Biomass and coal fluidized bed co-gasification method

A technology of fluidized bed gasification and biomass, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

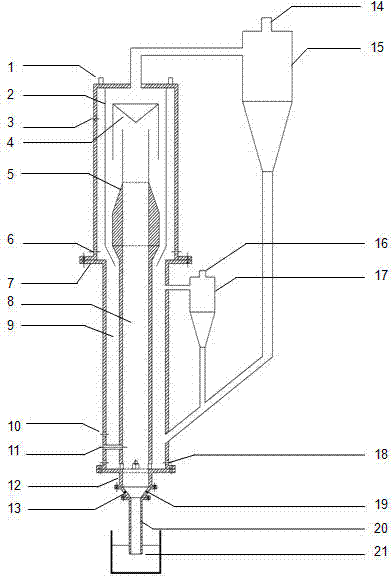

[0047] Such as figure 1 ,use figure 1 The technical process, implement a kind of biomass and coal fluidized bed co-gasification method of the present invention, this method is to carry out according to the following steps:

[0048] Step 1, raw material pretreatment. In the method of the present invention, the raw material is based on the living environment in the countryside, the stalks of agricultural and forestry crops other than fruits, and the leaves, stems, stems, etc. containing lignin, and the biomass is pulverized into smaller than 5mm pellets; then pulverize coal materials including low volatile pulverized coal, powdered coke or coal gangue into 0.1-2mm pellets, and the mass ratio of biomass pellets to coal pellets is 0.25-1:1 The ratio is mixed evenly to form a biomass coal mixture, which is set aside;

[0049] Step 2, gasification is carried out in the fluidized bed gasification outer cylinder 9 . The biomass coal mixture is fed into the upper L valve 7 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com