Treatment method of cycle tail gas in Fischer-Tropsch synthetic oil process

A Fischer-Tropsch synthetic oil and process cycle technology, which is applied in the petroleum industry, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures, can solve the problems of complex process operation and large equipment investment, and achieve simple process flow and low equipment investment , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

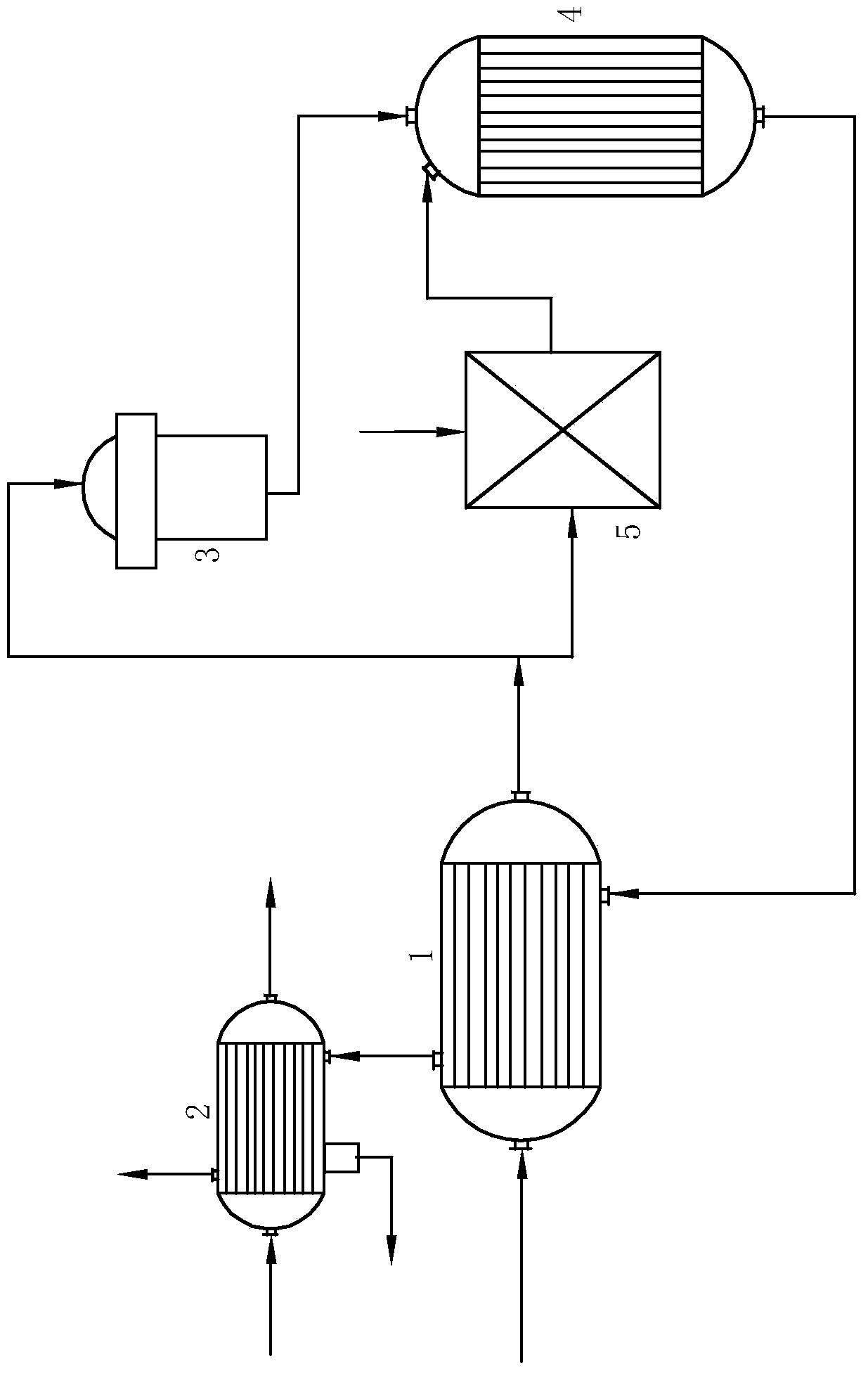

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, the treatment method of the Fischer-Tropsch synthetic oil process cycle tail gas comprises the following steps:

[0019] The circulating tail gas from the Fischer-Tropsch synthesis reactor at a temperature of about 60 °C and a pressure of 2.24 MPa contains CH 4 、C 2 h 6 、C 3 h 8 、C 4 h 10 and C 5+ , entering the first heat exchanger 1 and exchanging heat with the syngas from the catalytic combined reforming reactor to 600-700°C. The first circulating exhaust gas with a volume flow rate of 60% enters the plasma generator 3 . Under the action of enhanced electric field, various gas components in the circulating exhaust gas are excited, the gas temperature rises to about 2727°C, and a large number of high-energy electrons are generated. These high-energy electrons interact with the gas molecule CH 4 、H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com