Exhaust system for power generating apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

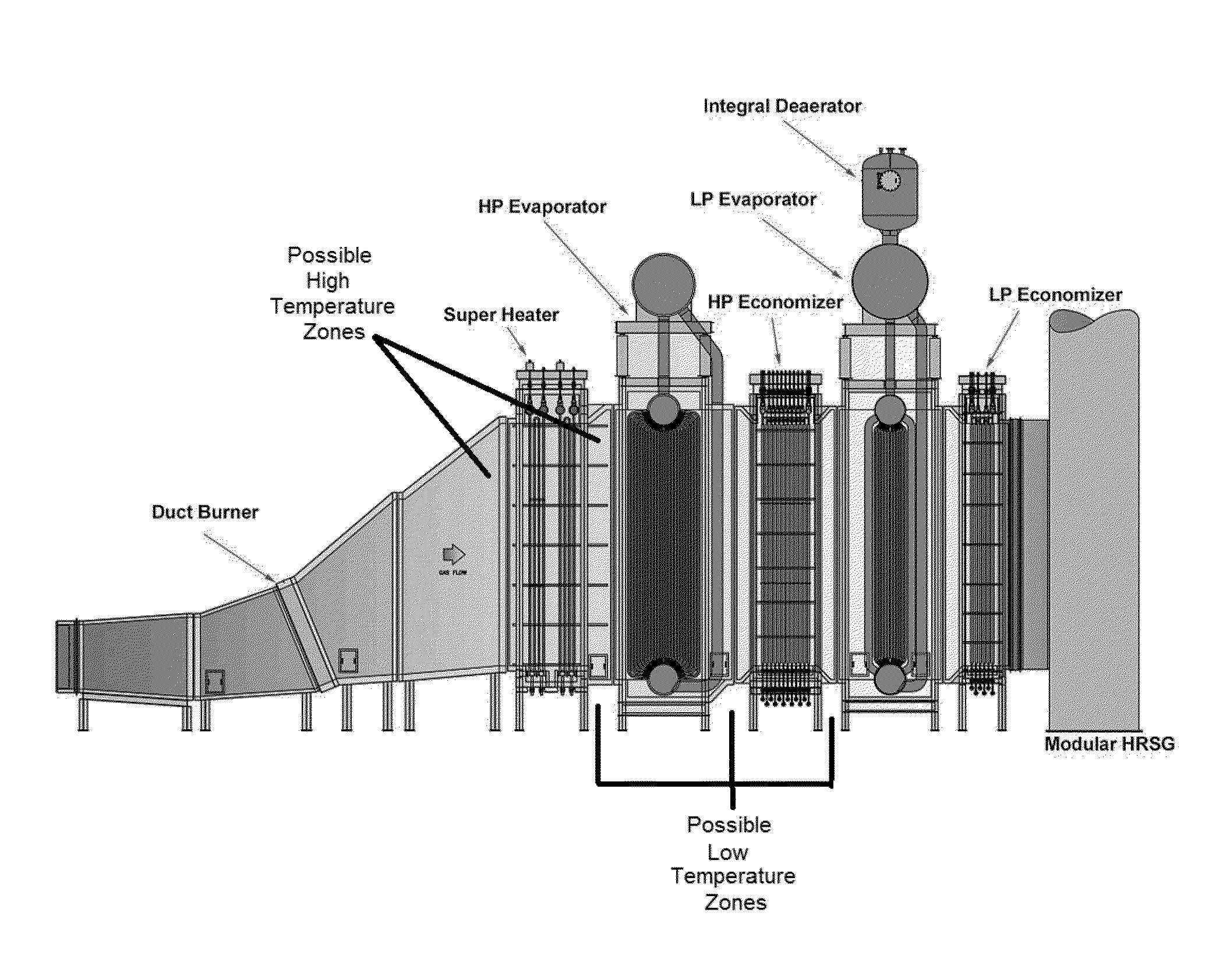

[0025]In this invention, it has been realized that a coupled oxidation catalyst system, wherein a first bed of oxidation catalyst is placed in a higher temperature region to allow the gas turbine to begin reducing emissions during start-up, and a second bed of oxidation catalyst is placed in a lower temperature region to provide additional catalyst surface and complete the desired CO and VOC reduction once the power generating apparatus has started up, can provide superior overall performance, reduce cost, and be less susceptible to poisoning than the current approach of using a single oxidation catalyst bed.

