Gasifying device for recycling biomass for engine exhaust

A technology of waste gas recirculation and gasification device, which is applied in the direction of power plant, arrangement combined with internal combustion engine fuel supply, transportation and packaging, etc., to achieve the effect of increasing biomass gasification temperature, increasing gasification efficiency and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

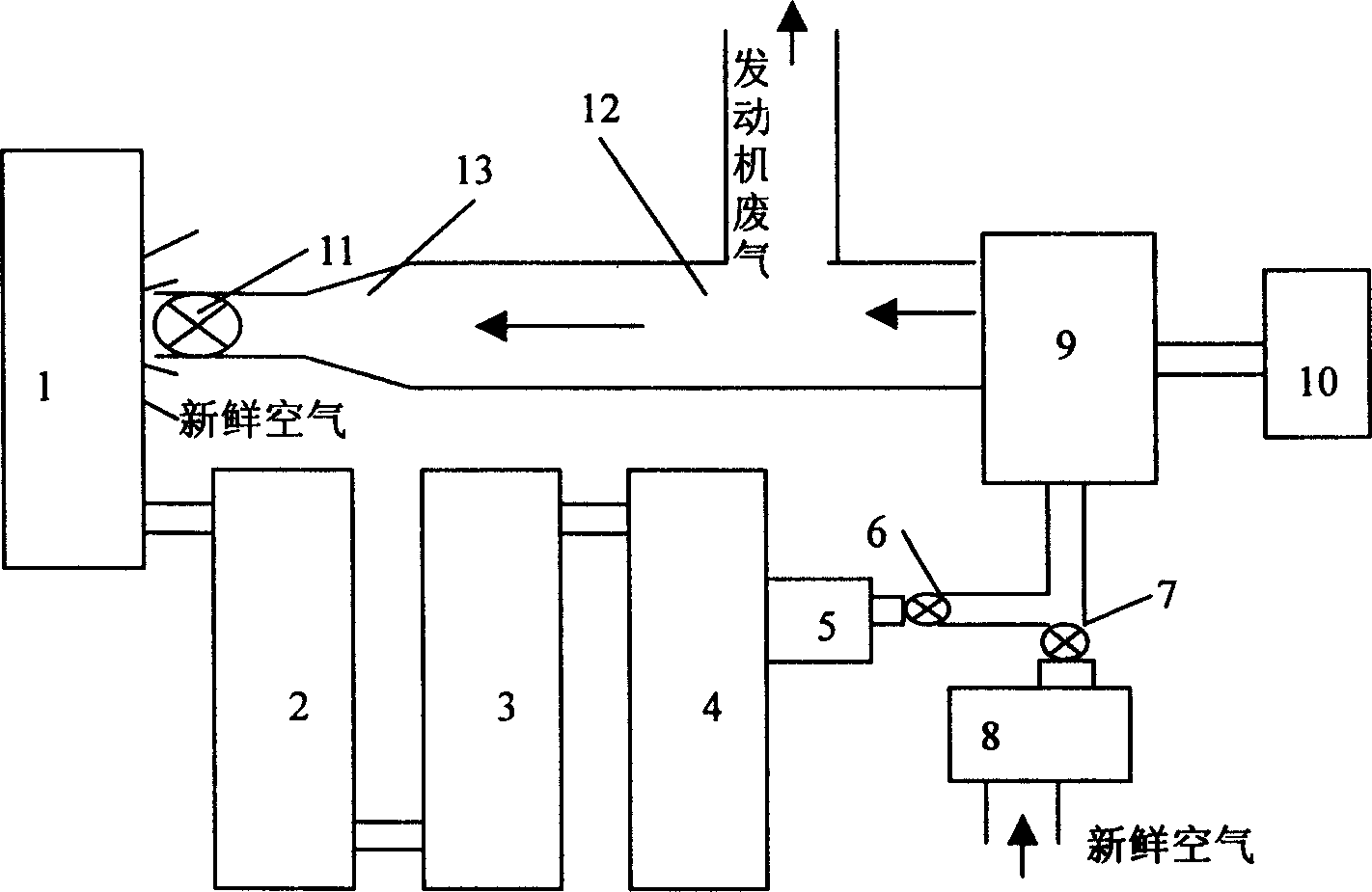

[0016] Such as figure 1 As shown, the embodiment of the present invention adopts a simple and reliable downdraft biomass gasifier 1 to gasify the biomass, cool the high-temperature biomass gas through the partition cooler 2, and pass through the swirl filters 3 and 4. The two-stage cyclone filter removes impurities such as ash and tar, and enters the biomass gas pressure regulator box 5, and the biomass gas flow control valve 6 controls the amount of gas entering the engine.

