Viscometer

A viscometer and measuring head technology, which is applied in the direction of instruments, scientific instruments, flow characteristics, etc., can solve the problem of inability to measure the viscosity of high-temperature and low-viscosity molten salt, and achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be given below in conjunction with the drawings and described in detail.

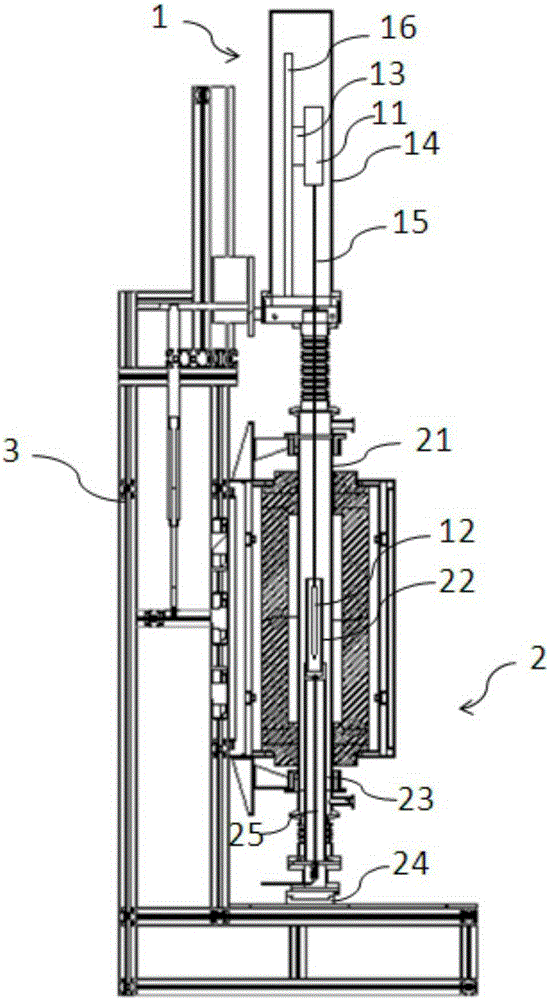

[0031] The viscosity meter according to the present invention includes a testing device 1, a heating device 2 and a frame 3, wherein the testing device 1 and the heating device 2 are both arranged on the frame 3.

