Series water tank recovering waste heat in air radiation type refrigerating system

A refrigeration system and air heat dissipation technology, which is applied in air conditioning systems, heating methods, ventilation systems, etc., can solve problems such as compressors not working properly, achieve good waste heat recovery effects, reduce pollution, and simple design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

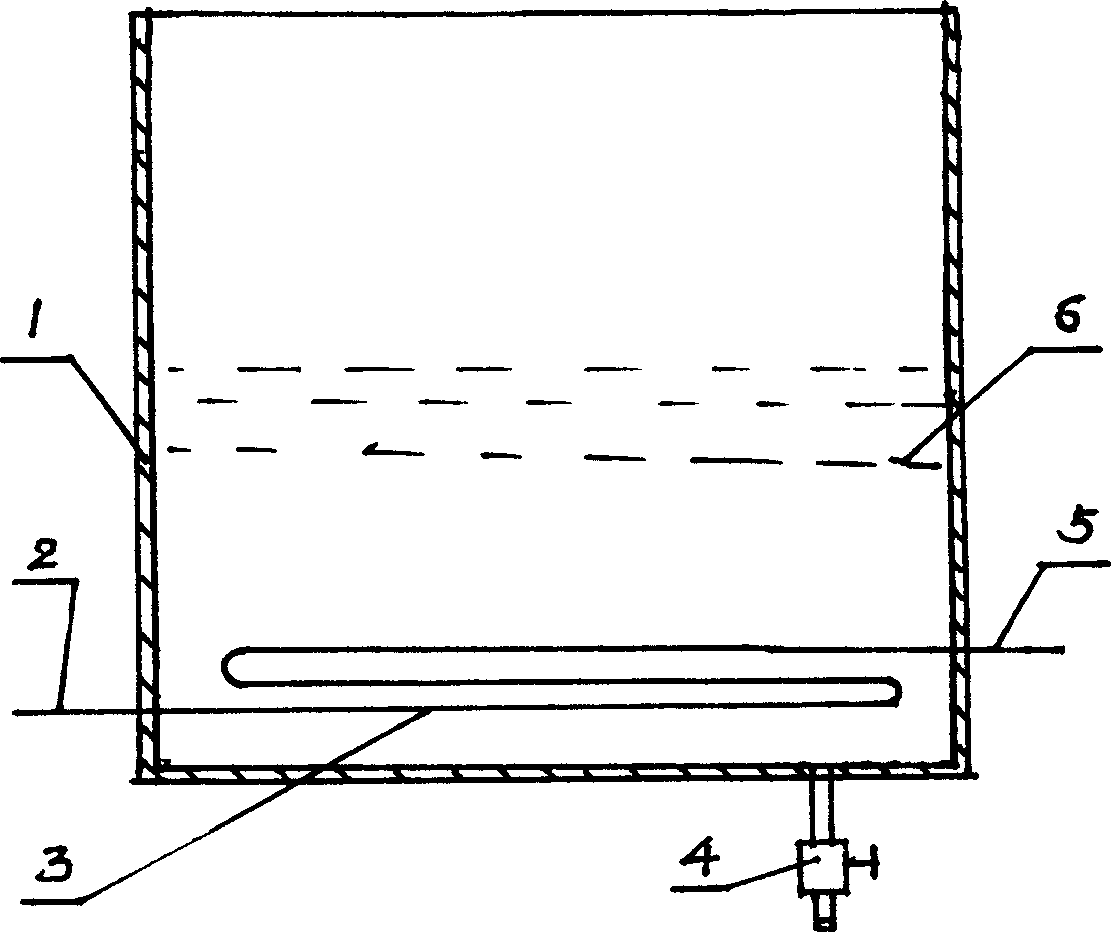

[0009] in figure 1 In the illustrated embodiment, under the premise that the working principle and structural connection mode of the existing air-cooling refrigeration system remain unchanged, only the high-pressure refrigerant liquid pipe port (2) connected to the high-pressure end of the refrigeration compressor is connected through After the sealing method penetrates into the water tank (1), it is simmered into a curved serpentine or spiral shape (3), and after passing out of the water tank (1) in a sealed form, the high-pressure refrigerant nozzle (5) ) Is still connected with the original air radiator, the bottom of the water tank (1) has a water discharge valve (4), the water tank (1) can be filled with tap water (6) or no water, and the rest remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com