Patents

Literature

89results about How to "Heating evenly and efficiently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

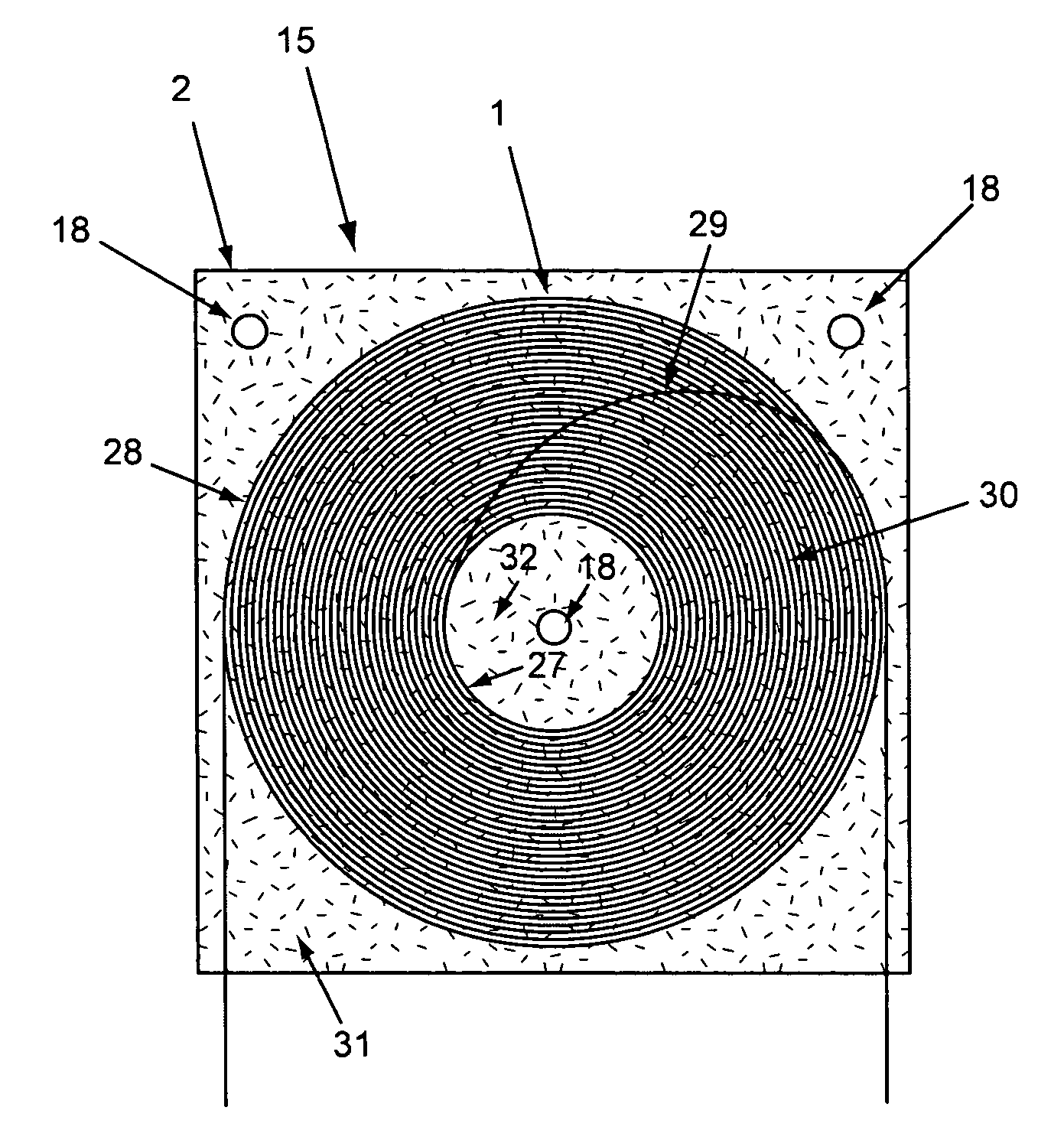

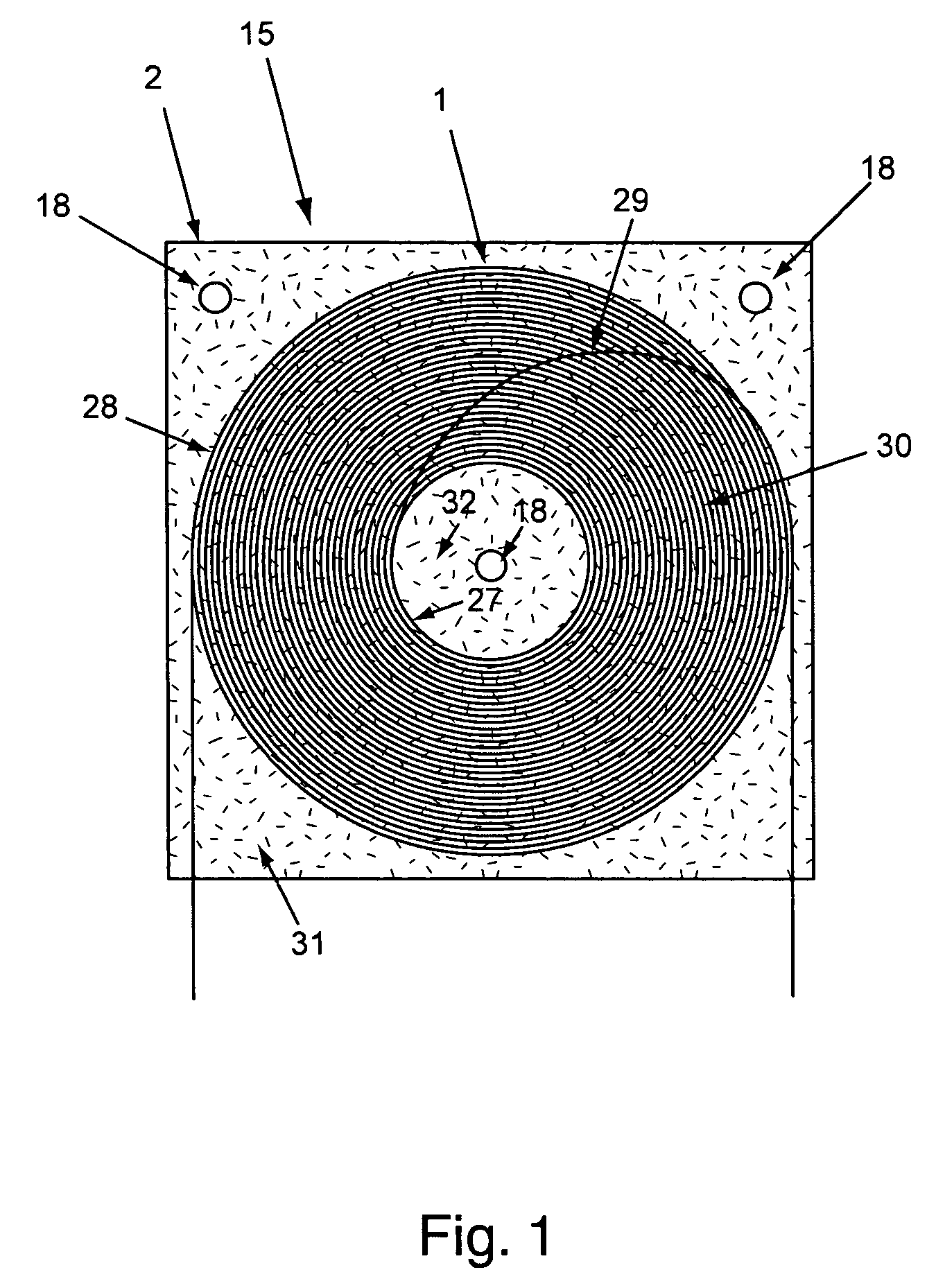

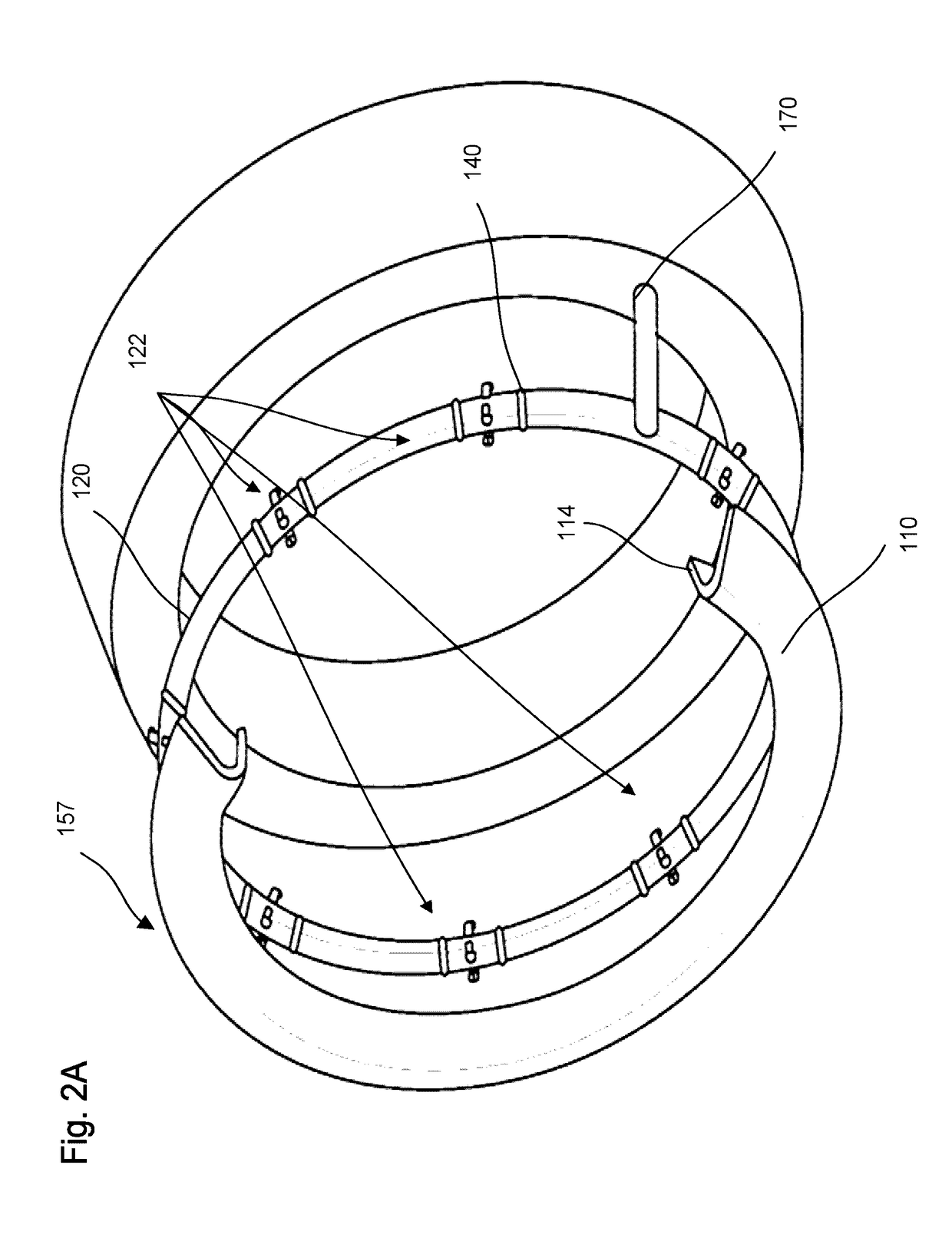

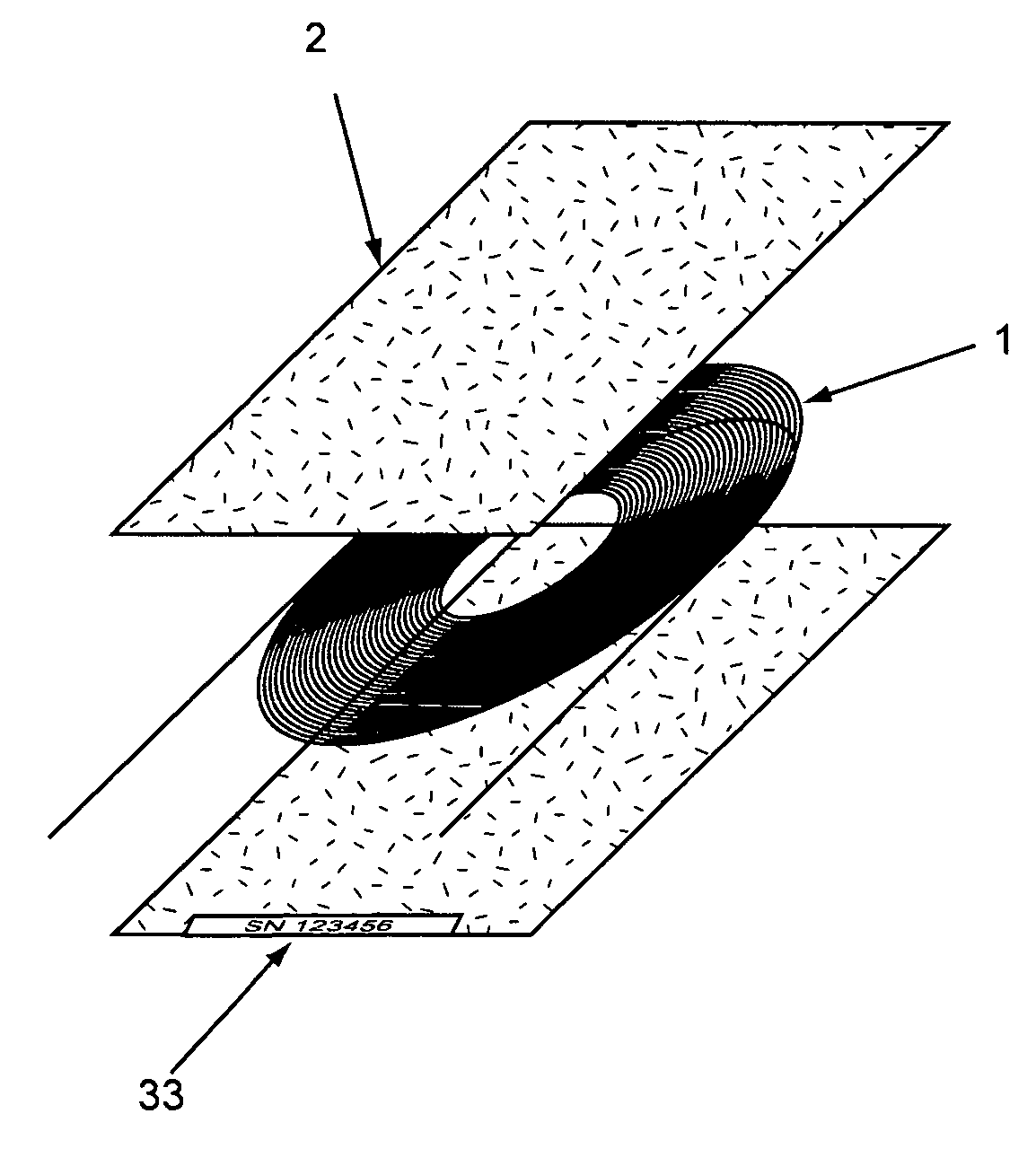

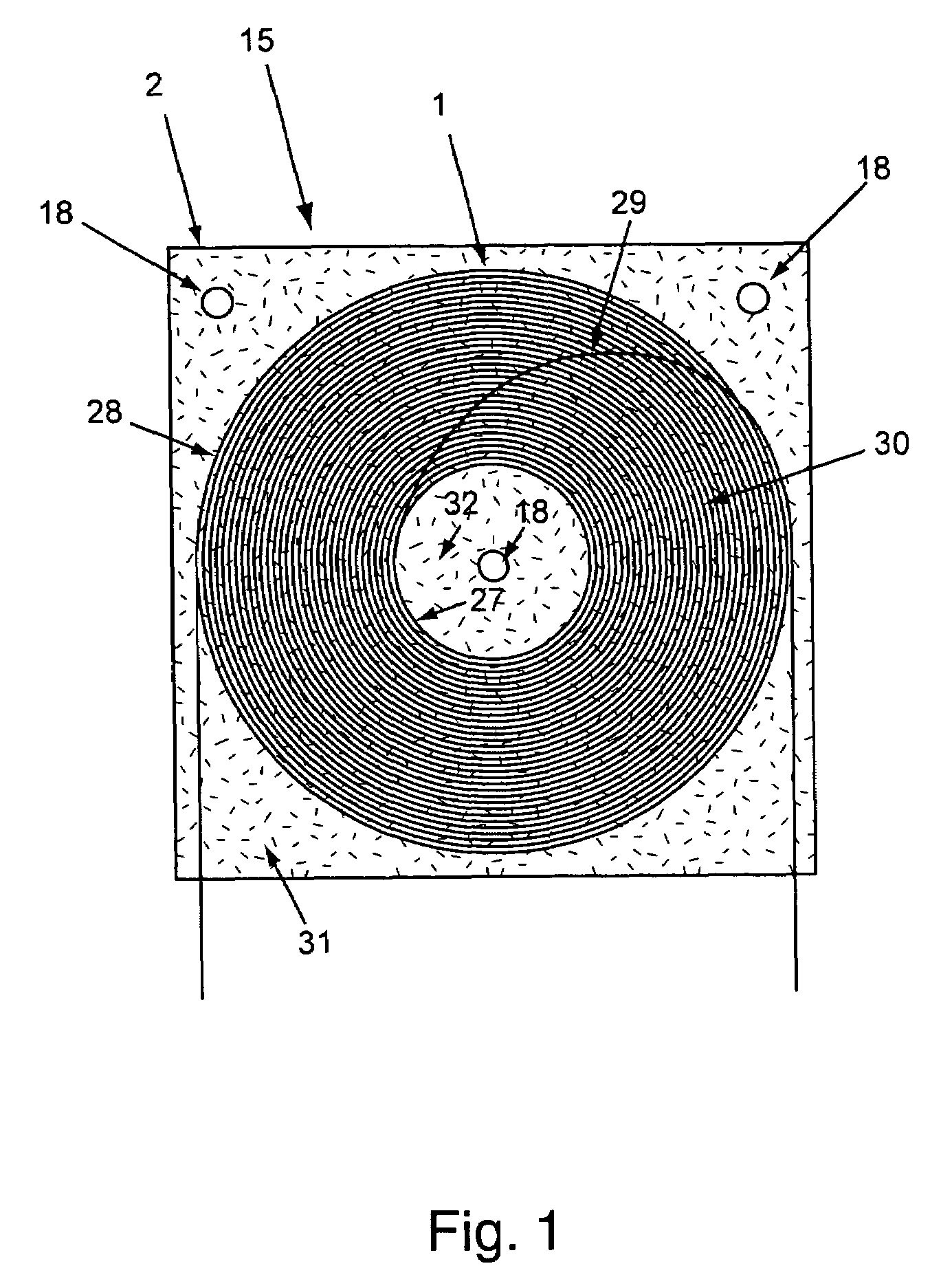

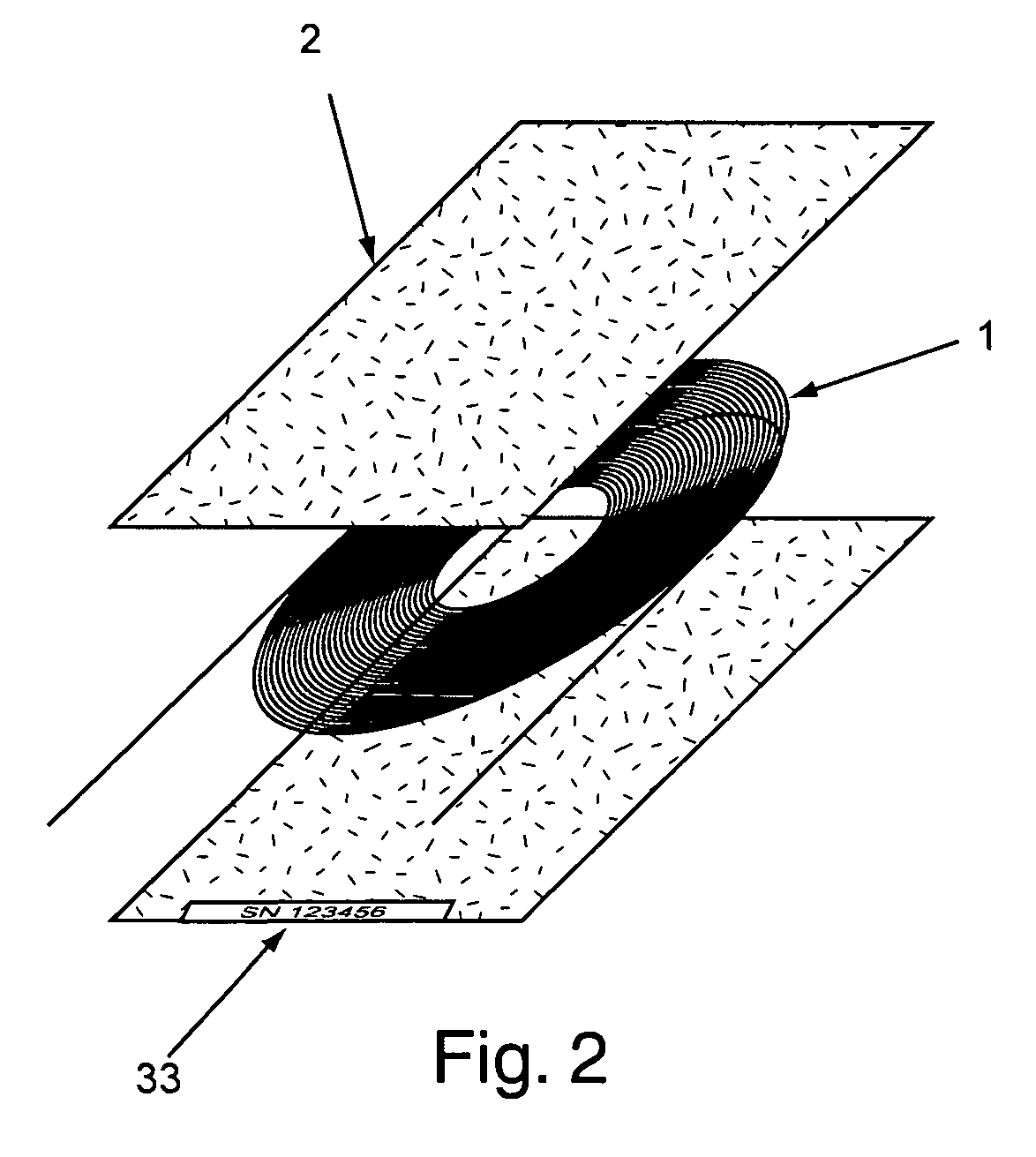

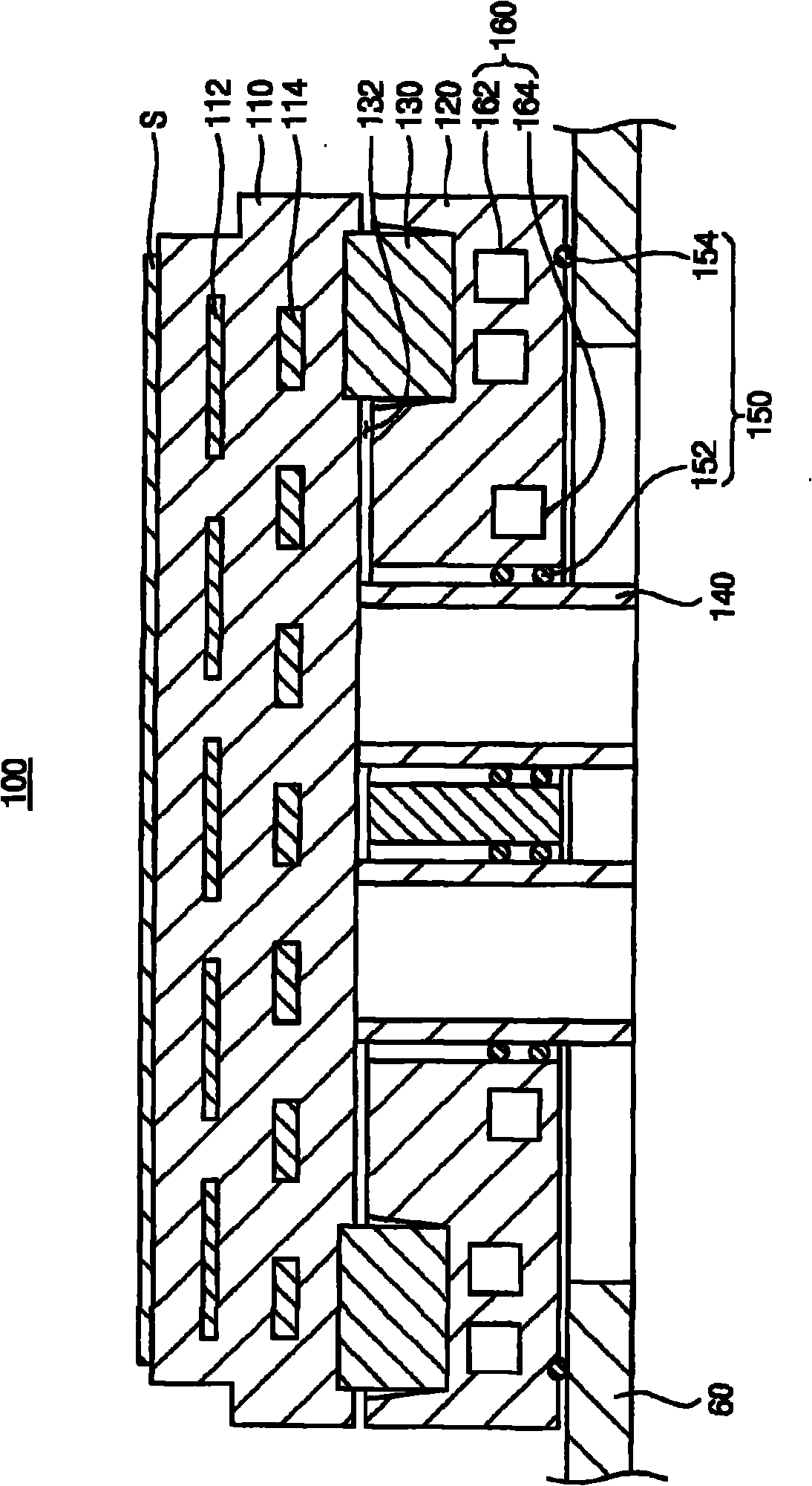

Flat spiral capillary column assembly with thermal modulator

InactiveUS20060283324A1Reduce the temperatureEfficient executionComponent separationDispersed particle separationCapillary gas chromatographyCapillary Tubing

The nature of this invention encompasses the creation of a capillary gas chromatography (GC) column assembly and a thermal modulator used to heat or cool the column assembly in a very thermally and chromatographically efficient manner. The GC column assembly described herein consists of capillary GC column material, such as fused silica or metal capillary tubing, which is constrained to lie in a flat, ordered, spiral pattern and then encased between two thin opposing surfaces. The resulting column assembly is flat, dimensionally stable and can be very efficiently thermally modulated. The resulting column assembly also takes up very little space, has very little thermal mass, and can be easily and accurately manufactured. The column assembly can be adapted for chromatographic use by affixing it to the surface of a thermal modulator described herein by means of adhesive force or by mechanical compression, and then by attaching the free ends of the exposed column material to the input and output ports of the chromatographic device. The temperature of the thermal modulator and capillary column assembly is to be controlled by the chromatographic device or by standalone temperature controlling electronics. The thermal modulator described herein contains an element for temperature modulation of the capillary column assembly to which it is attached and a temperature sensing element for providing accurate temperature feedback to the controlling electronics. The overall result of this when coupled to a chromatographic device is maximally efficient chemical separations in a small space with minimal power consumption.

