Novel fixed bed slag gasification reaction furnace and gas production method thereof

A technology for slag gasification and fixed bed, which is applied in the field of liquid slag discharge, staged gasification reaction furnace, and fixed bed slag gasification, and can solve the problems of complicated control of slag discharge method, unfavorable synthetic ammonia production, low operation reliability, etc. problems, to achieve the effect of high engineering application and economic operation value, high practical application value, and high effective gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

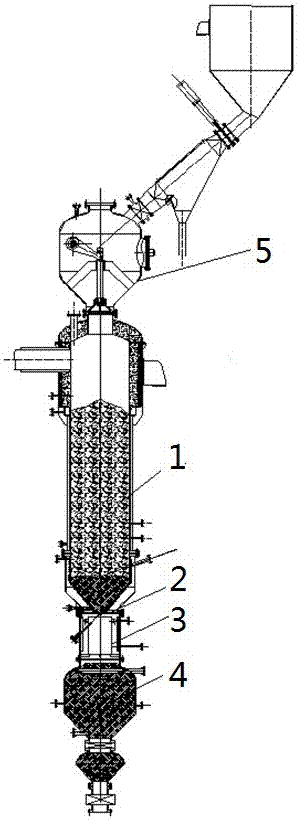

[0052] The present invention is described in detail below in conjunction with accompanying drawing:

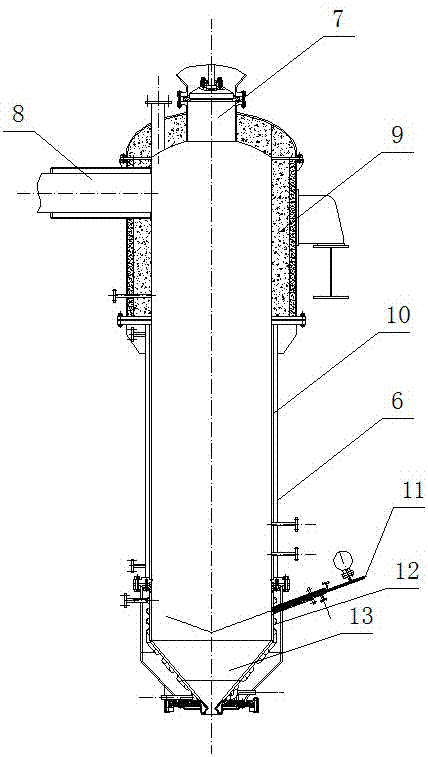

[0053] A new fixed-bed slag gasification reaction furnace, which includes a gasification furnace hearth 1, a slag port 2, a combustion chamber 3, a chill chamber 4, and an automatic coking or coal machine 5;

[0054] It is characterized in that: the furnace 1 of the gasifier includes: a shell 6, a furnace inlet 7, a furnace outlet 8, a lining refractory material 9, a water wall 10, an oxygen steaming nozzle 11, a water cooling coil 12, and a slag pool 13;

[0055] The furnace inlet 7 is connected to the lower distributor 37 of the automatic coking or coal machine 5;

[0056] The furnace outlet 8 is connected to the cyclone separator of the crude gas outlet;

[0057]The slag pool 13 is connected to the slag port 2;

[0058] The oxygen steaming nozzle 11 is connected to the molten slag pool 13;

[0059] The upper end of the slag port 2 is connected to the molten slag pool 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com