Energy-saving stove with inductive fire-control pot frame and fire control method

A cooker and pot support technology, which is applied in the field of energy-saving cookers, can solve the problems that electronic sensors cannot continue to work stably, mechanical switches cannot be made fine and durable, frequent feeding or refueling operations, etc., to ensure continuous work without overheating and improve stability performance and safety, and the effect of securing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

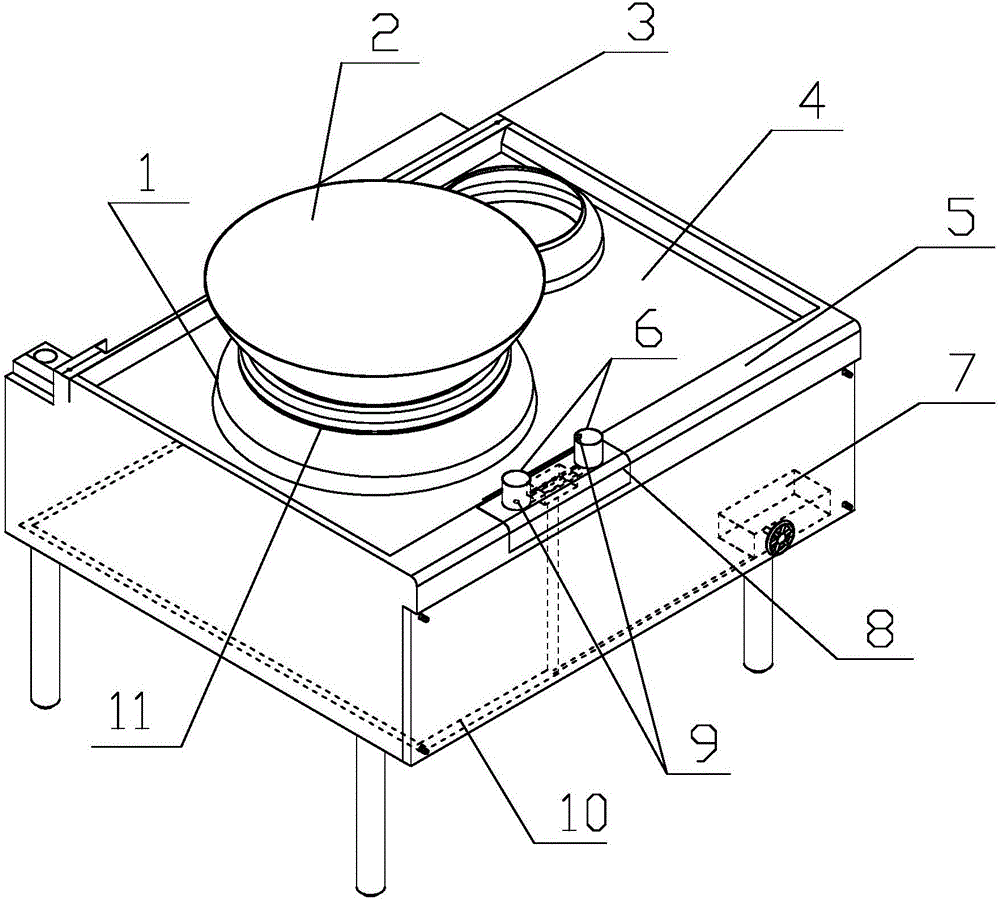

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 The shown energy-saving cooker with induction fire control pot support includes a hearth, a cooktop 4 and a fire control device 7. The fire control device is used for ignition start and fire control. On the basis of the most common cooker, a fire side pot support 8 and an electronically controlled Fire controller7.

[0031] The pot rack 8 by the fire is located on the edge of the operator side of the stove top 4, and is used for temporarily placing pots and utensils during the cooking process for adding or changing materials. close roasting. The pot stand 8 beside the fire is provided with supporting feet 6. In the embodiment, the toes of the supporting feet face upwards to support the pot. One to three supporting legs can be provided, and a sensing pot position is provided inside the supporting legs. Sensing facilities9.

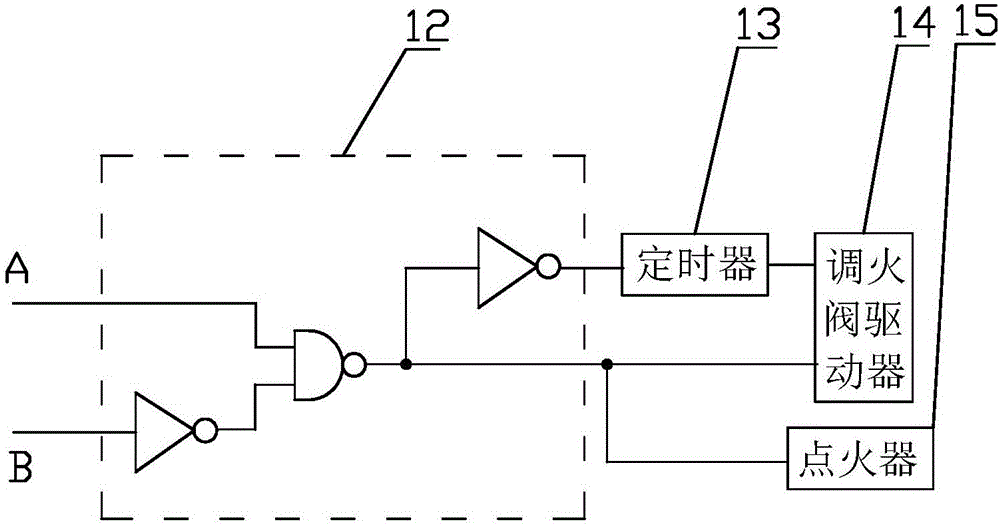

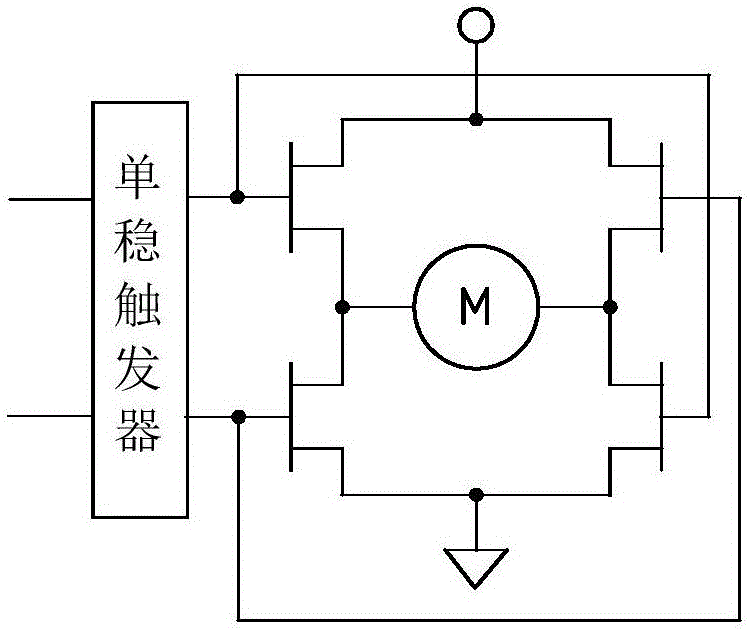

[0032] The sensing facility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com