Owner:ROQUES NED J

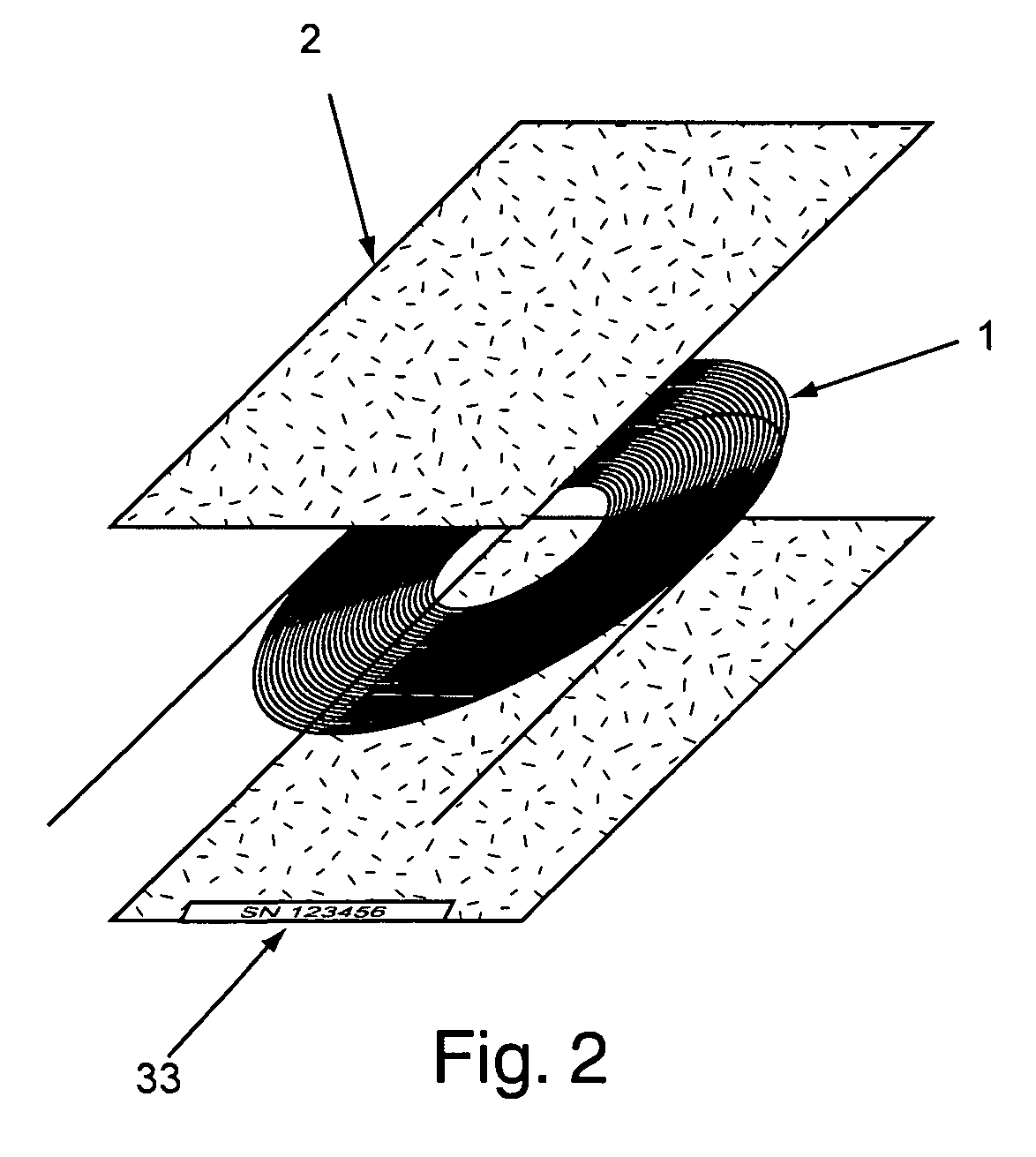

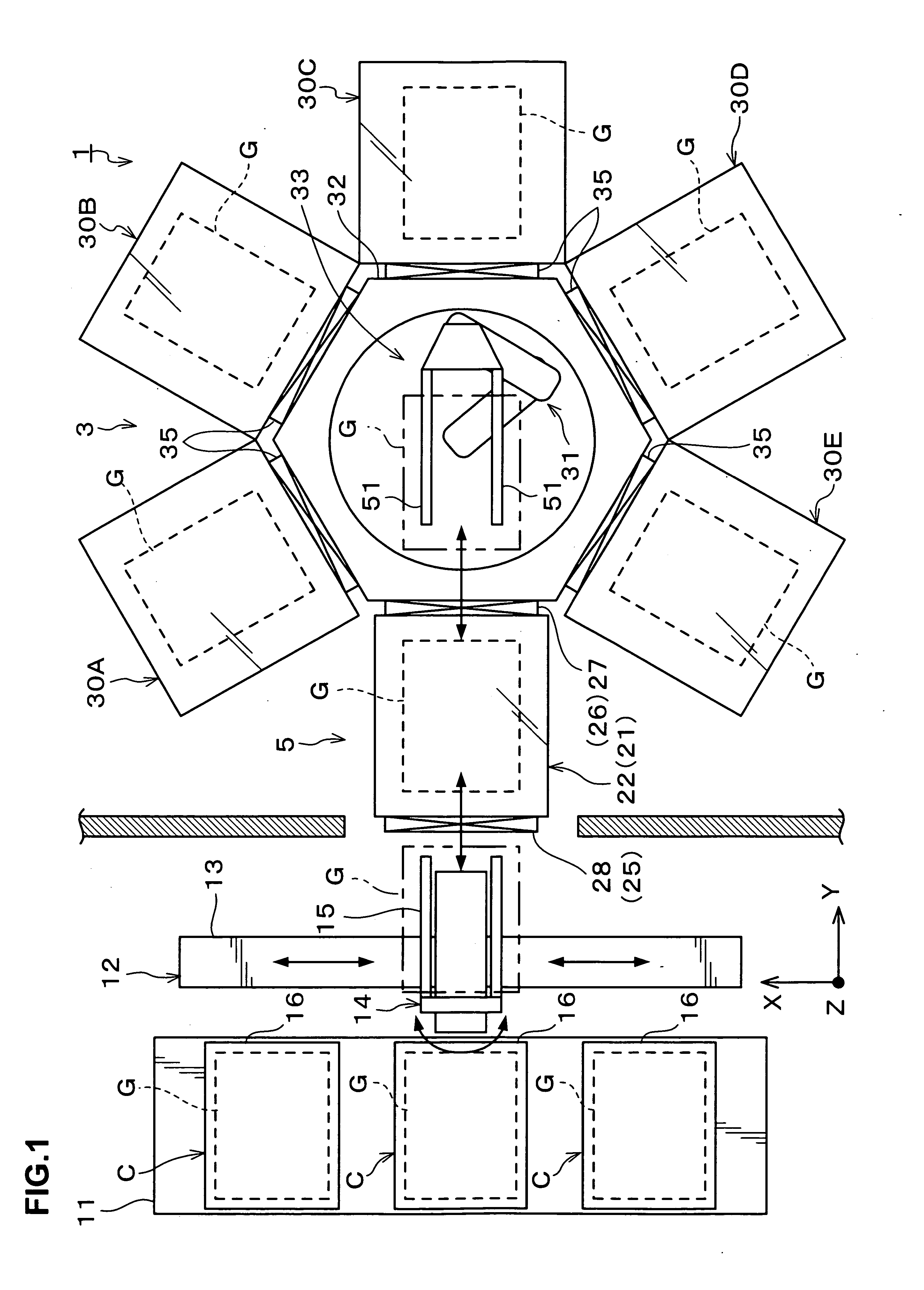

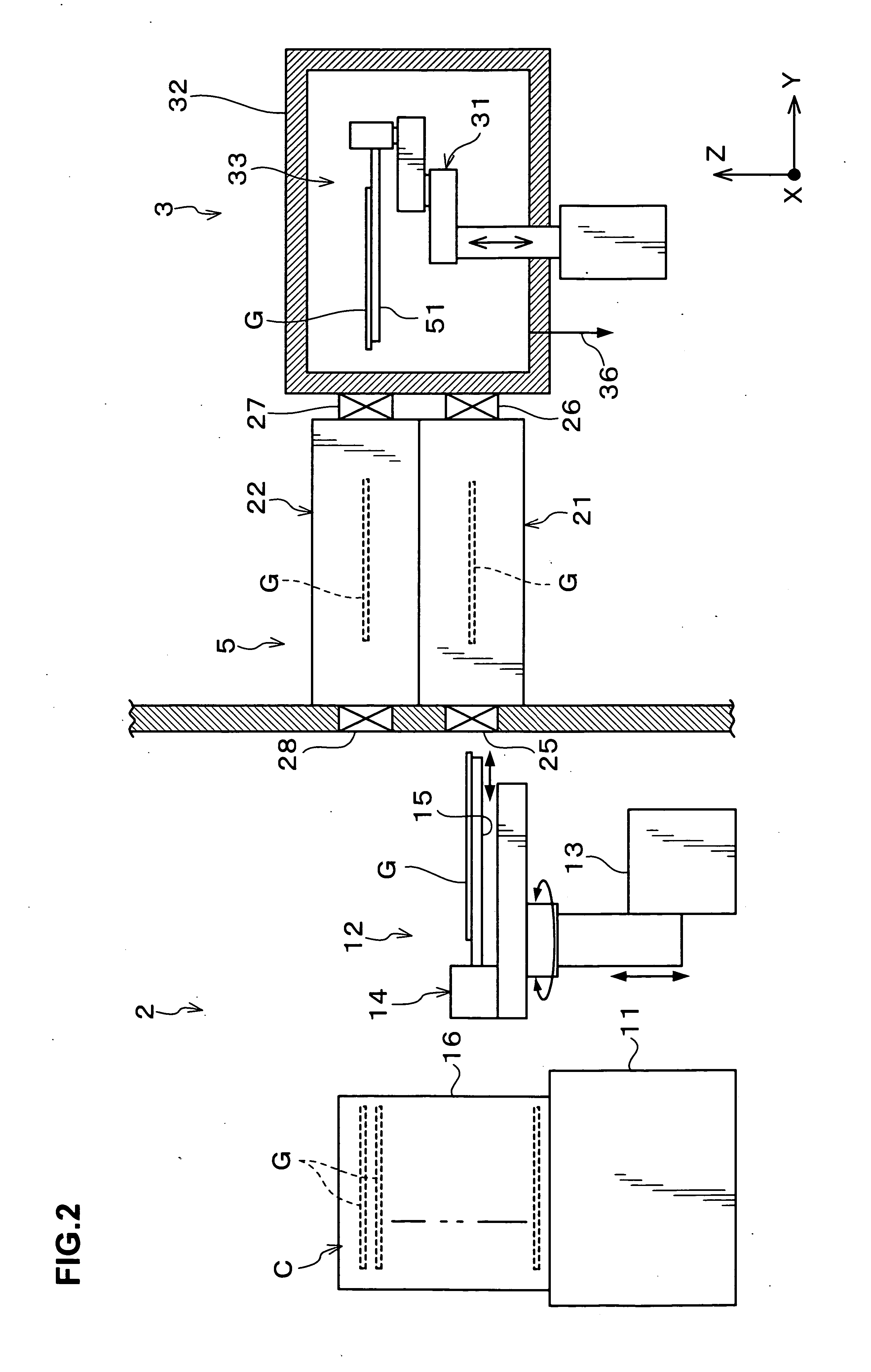

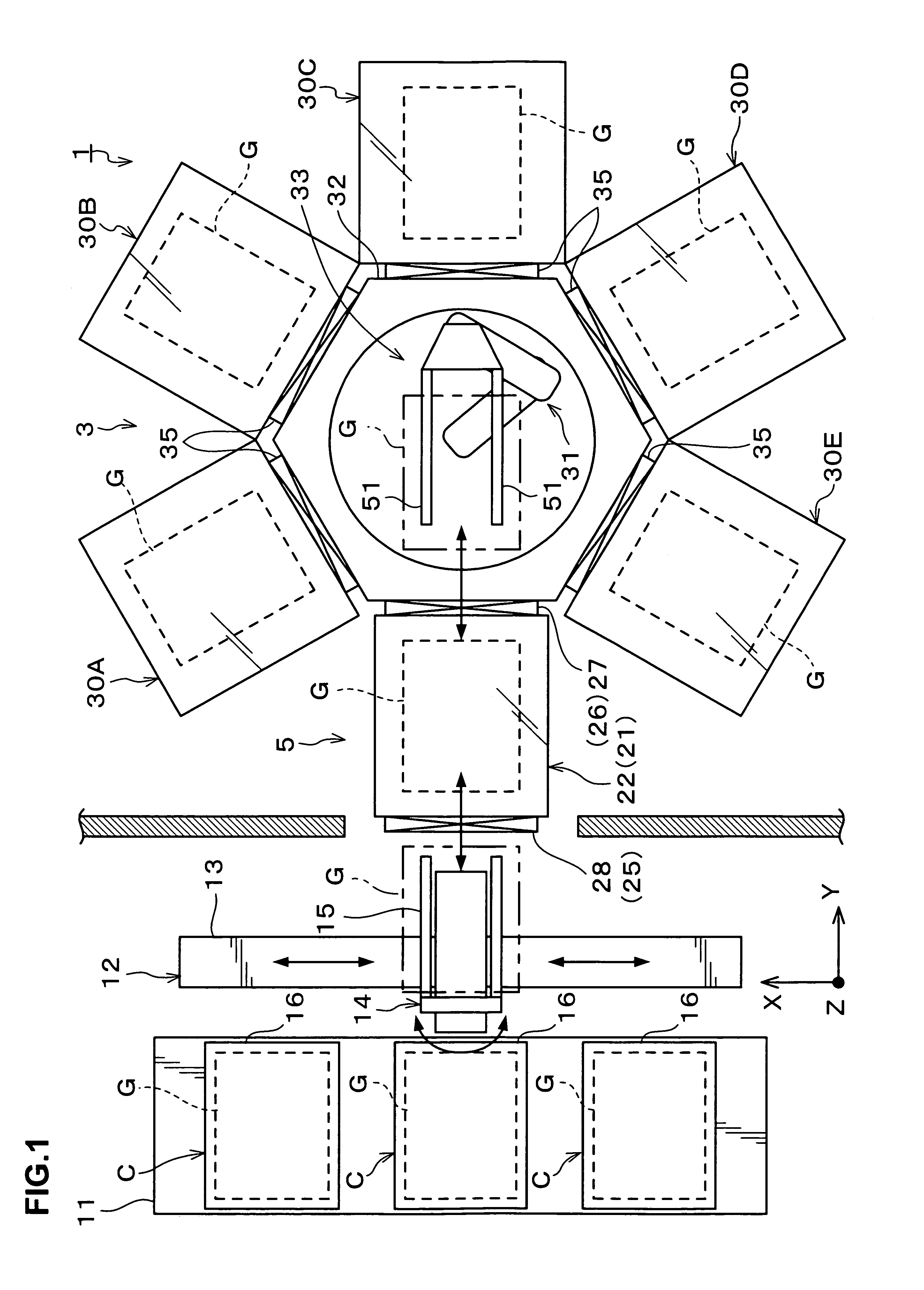

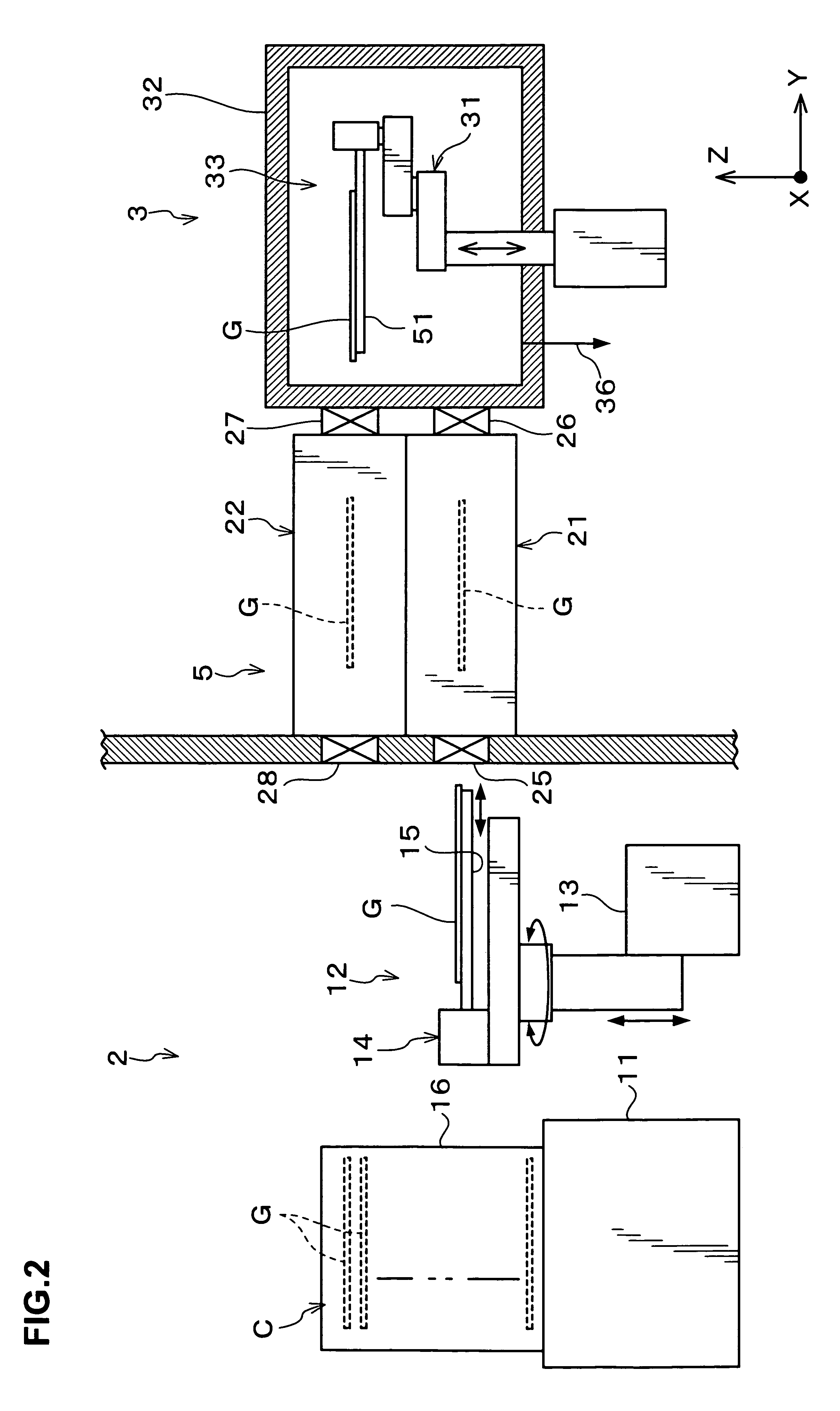

Load lock apparatus, processing system and substrate processing method

InactiveUS20060231027A1Improve thermal conductivityEffective temperature controlLiquid fillingSemiconductor/solid-state device manufacturingTemperature controlEngineering

A load lock apparatus including a carry port provided on a side of a carry-in / out section for carrying a substrate in / out from / to the outside, and a carry port provided on a side of a processing section for processing the substrate, includes: a temperature controlling plate for controlling a temperature of the substrate, the temperature controlling plate configured including a plate body made of a porous material and a temperature controlling gas supply path for supplying a temperature controlling gas controlled in temperature to the plate body. The temperature controlling gas passes through the plate body, blows out from a surface of the plate body, and is supplied to the substrate.

Owner:TOKYO ELECTRON LTD

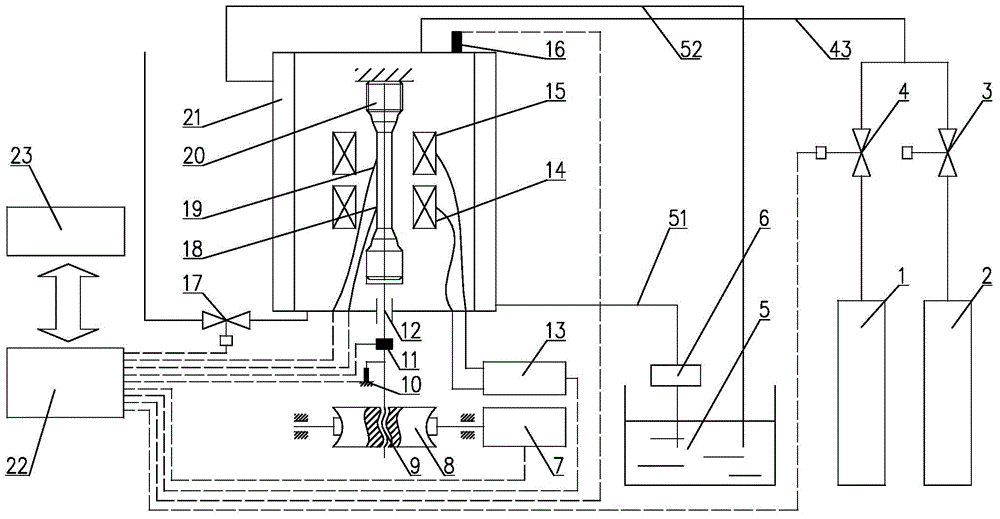

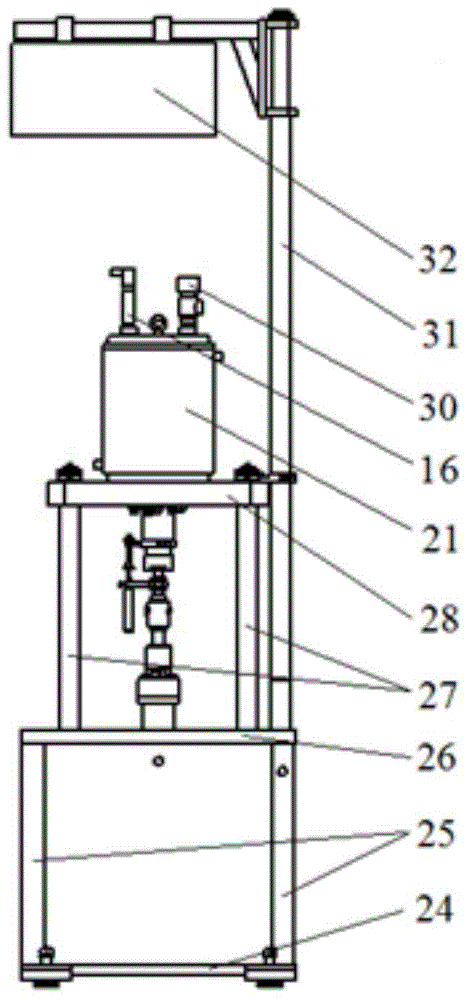

Device for testing material properties in high-temperature hydrogen environment

ActiveCN104897476AReasonable and reliable device structureShort heat transfer chainWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesProcess engineeringHydrogen supply

The invention relates to a device for testing material properties in a high-temperature hydrogen environment. The device comprises a hydrogen environment box and a host machine loading framework, wherein a test sample is arranged in the hydrogen environment box; a pull rod is mounted on the host machine loading framework; the hydrogen environment box is arranged on the host machine loading framework; an upper clamping part, a lower clamping part and an electrical heating component are arranged in the hydrogen environment box; the pull rod penetrates through the hydrogen environment box and is fixedly connected with the lower clamping part; the hydrogen environment box is connected with a hydrogen supply pipe; an air-relief solenoid valve is arranged on the hydrogen environment box. The device further comprises sensors and a control component, wherein the sensors are used for monitoring test sample stress load, test sample deformation, test sample environment temperature and test sample ambient hydrogen pressure; the control component is used for monitoring and processing the information collected by the sensors. The device can be used for testing the creep property, stress rupture property and tension-tension alternating load fatigue property of a metal material in the hydrogen environment, can ensure the accuracy of testing results, works reliably and stably and has high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST +1

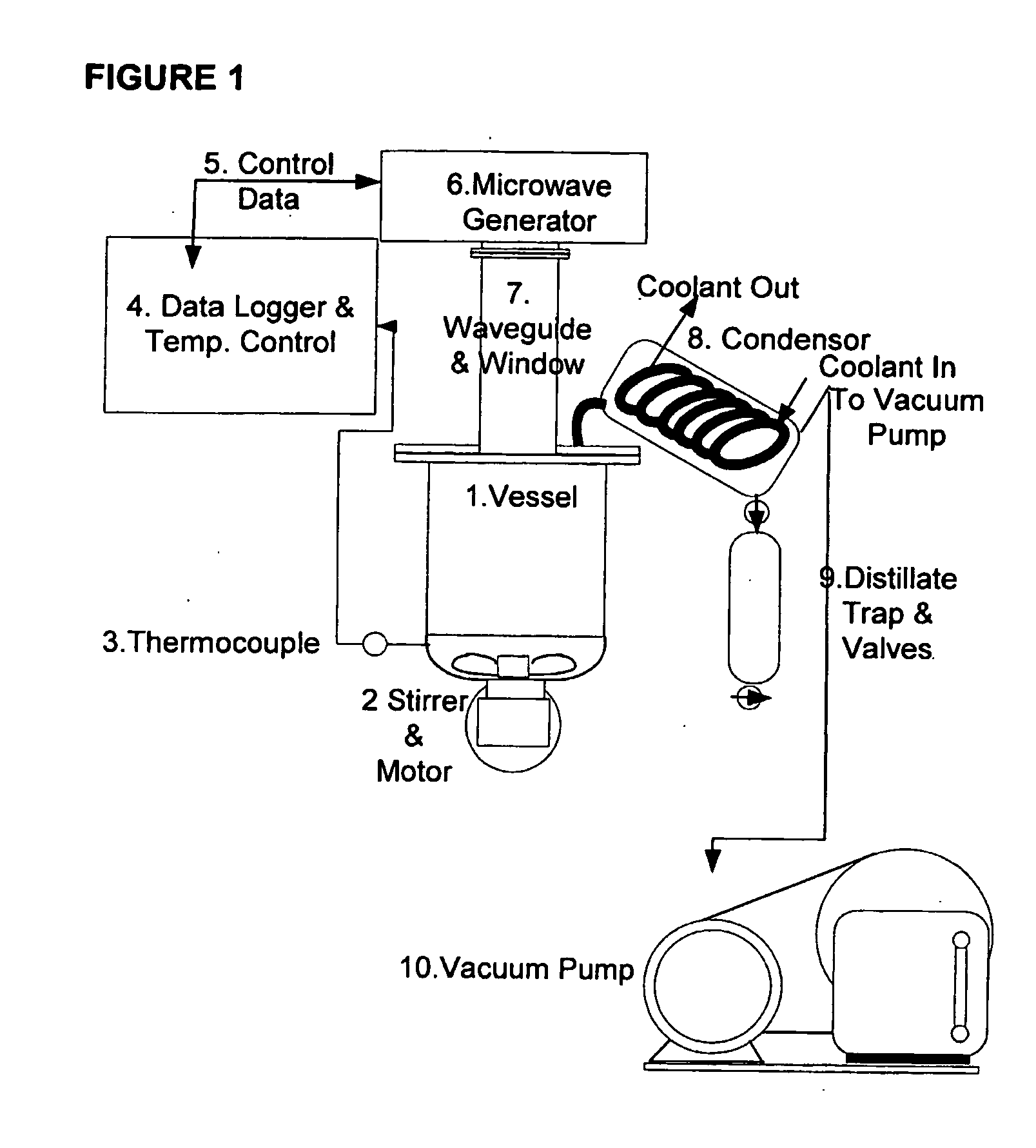

Process for recycling waste plastics

A process for recycling plastic material by reducing a sample of plastic material to form plastic particles having a desired particle size; providing a susceptor agent to the plastic particles which imparts a dielectric property to the plastic particles; providing a bonding agent to the plastic particles; and treating the plastic particles with microwave energy to form a useable plastic material.