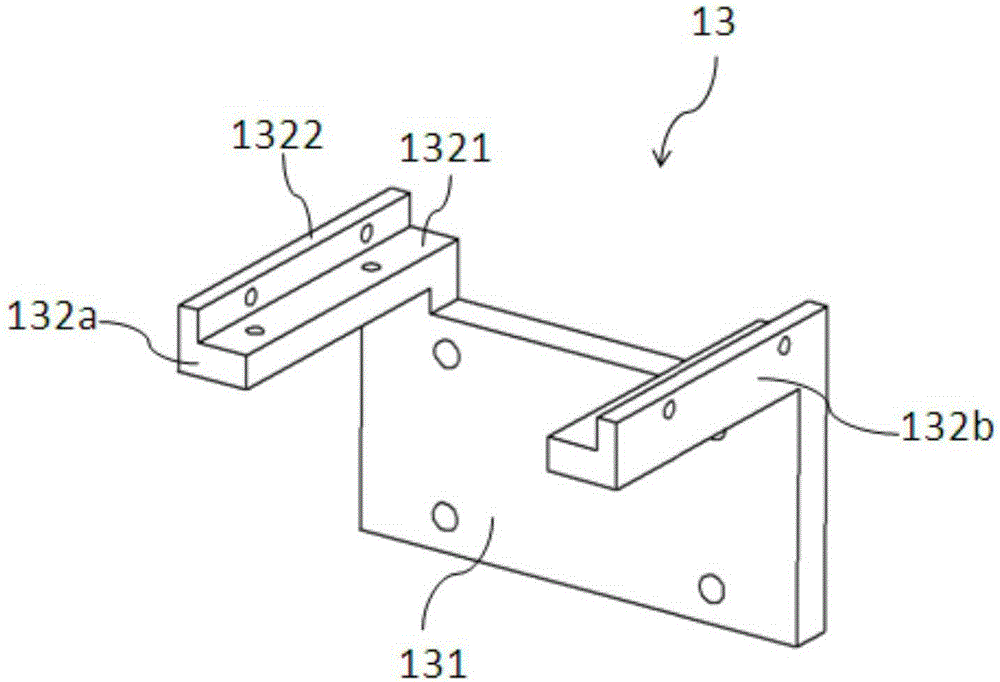

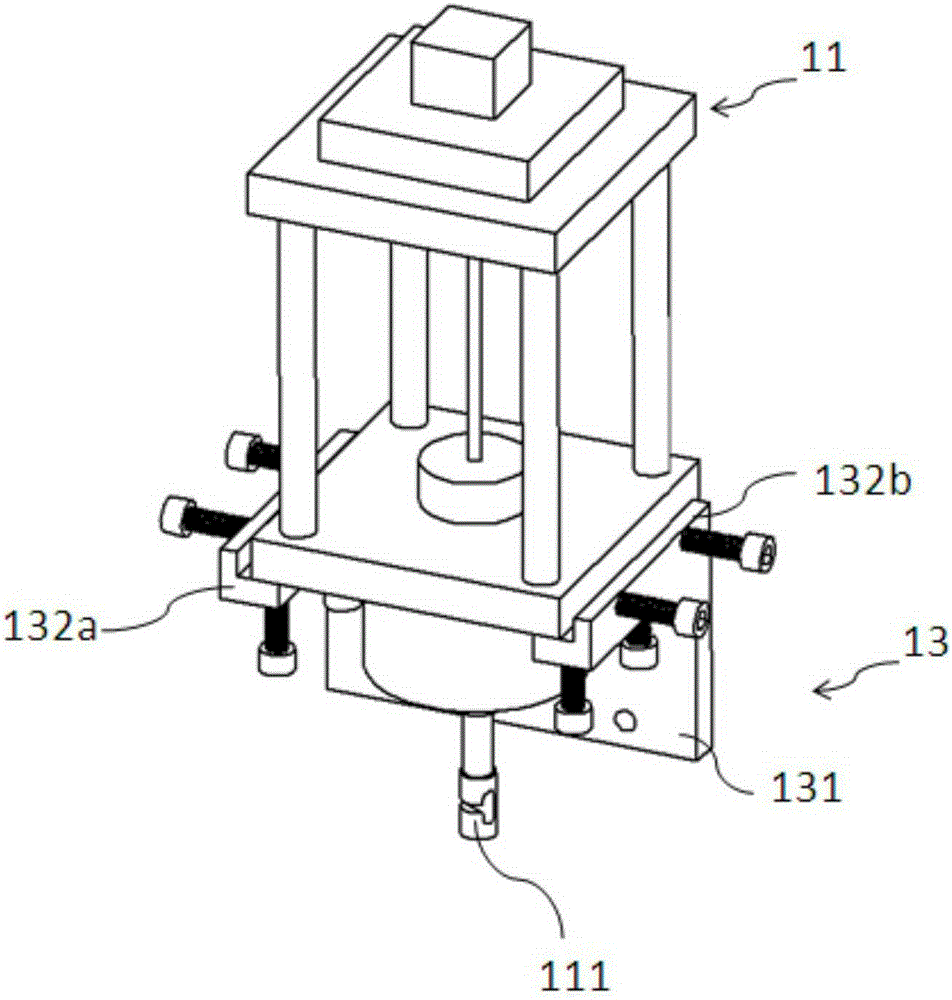

[0032] The testing device 1 includes a measuring head 11, a rotor 12, a measuring head support 13, a cover 14, a platinum wire 15 and a vertical threaded rod 16. Among them, the measuring head 11, the measuring head support 13, the vertical threaded rod 16 and part of the platinum wire 15 are contained in the cover 14. The specific structure of the measuring head 11 is similar to that of the measuring head of the existing measuring instrument, which will not be repeated here, and only the differences from the prior art will be described below. The measuring head 11 is supported on the vertical threaded rod 16 through the measuring hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com