Start-up compound burner for water-coal-slurry or coal dust gasification furnace

A technology of coal water slurry and coal powder, which is applied in the direction of combined combustion mitigation, gas fuel burner, burner, etc., can solve the problems of low utilization rate of equipment and devices, reduced service life of refractory bricks, and long time for dealing with flameout accidents, etc. Achieve the effects of remote, timely and rapid processing, saving space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

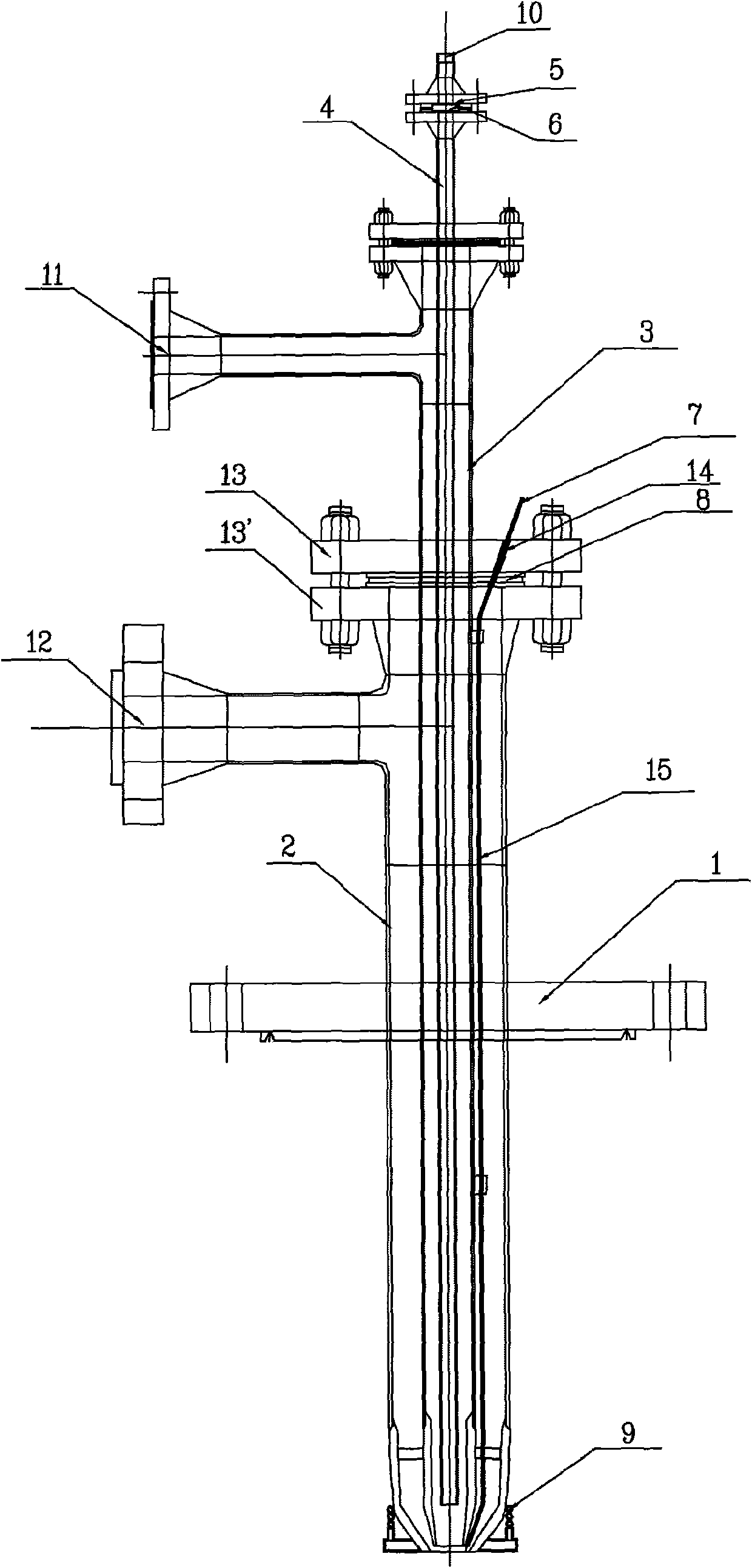

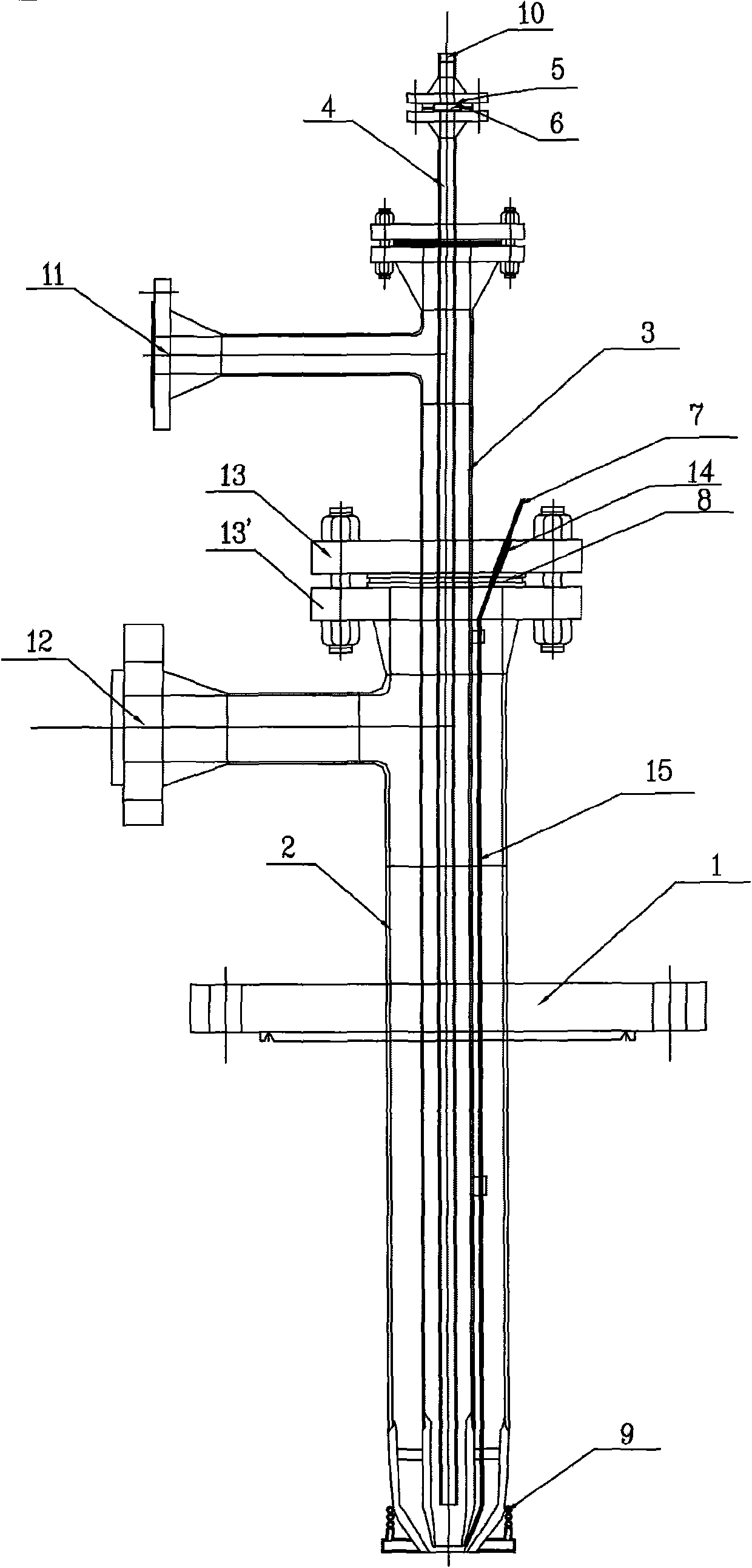

[0034] Such as figure 1 As shown, the composite burner of the gasification furnace of the present invention is connected to the gasification furnace through the installation flange 1 . Open a hole in the center of the mounting flange 1 and weld the fuel gas channel pipe 2. The fuel gas channel pipe connects to the fuel gas inlet 12 through the flange. A combustion-supporting gas channel pipe 3 is installed in the fuel gas channel pipe 2. The installation method is through two The flanges 13 and 13' are connected, and the combustion-supporting gas passage pipe 3 must maintain coaxiality with the fuel gas passage pipe 2 during welding and installation. The front ends of the fuel gas passage pipe 2 and the combustion-supporting gas passage pipe 3 are closed.

[0035] The general fuel gas of the gasifier is coal gas, synthetic gas or liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com