Owner:LARK DAVID J +1

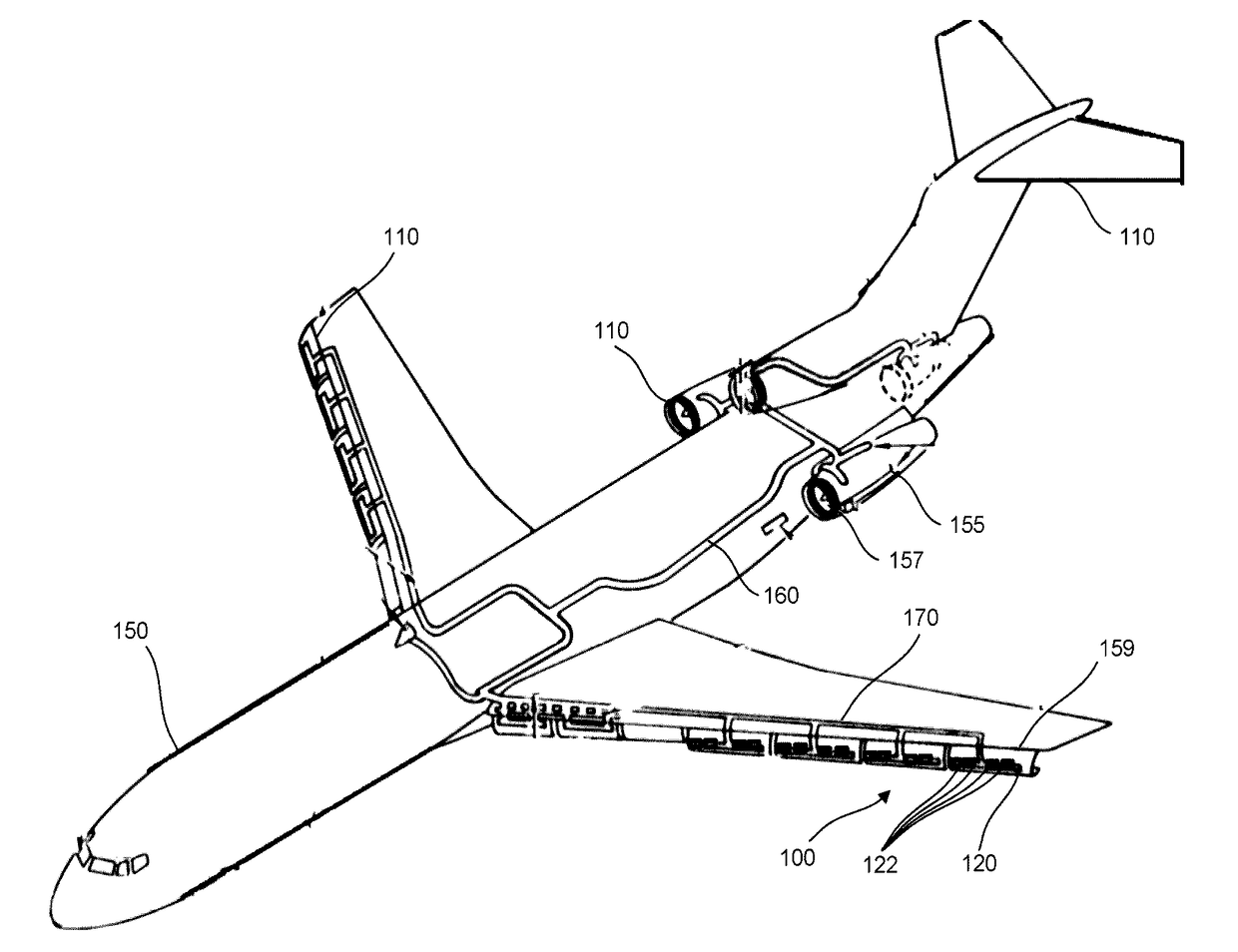

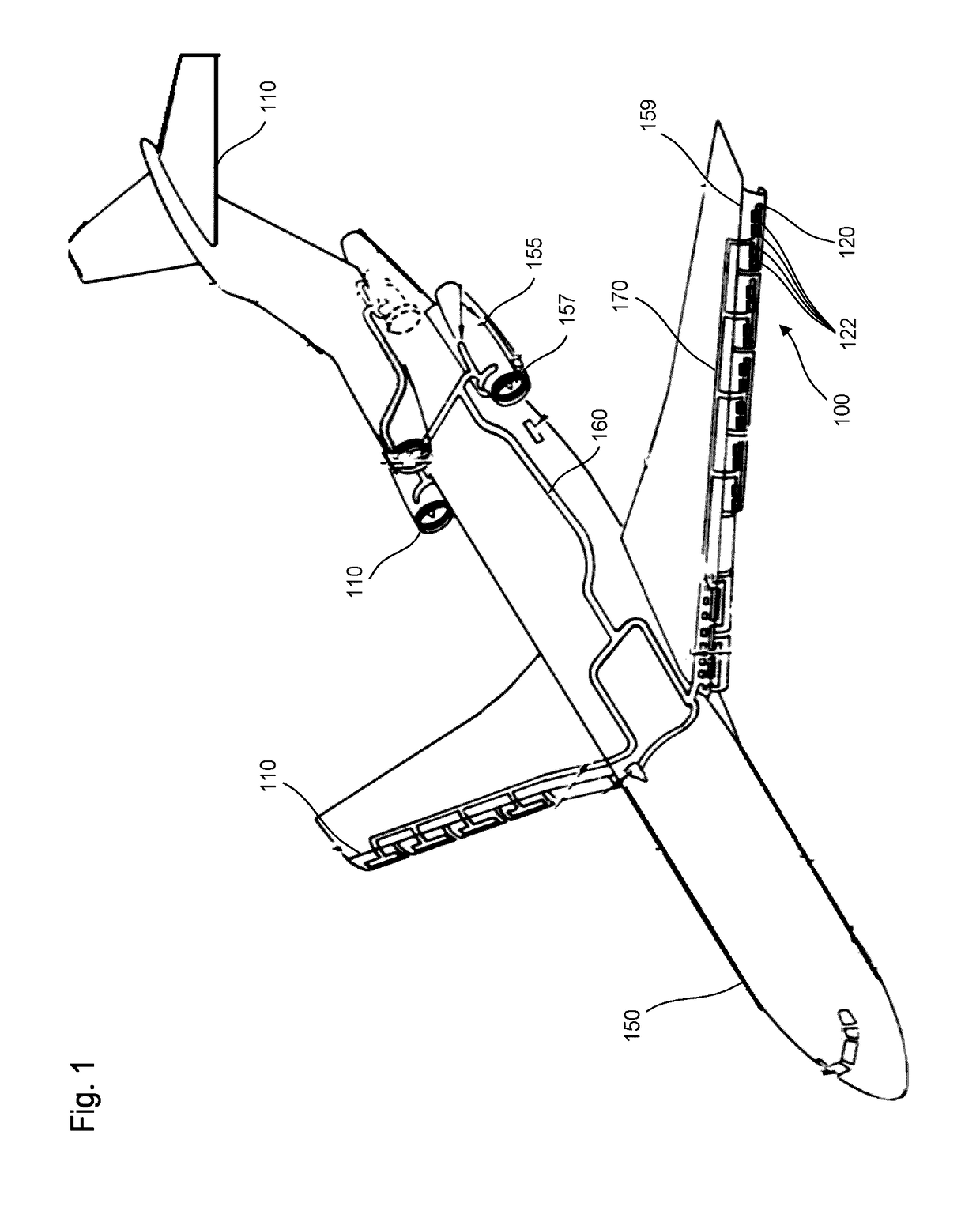

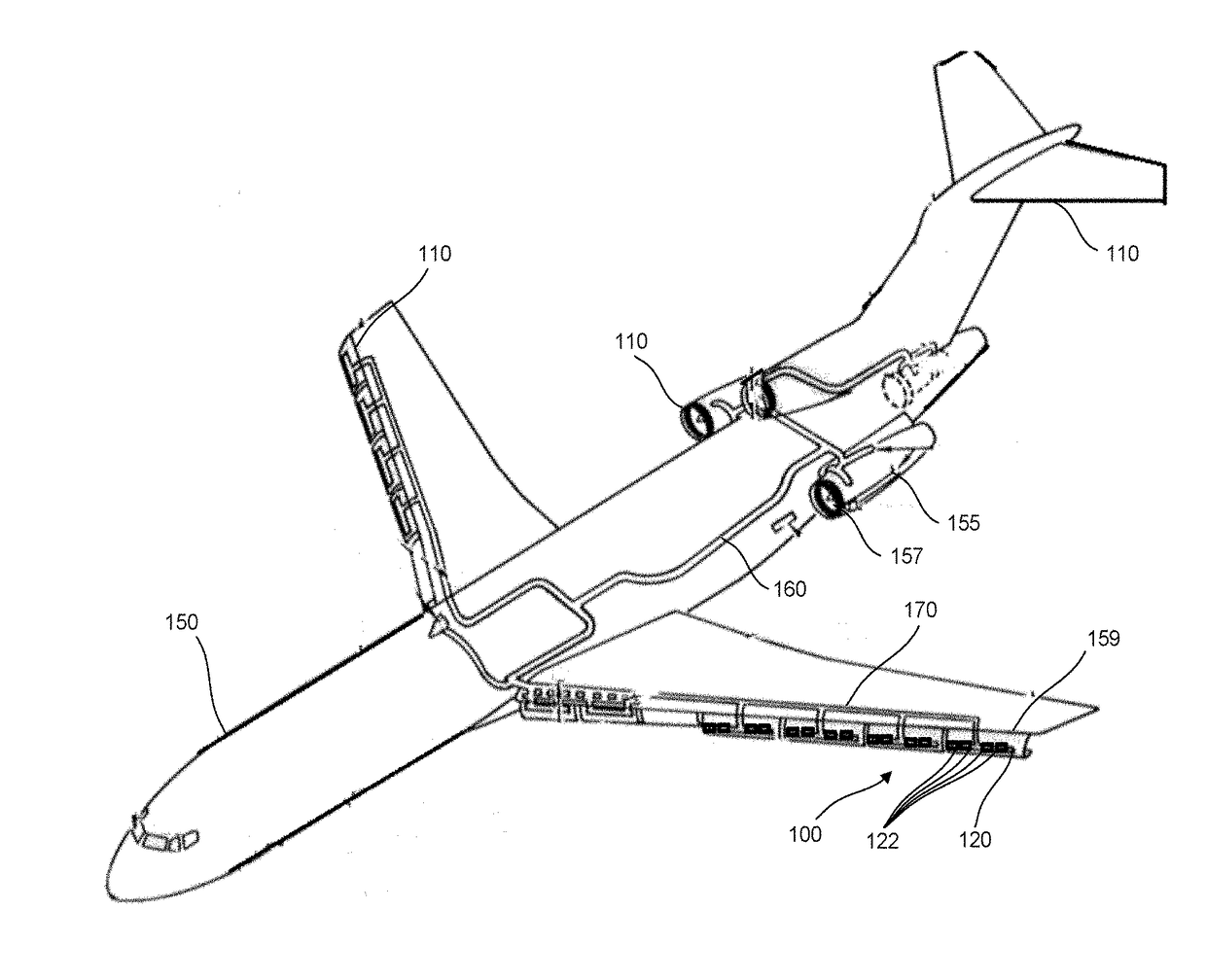

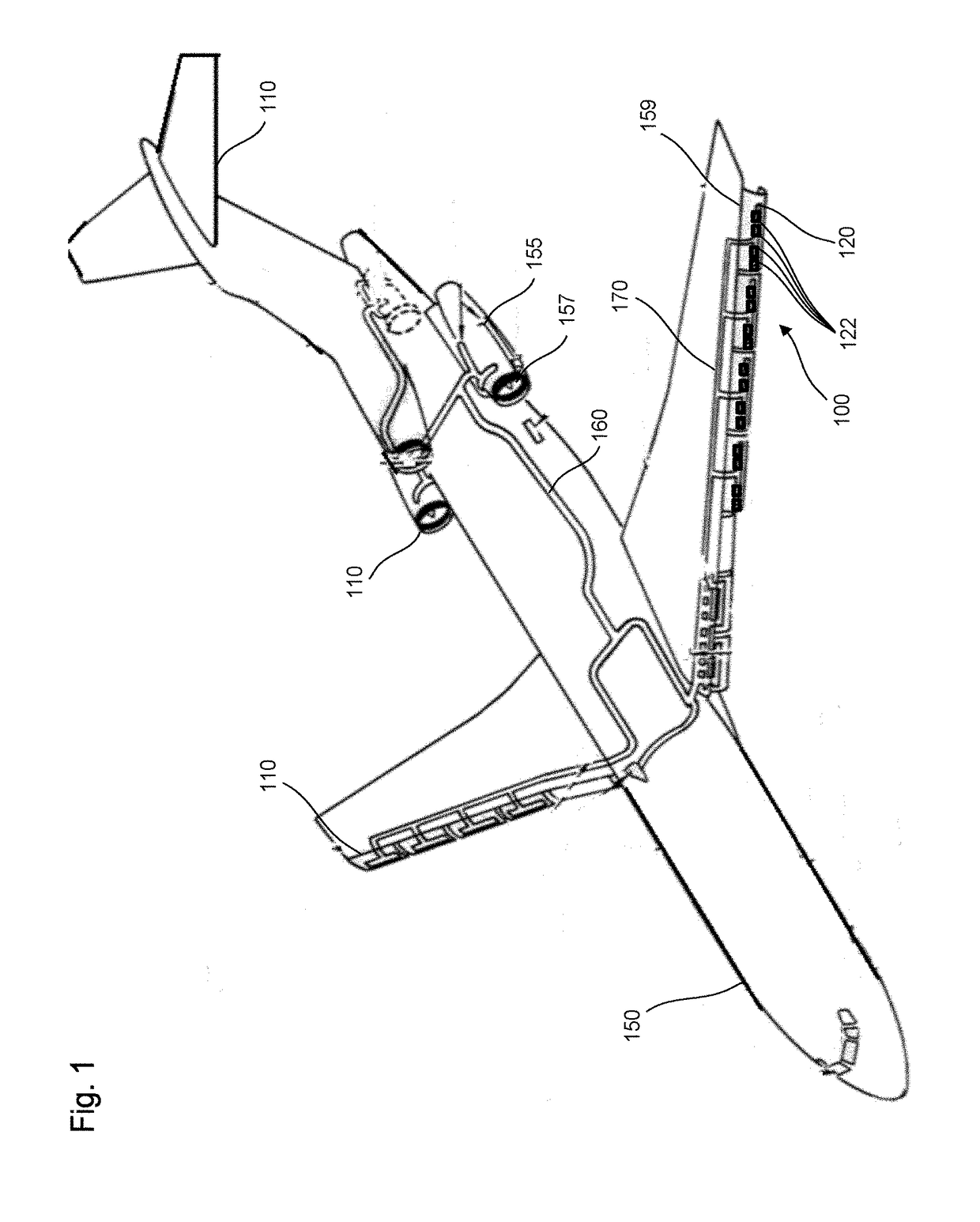

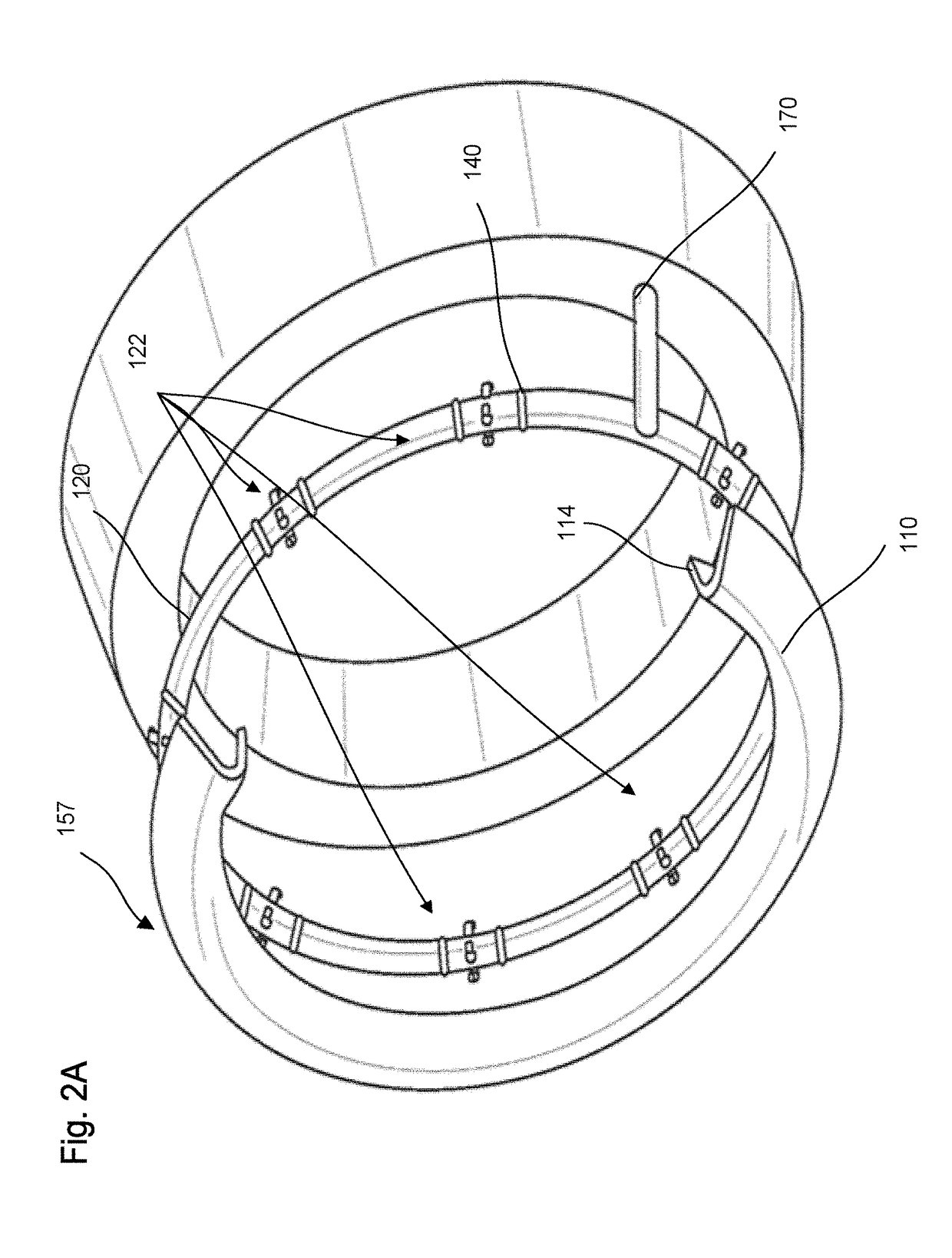

Anti-icing apparatus and system

InactiveUS20170166313A1Effectiveness and efficiencyEnsure efficiency and effectivenessAircraft power plant componentsDe-icing equipmentsWorking fluidEngineering

An anti-icing apparatus includes an anti-icing piccolo tube for an aircraft component with a plurality of self rotating elements. Each self rotating element of the plurality of self rotating elements includes a first inlet to receive a working fluid, a second inlet to receive the working fluid, a peripheral layer that connects the first inlet and the second inlet, and a plurality of outlets placed on the peripheral layer that expulses the working fluid through jets. The jets rotate each self rotating element and dynamically impinges the working fluid on an internal surface of the aircraft component.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

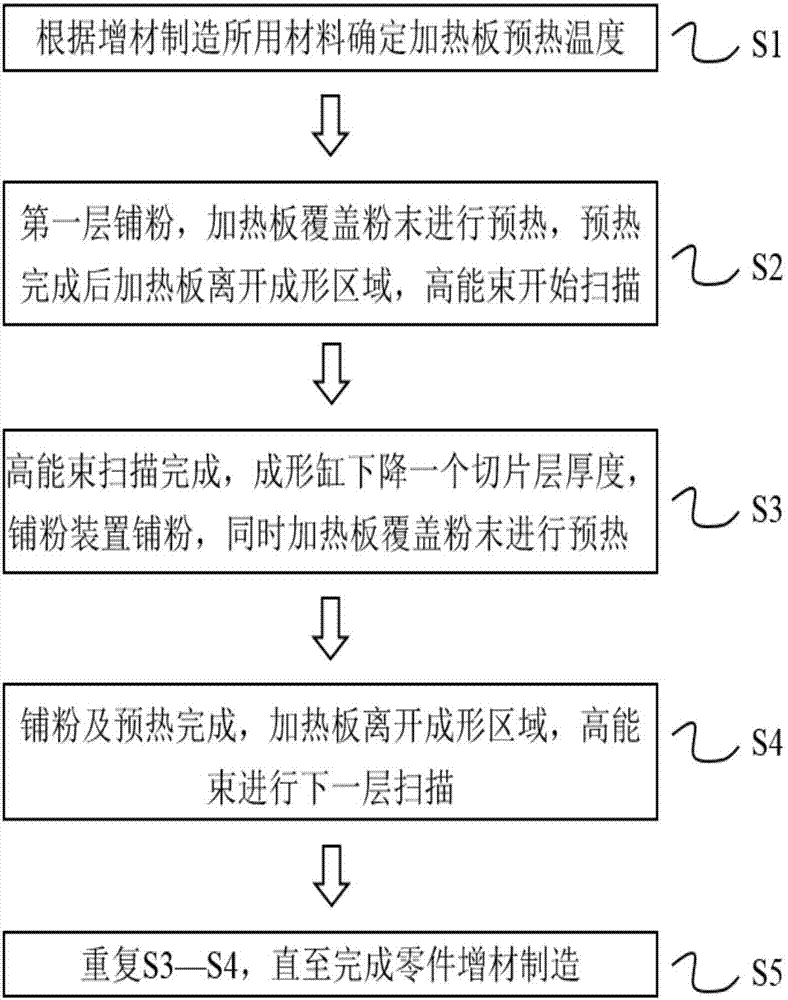

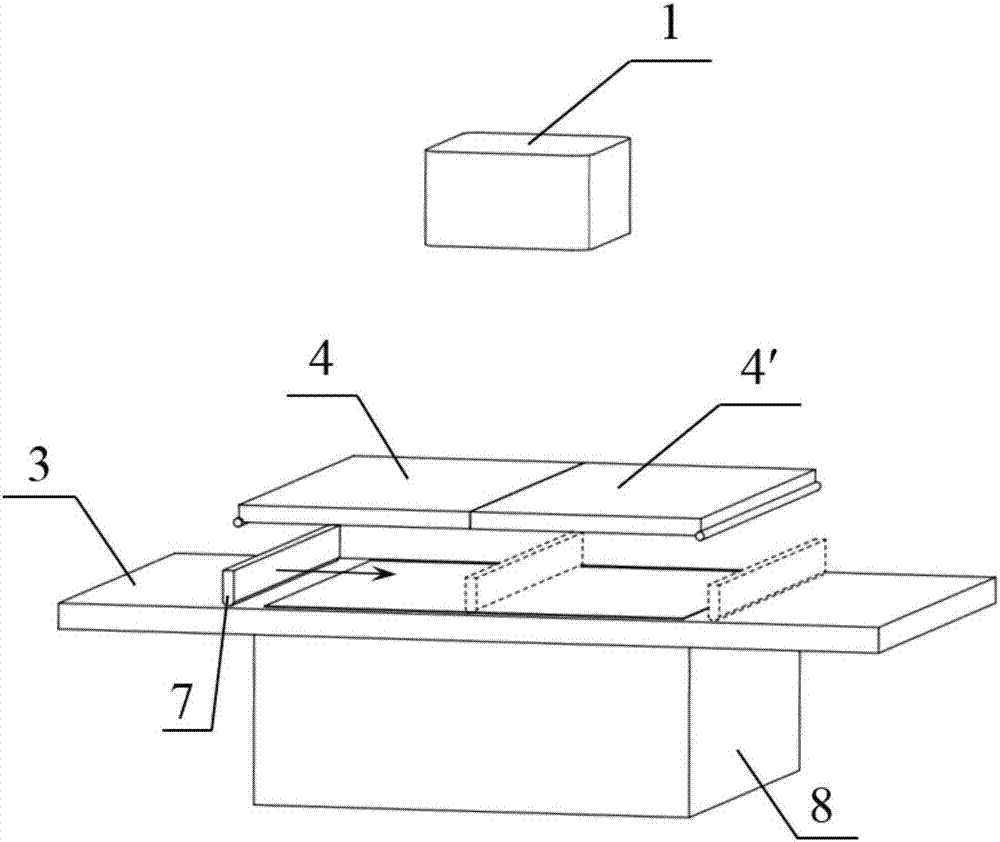

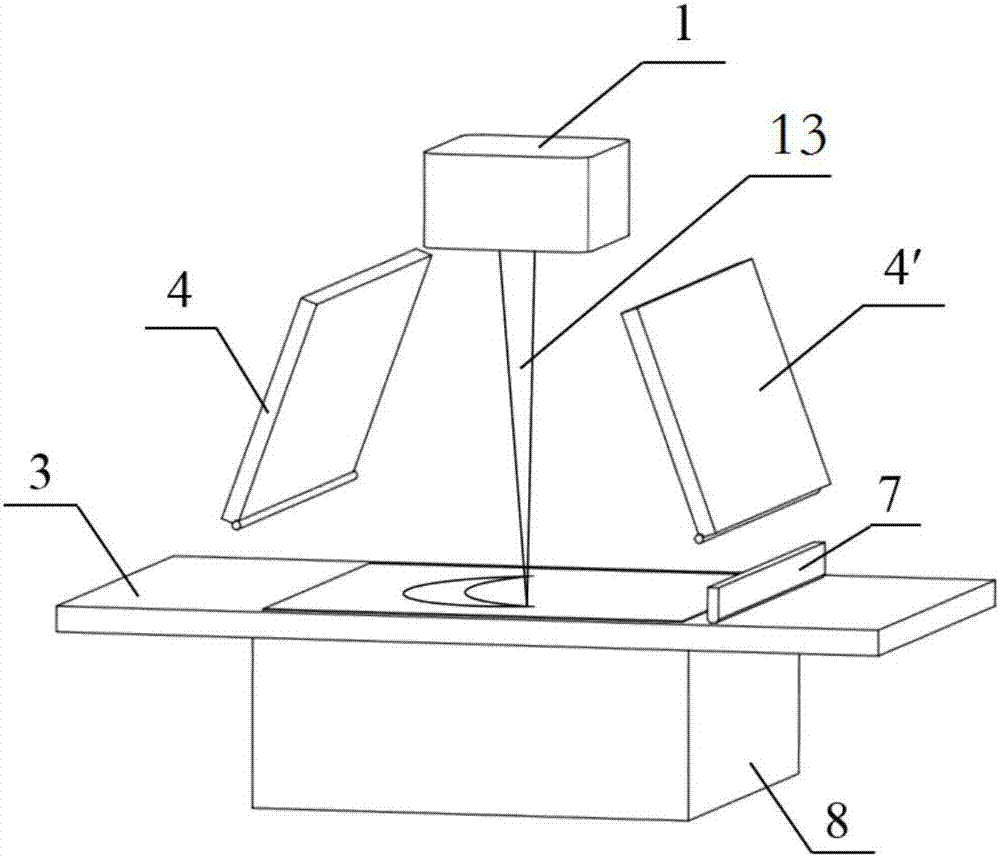

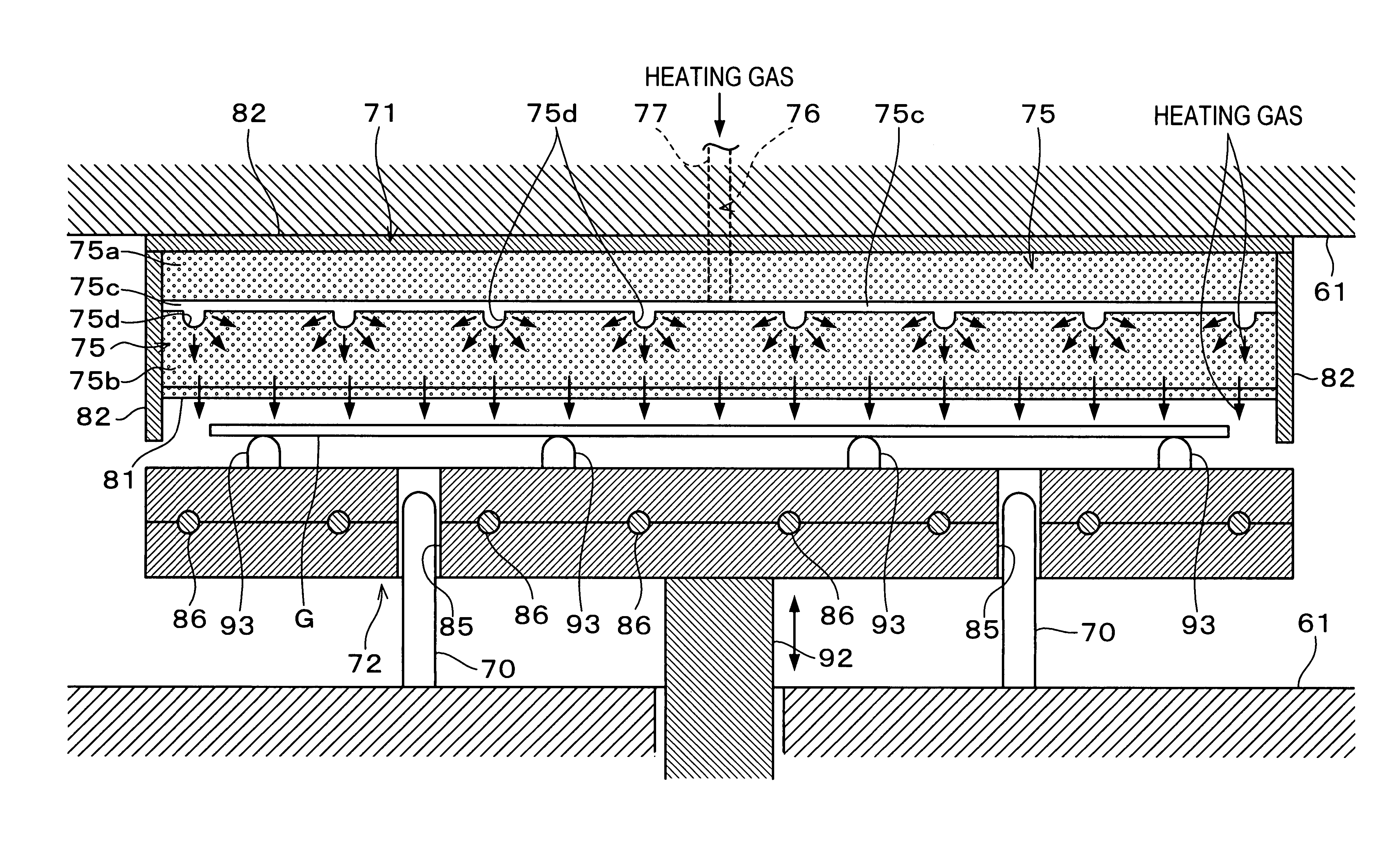

Preheating method and device suitable for powder laying type additive manufacturing

ActiveCN107379527AMonitor temperature in real timeHeating high temperatureManufacturing heating elementsIncreasing energy efficiencyControl systemMetallurgy

The invention provides a preheating method and device suitable for powder laying type additive manufacturing, and belongs to the technical field of additive manufacturing. A movable type plane heating plate capable of covering a whole powder bed is arranged over the powder bed, the mounting height of the plane heating plate is slightly larger than a powder laying device, in the powder laying process, the powder bed and parts are preheated, after powder laying is finished, a plane light source is closed and put away, and the phenomenon that in the machining process, the plane heating plate blocks a high-energy beam is avoided. In the heating process, a temperature measuring sensor is used for monitoring the temperature of the powder bed in real time, a control system is adopted to implement feedback control over preheating of the powder bed according to the temperature monitoring result, full-breadth covering type heating is adopted, and the powder bed and formed parts are subject to high-temperature, efficient and unifier preheating. The invention further provides the device achieving the above method. The method is wide in application material and high in expansibility and is particularly suitable for powder laying type additive manufacturing of multiple large-breadth high-energy beams.

Owner:HUAZHONG UNIV OF SCI & TECH

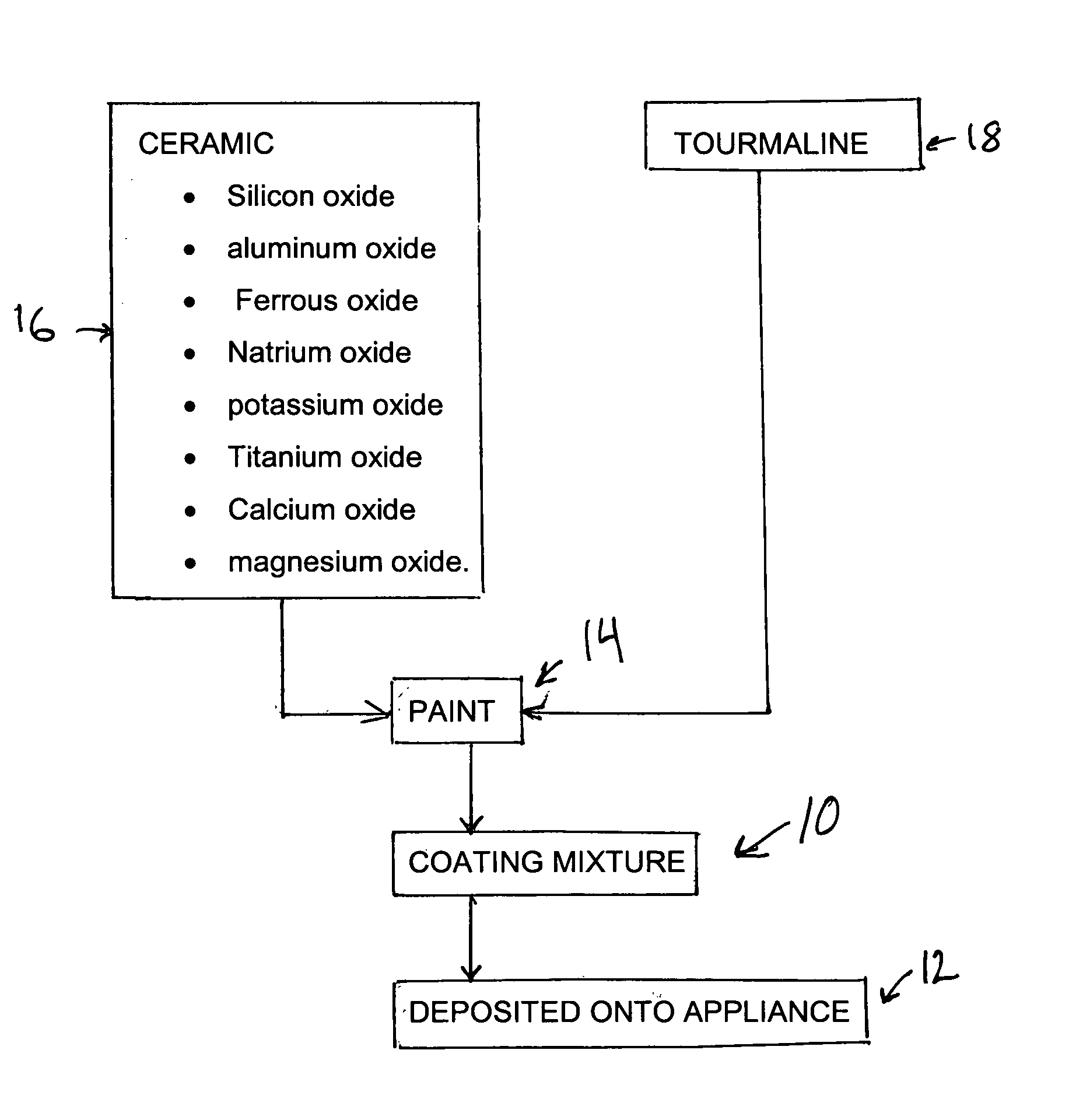

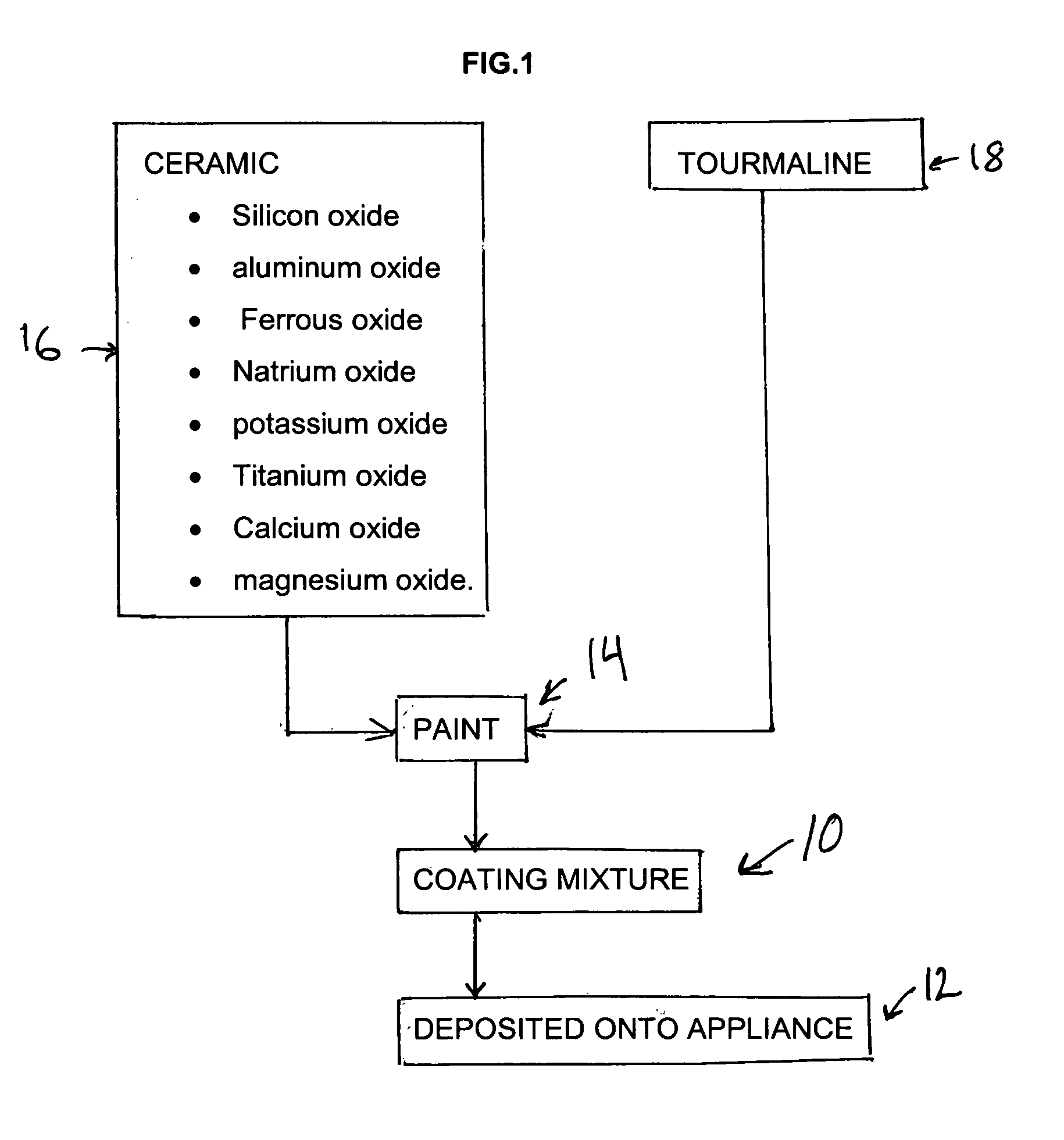

Ceramic and tourmaline hair appliances

InactiveUS20070029302A1Distribute heat efficiently and evenlyEasy dischargeCurling-ironsCurling-tongsIron(II) oxideSilicon oxide

A coating mixture is applied to a hair appliance such as a styling iron, a dryer, or a roller by being mixed with a paint or by other known deposition means, and includes a ceramic component and a tourmaline component. Preferably, the ceramic component contains one or more of Silicon oxide, aluminum oxide, Ferrous oxide, Natrium oxide, potassium oxide, Titanium oxide, Calcium oxide, and magnesium oxide. The tourmaline component comprises crushed tourmaline particles of a size and concentration generally known in the art. By applying both components, preferably in the form of a mixed paint, a surface on an appliance or accessory that is adapted to receive heat will emit ions and, due to the known characteristics of both ceramic and tourmaline, will retain and distribute heat efficiently and evenly.

Owner:CONAIR CORP

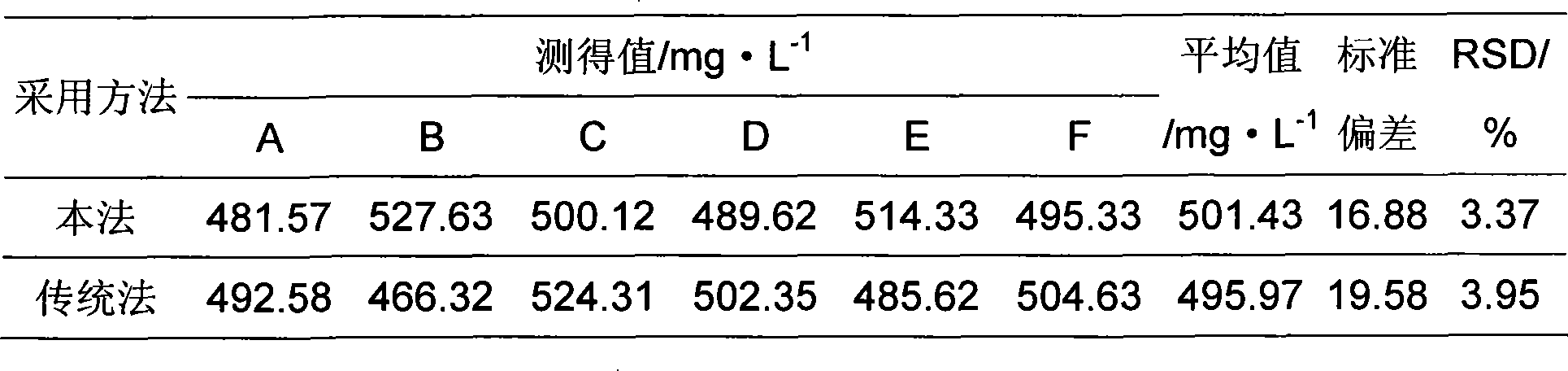

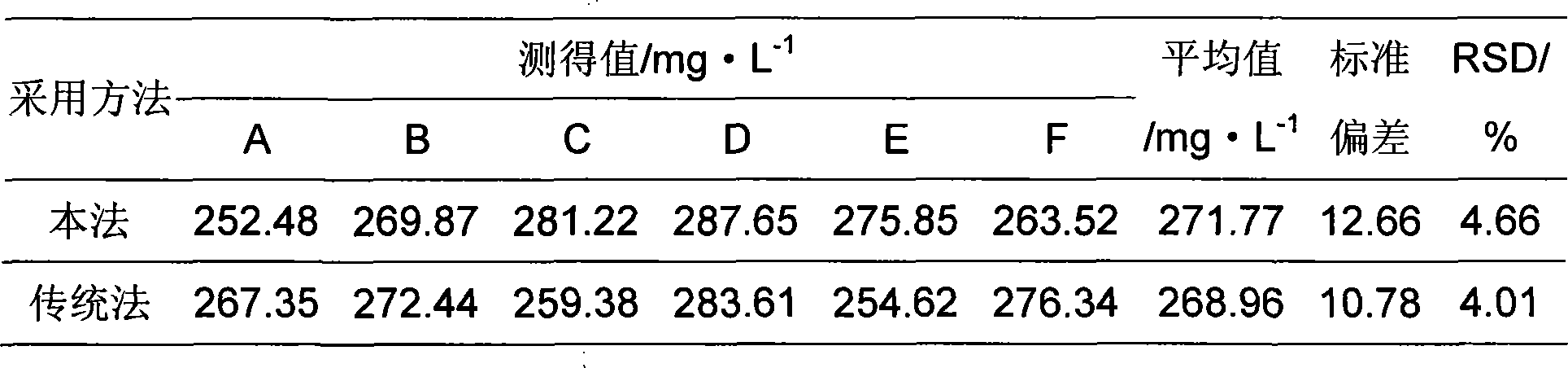

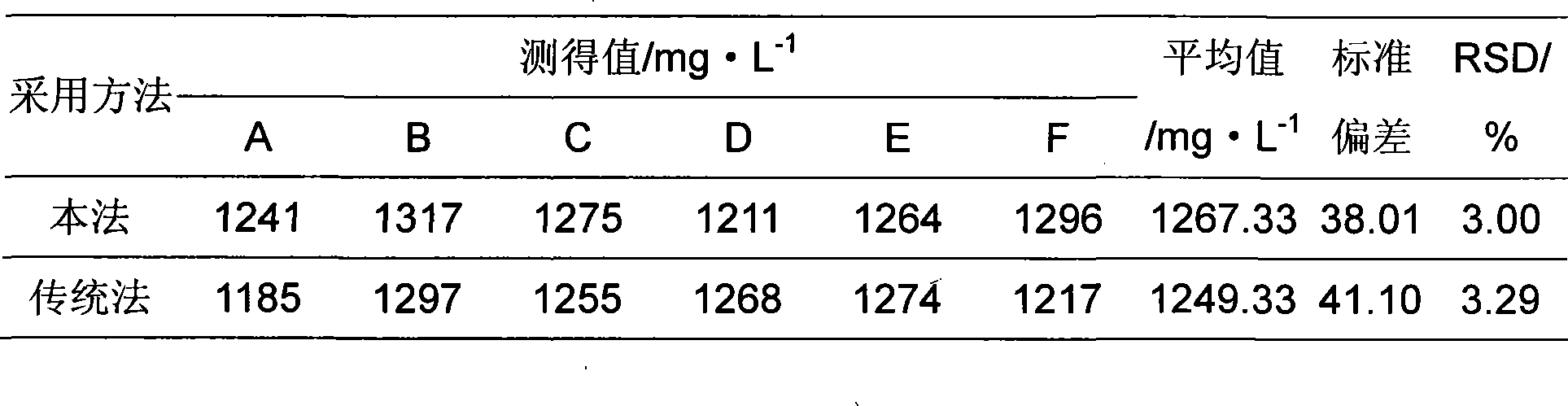

Rapid preprocessing method for measuring total phosphorus content in deposit

InactiveCN101251489AReduce energy consumptionEasy to carryMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPretreatment methodFiltration

The invention discloses a quick pretreatment method for measuring the total phosphorus content in sediments, belonging to the environmental monitoring technical field. The invention comprises the following steps: A. pretreatment of a soil sample: the soil sample is weighed, dried to the constant weight, taken out, cooled and grinded to over 60 meshes under drying conditions, weighed and then transferred into a slaking pipe; B. slaking pretreatment: distilled water and potassium persulphate solution are added and placed into a slaking hole of a COD slaking instrument, and simultaneously blank solution is taken and processed together with a sample to be detected with the same method; C. slaking; D. filtration: after slaking is finished, the sample in the slaking pipe is leached out by the distilled water, filtered to a container by a filter paper or a filter membrane, diluted, colored and finally measured and calculated according to the general spectrophotography. Compared with the prior pretreatment method, the quick pretreatment method for measuring the total phosphorus content in the sediments has the advantages of quick measurement, few equipment used, low energy consumption, simple experimental conditions, easy carryover of experimental equipment, suitability for on-scene monitoring, and safe experimental process.

