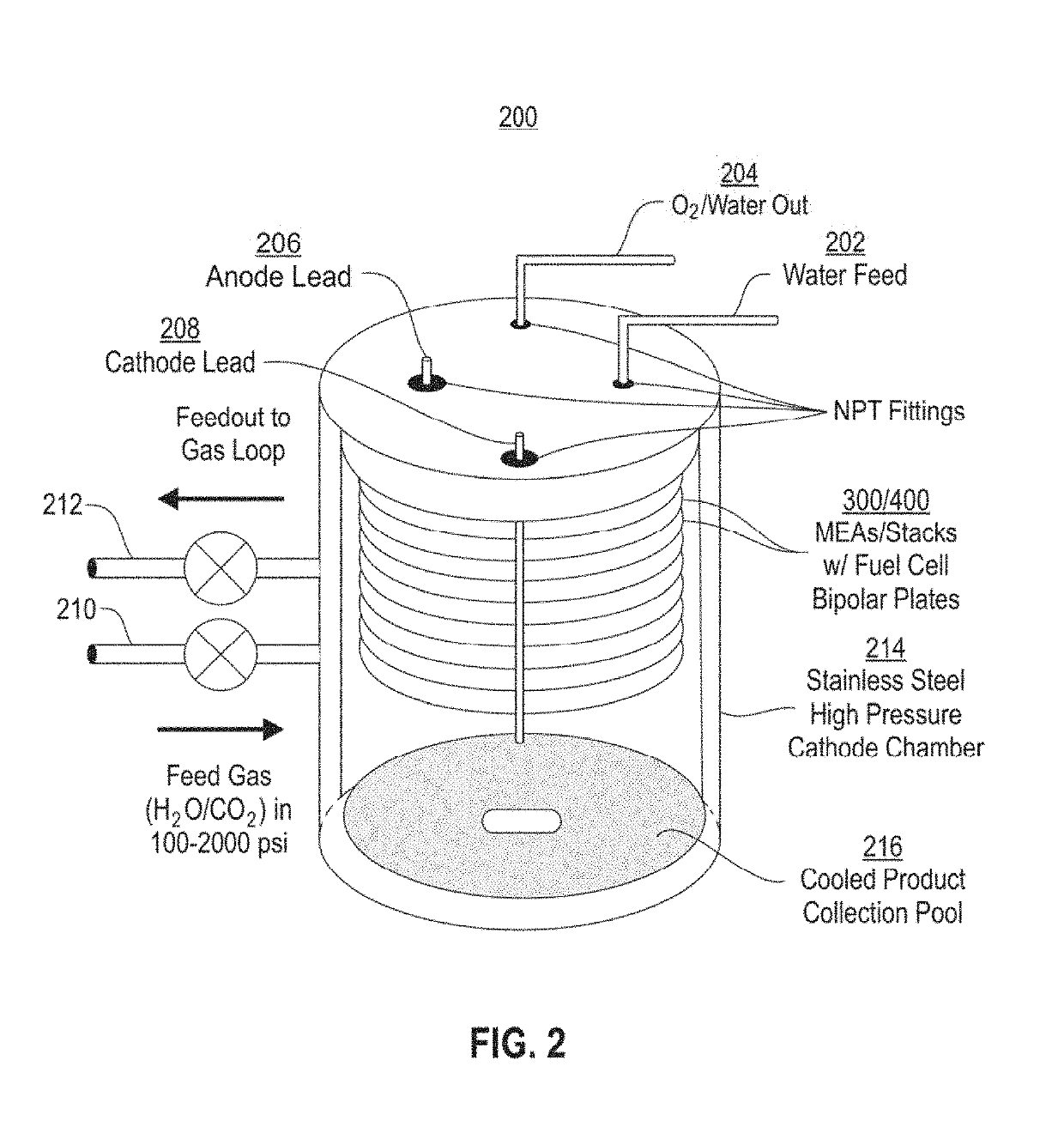

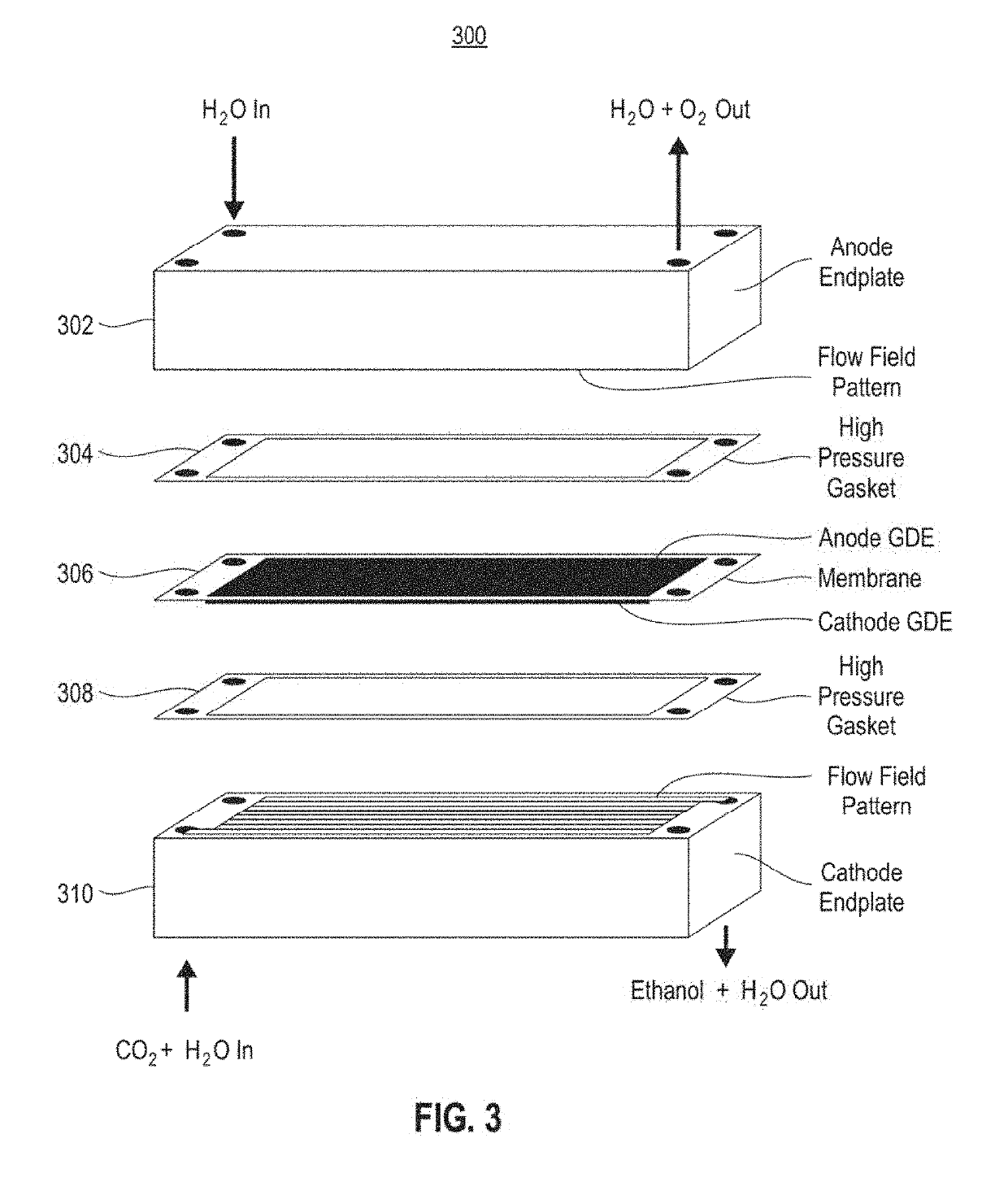

Systems and methods for variable pressure electrochemical carbon dioxide reduction

ActiveUS20190233952A1Reduce CO2CellsAlcoholic beverage preparationElectrochemical responseCarbon dioxide

Electrochemical devices, such as membrane electrode assemblies and electrochemical reactors, are described herein, as well as and methods for the conversion of reactants such as carbon dioxide to value-added products such as ethanol. In certain aspects, the membrane electrode assemblies are configured to allow for distributed pressure along the cathodic side of a membrane electrode assembly is described. The pressure vessel acts as a cathode chamber, both for the feed of reactant carbon dioxide as well as collection of products. The designs described herein improves the safety of high pressure electrochemical carbon dioxide reduction and allows for varied pressures to be used, in order to optimize reaction conditions. Configurations optimized for producing preferred products, such as ethanol, are also described.

