Method and system for recovering waste heat from INBA slag washing water of blast furnace

A waste heat recovery system and slag flushing water technology, applied in the direction of improving process efficiency, etc., can solve problems such as poor waste heat recovery effect, poor heat exchange effect, complex facilities, etc., to reduce wear, prolong service life, and ensure safety and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

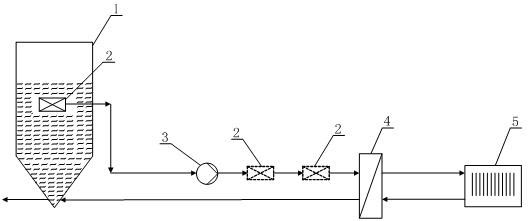

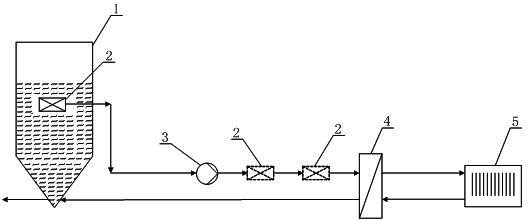

[0022] Such as figure 1 As shown, the blast furnace INBA slag flushing water waste heat recovery system is composed of a filter 2, a water pump 3 and a heat exchanger 4.

[0023] The cycle process of the blast furnace slag washing water is as follows: the high temperature slag washing water in the upper part of the hot water pool 1 is filtered through the primary filter 2 to remove larger particles; the slag washing water from the primary filter flows into the water pump 3 for pressurization; The enlarged slag washing water flows into the secondary filter for swirling and slag removal, and some smaller particles are filtered out; the slag washing water that has been filtered twice enters the tertiary filter for the third filtration to ensure that it flows into the heat exchange The water quality of the slag flushing water in the device 4 is better, which plays a role in protecting the heat exchanger 4; the slag flushing water after the triple filtration enters the heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com