Owner:NANJING UNIV

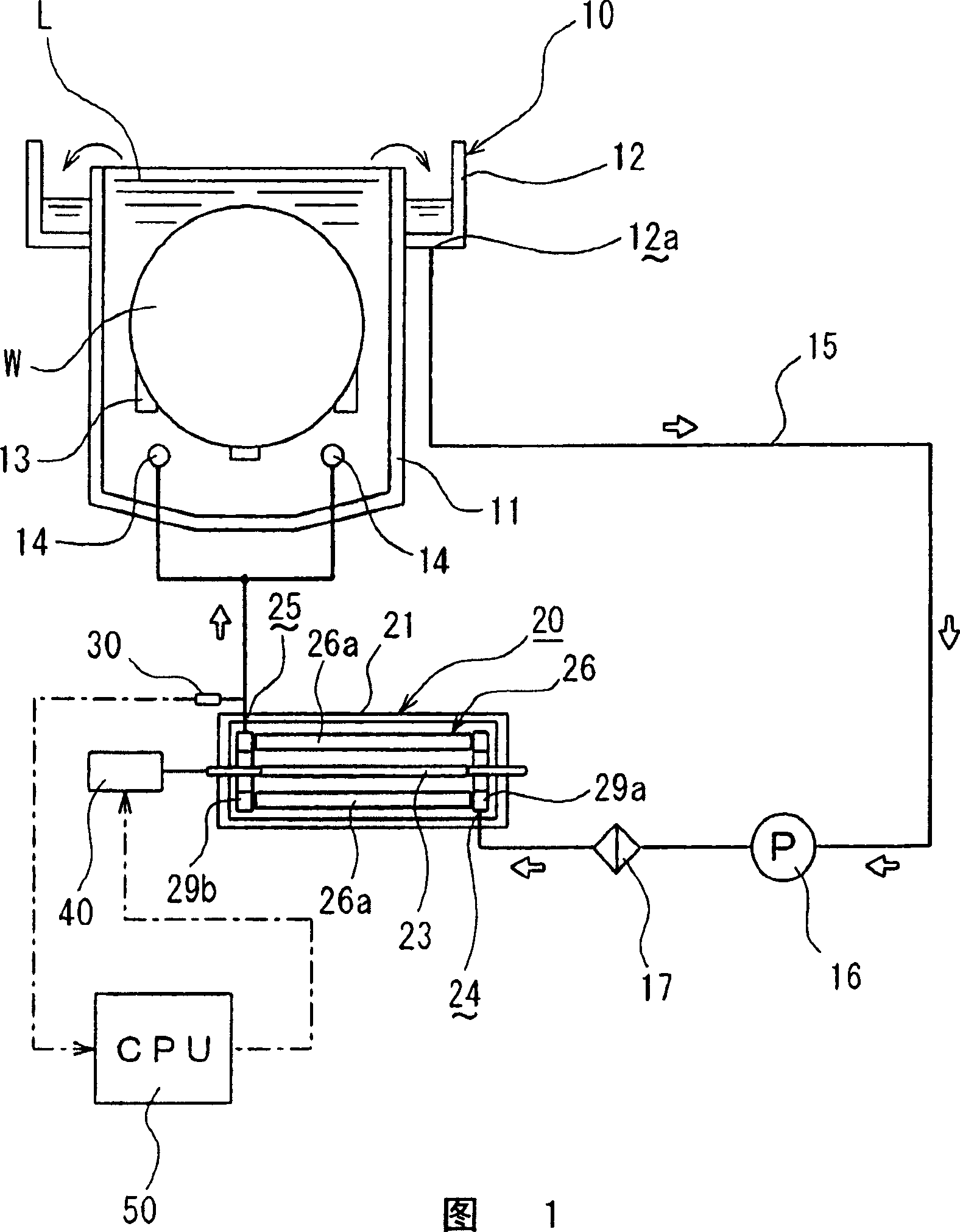

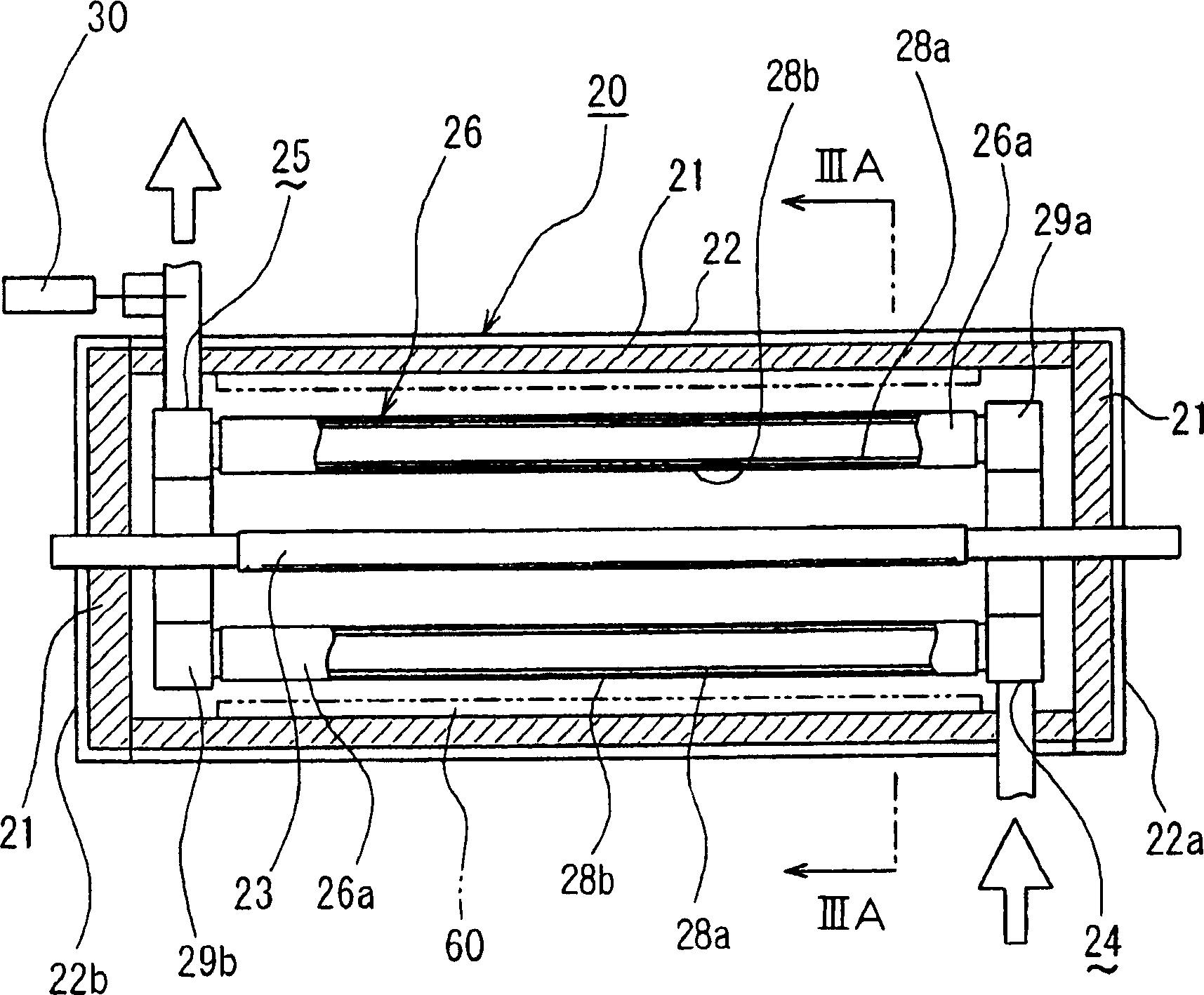

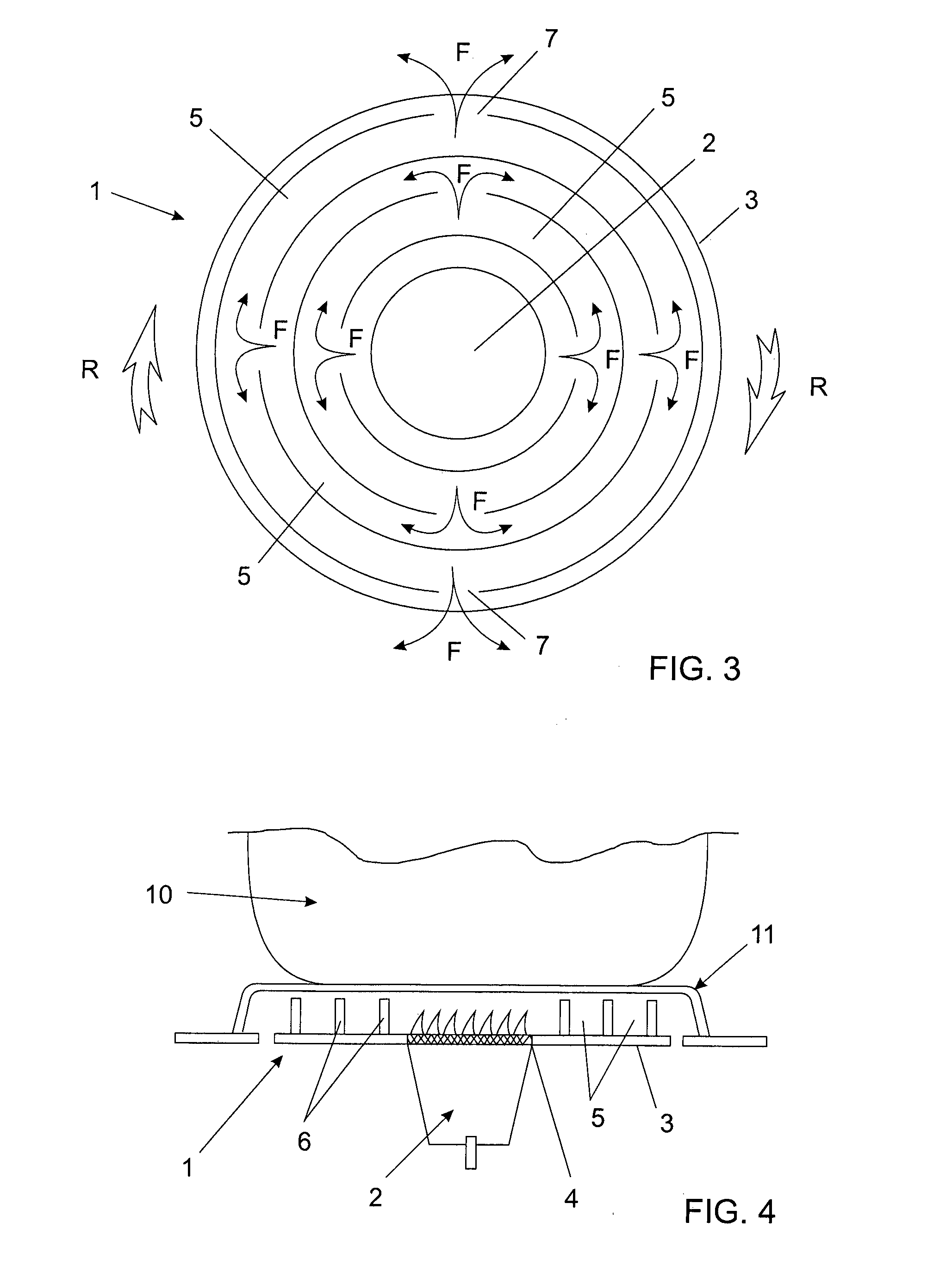

Load lock apparatus, processing system and substrate processing method

InactiveUS7624772B2Improve thermal conductivityEffective temperature controlLiquid fillingSemiconductor/solid-state device manufacturingTemperature controlProduct gas

A load lock apparatus including a carry port provided on a side of a carry-in / out section for carrying a substrate in / out from / to the outside, and a carry port provided on a side of a processing section for processing the substrate, includes: a temperature controlling plate for controlling a temperature of the substrate, the temperature controlling plate configured including a plate body made of a porous material and a temperature controlling gas supply path for supplying a temperature controlling gas controlled in temperature to the plate body. The temperature controlling gas passes through the plate body, blows out from a surface of the plate body, and is supplied to the substrate.

Owner:TOKYO ELECTRON LTD

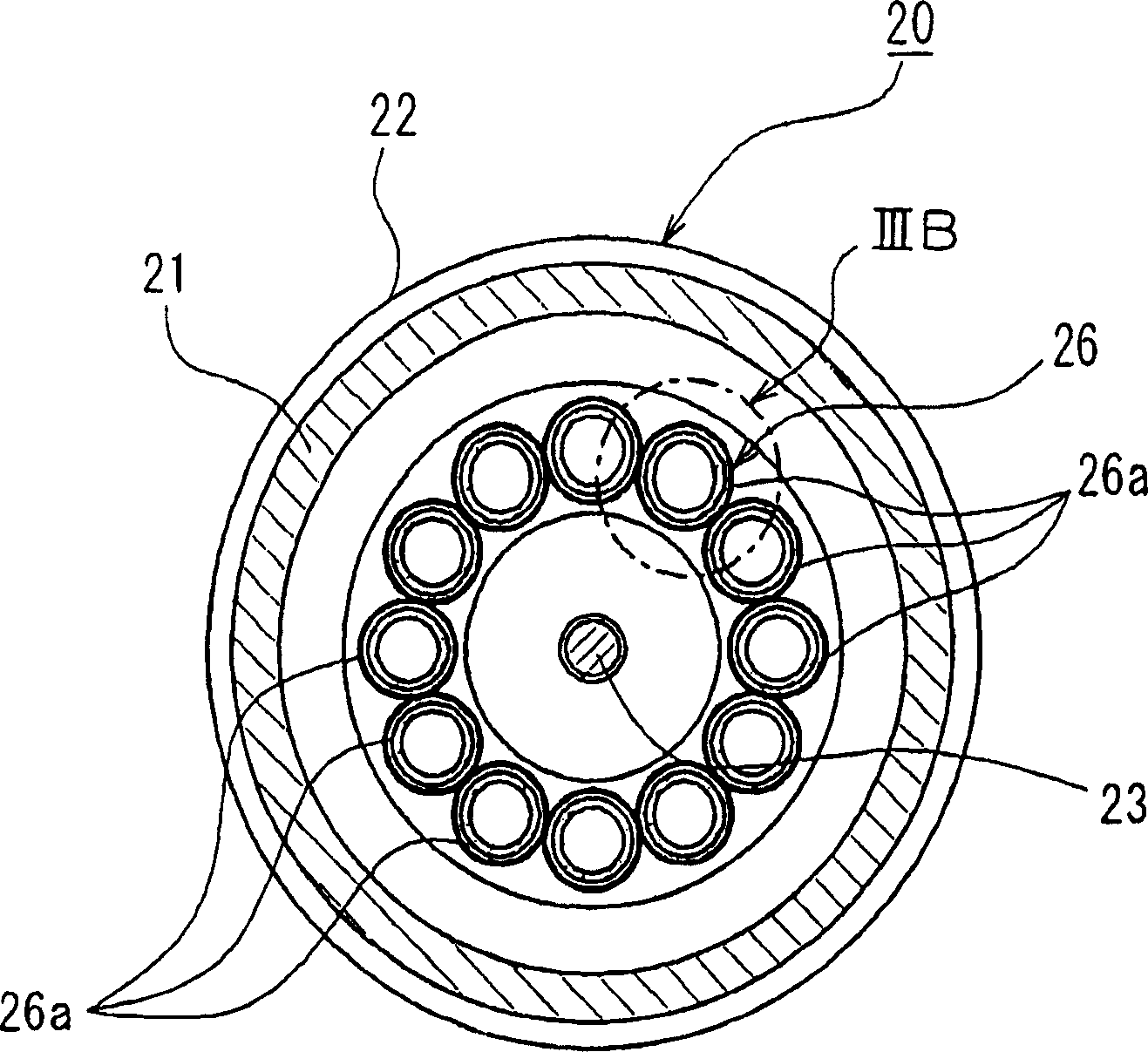

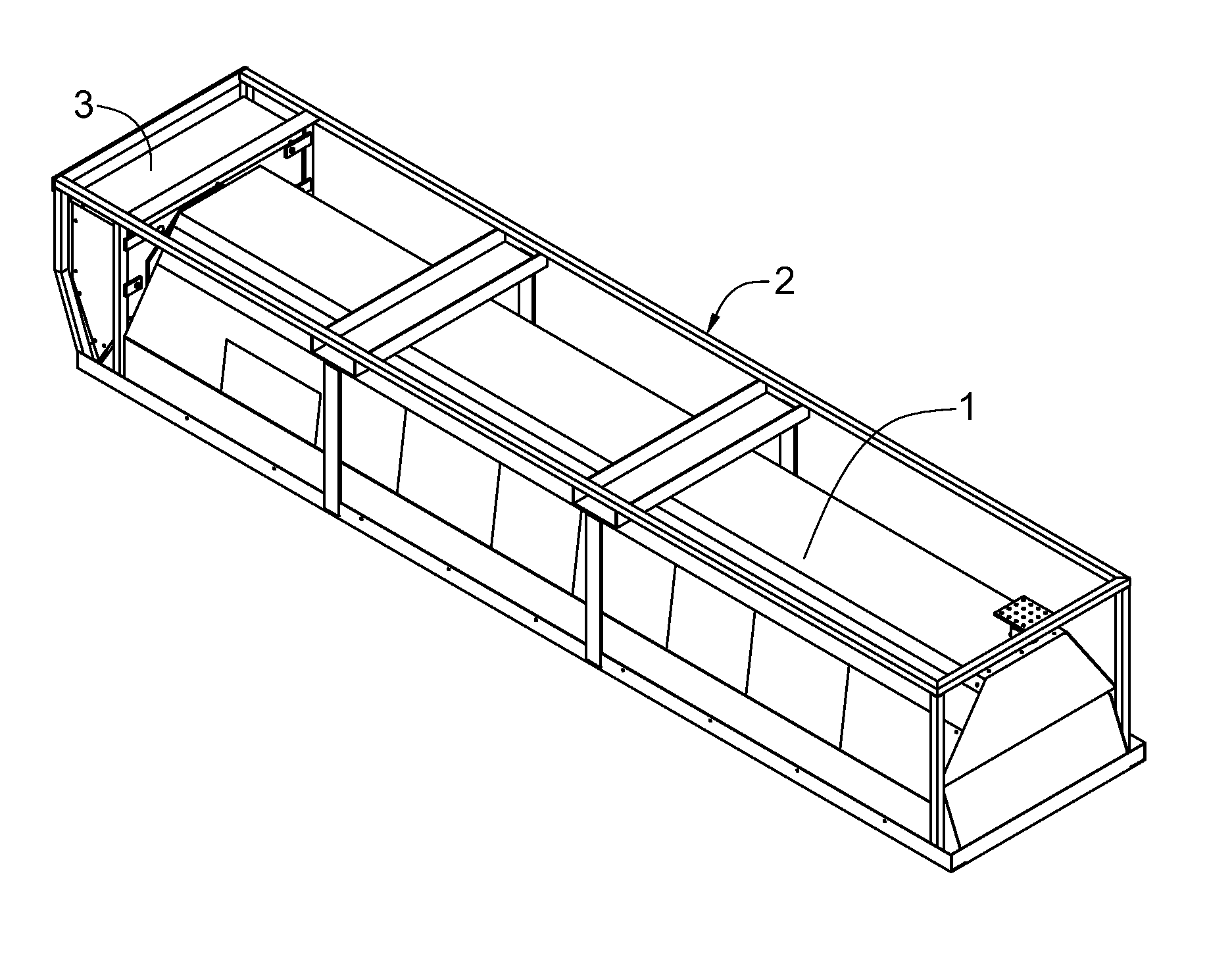

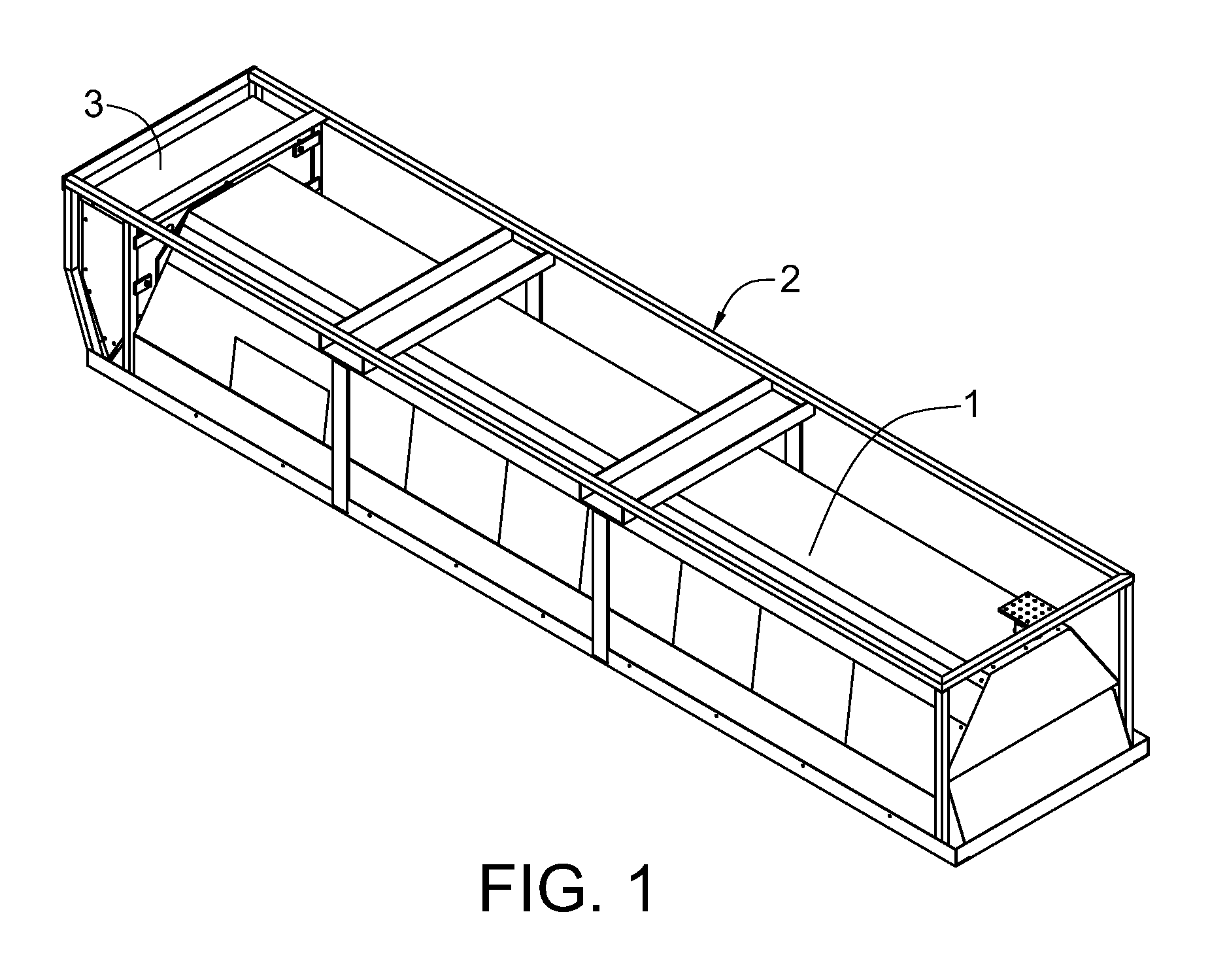

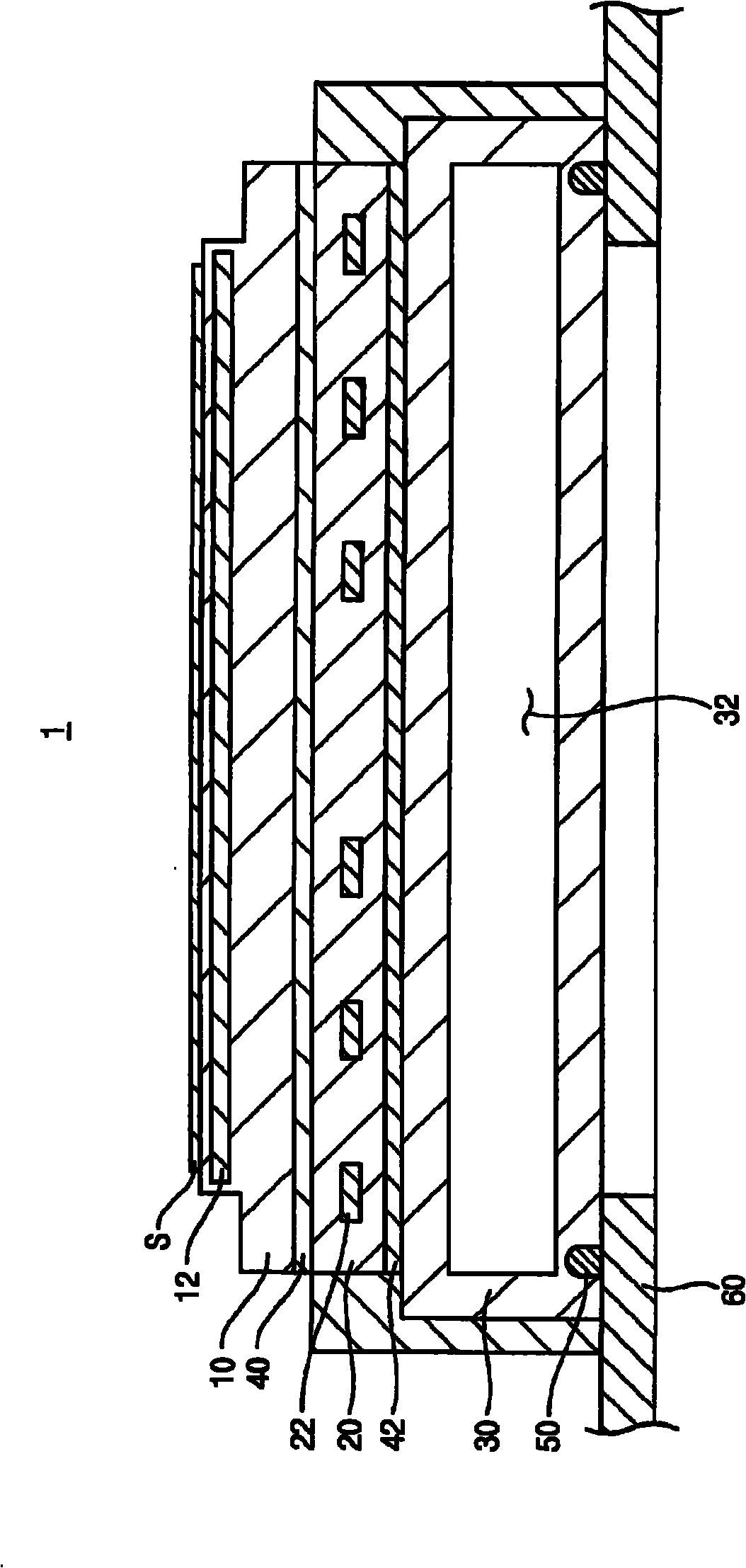

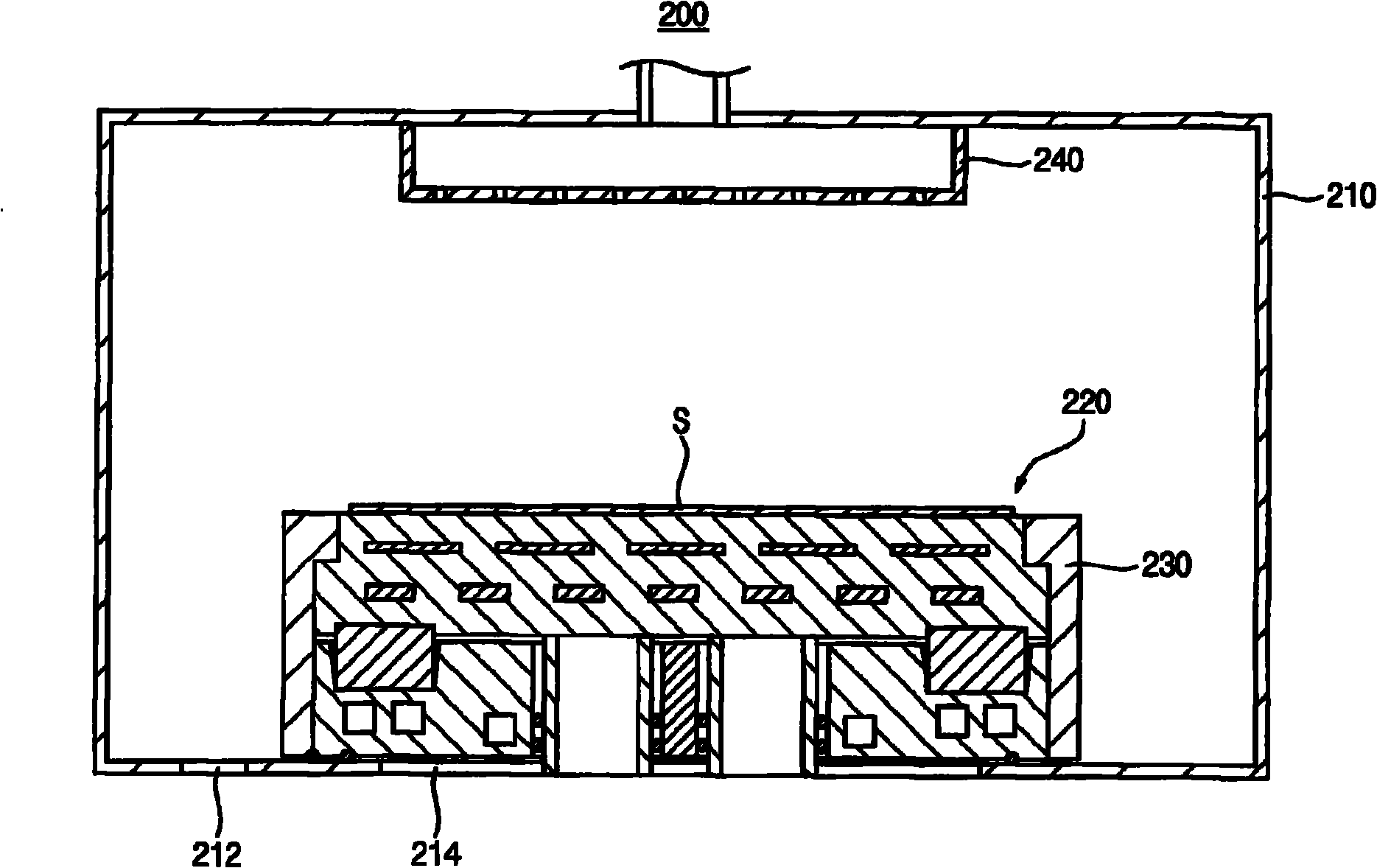

Flat spiral capillary column assembly with thermal modulator

InactiveUS7513936B2Low in thermal massHeating evenly and efficientlyComponent separationDispersed particle separationCapillary TubingCapillary column

The gas chromatography (GC) column assembly described herein consists of capillary GC column material, such as fused silica or metal capillary tubing, which is constrained to lie in a flat, ordered, spiral pattern and then encased between two thin opposing surfaces. The resulting column assembly is flat, dimensionally stable and can be very efficiently thermally modulated. The resulting column assembly also takes up very little space, has very little thermal mass, and can be easily and accurately manufactured. The column assembly can be adapted for chromatographic use by affixing it to the surface of a thermal modulator described herein by means of adhesive force or by mechanical compression, and then by attaching the free ends of the exposed column material to the input and output ports of the chromatographic device.