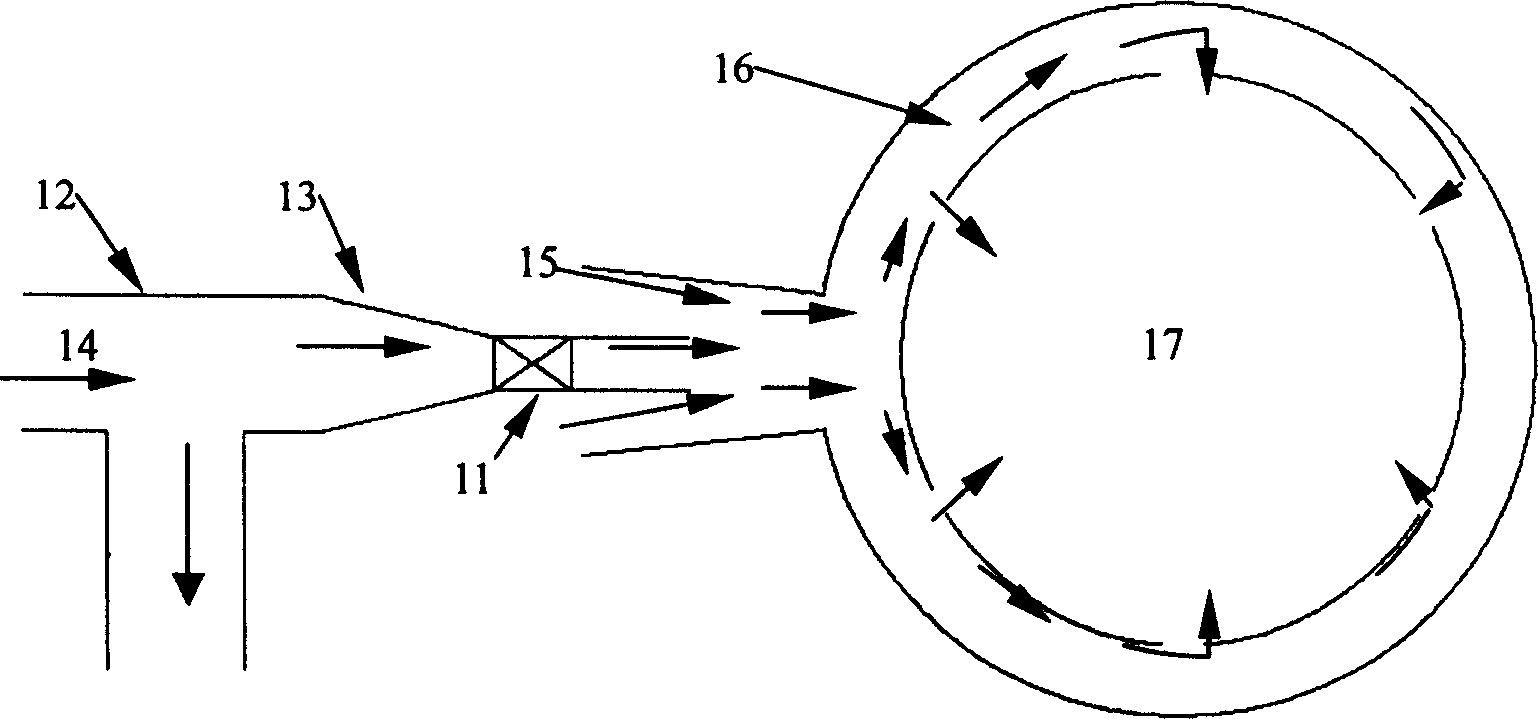

[0017] The engine exhaust gas recirculation biomass gasification device described in the present invention is as figure 2 As shown, it is provided with the bifurcated exhaust pipeline 12 of the dual-fuel engine, which is connected with the gasifier circumferential air inlet 16 through the reducer 13 and the exhaust gas recirculation control valve 11 located on the pipeline; Part of the high-temperature exhaust gas 14 at a certain pressure passes through the bifurcated exhaust pipe 12 and is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com