Swirl-flow type gasification furnace and swirl-flow type gasification process

A gasification furnace and swirling flow technology, applied in the field of coal chemical industry, can solve the problems of large one-time investment and complicated design, and achieve the effects of high gasification efficiency, convenient operation and excellent technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

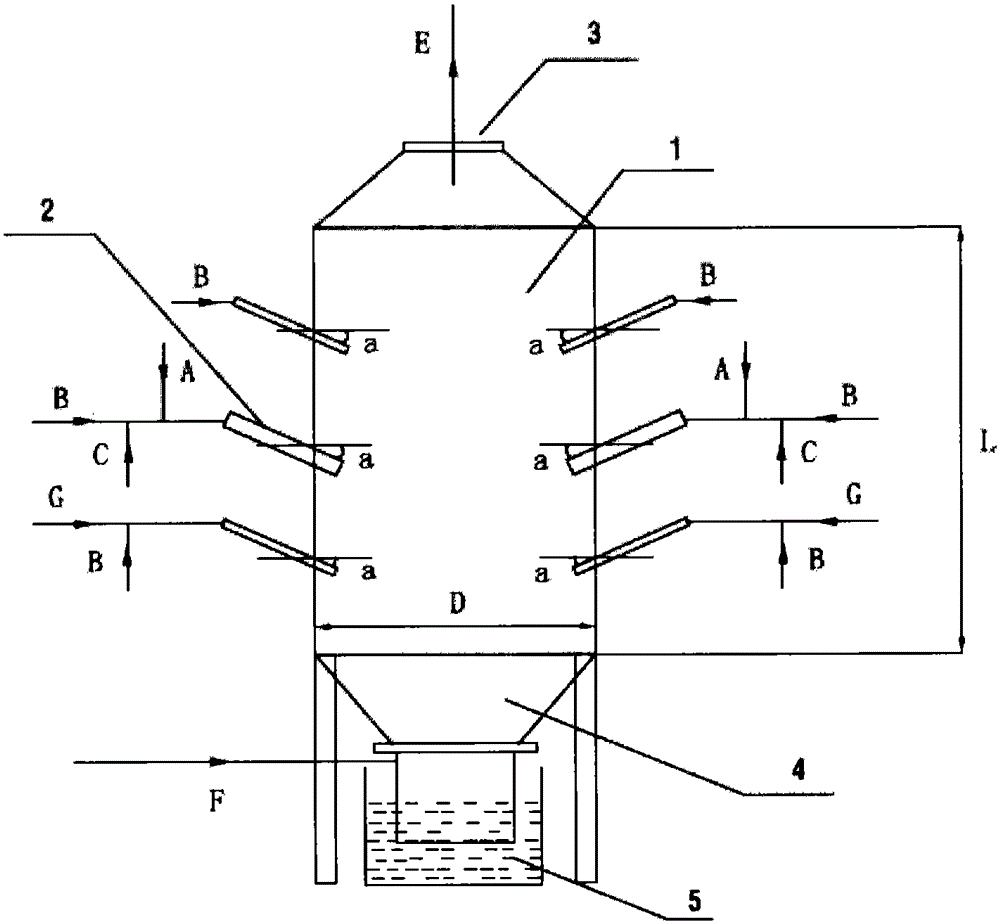

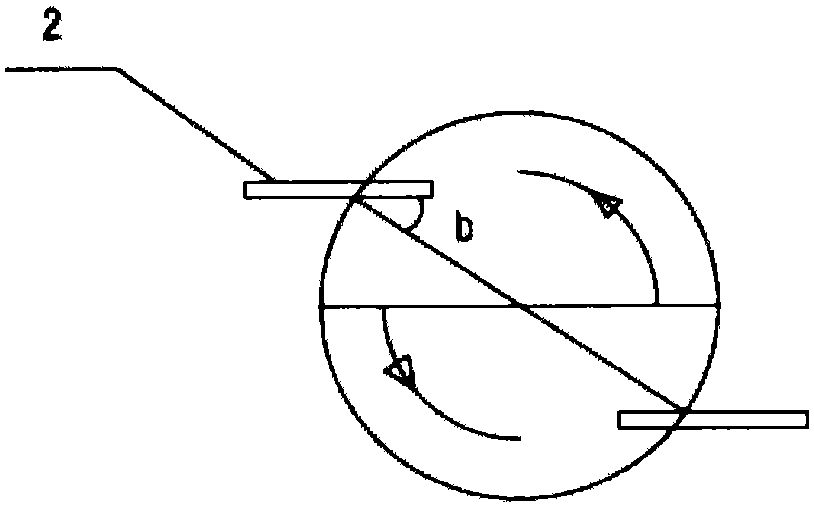

[0036] A swirling flow gasifier, comprising a furnace body 1, a feed lance 2, a gasification gas outlet 3 positioned at the top of the furnace body, and a slag chamber 4 positioned at the bottom of the furnace body; the outer wall of the furnace body 1 adopts Carbon steel, the interlayer is thermal insulation fiber cotton, the inner layer is refractory castable, the length-to-diameter ratio of the furnace body is 1:1; the feed spray gun 2 is arranged in the middle of the furnace body 1, and the feed spray gun is set as Layer layout, the number of feed spray guns in each layer is two, and the two feed spray guns in each layer are arranged symmetrically along the circumference of the furnace body, and the feeding method of the spray guns is tangential feeding; The angle is 50°, and the spray gun is inclined downward at 0°; the feed spray gun arranged in a single layer is the first spray gun, which is used for feeding gasification raw materials and gasification agents, and the fir...

Embodiment 2

[0038] A swirling flow gasifier, comprising a furnace body 1, a feed lance 2, a gasification gas outlet 3 positioned at the top of the furnace body, and a slag chamber 4 positioned at the bottom of the furnace body; the outer wall of the furnace body 1 adopts Stainless steel material, the interlayer is thermal insulation fiber cotton, the inner layer is refractory castable, the aspect ratio of the furnace body is 2:1; the feed spray gun 2 is arranged in the middle of the furnace body 1, and the feed spray gun is set as two Layer layout; the number of feed spray guns in each layer is two, and the two feed spray guns in each layer are arranged symmetrically along the circumference of the furnace body, and the feeding method of the spray guns is tangential feeding; The angle is 35°, and the spray gun is tilted down by 30°; the slag chamber 4 is provided with a pure oxygen injection lance to replenish pure oxygen to maintain a higher temperature in the slag chamber and realize liqu...

Embodiment 3

[0040]A swirling flow gasifier, comprising a furnace body 1, a feed lance 2, a gasification gas outlet 3 positioned at the top of the furnace body, and a slag chamber 4 positioned at the bottom of the furnace body; the outer wall of the furnace body 1 adopts Stainless steel material, the interlayer is thermal insulation fiber cotton, the inner layer is refractory castable, the length-to-diameter ratio of the furnace body is 2:1; Layer layout; the number of feed spray guns in each layer is two, and the two feed spray guns in each layer are arranged symmetrically along the circumference of the furnace body, and the feeding method of the spray guns is tangential feeding; The angle is 45°, and the spray gun is tilted down by 10°; the slag chamber 4 is equipped with a pure oxygen spray gun to supplement pure oxygen to maintain a higher temperature in the slag chamber and realize liquid slag discharge; the lower part of the slag chamber is provided with a slag pool 5. The slag pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com