Owner:ROQUES NED J

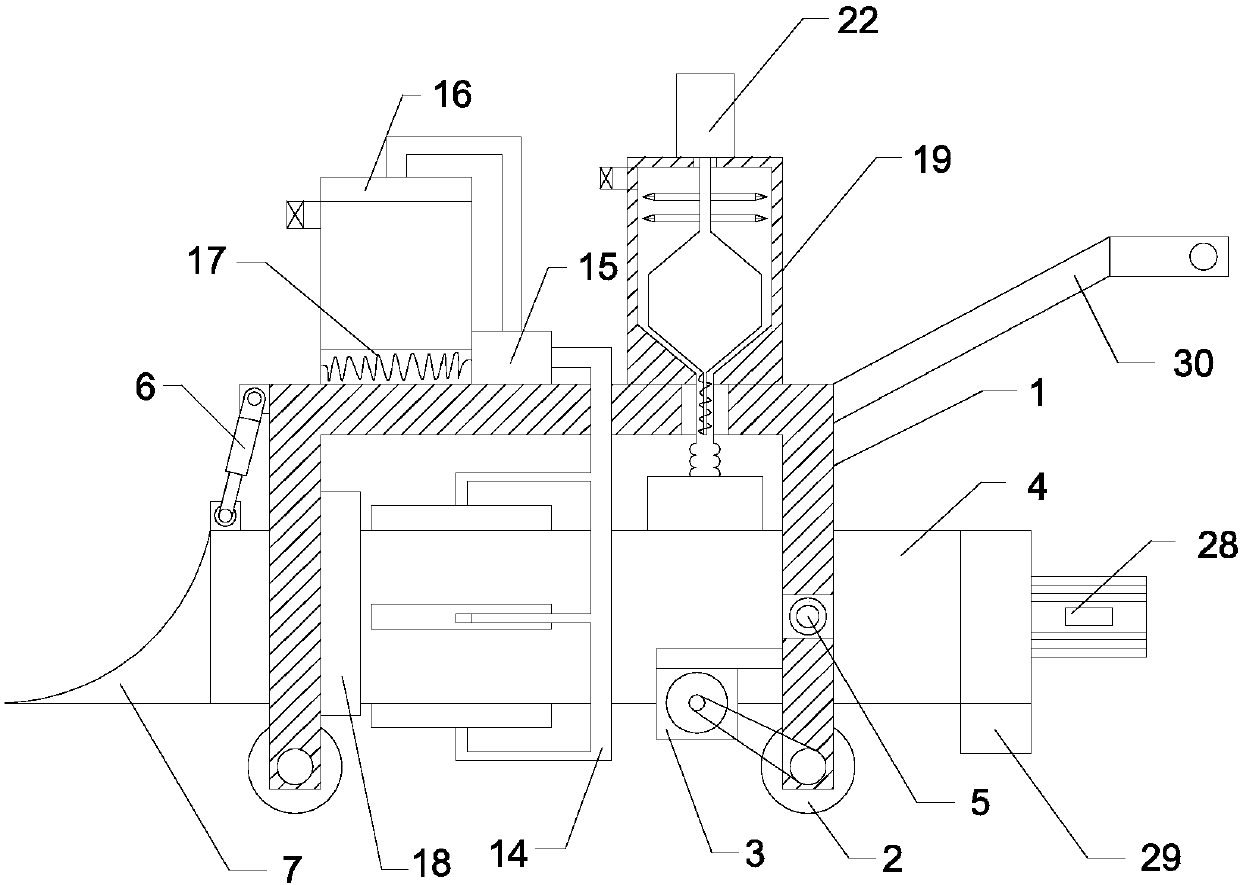

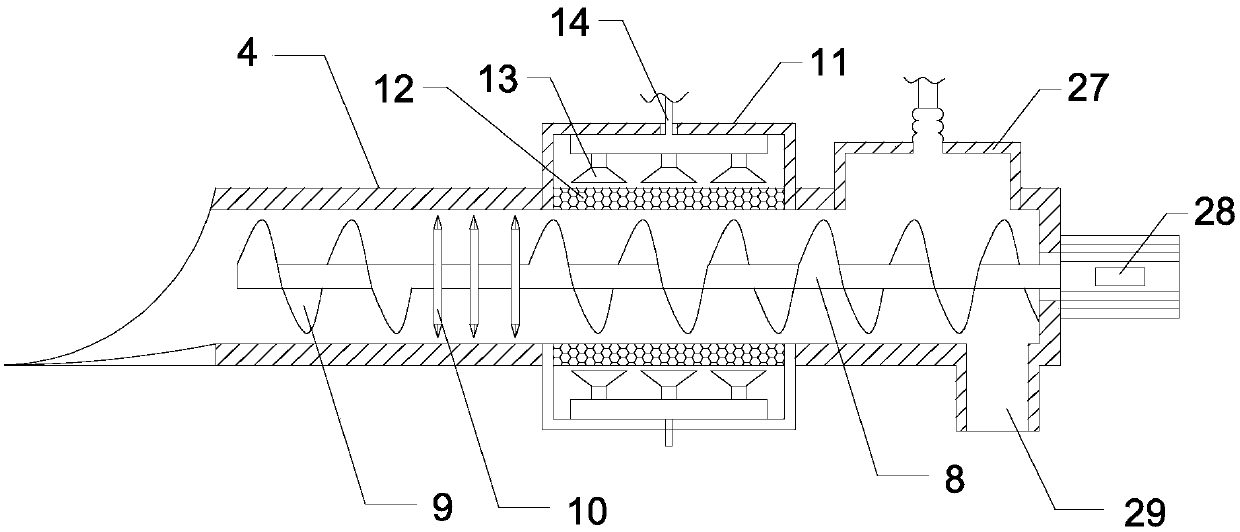

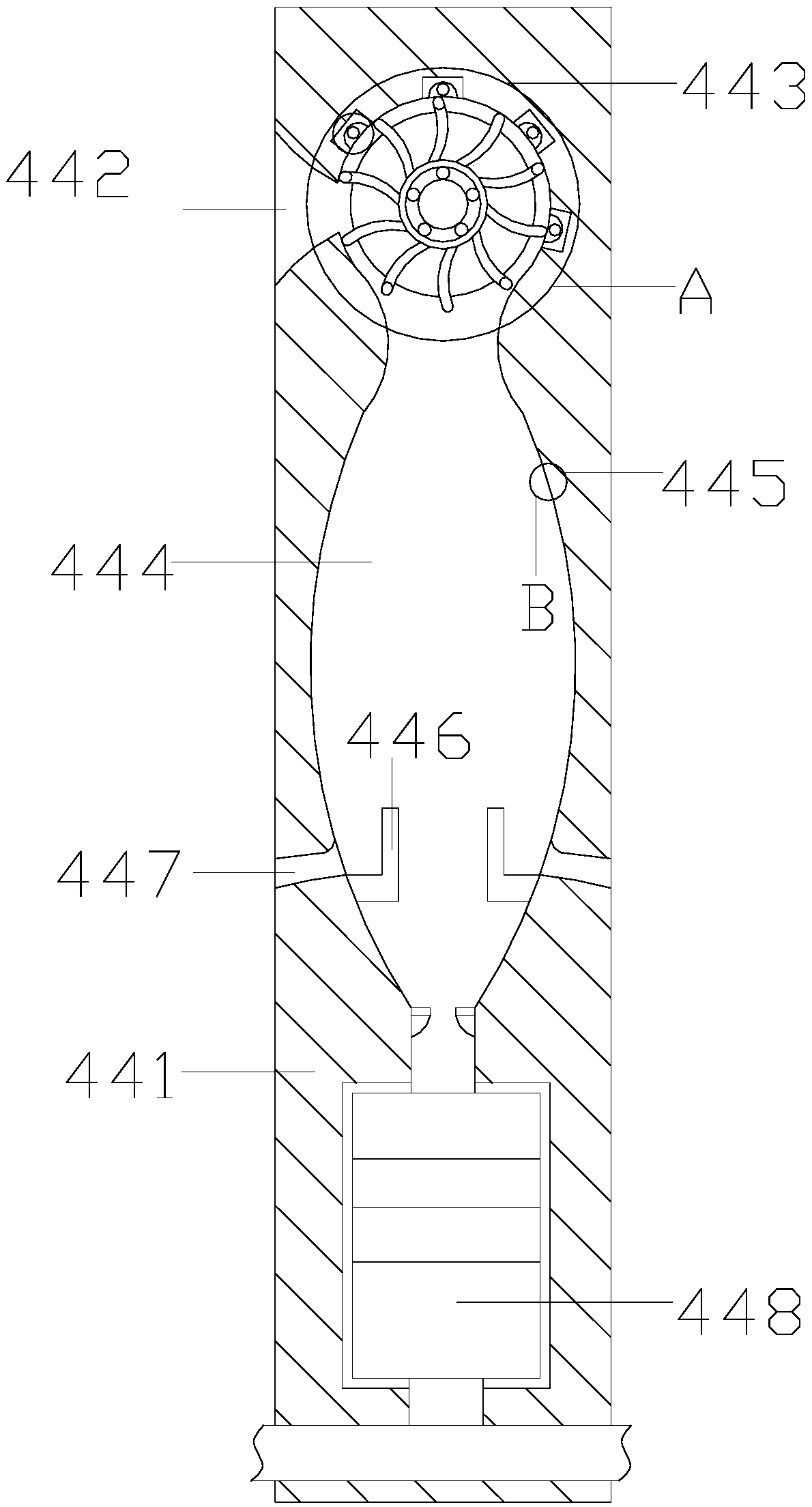

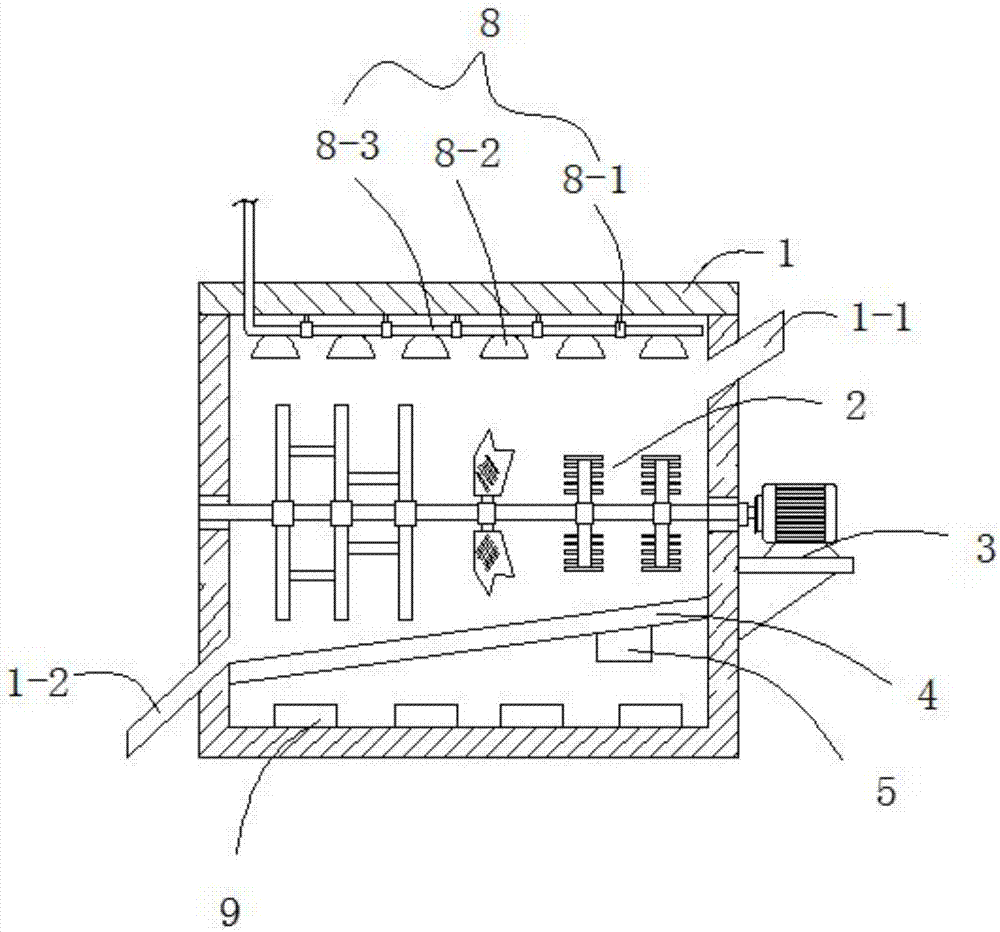

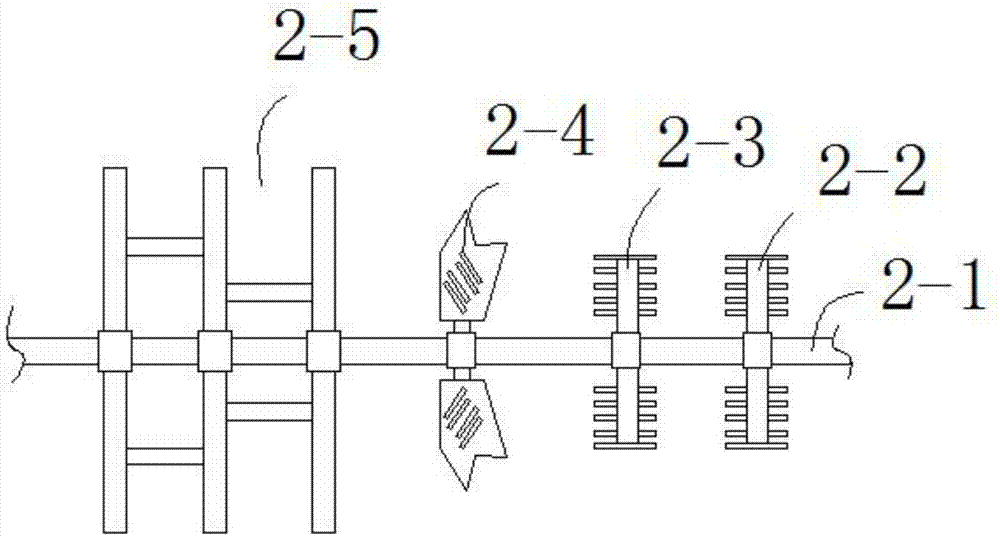

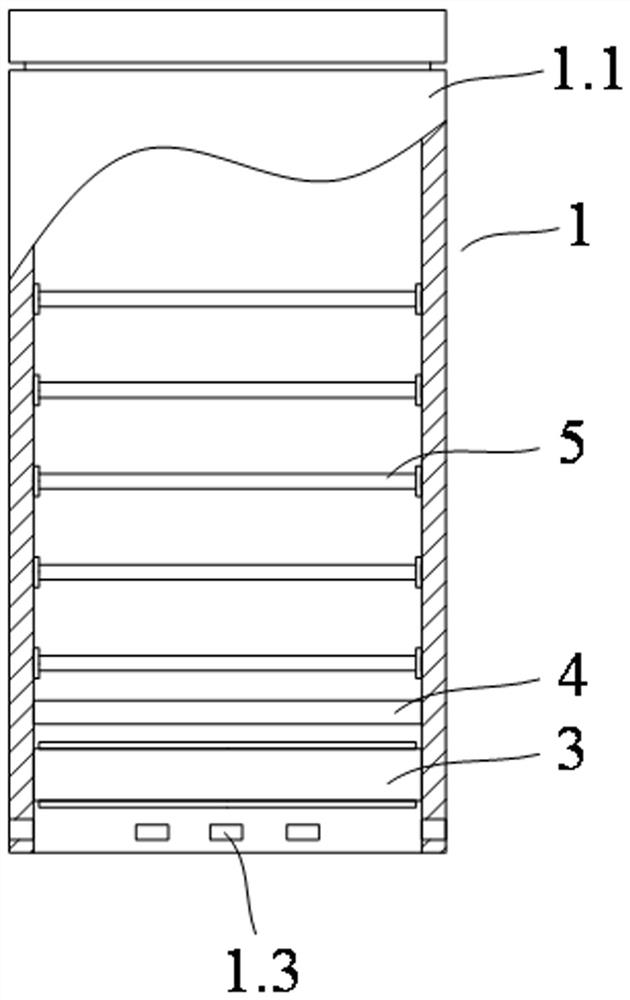

Efficient soil disinfection and fertilization device

InactiveCN107548592AHeating evenly and efficientlyImprove sterilization efficiencySpadesSteam soil sterilisationSpiral bladeAgricultural engineering

The invention discloses an efficient soil disinfection and fertilization device. The efficient soil disinfection and fertilization device comprises a frame, a rotating drum is arranged among the support legs of the frame, and the left of the rotating drum is fixedly connected with a shovel bucket; a first driving shaft is arranged inside the rotating drum and fixedly connected with first spiral blades. The efficient soil disinfection and fertilization device can dig out deep soil through the shovel bucket and the rotating drum, stir the soil through the spiral blades and crush clods through crushing blades; the efficient soil disinfection and fertilization device also comprises a steam generating device, which can generate steam and uniformly and efficiently heat the soil through circumferentially-distributed atomizing spray nozzles to greatly improve the soil disinfecting efficiency and effects; the crushing blades and a grinding barrel can crush fertilizer into powder and then the spiral blades can efficiently mix the powder fertilizer with the soil to improve the fertilizer application uniformity and effects, to save fertilizer and to improve the working efficiency.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

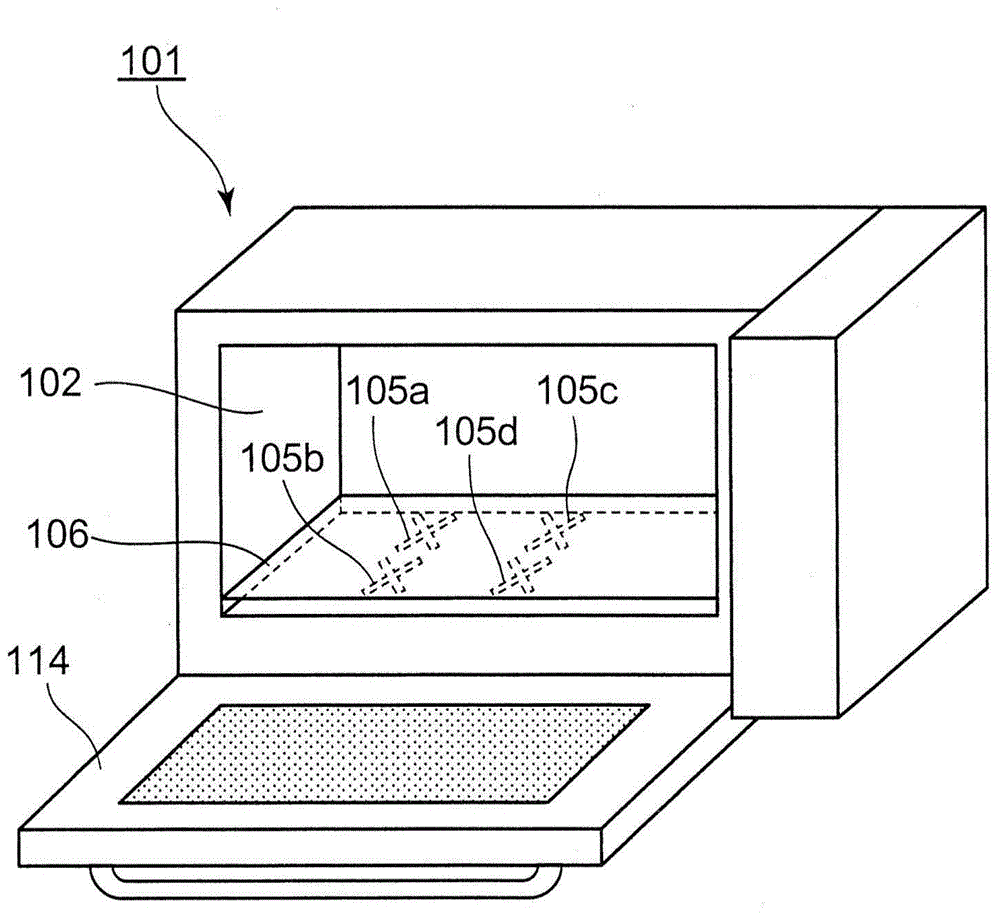

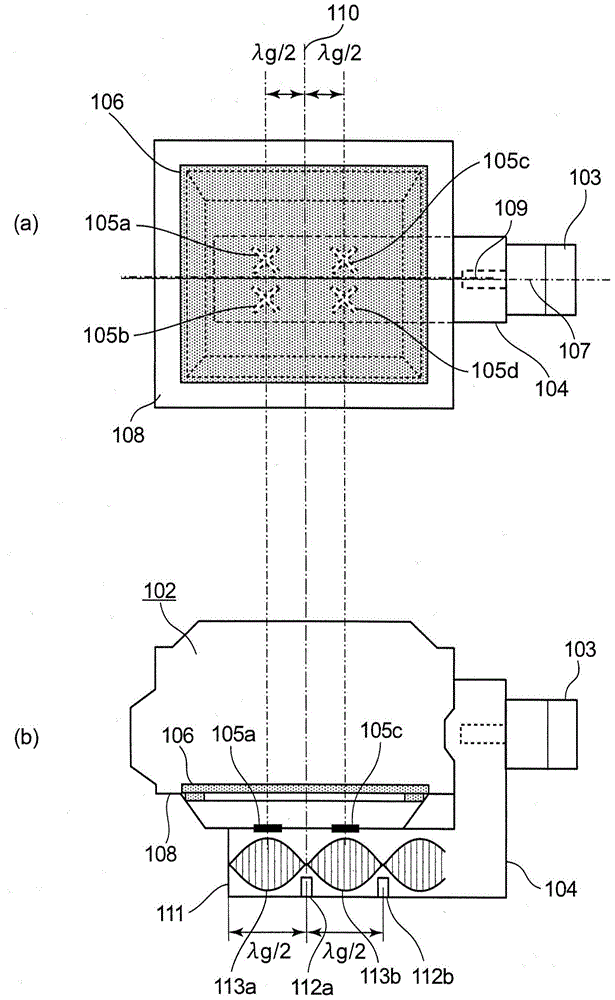

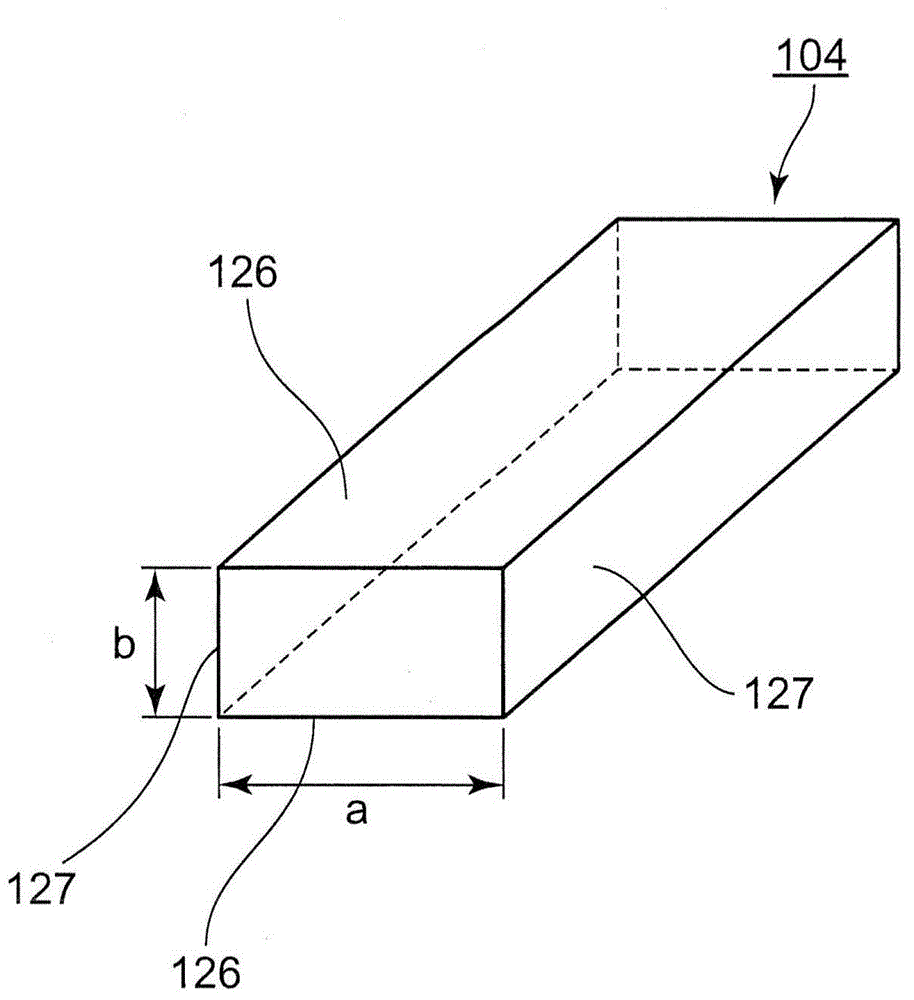

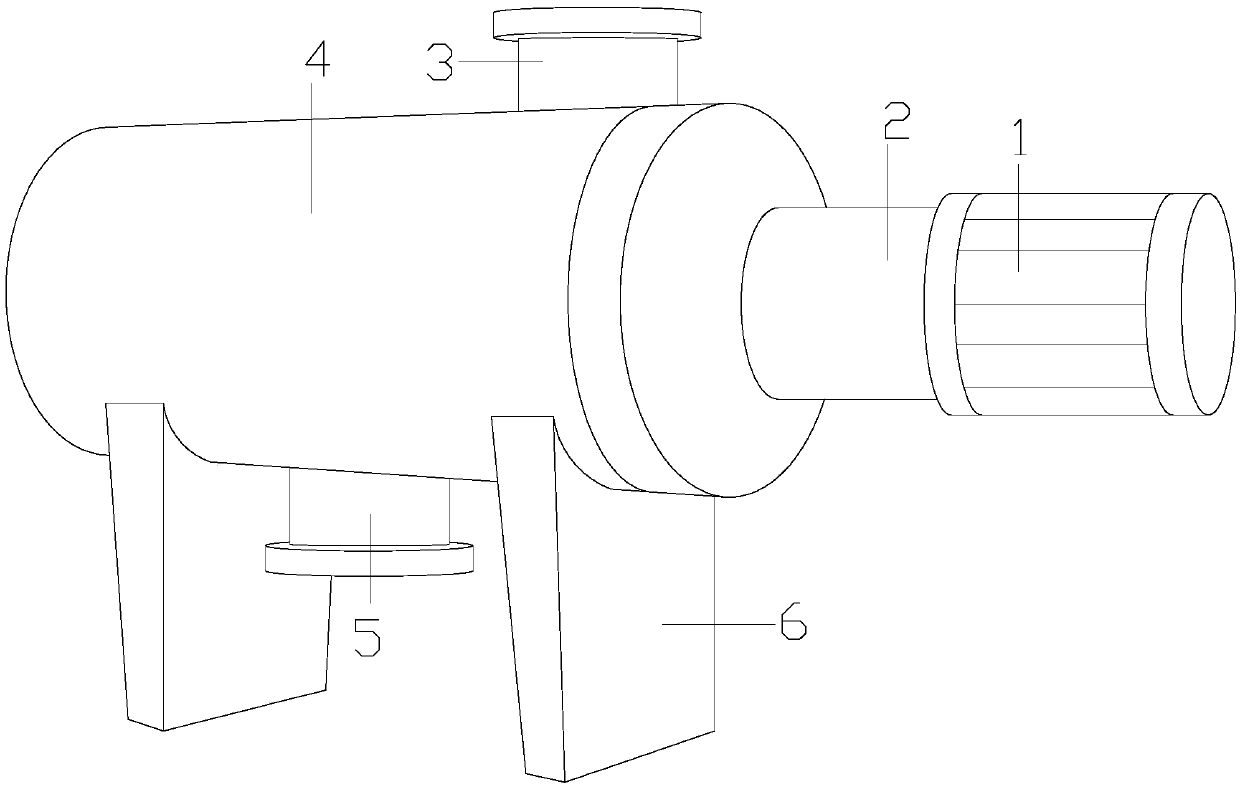

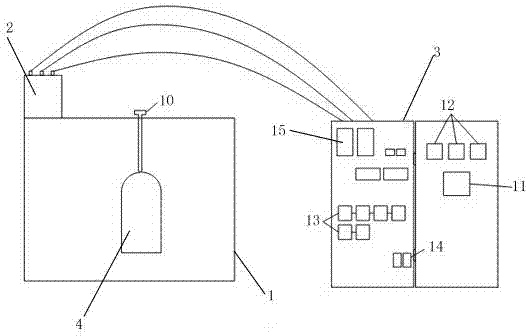

Microwave heating device

ActiveCN103916998AHeating evenly and efficientlySuppression of scorchingMicrowave heatingMicrowaveThermodynamics

The invention provides a microwave heating device which can uniformly and efficiently heat an object to be heated without using a driving mechanism and can suppress the bottom of the object to be heated from being scorched even though the object to be heated in a small shape. The microwave heating device includes a heating chamber (102) for receiving the object to be heated, a microwave generation part (103) for generating microwaves, a wave guide pipe (104) for transmitting microwaves, a plurality of microwave radiation parts (105a, 105b, 105c, 105d) for radiating microwaves into the heating chamber (102) from the wave guide pipe (104), standing waves are generated in the heating chamber (102), and the center (144) of the bottom (108) of the heating chamber (102) carrying the object to be heated generates a part between the antinode and the node of the standing waves.

Owner:PANASONIC CORP

Anti-icing apparatus and system

InactiveUS9815558B2Ensure efficiency and effectivenessHeating evenly and efficientlyAircraft power plant componentsDe-icing equipmentsWorking fluidEngineering

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

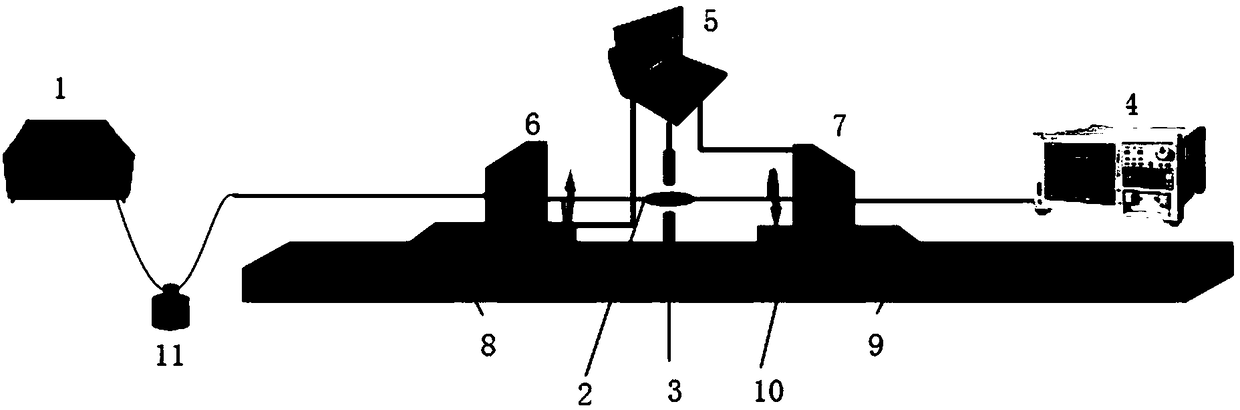

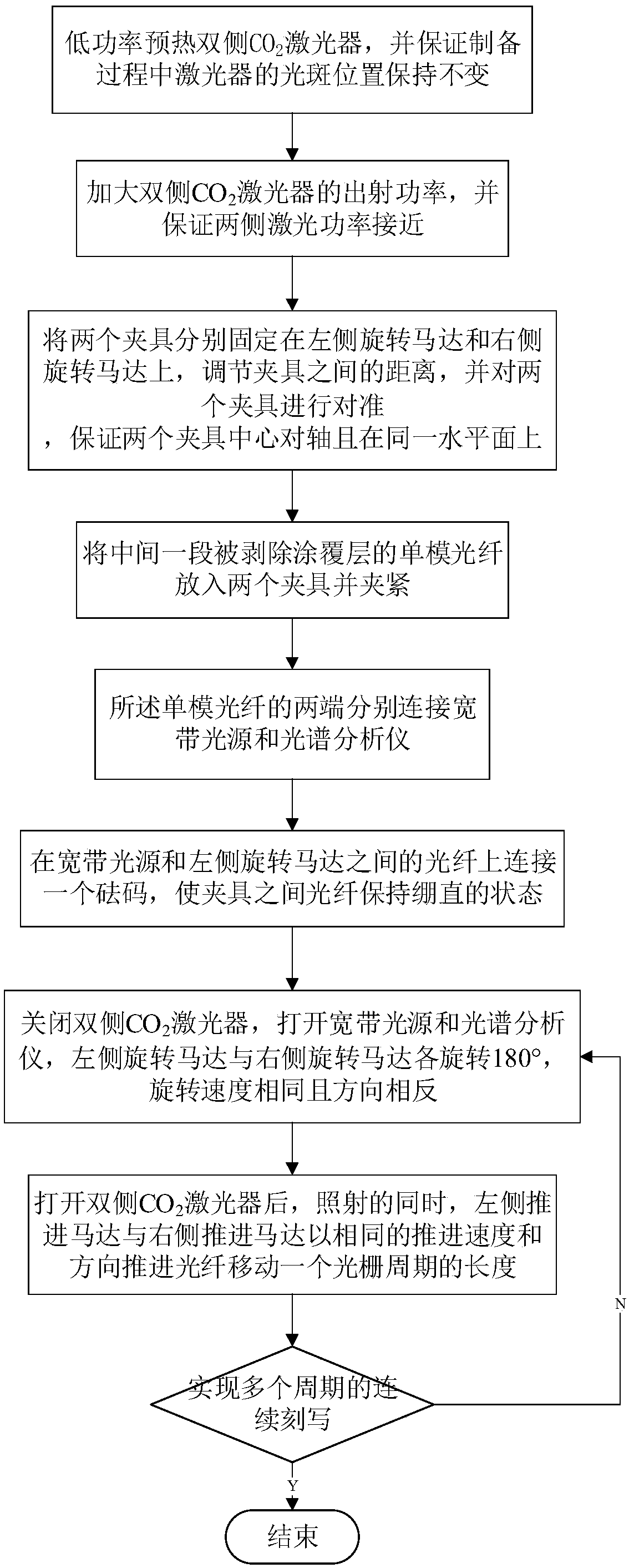

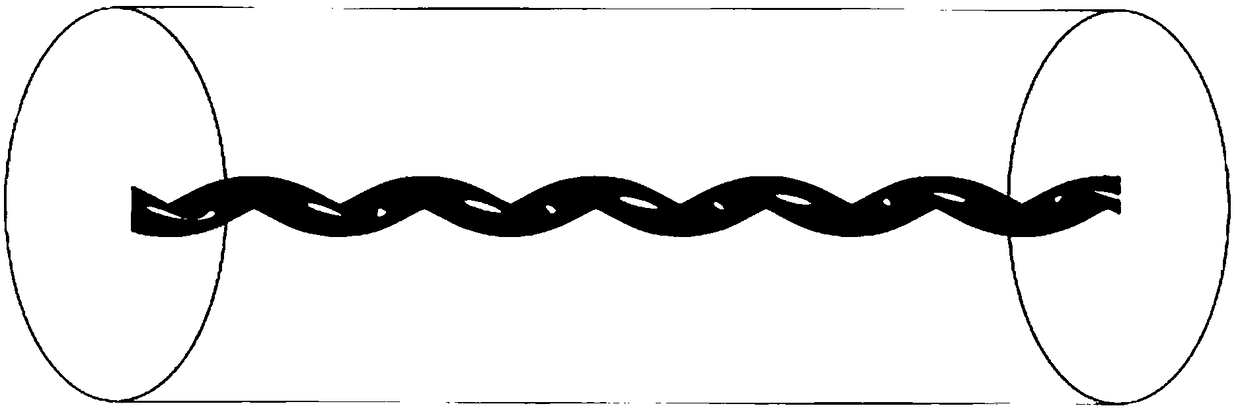

Preparation method for writing in spiral long-period fiber Bragg grating based on bilateral CO2 laser

InactiveCN109471216AHeating evenly and efficientlyCladded optical fibreOptical waveguide light guideGratingLong-period fiber grating