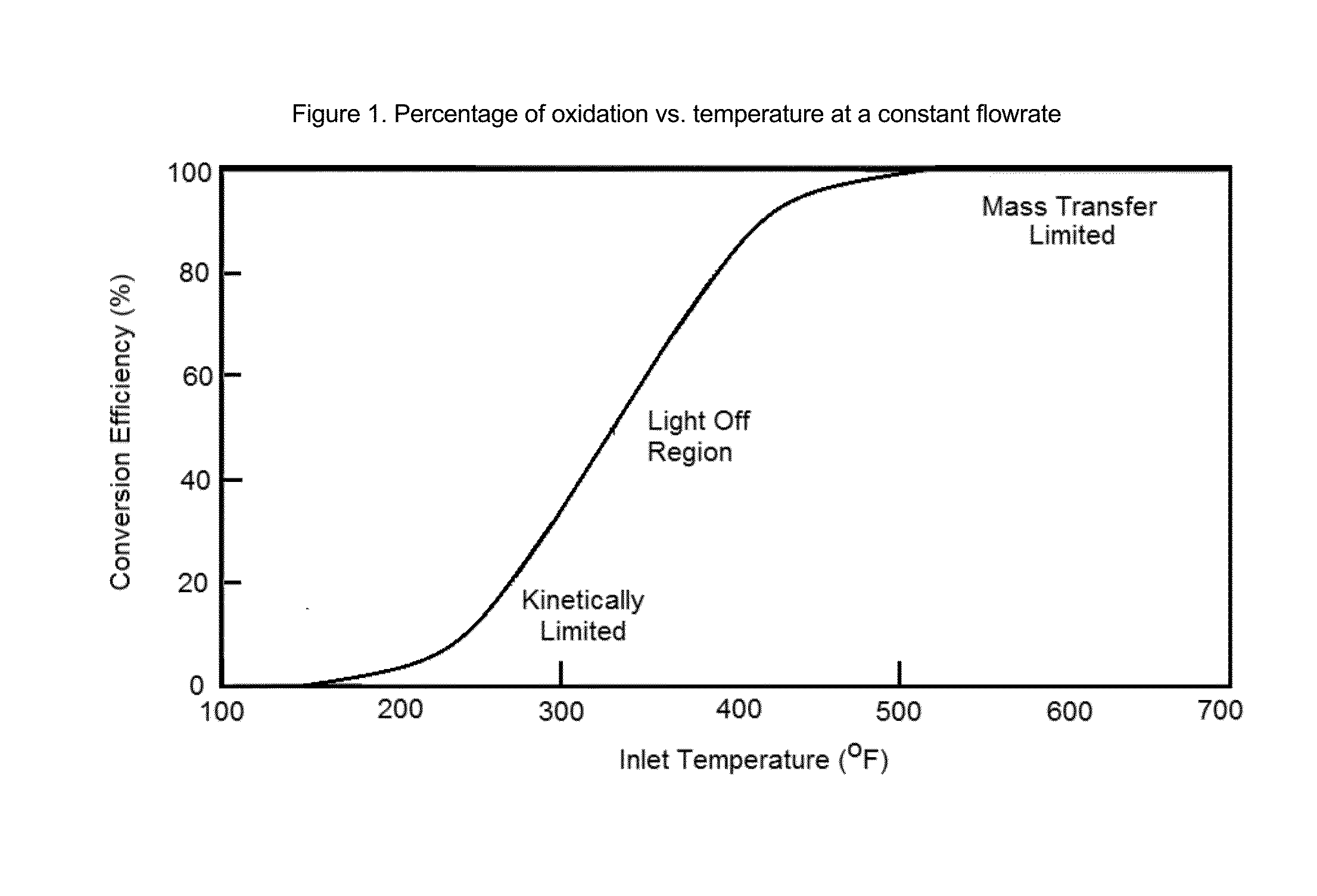

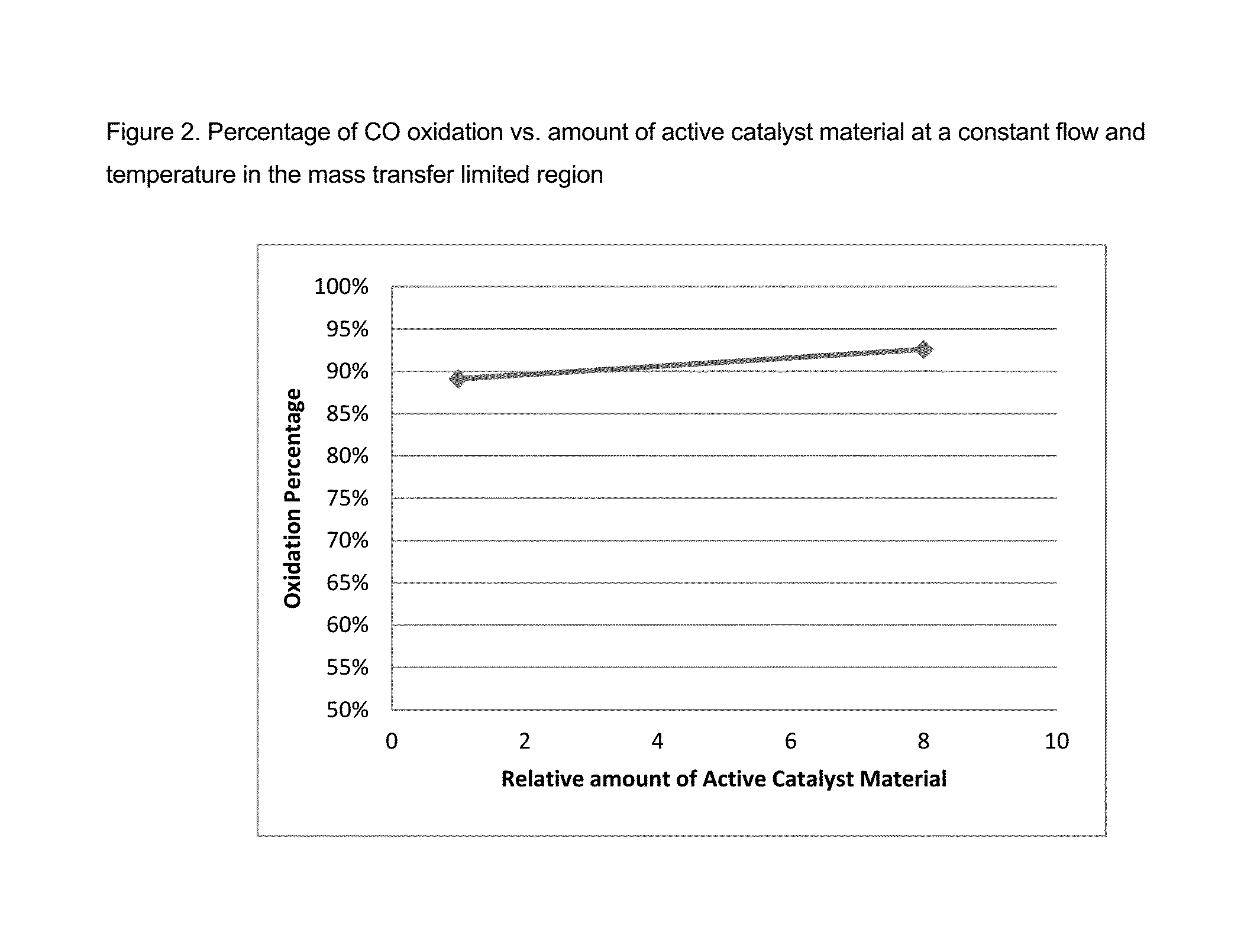

[0026]The oxidation of CO and VOC in a catalytic system is dependent on the operating temperature and the reaction residence time. The temperature at which an oxidation catalyst begins to oxidize CO and VOCs is called the light-off temperature. The light-off temperature is related to the concentration of active catalyst material in the catalyst. The higher the concentration of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com