Slag gasification reaction furnace for preparing carbon monoxide, and gas preparation method thereof

A slag gasification and carbon monoxide technology, which is applied in the fields of instrumentation and automation technology, chemical engineering, chemical machinery, and chemical technology, can solve the problems of large investment, difficult processing, and high methane content, so as to ensure safe gasification and uniform distribution , the effect of reasonable flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

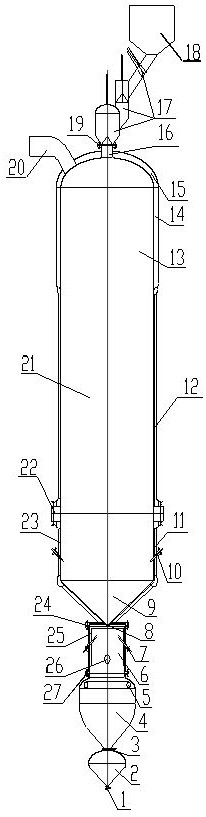

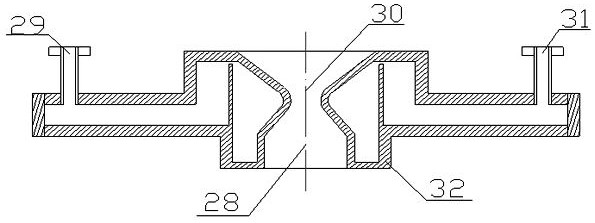

[0052] Such as Figure 1-Figure 2 As shown, a slag gasification reaction furnace for preparing carbon monoxide includes a gasification furnace body 24, a slag port 8, a combustion nipple 6, a quench chamber 4 and an automatic coking machine 17;

[0053] The gasification furnace body 24 includes: a shell 12, an upper cylinder body 13, a furnace inlet 16, a gas outlet 20, a lining refractory brick 14, a water jacket 11, a gasification agent nozzle 10, a water cooling coil 25, a melting Slag pool 9, furnace cover 15 and connecting large flange 21;

[0054] The furnace inlet 16 is connected to the lower distributor flange 19 of the automatic coking machine 17;

[0055] The furnace cover 15 is connected to the upper cylinder body 13, and the gas outlet 20 is located on the furnace cover 15;

[0056] The upper cylinder 13 is connected to the slag pool 9 with a large flange 21;

[0057] The gasifying agent nozzle 10 is connected to the molten slag pool 9;

[0058] The slag port 8...

Embodiment 2

[0073] A new gas production method using a slag gasification reaction furnace to prepare carbon monoxide. The high-temperature coal gas generated in the lower part of the slag gasification reaction furnace is in countercurrent contact with the raw materials from the furnace inlet 16. The temperature in the drying area is less than 500 ° C. The raw material is heated and dried by the hot gas, and the water is removed here. The dried carbon layer continues to move down and enters the carbonization zone at 500-900°C. After the gas undergoes a series of equilibrium endothermic reactions, the crude gas is cooled, and the raw material is partially gasified. At the same time, the temperature of the raw material rises and enters the combustion zone, and the mixed gaseous CO 2 Oxygen and gas enter the bottom of the gasifier with a high-speed airflow through the gasification agent nozzle 10. The oxygen reacts quickly with the coal in the combustion zone and releases a large amount of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com