The invention discloses a preparation method for writing in a spiral long-period fiber Bragg grating based on a bilateral CO2 laser. By adopting the bilateral CO2 laser, emitting laser can be perpendicularly irradiated to the region where a coating layer is removed from single mode fiber from the two sides, and CO2 laser beams are formed in two directions by a certain angle and emitted into the optical fiber with no overlapping. The two laser beams meet at the two sides of the optical fiber, a large-angle wrapping hot field is formed, and the uniform and effective optical fiber heating processcan be achieved. Torsion and irradiation boosting are separated, the CO2 laser freezes the mechanically-introduced torsion into the optical fiber, the periodic refractive index is introduced for modulation, the special long-period fiber Bragg grating is formed, and the technical problems that when laser heating and screwing are performed at the same time, due to the fact that the optical fiber issubjected to motor torsion and laser impact force at the same time, the optical fiber is likely to deform, the stepped structure is formed, and consumption is increased are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

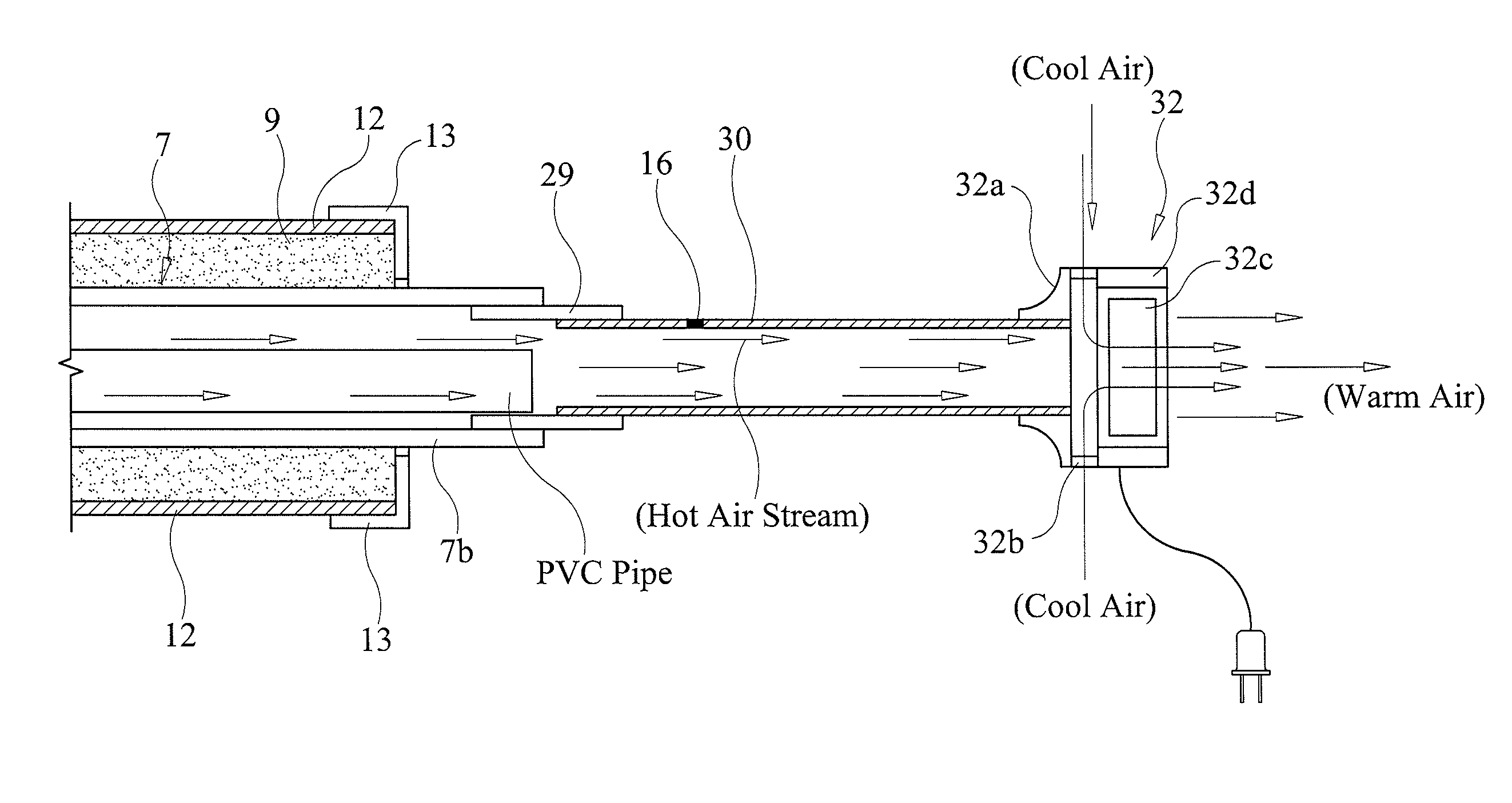

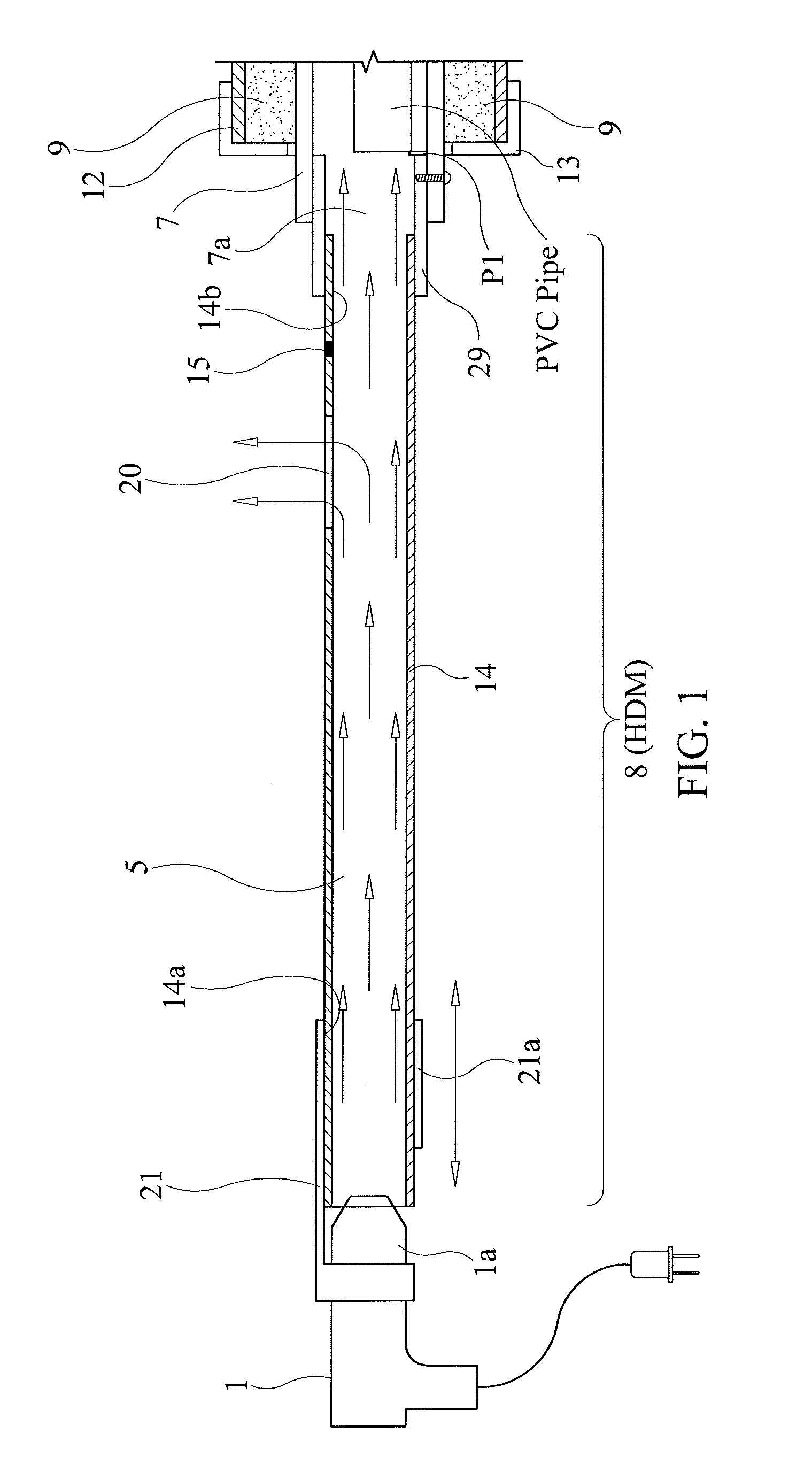

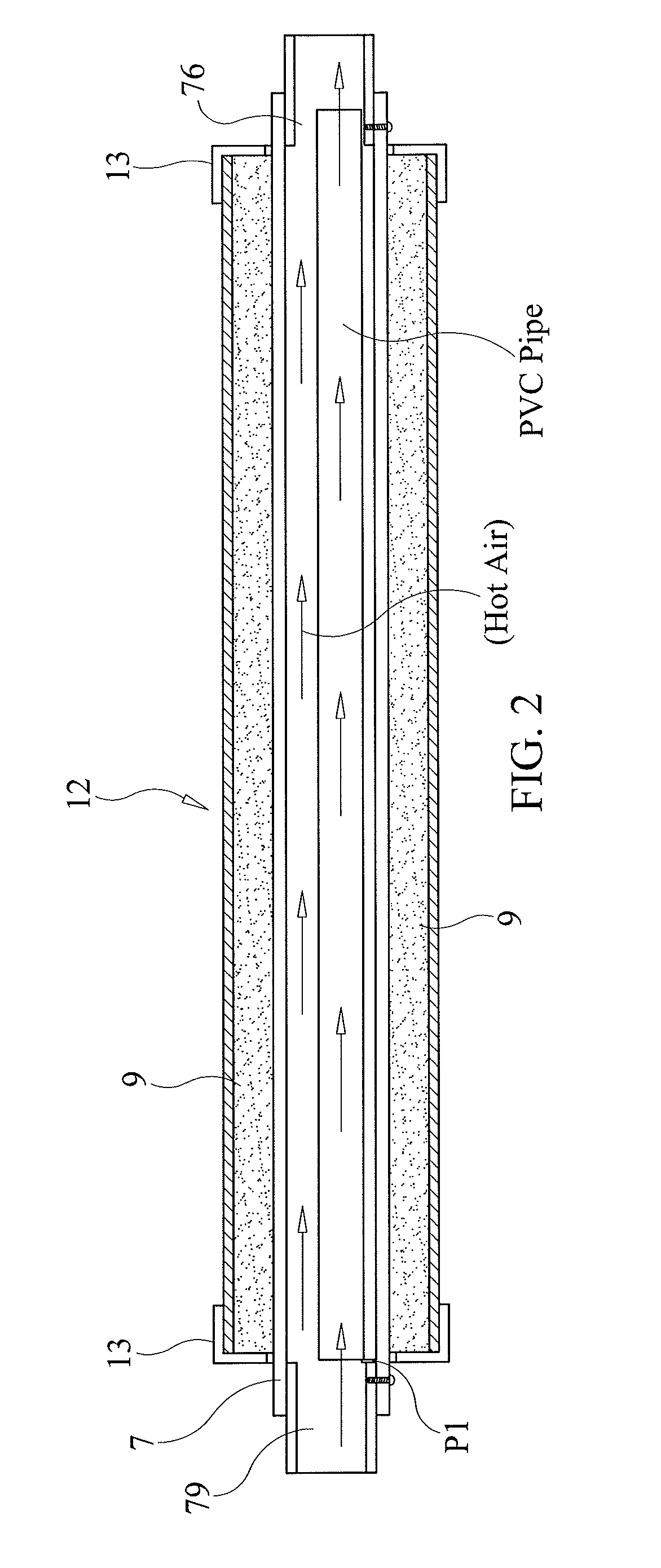

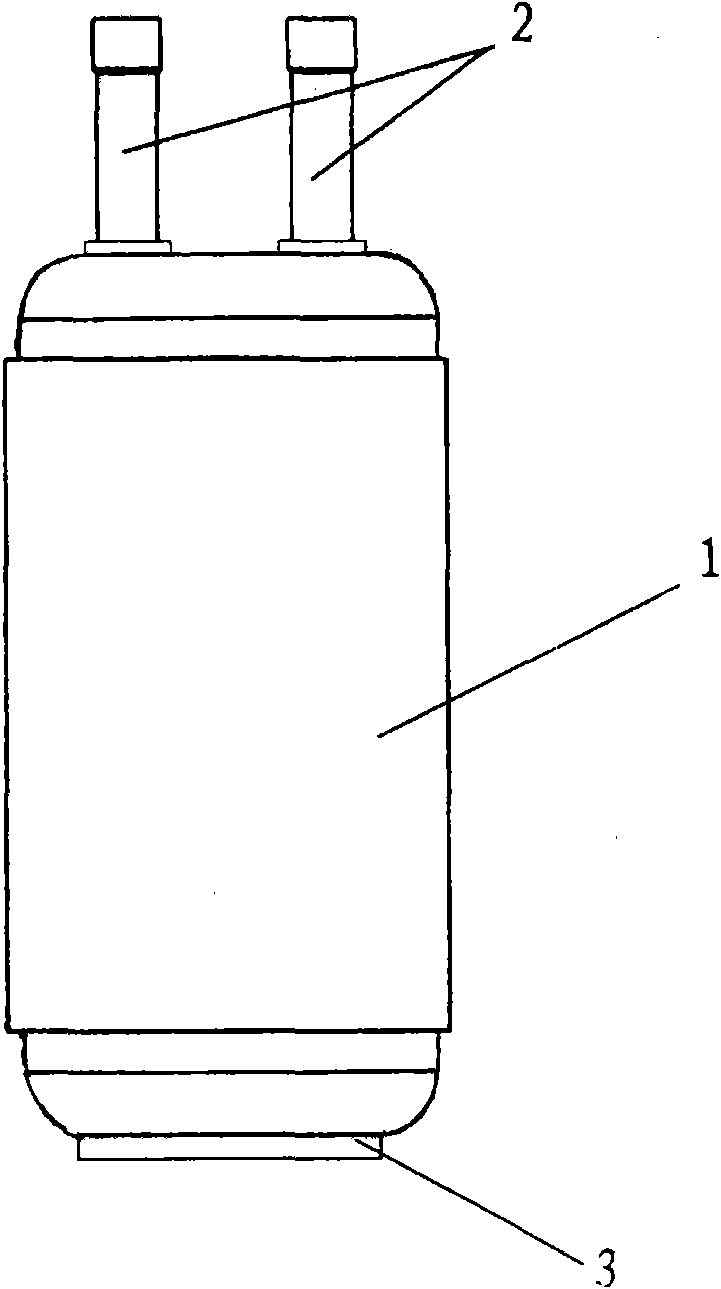

Portable heater device for bending plastic pipe

ActiveUS9146042B1Little waste of energyInexpensive to manufactureAir heatersCooking vesselsEngineeringMechanical components

Owner:KUROSU ALAN

Manufacturing clamp for induction electric heater of liquid collection tank of gas-liquid separator

InactiveCN101644513AHeating evenly and efficientlyIncrease contact areaSteam generationRefrigeration componentsElectricityElectrical resistance and conductance

The invention relates to a manufacturing clamp for induction electric heater, which consists of a cylindrical internal cylinder and curved surface shells. Two pieces of symmetrical curved surface shells are fixed on the outer side of the internal cylinder by a metal threaded rod, and arc-shaped gaps are reserved between the internal cylinder and the curved surface shells. A winding core of the electric heater is formed by winding a resistance wire in the gaps between the internal cylinder and the curved surface shells along the outer wall of the internal cylinder, and the wall of the internalcylinder is provided with four symmetrical threading holes used for selecting the starting position of winding the resistance wire randomly. A locking piece arranged outside the curved surface shellscan rotate at the end of the metal threaded rod, and the locking piece is rotated to separate the curved surface shells from the metal threaded, and to take the manufactured induction electric heaterdown. The induction electric heater consists of double-cambered-surface winding cores of the electric heater, is fixed on the outer side of a liquid collection tank through a clamp, and is suitable for the liquid collection tanks of all gas-liquid separators; besides, by enlarging the contact area of the electric heater and the liquid collection tank, the electric heater heats the gas-liquid separators more evenly and effectively; moreover, the electric heater is very convenient to mount, maintain and replace, and the reliability of an air container is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

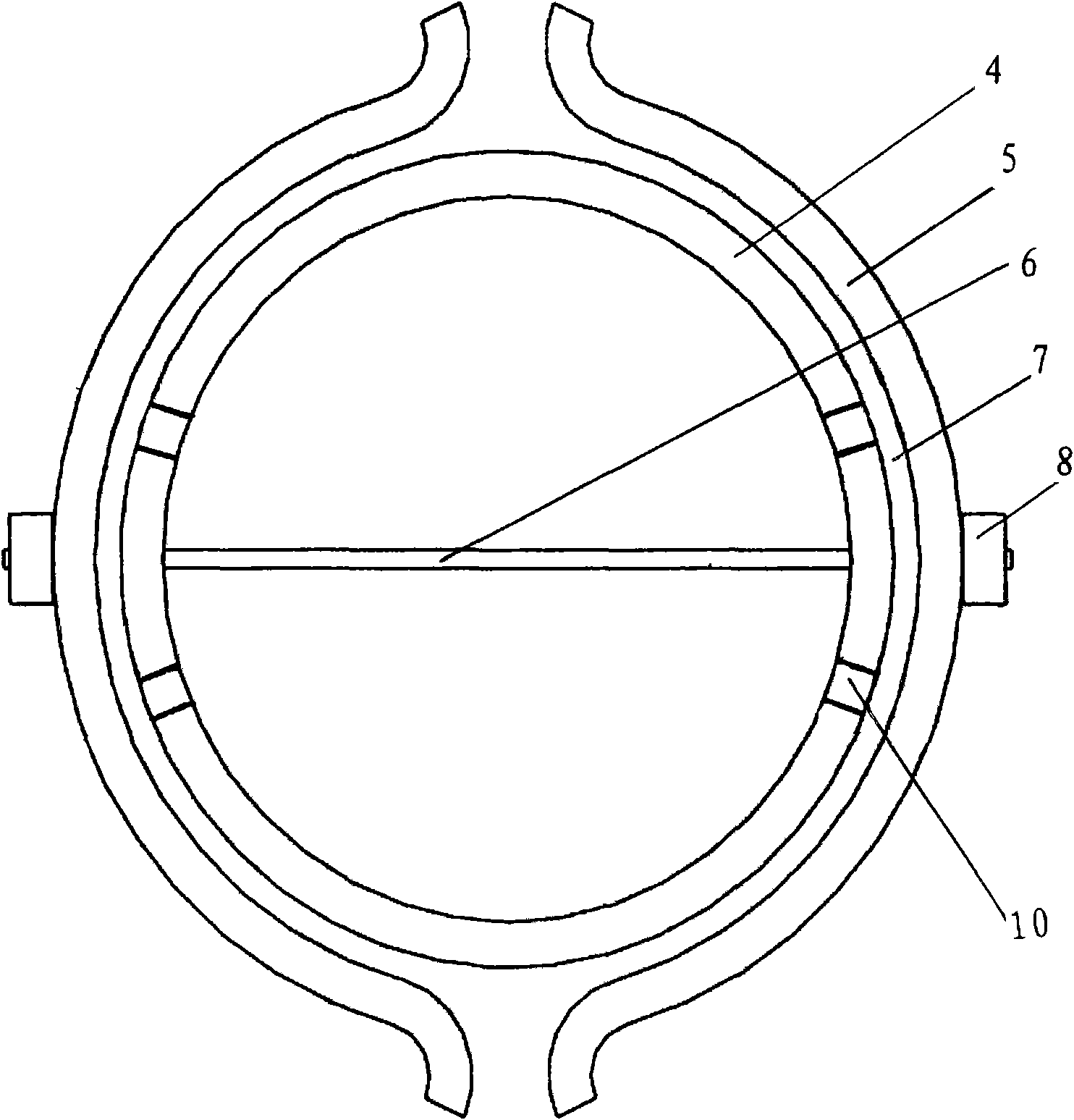

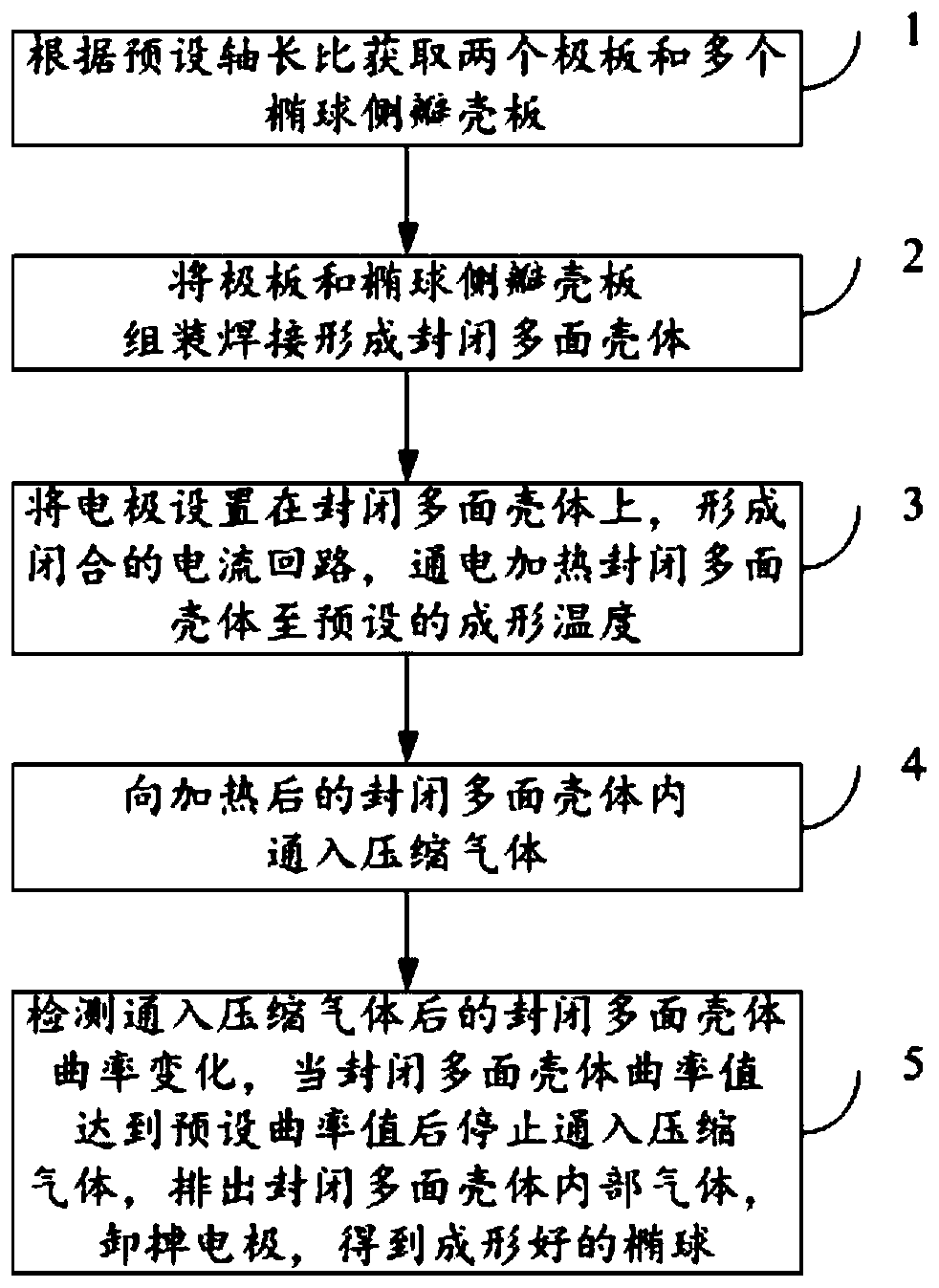

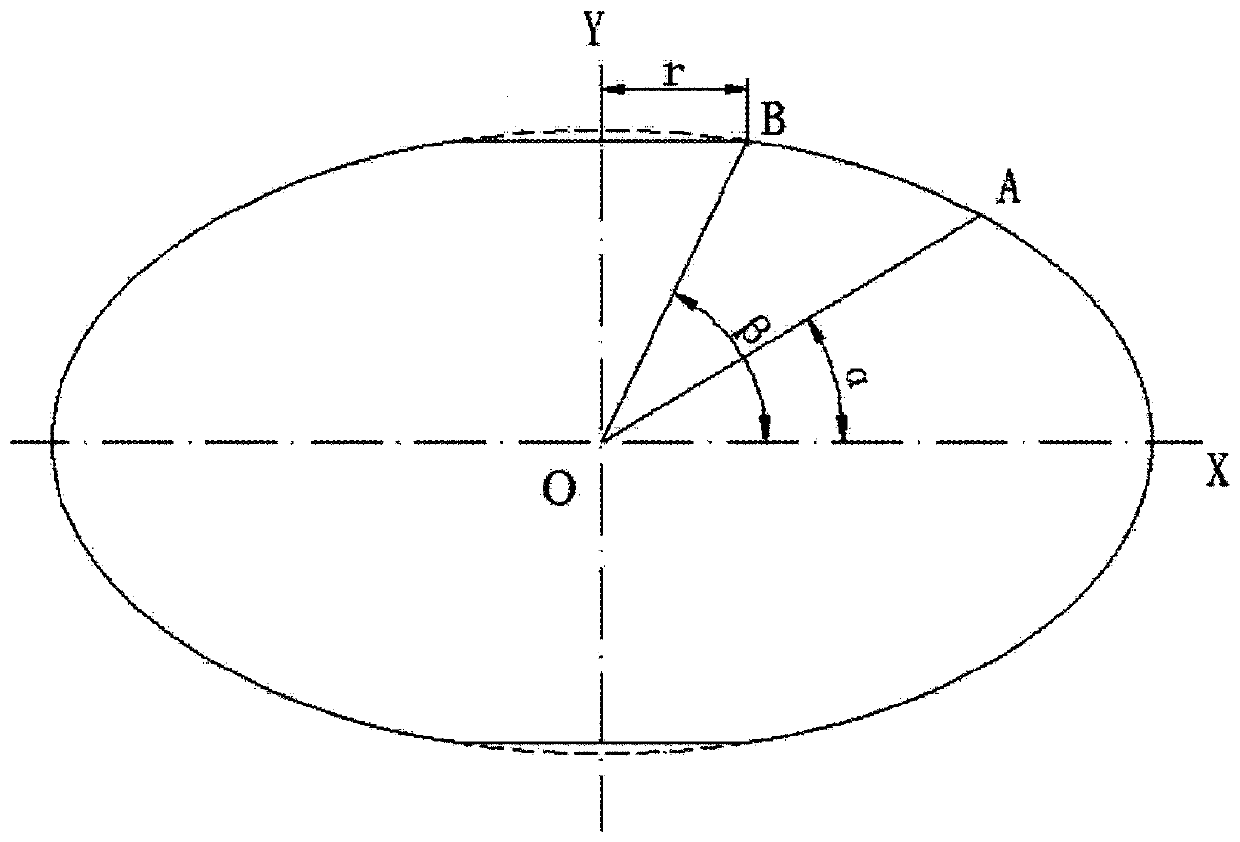

Ellipsoid air pressure forming method based on electric current self-resistance heating

ActiveCN109909395AReduce manufacturing costReduce technical riskArc welding apparatusWelding/soldering/cutting articlesPlastic propertyEllipsoid

The invention discloses an ellipsoid air pressure forming method. The plasticity of an aluminum alloy and a welded joint is improved through an electric current self-resistance heating shell, and compressed gas is used for pressurizing the sealed multi-face shell to form an ellipsoid under the heating condition. In specific, two polar plates and ellipsoid side lobe shell plates are assembled and welded to form the closed multi-face shell; electrodes are arranged on the closed multi-faceted shell, energizing and heating to a preset temperature, and introducing a compressed gas into the shell; the closed multi-face shell, electrification is carried out for heating to the preset temperature, and then the compressed gas is led into the shell; and the closed multi-face shell deforms under the action of internal gas pressure, leading of the gas is stopped until the shell with the desired curvature is obtained, the gas is discharged, the electrodes are removed, and the formed ellipsoid is obtained. According to the ellipsoid air pressure forming method, an electric current self-resistance heating manner is adopted, a large-sized heating furnace is prevented from being used, and the manufacturing cost and the technical risk of the large-diameter ellipsoid are greatly reduced; and an aluminum alloy base material and the welded joint are subjected to air pressure bulging under the heating state, the forming property is remarkably improved, and the problem of cracking of a welded zone during normal temperature forming of the large-diameter aluminum alloy ellipsoid is solved.

