Emulsified asphalt plant-mixed cold recycled asphalt mixture and preparation method thereof

A technology of asphalt mixture and emulsified asphalt, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve resource waste, air, water and soil pollution, weaken the low temperature resistance of emulsified asphalt cold recycled mixture Cracking performance, anti-fatigue performance and other issues, to achieve the effect of reducing the amount of carbon dioxide and solving the problem of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

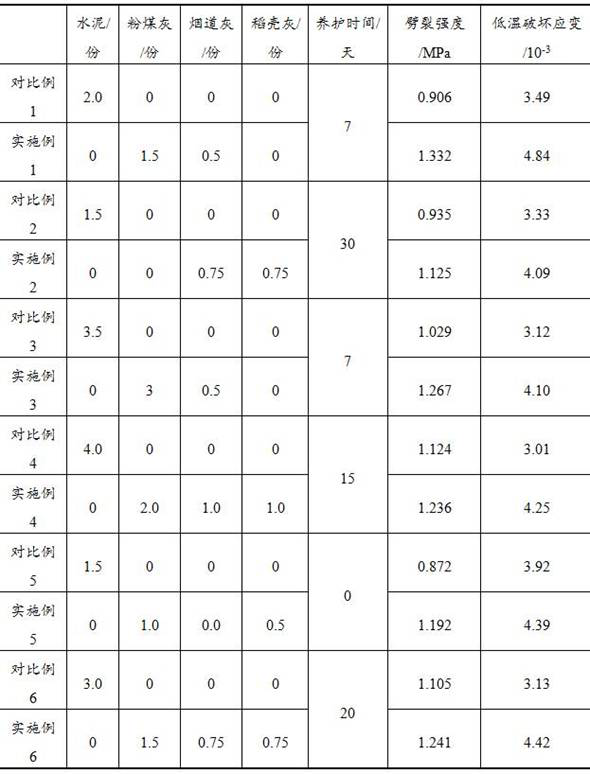

[0026] Weigh 16 parts of new aggregate, 46 parts of the first old aggregate, 17.5 parts of the second old aggregate, 15 parts of the third old aggregate, 5.5 parts of mineral powder, 4.8 parts of emulsified asphalt, 4.8 parts of water, and 1.5 parts of fly ash Parts (fineness 35μm), flue ash 0.5 part (fineness 55μm), according to my country's industry standard "Technical Specifications for Highway Asphalt Pavement Recycling" (JTG / T 5521-2019) and "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011) Formed Marshall specimens, the test mold was taken out after curing in a blast oven at 60°C for 42 hours, and then demoulded after cooling at room temperature for 12 hours; then put the specimen back into the blast oven at 60°C for 7 days Take it out, and measure the 15°C splitting strength and -10°C low temperature failure strain, as shown in Table 1.

[0027] It can be seen from Table 1 that, compared with cement-emulsified asphalt plant cold recy...

Embodiment 2

[0031] Weigh 18 parts of new aggregate, 43 parts of the first old aggregate, 17 parts of the second old aggregate, 18 parts of the third old aggregate, 4 parts of mineral powder, 4.6 parts of emulsified asphalt, 4.9 parts of water, and 0.75 parts of flue ash Parts (fineness: 45 μm), rice husk ash 0.75 parts (fineness: 55 μm), according to the national industry standard "Technical Specifications for Recycling of Highway Asphalt Pavement" (JTG / T 5521-2019) and "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011) Formed Marshall specimens, the test mold was taken out after curing in a blast oven at 60°C for 42 hours, and then demoulded after cooling at room temperature for 12 hours; then put the specimen back into a blast oven at 60°C for 30 days Take it out, and measure the 15°C splitting strength and -10°C low temperature failure strain, as shown in Table 1.

[0032] It can be seen from Table 1 that compared with cement-emulsified asphalt pl...

Embodiment 3

[0036] Weigh 20 parts of new aggregate, 41 parts of the first old aggregate, 22 parts of the second old aggregate, 13 parts of the third old aggregate, 4 parts of mineral powder, 4.3 parts of emulsified asphalt, 4.5 parts of water, and 3 parts of fly ash Parts (fineness 32μm), flue ash 0.5 part (fineness 50μm), according to my country's industry standard "Technical Specifications for Highway Asphalt Pavement Recycling" (JTG / T 5521-2019) and "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011) Formed Marshall specimens, the test mold was taken out after curing in a blast oven at 60°C for 42 hours, and then demoulded after cooling at room temperature for 12 hours; then put the specimen back into the blast oven at 60°C for 7 days Take it out, and measure the 15°C splitting strength and -10°C low temperature failure strain, as shown in Table 1.

[0037] It can be seen from Table 1 that compared with cement-emulsified asphalt plant cold recycled mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com