Heat exchanger and energy-saving shower

A heat exchanger and heat exchange plate technology, which is applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of difficult processing, difficult to form, etc. Good effect of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

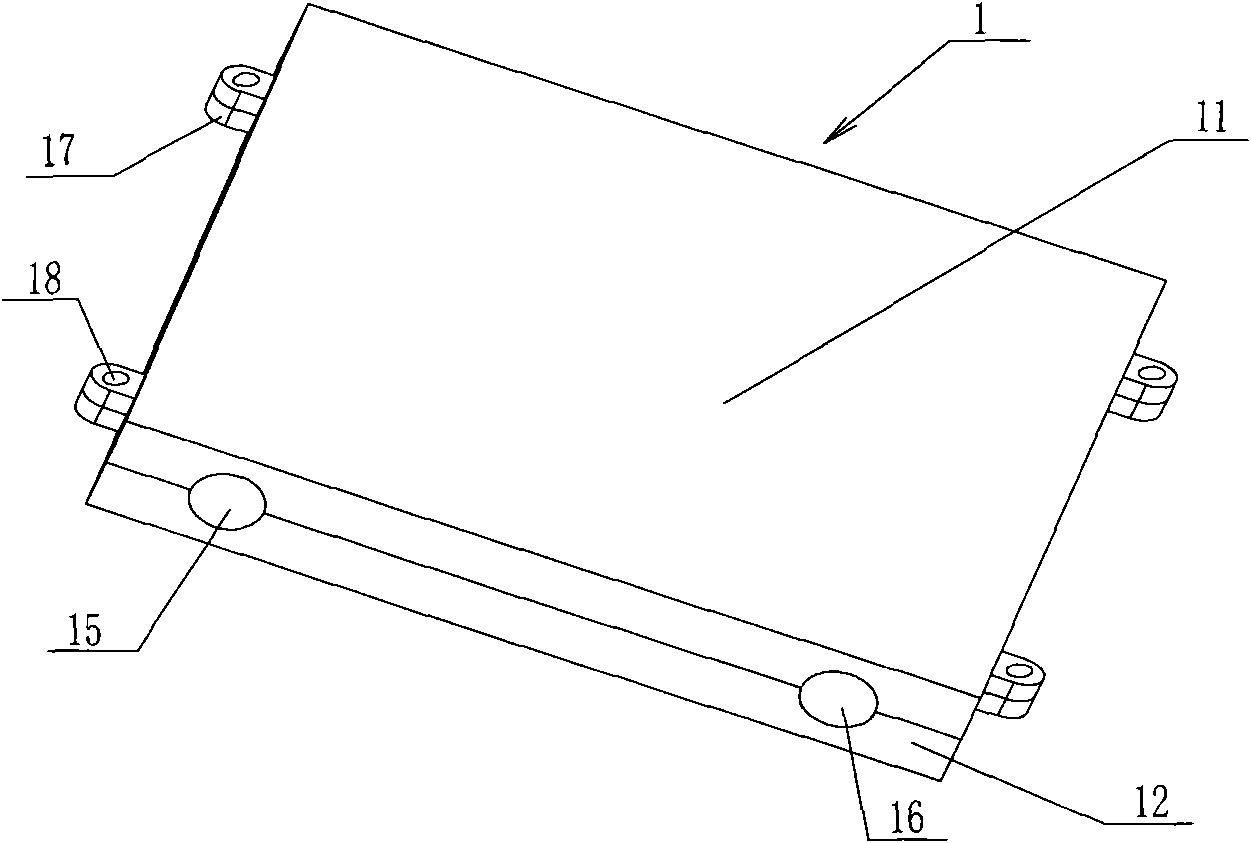

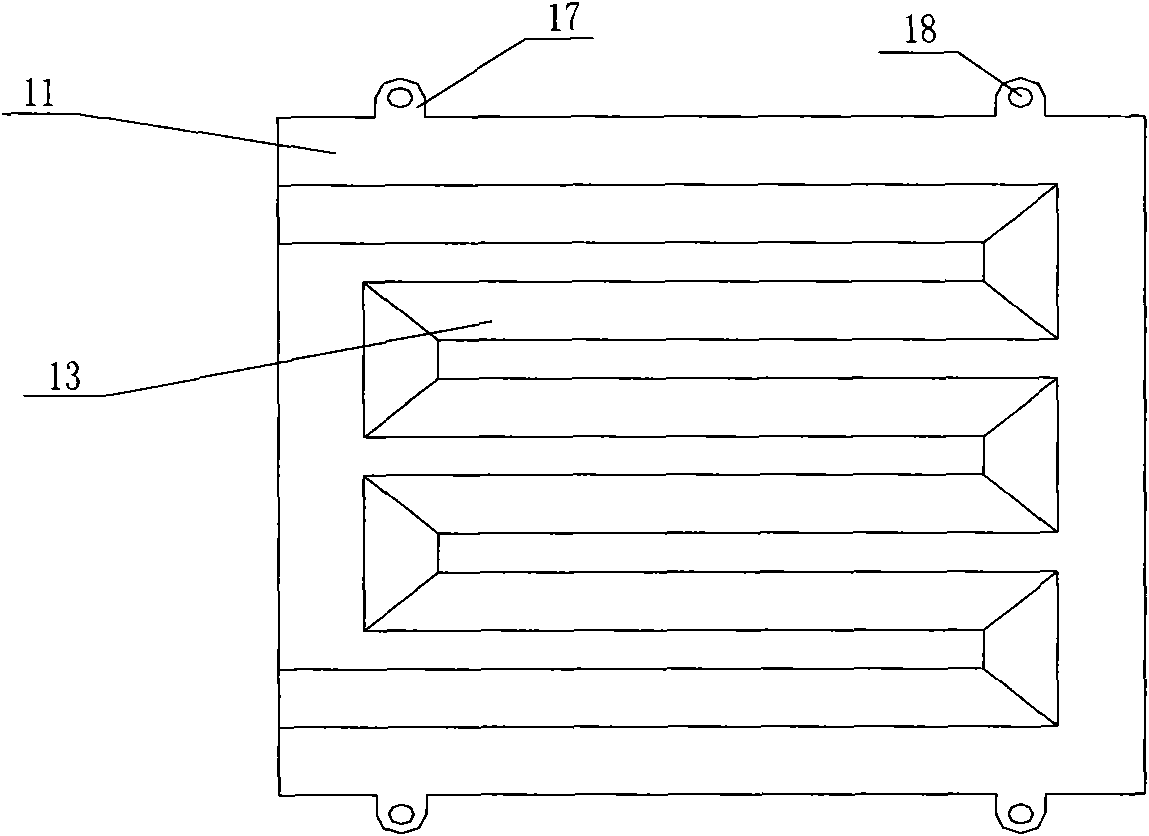

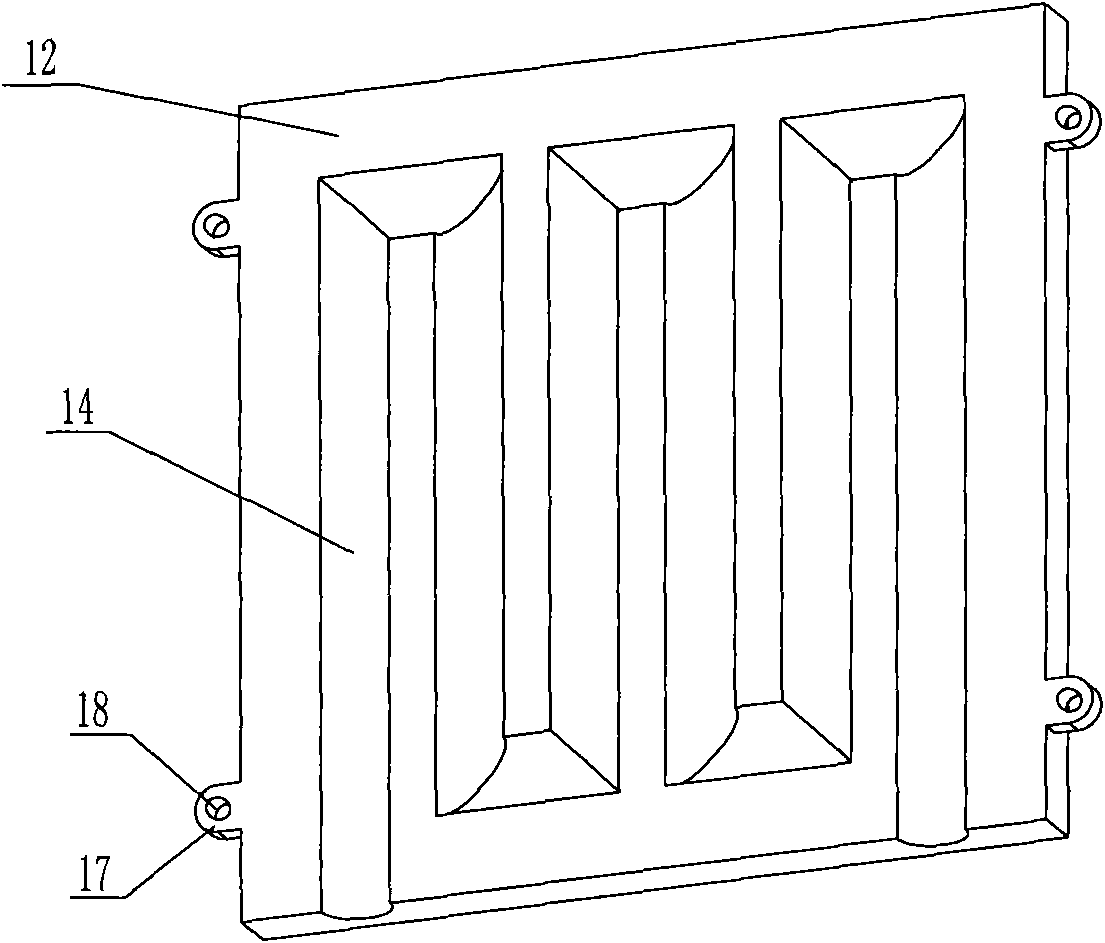

[0041] refer to Figure 1 to Figure 3 As shown, in order to separately process water flow channels or water flow grooves on the split structure of the main heat exchange part, the main heat exchange part in this embodiment is composed of an upper heat exchange plate 11 and a lower heat exchange plate 12, and the upper heat exchange plate 11 has a meandering upper water flow tank 13, the water inlet of the upper water flow tank 13 is located on one side of the upper heat exchange plate 11, the water outlet is located on the same side or the opposite side of the upper heat exchange plate 11, and the lower heat exchange plate 11 A lower water flow channel 14 is oppositely arranged on the plate 12, and the upper heat exchange plate 11 and the