Owner:DALIAN UNIV OF TECH

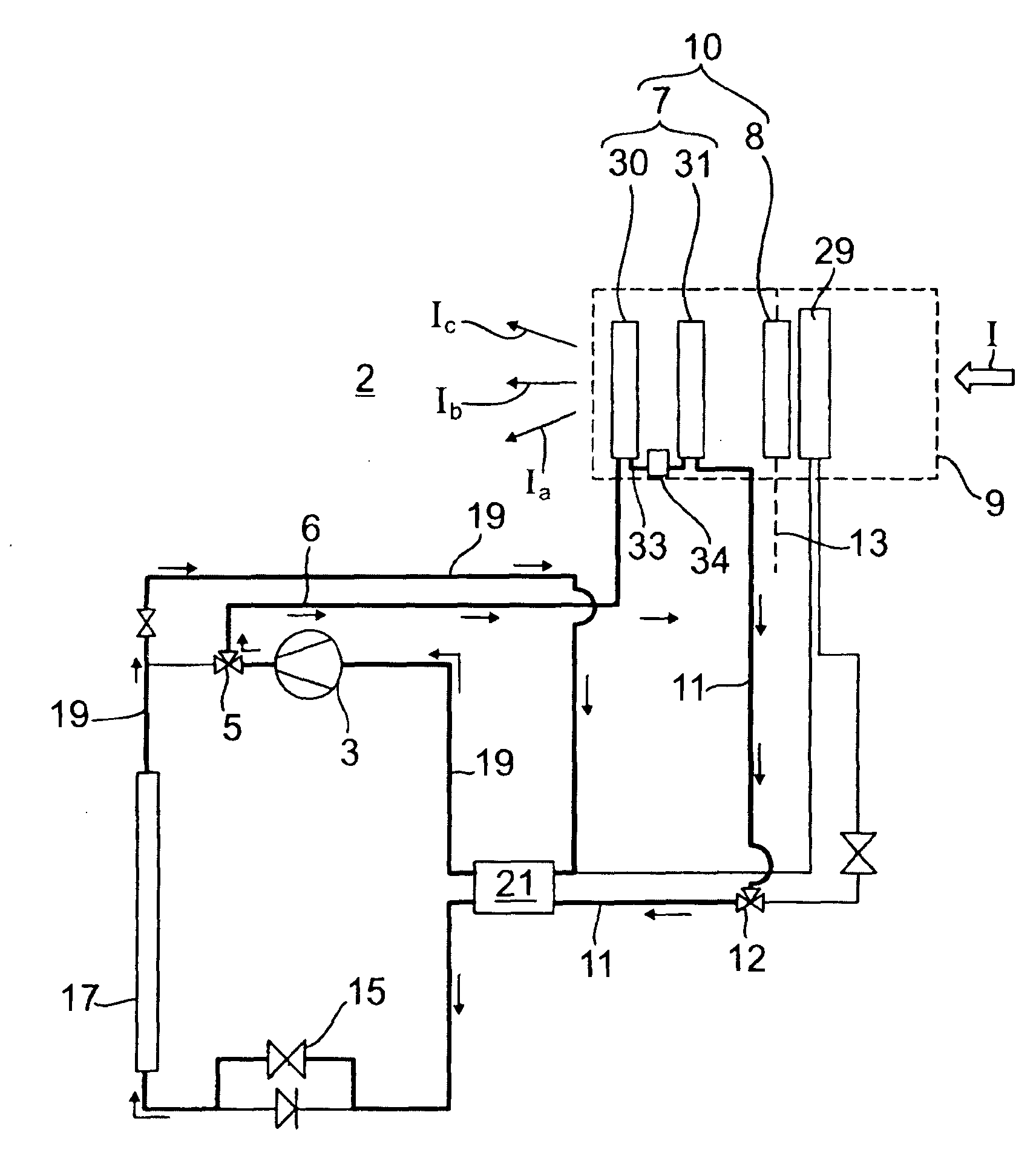

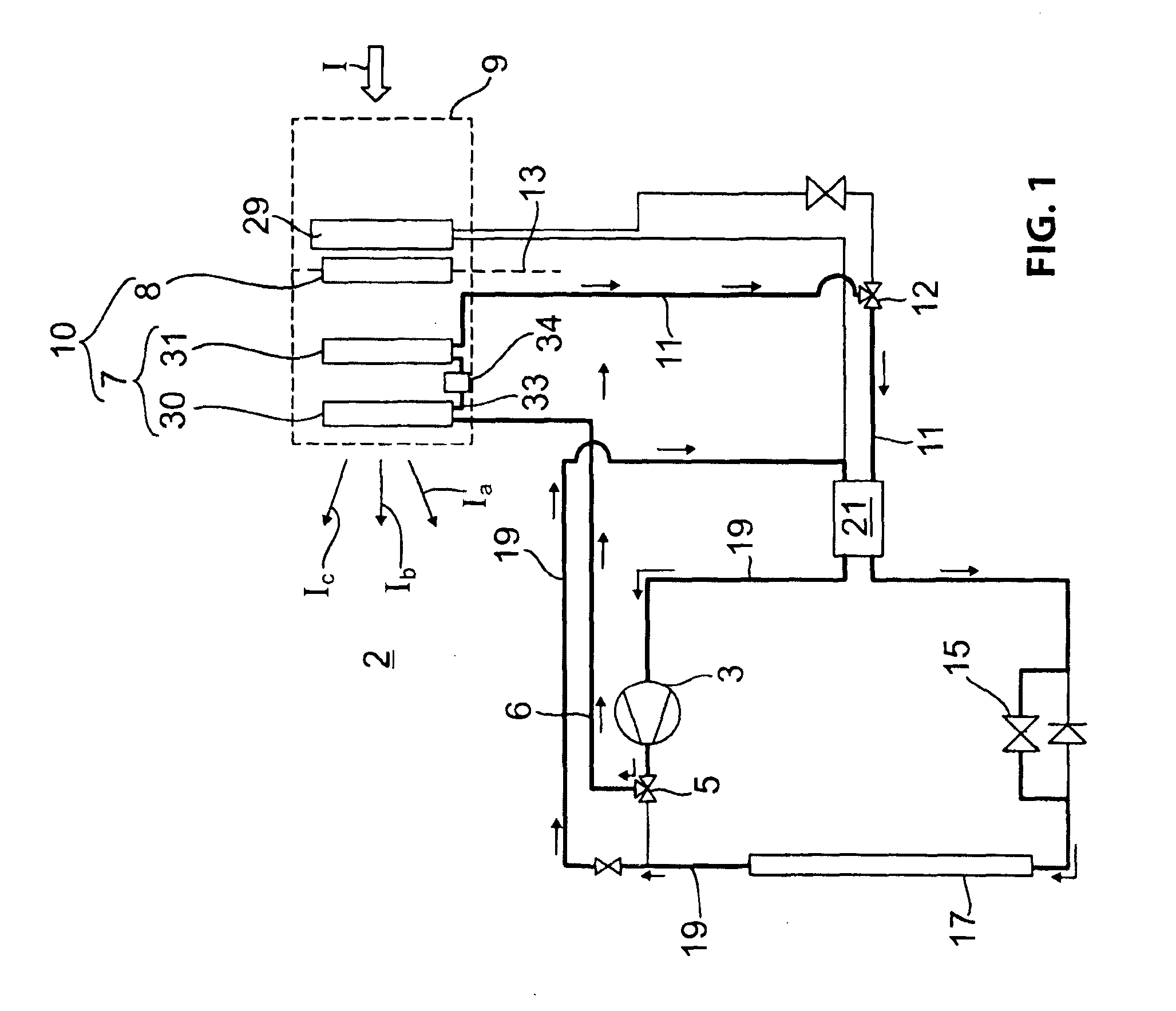

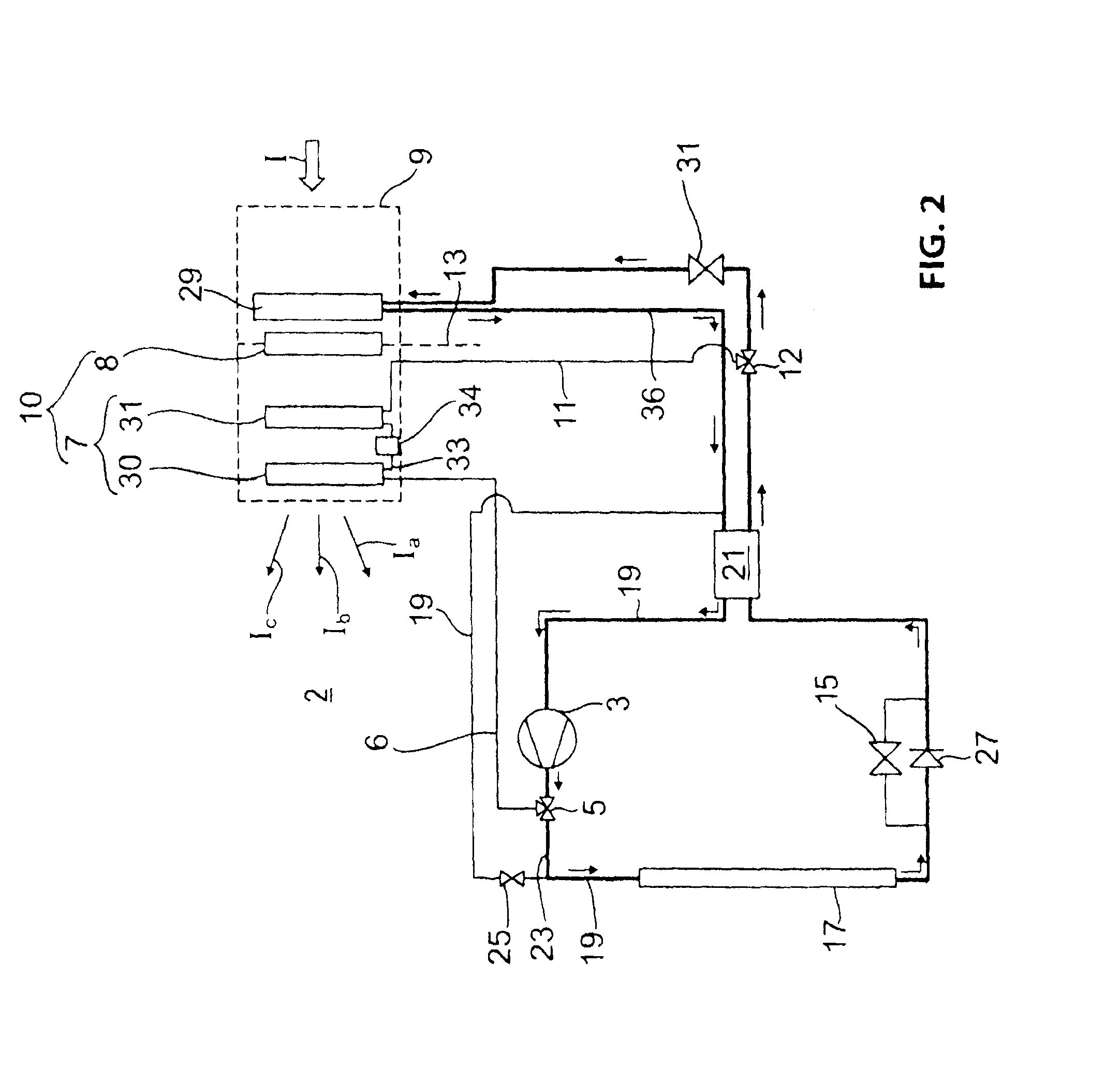

Vehicle with air conditioner

InactiveUS20140138049A1Easy to coverHeating evenly and efficientlyAir-treating devicesVehicle heating/cooling devicesSuper coolingEngineering

The invention relates to a vehicle with an air conditioner for heating inlet air flowing into a vehicle interior, the air conditioner including: a heater heat exchanger thermally coupled through a coolant cycle with a drive unit or similar; and a supplemental heat exchanger which is connected to a refrigerant cycle of the air conditioner and which transfers heat to the inlet air in heating mode, wherein the supplemental heat exchanger is configured with at least two rows including a first heat exchanger row and a second heat exchanger row in a refrigerant flow direction, wherein the first heat exchanger row and the second heat exchanger row are arranged in a refrigerant flow direction so that super cooling of a condensed refrigerant is provided in the second heat exchanger row and at least heat extraction of the refrigerant is provided in the first heat exchanger row.

Owner:AUDI AG +1

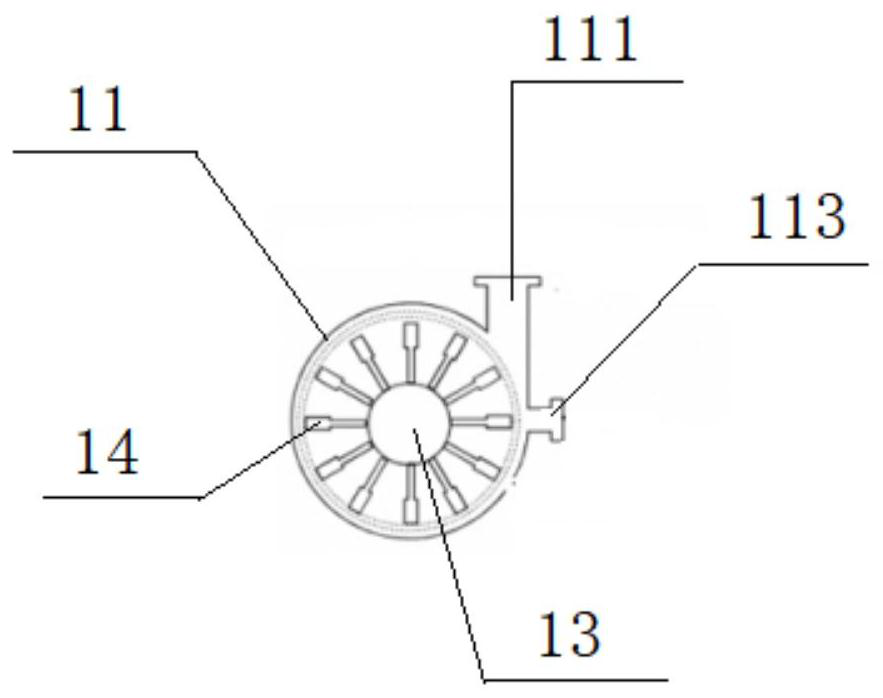

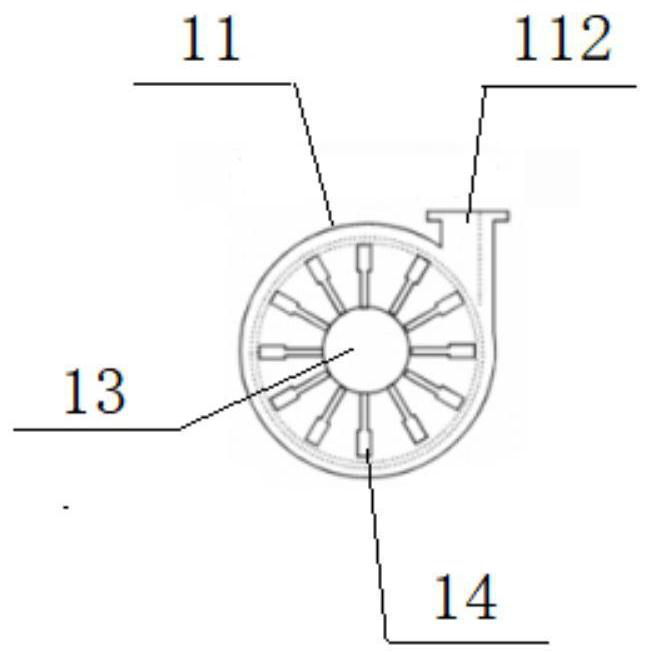

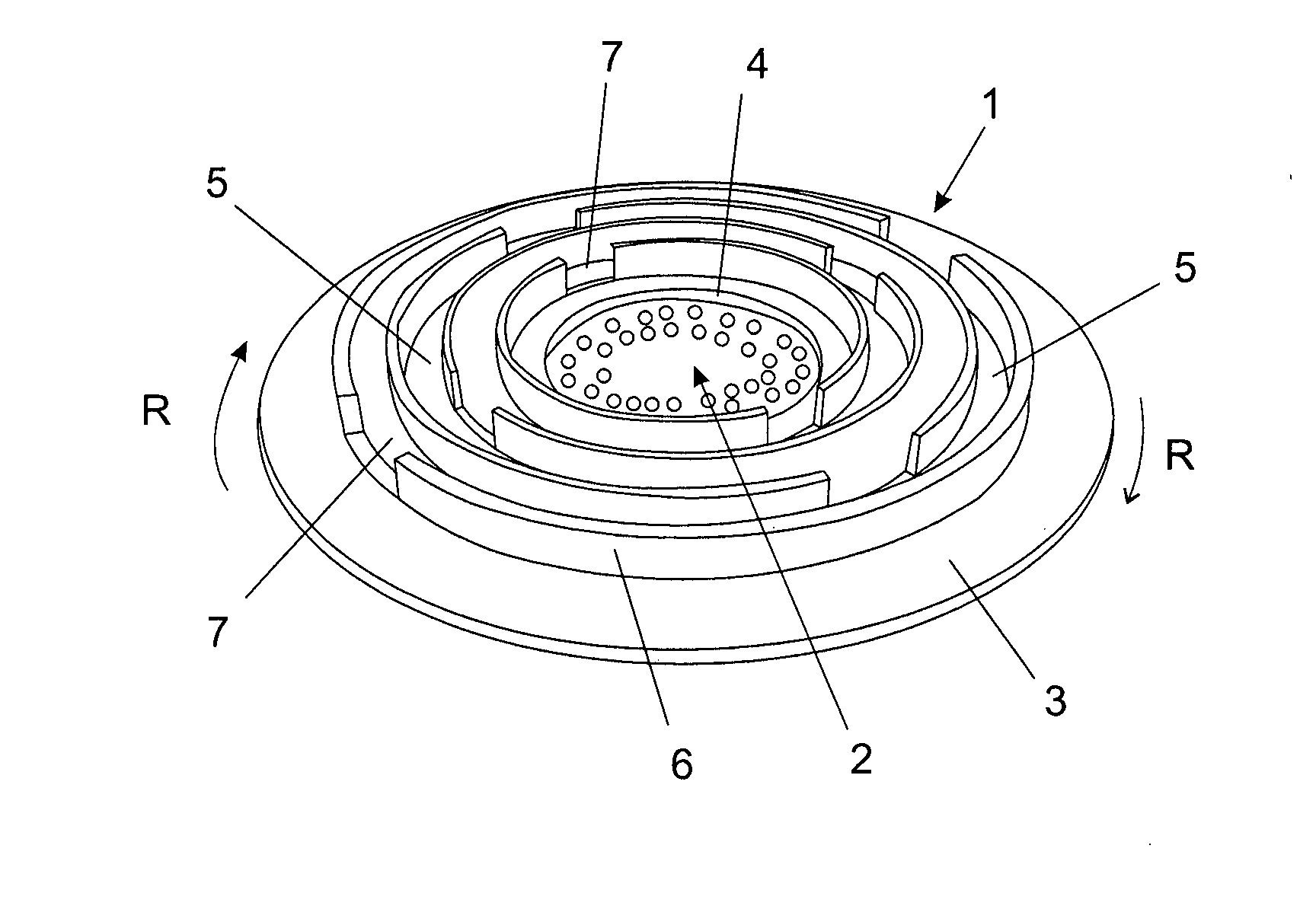

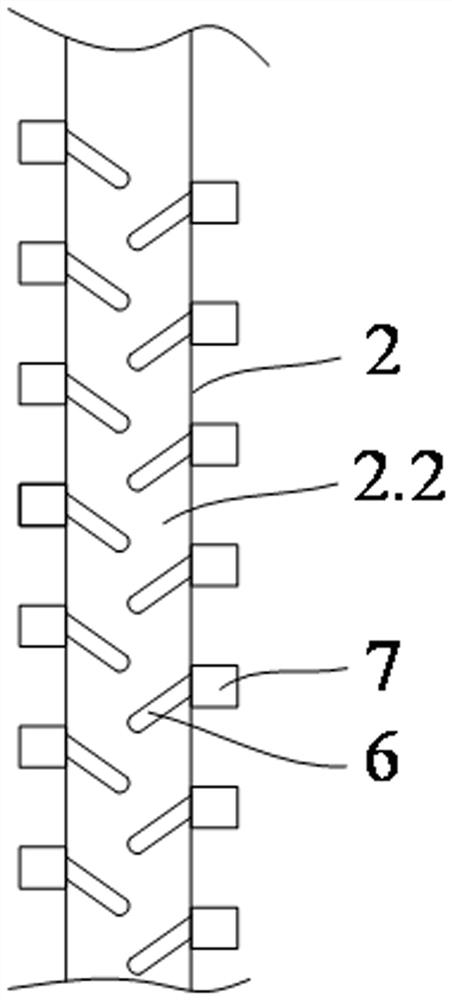

Rotational flow thermal vibration drying machine and rotational flow thermal vibration drying system

PendingCN113024056ARealize self-cleaningThere will be no sticking phenomenonCombination devicesSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to the technical field of wet sludge drying, in particular to a rotational flow thermal vibration drying machine and a rotational flow thermal vibration drying system. The rotational flow thermal vibration drying machine comprises: a hollow drying chamber, wherein one end of the drying chamber is provided with a feeding port and an air inlet, and the other end of the drying chamber is provided with a discharging port; a heat source jacket which is arranged around the outer side of the drying chamber, wherein a medium serving as a heat source circulates in the heat source jacket, and a heat source outlet and at least one heat source inlet are formed in the heat source jacket; a rotating shaft which is arranged in the middle of the drying chamber and penetrates through the two ends of the drying chamber, wherein a driving motor used for driving the rotating shaft to rotate is arranged on the outer side of the drying chamber; and paddles which are mounted on the rotating shaft. The drying machine has a self-cleaning capability, so that the wall sticking phenomenon is avoided; The safe operation of the system is ensured by high-degree inerting circulation; and the drying machine is high in heat exchange efficiency, high in heat transfer speed and high in sludge drying speed. When the drying system is used, irritant gas cannot be discharged to the periphery, and secondary pollution to air is avoided.

Owner:山东驰盛新能源设备有限公司

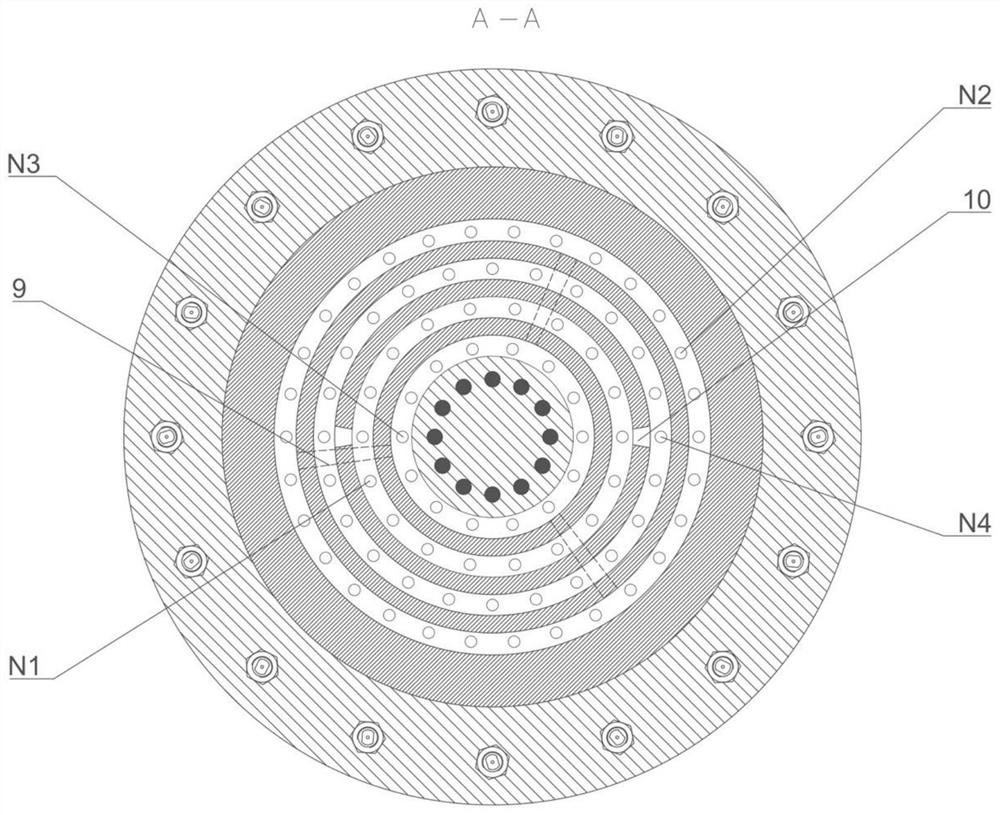

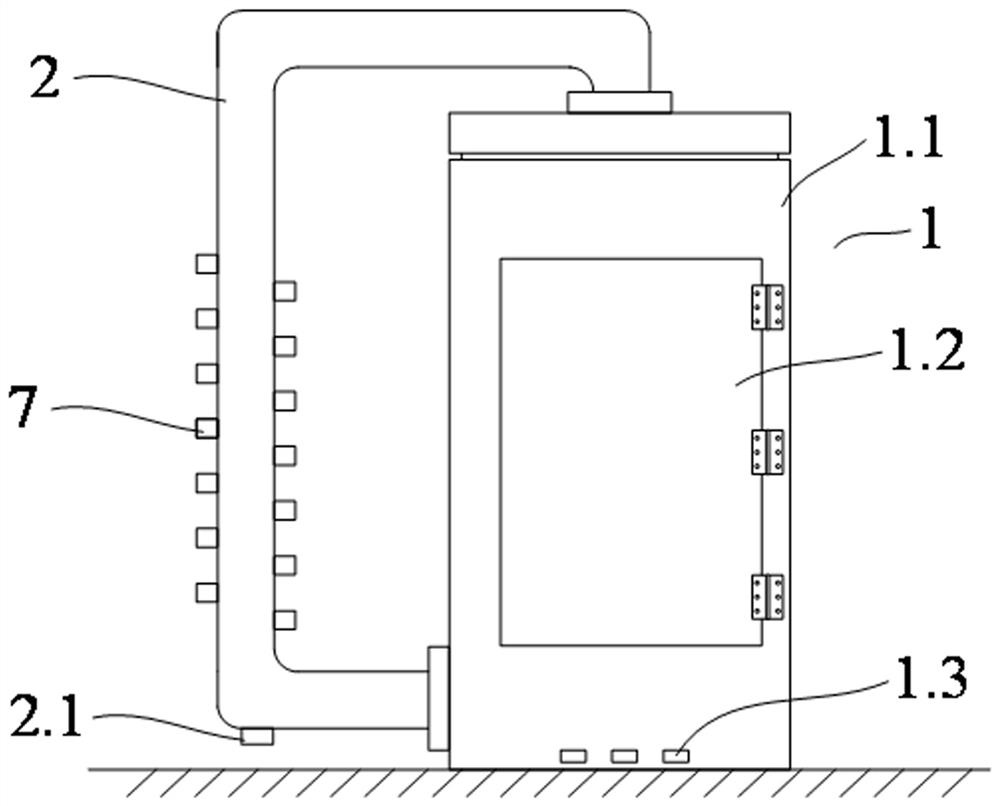

Fluid heating apparatus

ActiveCN1892094AHeating evenly and efficientlyPipeline systemsStationary tubular conduit assembliesBlack paintEngineering

Disclosed is a fluid heating apparatus including a halogen lamp 23, and a tubular structure 26 surrounding the heating lamp and having a fluid inlet 24 and a fluid outlet 25. The tubular structure 26 comprises plural straight pipes 26a arrayed circumferentially around the halogen lamp 26, with adjacent straight pipes 26a being in contact with each other, or being slightly spaced from each other. At least the surfaces, facing the halogen lamp 26, of the straight pipes 26a are coated with a black paint 27, or a radiant-light-absorbing paint.

Owner:TOKYO ELECTRON LTD

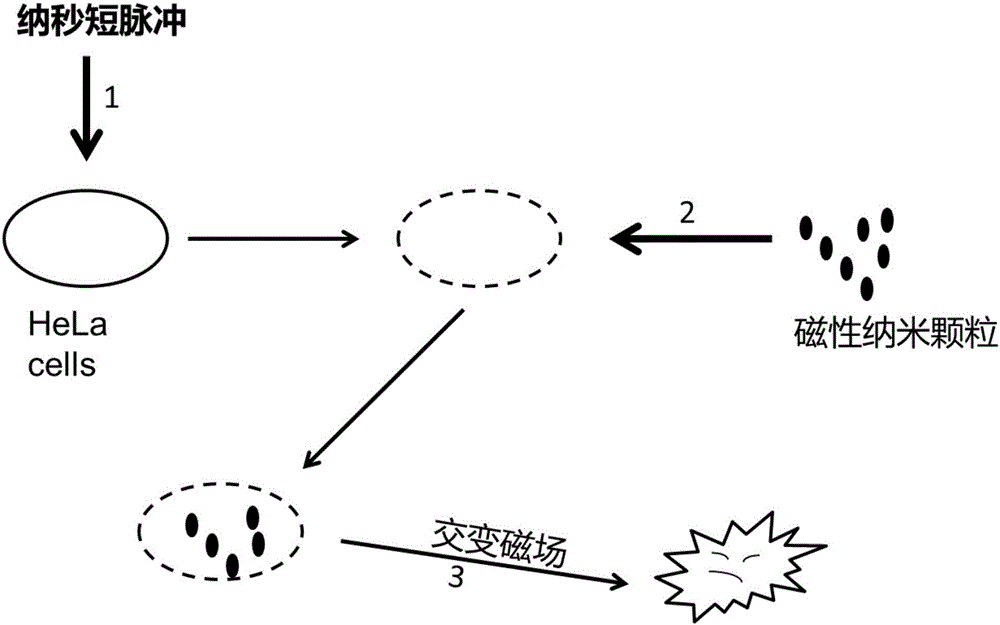

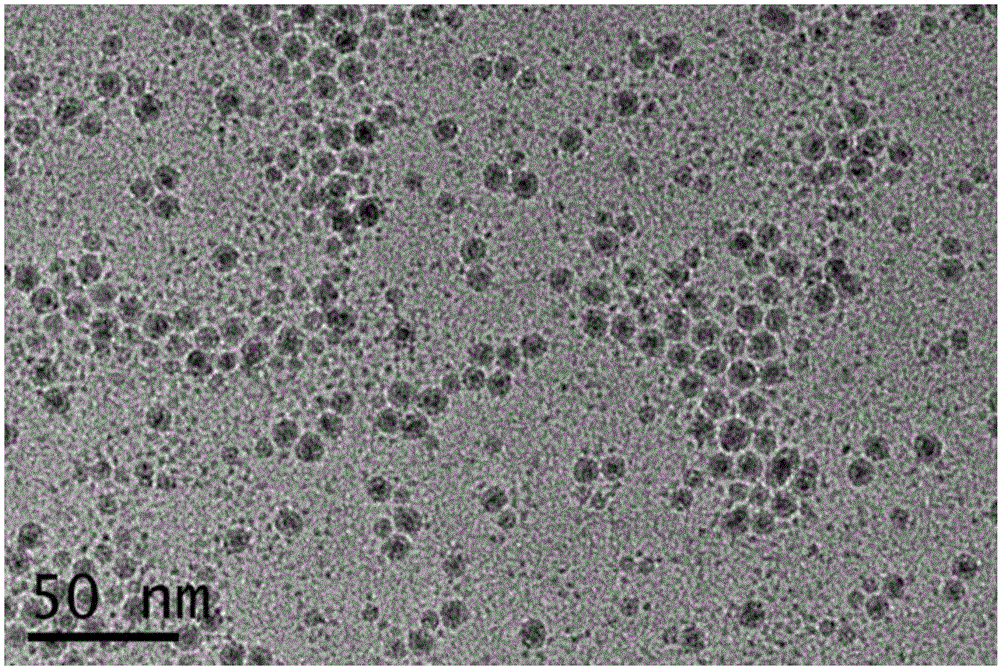

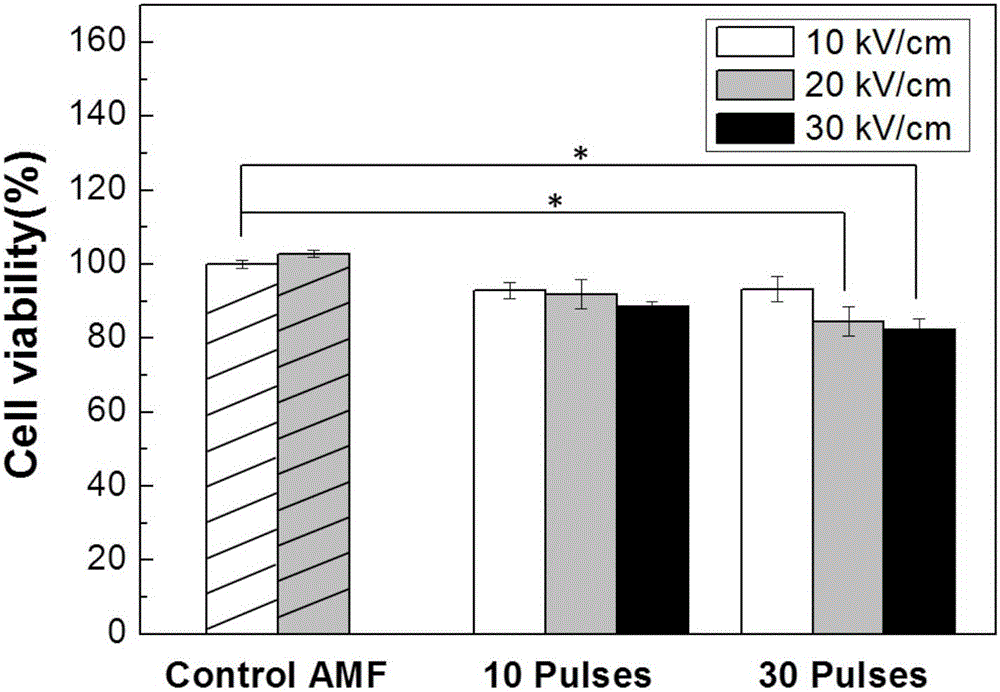

Method for promoting nanoparticles to enter cells efficiently based on nanosecond pulsed electric field

InactiveCN105903014AHeating evenly and efficientlyEnergy modified materialsEpidermal cells/skin cellsIntracellularNanoparticle

The invention discloses a method for promoting nanoparticles to enter cells. The method for promoting the nanoparticles to enter the cells has the advantages that the cells are subjected to pretreatment by the nanosecond pulsed electric field to promote the number of the nanoparticles entering the cells to be increased remarkably and are heated uniformly and effectively under the action of an alternating magnetic field, the pure nanosecond pulsed electric field has little effect on activity of the cells, and accordingly the method verifies that the nanosecond pulsed electric field is capable of promoting the nanoparticles to enter the cells effectively as a safe physical pretreatment means and is of potential clinical application value on cell imaging and treatment.