Owner:AIR CO HLDG INC

Apparatus and method for using solar radiation in electrolysis process

InactiveUS20150047985A1Increase chanceGenerating cleanCellsSolar heating energyElectrolysisElectromagnetic radiation

A solar-driven apparatus is provided having: a cavity having at least one optical window for collecting electromagnetic radiation associated with solar energy impinging on said at least one optical window; a reaction assembly located inside the cavity and adapted to enable carrying out electrolysis process of at least one raw fluid utilizing energy derived partially from the solar radiation and partially from an electric source; one or more ingress units operative to allow introduction of the raw fluid into the apparatus; and one or more egress units operative to allow exit of the electrolysis process' products from the solar driven apparatus.

Owner:YEDA RES & DEV CO LTD

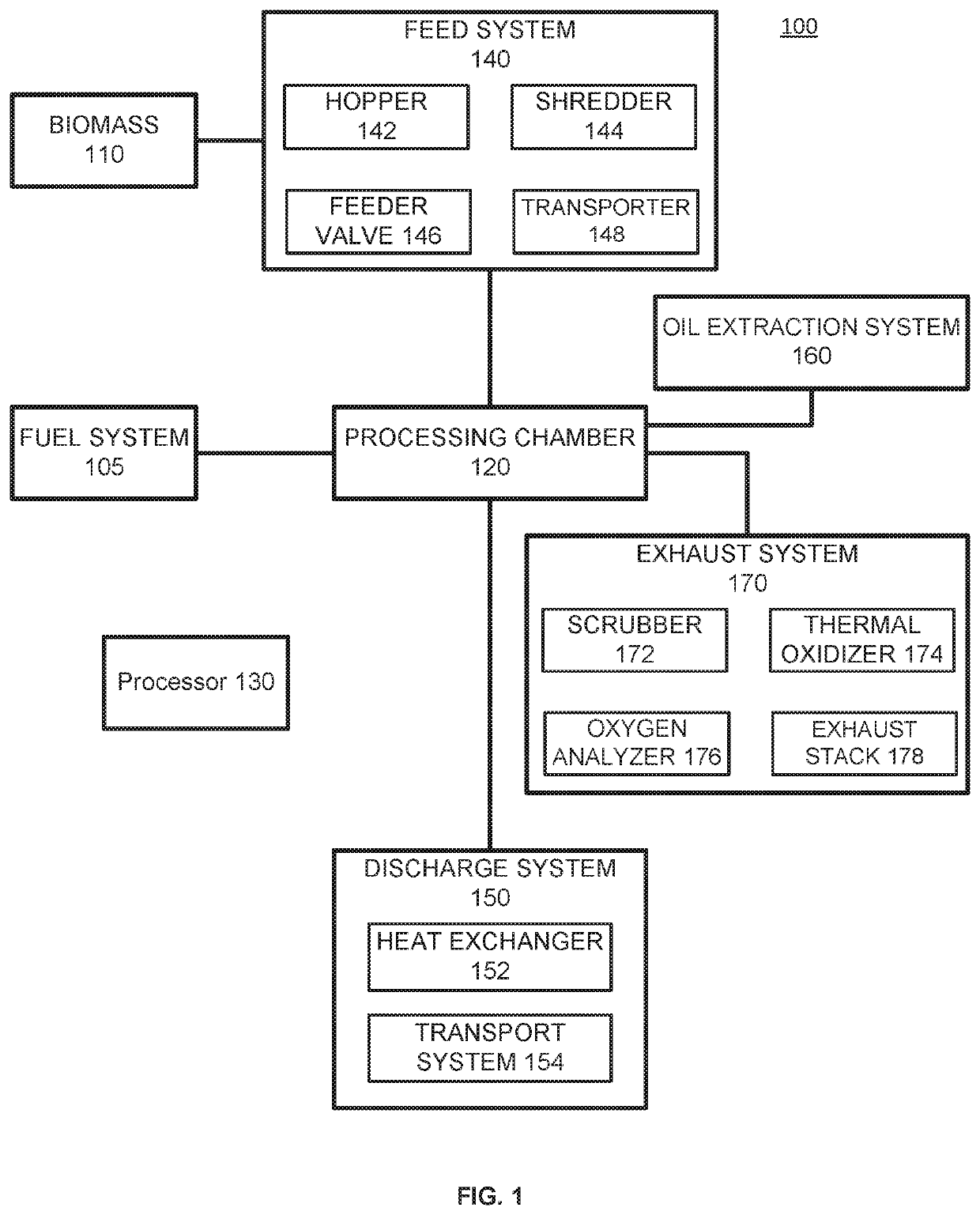

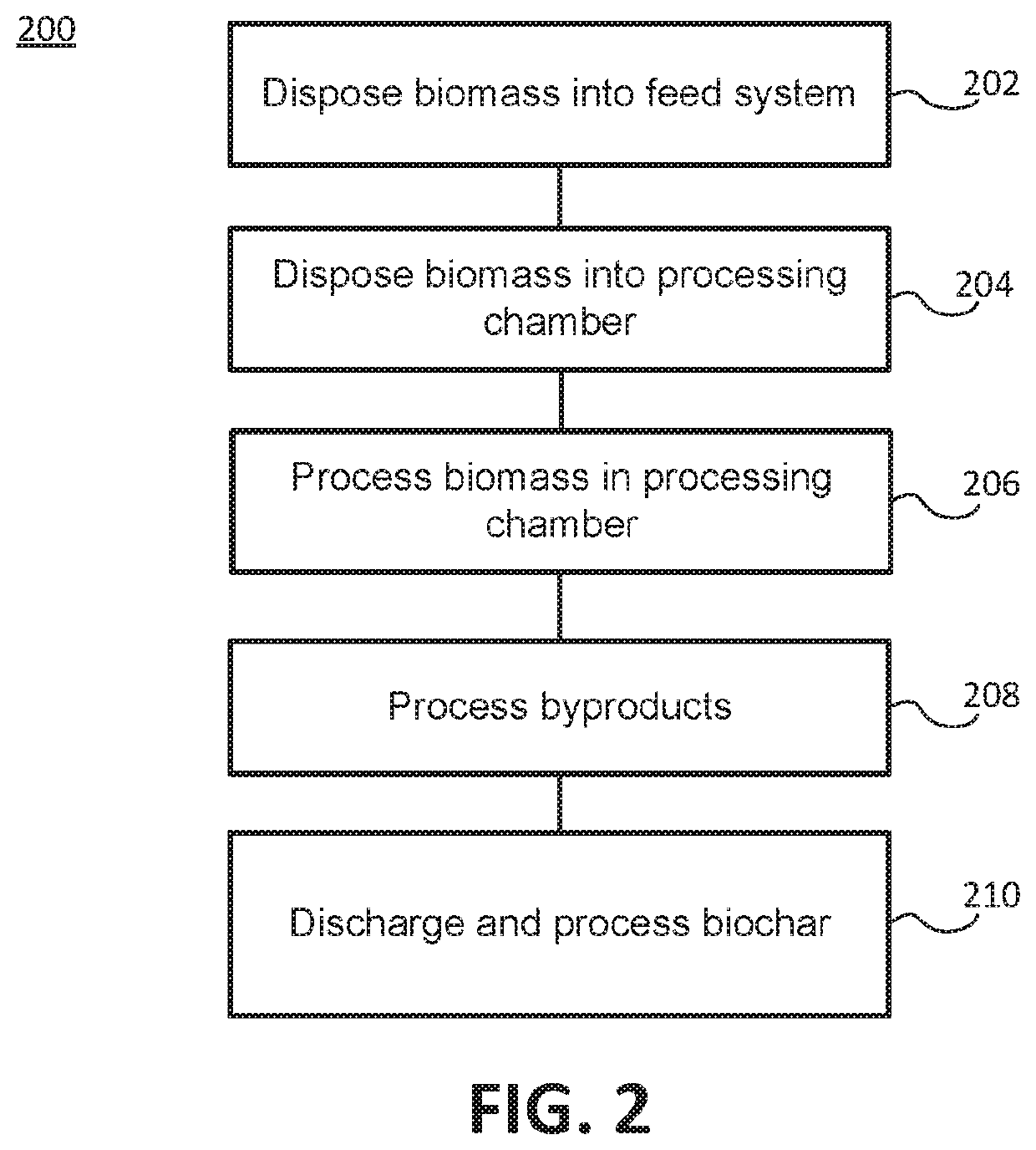

Methods and Systems for Producing Biochar

InactiveUS20200346929A1Increasing and improving agricultural outputReduce harmful effectsExcrement fertilisersBiofuelsCellulose acetateOrganic chemistry

In various embodiments, a method may comprise disposing biomass into a processing chamber; regulating at least one of a temperature and a pressure in the processing chamber; and / or processing the biomass to create biochar. The biomass may comprise cellulose acetate.

Owner:CAGIGAS JOHNNY KEITH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com