Preparation method for writing in spiral long-period fiber Bragg grating based on bilateral CO2 laser

A fiber grating, long-period technology, applied in the direction of cladding fiber, optical waveguide light guide, etc., can solve the problems of easy deformation of fiber, large loss, poor writing accuracy, etc., and achieve the effect of uniform and effective fiber heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

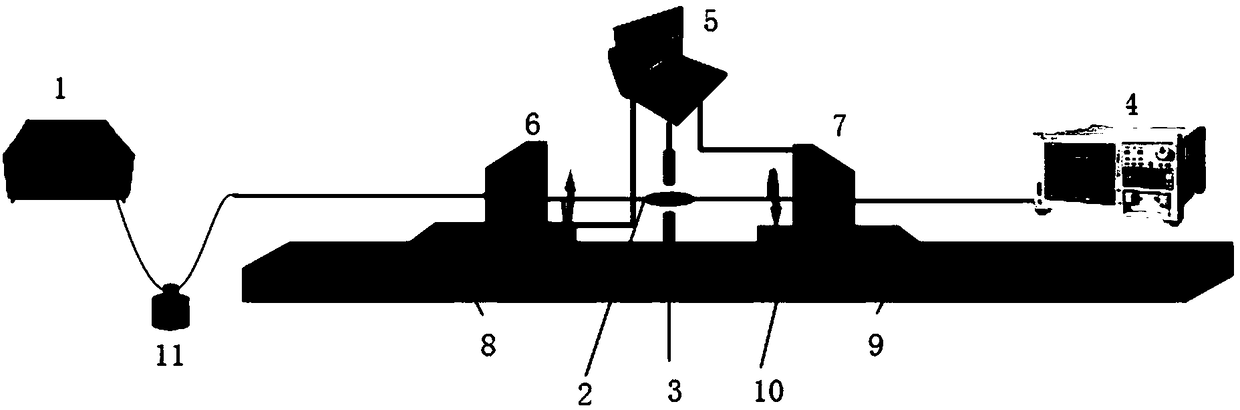

[0029] Such as figure 1 As shown, the whole preparation system consists of a broadband light source 1, a left rotary motor θL 6, a left propulsion motor ZL 8, a right rotary motor θR 7, a right propulsion motor ZR 9, and a double-sided CO 2 The laser 3, the single-mode optical fiber 2 stripped of the coating layer, the PC terminal 5, the spectrum analyzer 4, the clamp 10 and the weight 11 on the left and right motors constitute.

[0030] The single-mode optical fiber whose coating layer has been stripped in the middle is held by the clamps on the motors on both sides, and the two ends of the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com