Owner:PEKING UNIV

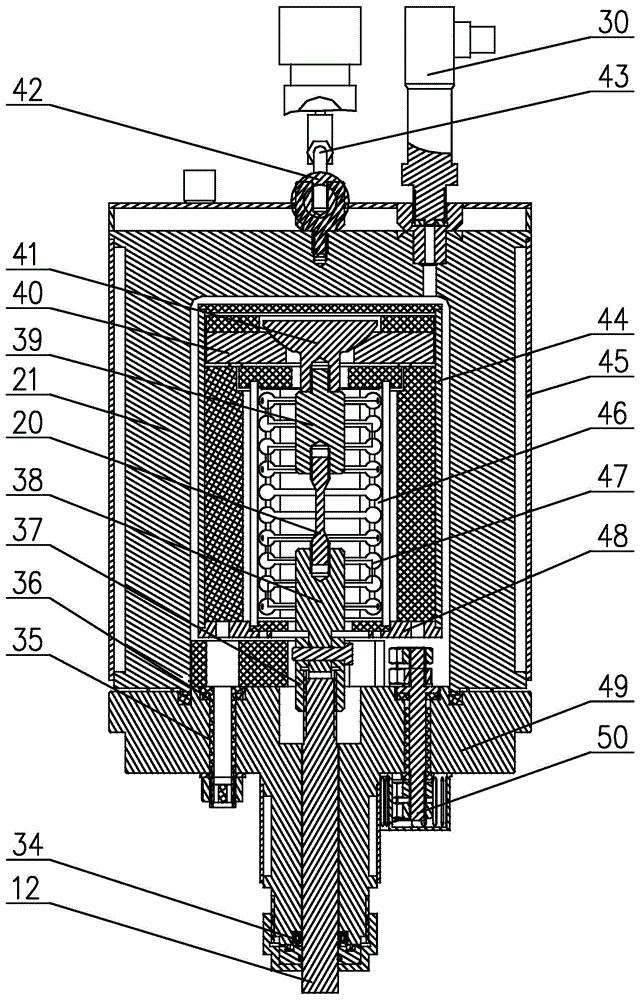

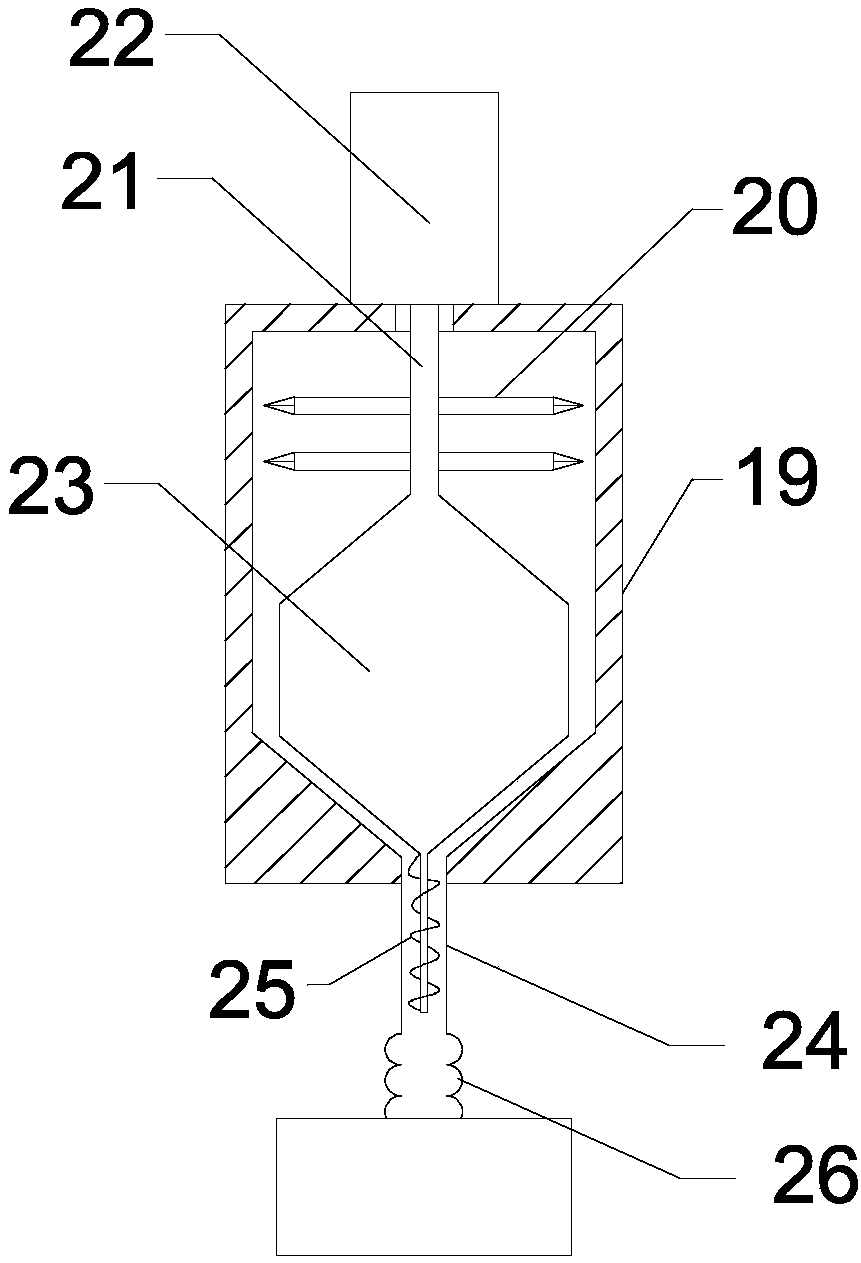

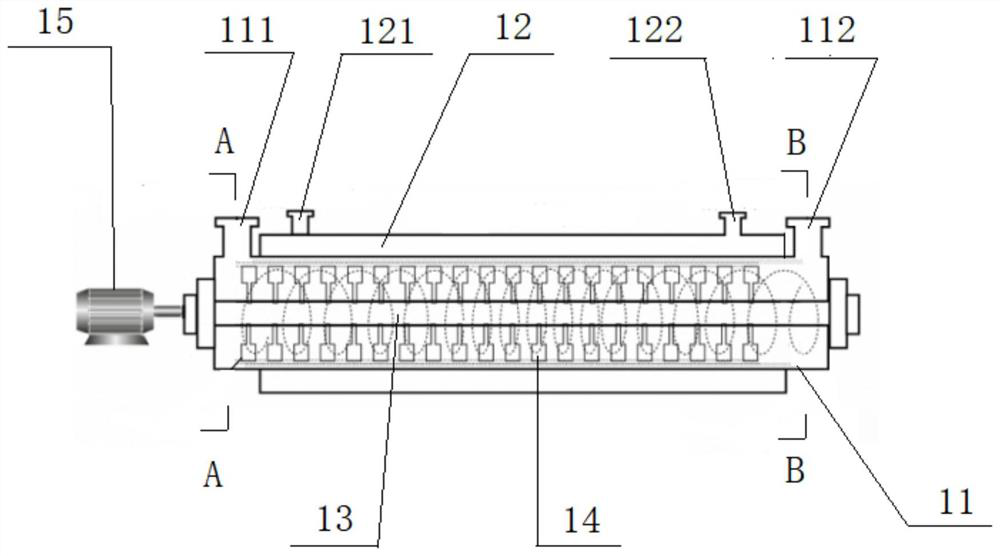

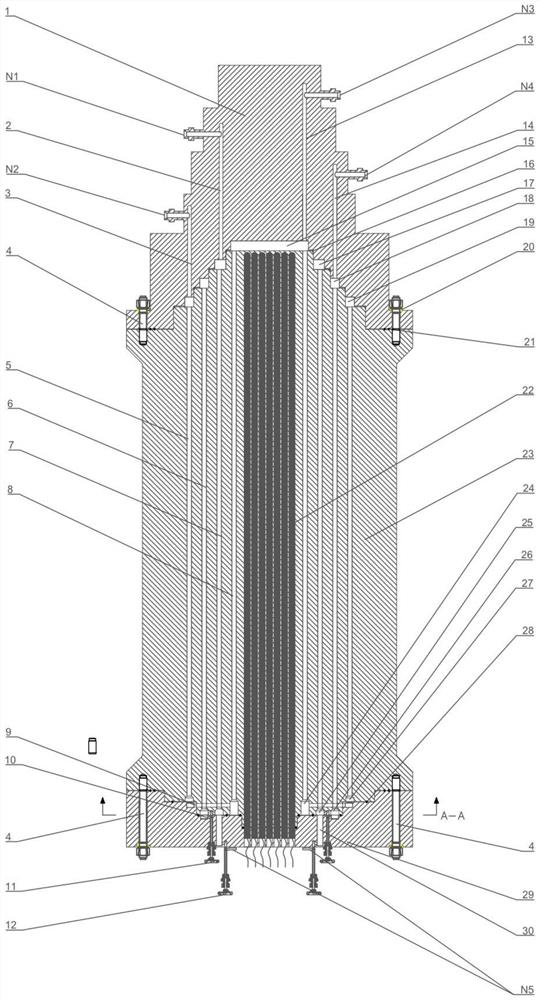

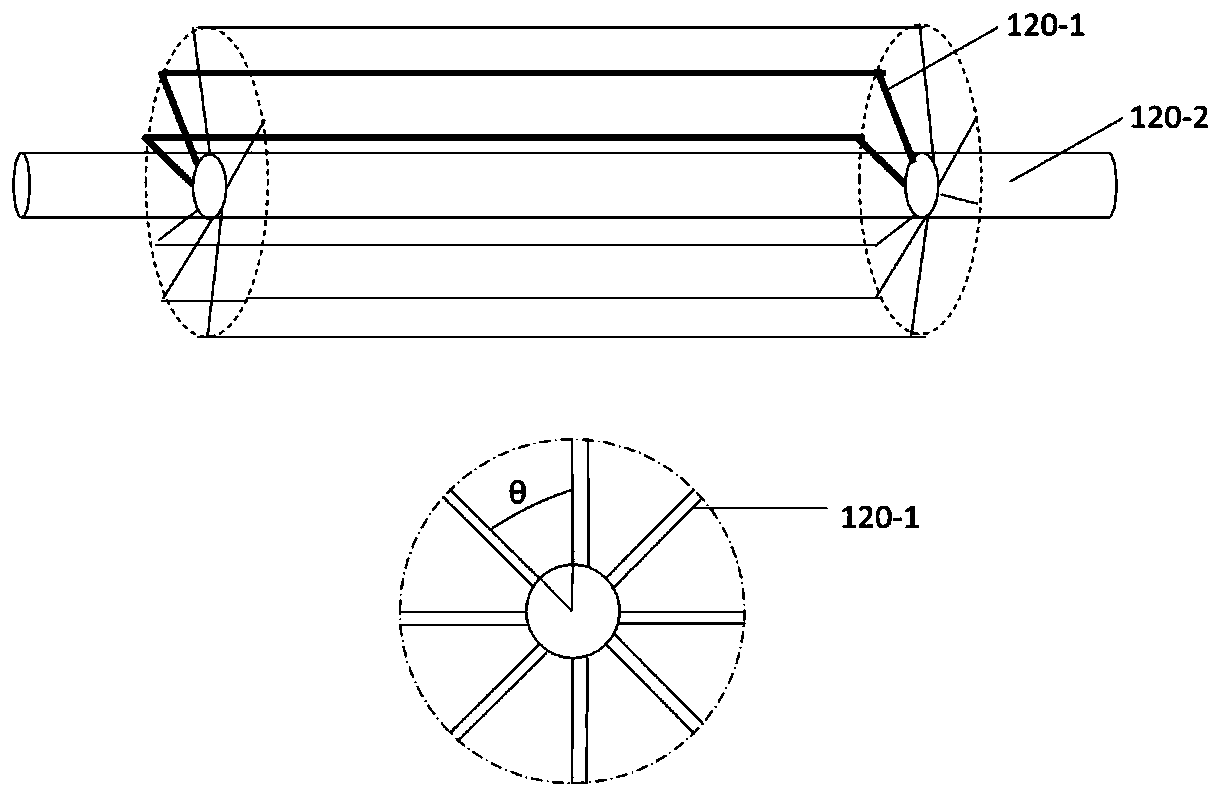

Controllable heating-heat regeneration device for preparing nano-powder by supercritical hydrothermal synthesis technology

ActiveCN111632568AIncrease contactEasy to recycleChemical/physical/physico-chemical stationary reactorsPressure vessel componentsHeater RodEngineering

The invention discloses a controllable heating-heat regeneration device for preparing nano-powder by a supercritical hydrothermal synthesis technology. Cold and hot fluid inlet and outlet flow channels are formed in a shunt matrix; a cold fluid forward flow channel, a cold fluid reverse flow channel, a hot fluid forward flow channel and a hot fluid reverse flow channel are arranged in a heat exchange matrix, electric heating rods are arranged in a central layer, a cold fluid connecting cavity, an upper annular cavity A, an upper annular cavity B and an upper annular cavity C are formed in theupper part of the heat exchange matrix, a lower annular cavity A, a lower annular cavity B, a lower annular cavity C and a lower annular cavity D are formed in the lower part of the heat exchange matrix, the hot fluid inlet flow channel, the upper annular cavity A, the hot fluid forward flow channel, the lower annular cavity B, a heat communication flow channel, the lower annular cavity C, the hotfluid reverse flow channel, the upper annular cavity B and the hot fluid outlet flow channel form a hot fluid loop; and the cold fluid inlet flow channel, the upper annular cavity C, the cold fluid forward flow channel, the lower annular cavity D, a cold communication flow channel, the lower annular cavity A, the cold fluid reverse flow channel, the cold fluid connecting cavity and the cold fluidoutlet flow channel form a cold fluid loop. According to the invention, the preheating temperature can be accurately controlled, the floor space is reduced, and heater microchannelizationI is achieved.

Owner:XI AN JIAOTONG UNIV

Uniform heating and mixing device for magnetic centrifugal bubble-removal road construction material

ActiveCN109518563AAvoid enteringIncrease speedLiquid degasification with magnetic fieldRoads maintainenceFiltrationHeat conducting

The invention discloses a uniform heating and mixing device for a magnetic centrifugal bubble-removal road construction material. The uniform heating and mixing device structurally comprises a rotarymotor, a heating circulating pump, a feeding pipe, a uniform circulating heat-conducting and bubble-removal device, a discharging pipe and a support base, wherein the heating circulating pump is mounted on the left side of the rotary motor. According to the uniform heating and mixing device, bubbles of a mixed solution bubbling outside a first heat-conducting pipe and a second heat-conducting aretimely removed through a flow-guiding and bubble-removal structure, the mixed solution and the bubbles are separated through different centrifugal forces of a magnetic centrifuging mechanism in a flow-guiding plate to the mixed solution and the bubbles, the mixed solution slowly flows downwards along an inner wall plate and is circulated through a draining hole, the separated bubbles are discharged into atmosphere through the filtration and purification of a filter, so that the situation that the quality of an asphalt mixed solution is influenced because the bubbles are dispersed in all directions and are difficult to be cleared is prevented.

Owner:泉州惠安兆尼商贸有限公司

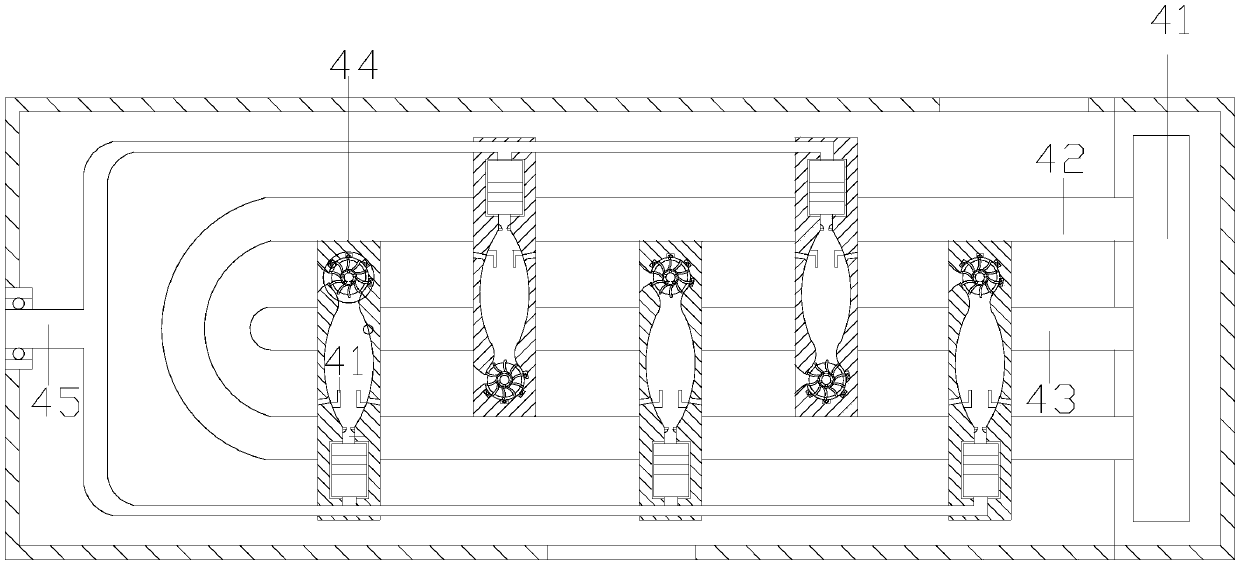

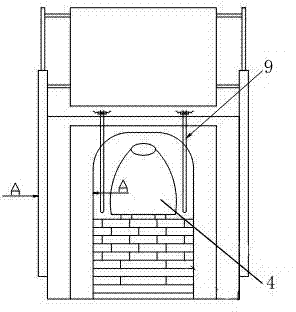

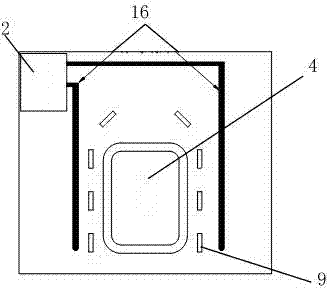

Electric crucible furnace equipment for glass dissolution and manufacturing method thereof

The invention discloses electric crucible furnace equipment for glass dissolution and a manufacturing method thereof. The electric crucible furnace equipment comprises a furnace body, wherein multiple transformers are arranged at the top of the furnace body; the transformers are externally connected with an electric control cabinet; the electric control cabinet is connected with the transformers and the electric equipment of the furnace body respectively; a crucible is arranged on the innermost layer of the furnace body; a four-layer thermal insulation structure is arranged outside the crucible and comprises a first-level thermal insulation brick layer, a second-level thermal insulation brick layer, a thermal insulation cotton layer and a steel cover layer sequentially from inside to outside; multiple heating rods are inserted into the furnace body; the ends of the heating rods stretching out of the furnace body are connected with the output ends of the transformers; and a thermocouple is inserted into the middle of the top of the furnace body. With the four-layer thermal insulation structure, the electric crucible furnace equipment disclosed by the invention effectively avoids the heat loss in the furnace; three transformers outputting different voltages provide three different working environments of low temperature, middle temperature and high temperature to the heating of the heating rods; and the moisture is removed sufficiently by the crucible and uniform and effective heating is obtained through low-temperature thermal insulation and middle-temperature thermal insulation, the cracking of the crucible is avoided, and the service life of the crucible is prolonged.

Owner:JIANGSU YITA NEW MATERIAL TECH

Apparatus and method for heating ground

ActiveUS8544460B2Provide heating efficiencyComplex thaw patternsOther heat production devicesIndirect heat exchangersProcess engineeringRadiation

An apparatus and method is provided for preparing frozen ground for construction-type work includes using arrays of heat sources placed over the surface to be heated. The apparatus can warm the surface in preparation for the construction activity with energy penetrating into the ground affording efficient thawing of materials below 20 centimeters of depth. Heat sources used in the array can include emitted infrared radiation.

Owner:BEFUS DALE

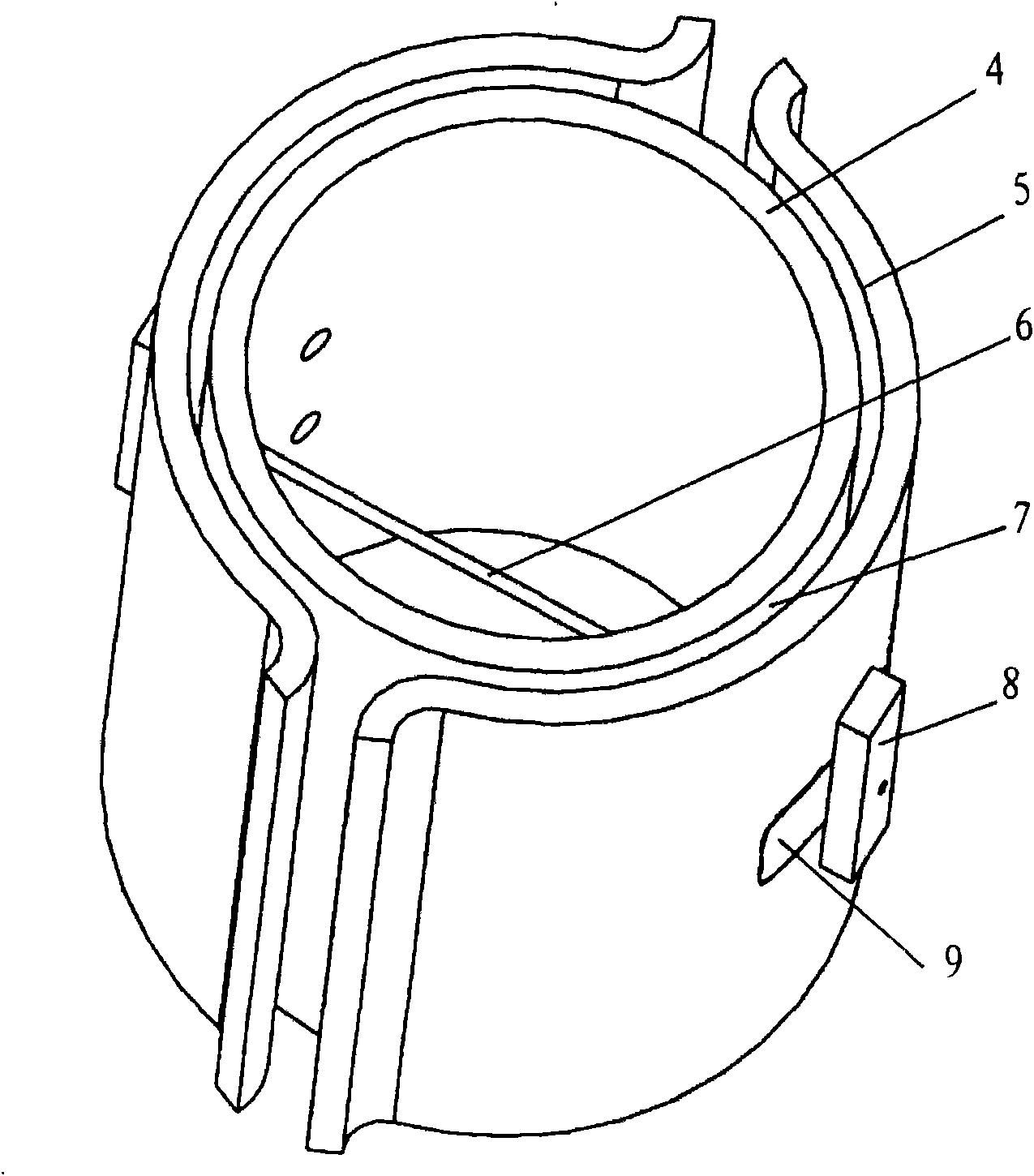

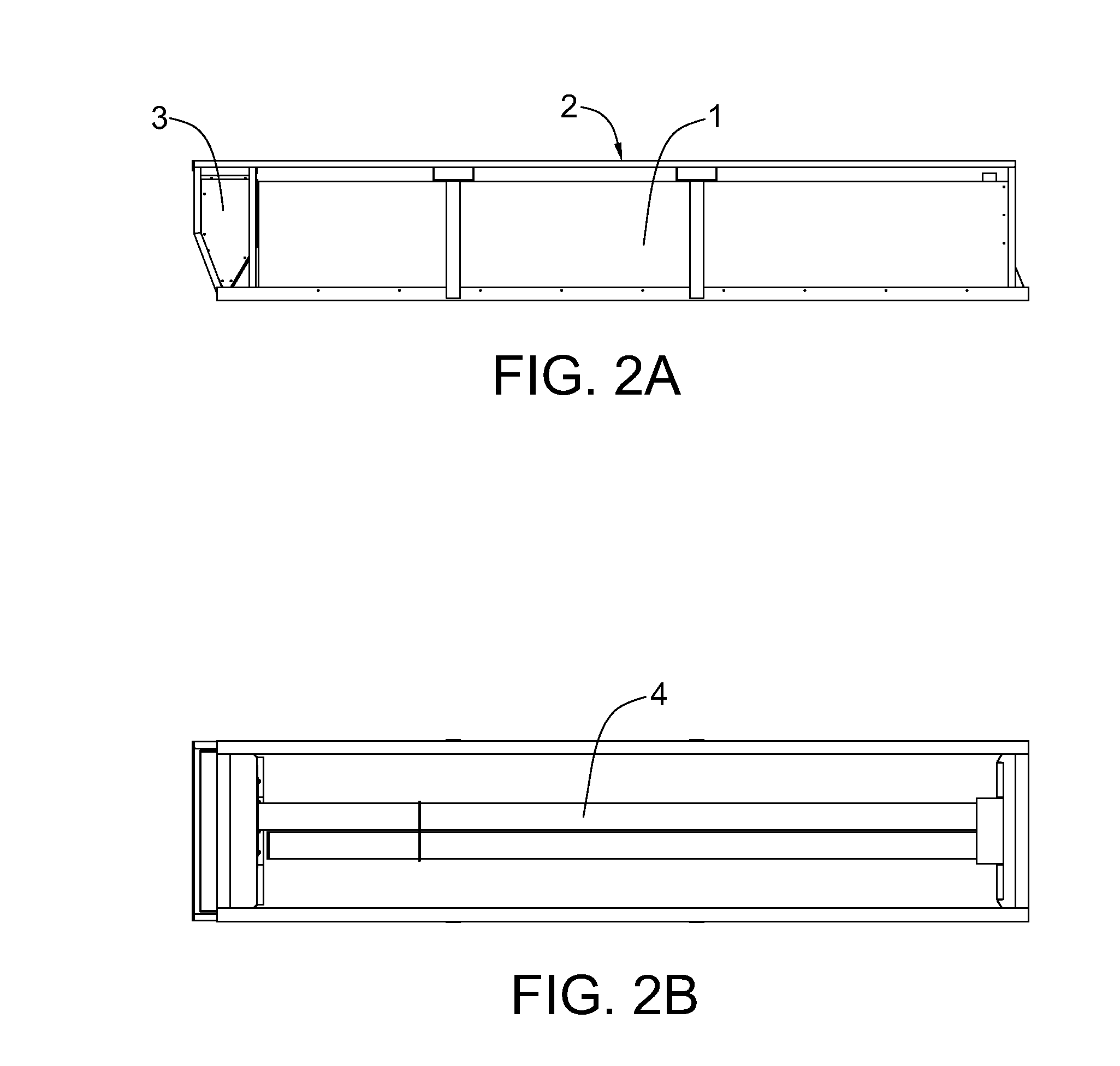

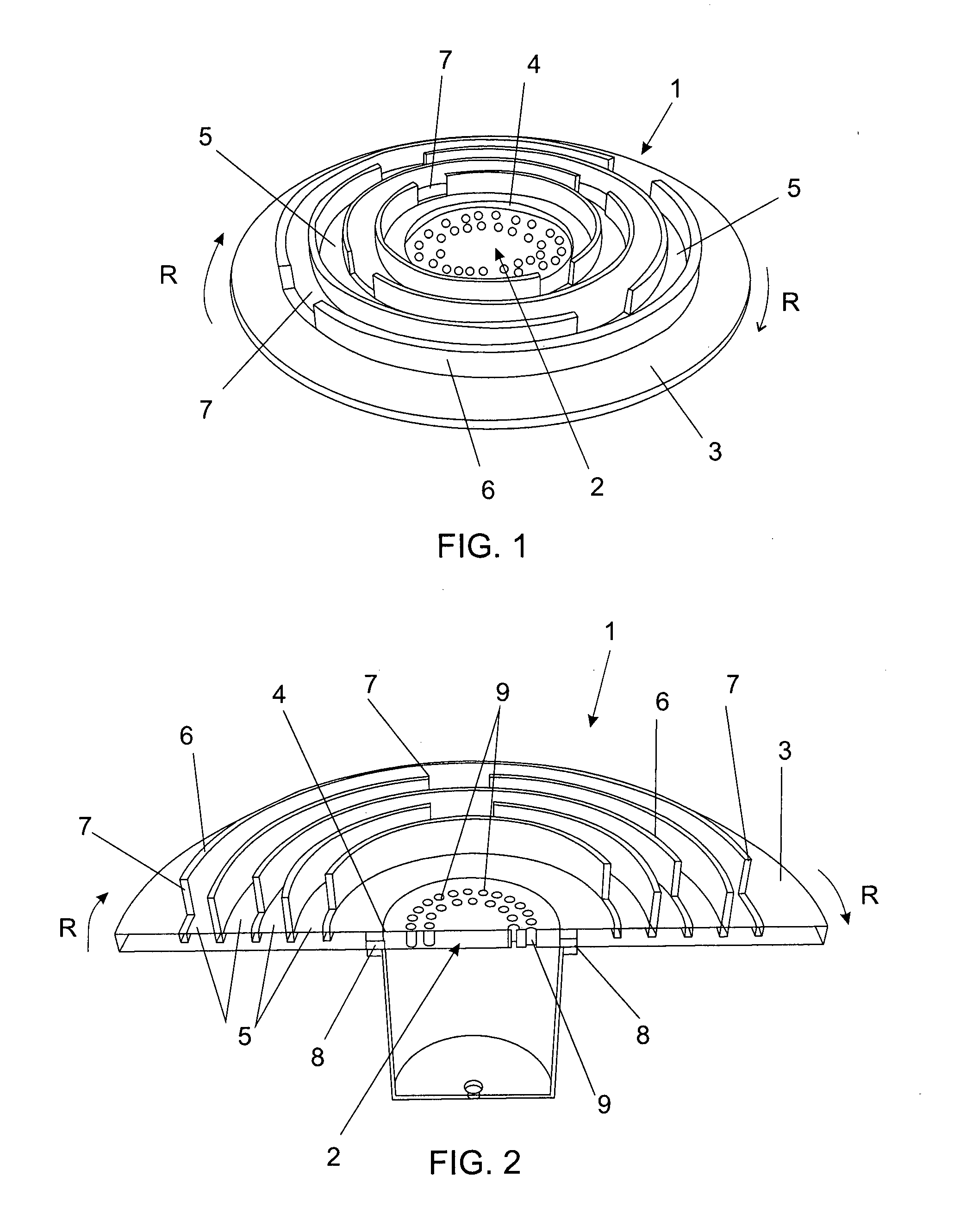

Gas flow directing device for burners of cooking appliances

InactiveUS20150253012A1Function increaseExtended stayDomestic stoves or rangesGaseous fuel burnerCombustorProcess engineering

The present invention refers to a gas flow directing device (1) for burners (2) of cooking appliances, comprising innovative technical and functional features capable of better using gases from combustion process. However, it is mainly directed to maximize the efficiency of heat exchange of burners with cooking utensils. More particularly, said gas flow directing device (1) of the present invention comprises a base (3) provided with opening (4) for fitting a burner (2), wherein said base (3) is arranged such that it can be freely rotated around the burner (2) and comprises at least a pathway (5) configured from the arrangement of at least one outwardly projected distribution wall (6) containing at least an opening (7).

Owner:WHIRPOOL SA

Unit for supporting a substrate and apparatus for processing a substrate having the same

InactiveCN101796898AHeating evenly and efficientlyReduce heatSemiconductor/solid-state device manufacturingSupport structure mountingBiomedical engineeringHeat transfer

A substrate support unit of a substrate processing apparatus includes a first support member, a second support member, a buffer member and a tube. The first support member has an electrode and a heater built-in and supports the substrate. The second support member is disposed beneath the first support member to support the first support member. The buffer member is disposed between the first support member and the second support member to form an air gap between the first support member and the second support member so as to reduce heat transfer between the first support member and the second support member. The tube is connected with a lower surface of the first support member. Further, the tube extends through the second support member and receives lines for applying power to the electrode and the heater.

Owner:MICOCERAMICS LTD

Drying equipment provided with stirring mechanism

InactiveCN107543393AReduce energy consumptionImprove economic efficiencyDrying solid materialsDrying machines with non-progressive movementsEngineeringField device

The invention discloses a drying equipment with a stirring mechanism, which relates to the technical field of drying equipment. The invention comprises a drying chamber, a material inlet and a material outlet connected to the inside of the drying chamber, and the inside of the drying chamber is inclined A vibrating partition is provided, and the outlet is located on the drying chamber on the lower side of the vibrating partition. The vibrating partition divides the drying chamber into an upper material chamber and a lower heating chamber, and a return air system is installed on the top of the upper material chamber. , the upper material chamber is provided with a horizontal stirring mechanism, the upper material chamber is provided with a drive mechanism to drive the horizontal stirring mechanism to rotate, and the lower heating chamber is provided with a heating source. The invention has the advantages of simple structure, uniform baking, high baking efficiency and The advantage of saving energy.

Owner:弘毅天承知识产权股份有限公司

Industrial hot air oven

InactiveCN112161468AEasy to separateTemperature stableDrying gas arrangementsDrying chambers/containersHot air ovenHeat conducting

The invention relates to an industrial hot air oven. The industrial hot air oven comprises a drying box and a circulating pipe, wherein the drying box comprises a box body and a box door; the box dooris connected with the box body in a hinge manner; the box door can seal a box opening of the box body; the upper end part of the circulating pipe is arranged at the upper end of the box body; the lower end part of the circulating pipe is arranged on one side of the box body and is communicated with the lower end part of the box body through a connecting piece; a fan, a heating pipe and a drying frame are arranged in the box body; the fan is arranged at the bottom of the box body; the heating pipe is arranged above the fan and is connected with the inner wall of the box body; the drying frameis arranged above the heating pipe and is connected with the inner wall of the box body; a heat conducting sheet is arranged on the inner side of the middle part of the circulating pipe; the upper endpart of the heat conducting sheet is connected with the inner wall of one end of the circulating pipe; the lower end part of the heat conducting sheet is close to the inner wall of the other end of the circulating pipe in an inclined manner; and a water outlet is formed in the lower end part of the circulating pipe. Compared with the prior art, the industrial hot air oven has the advantages thatthe energy consumption is reduced, the heat waste is reduced, and the drying efficiency is improved.

Owner:梁志川

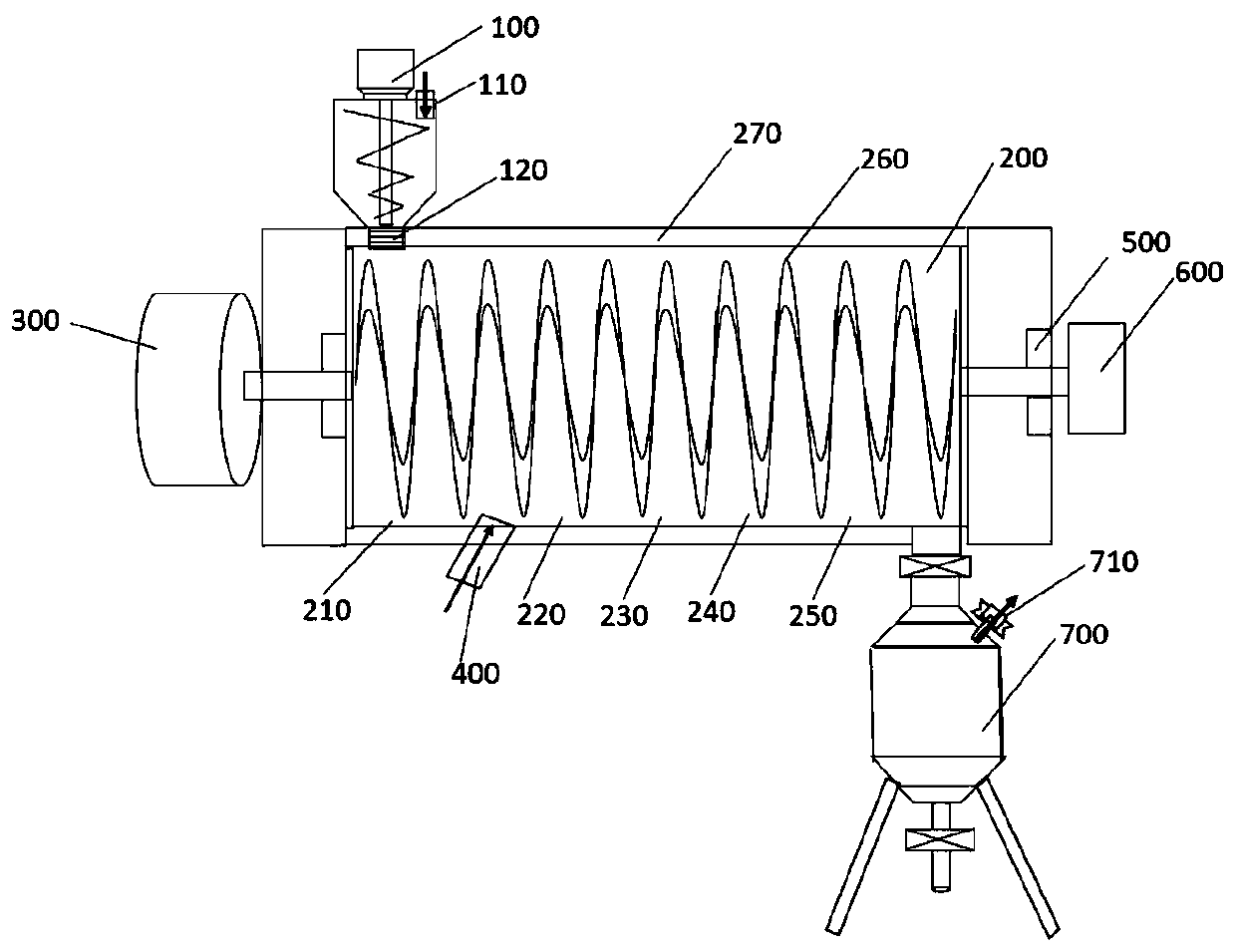

Device and method for preparing pre-foamed microcapsules

PendingCN110841571AIncrease productivityPrevent insufficient foamingMicroballoon preparationMicrocapsule preparationEngineeringMechanical engineering

The invention provides a device and method for preparing pre-foamed microcapsules. The device comprises (1) a feeding device, (2) a foaming device, wherein the foaming device sequentially comprises afeeding area, a dispersing area, a preheating area, a heating area and a cooling area in the transverse direction, the feeding area, the dispersing area, the preheating area, the heating area and thecooling area comprise integrally continuous shaftless screw structures, the feeding device is arranged in the feeding area, and the interior of the feeding device is communicated with the interior ofthe feeding area, (3) an in-cylinder blower device which is arranged in the dispersing area, wherein the interior of the in-cylinder blower device is communicated with the interior of the dispersing area, and (4) a collecting device which is arranged in the cooling area, wherein the interior of the collecting device is communicated with the interior of the cooling area. According to the preparation method, the foamable microcapsules can be effectively prevented from being bonded with one another in the heating foaming process, so that the non-caking pre-foaming microcapsules can be efficientlyand controllably prepared.

Owner:CRERAX SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com