lower heat exchange plate 12 are sealed and tightly connected, so that the upper water flow channel 13 and the lower water flow channel 14 form a circuitous water flow channel.

[0042] Specifically, the upper heat exchange plate 11 and the l...

Embodiment 2

[0046] refer to Figure 4 to Figure 9 As shown, the difference from Embodiment 1 is that the heat exchange part of the main body in this embodiment includes a heat exchange plate 11', a head I12' and a head II13', and there are at least two water flow channels 14' inside the heat exchange plate 11' , the water flow channel 14' is a one-way linear channel, on the inner side of the head I12' and the head II13' (the orientation here is defined by the installation state of the head I12' and the head II13') There are at least two water flow grooves 15' respectively, adjacent water flow grooves 15' are communicated at intervals, the end of the heat exchange plate 11' is inserted into the water flow groove 15', and is sealed and fastened with the head I12' and the head II13' Connected so that the water flow channel 15' communicates with the water flow channel 14' to form a circuitous water flow channel, and the water inlet 16' and water outlet 17' of the water flow channel 15' are lo...

Embodiment 3

[0054] refer to Figures 10 to 14 As shown, the difference from the second embodiment is that the water flow grooves 15' are arranged at intervals at the ends of the adjacent water flow channels 14' in the heat exchange plate 11', and are used to communicate with the adjacent water flow channels 14' at intervals, and the heat exchange plate 11' The ends of the head are sealed and fastened with the head I12' and the head II13' respectively, and the water inlet 16' and the water outlet 17' of the water flow channel 14' are located on the head I12' or the head II13'. This embodiment is the same Taking a row of four unidirectional water flow channels 14' formed in the heat exchange plate 11' as an example, the water inlet 16' and the water outlet 17' are located on the head II 13'.

[0055] In this embodiment, the sealing and fastening methods of the heat exchange plate 11', the head I12' and the head II13' can refer to the records in the second embodiment, and the specific use pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com