Device and method for preparing pre-foamed microcapsules

A technology of preparation device and foaming device, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of low utilization rate of equipment, complicated feeding procedure and high operating temperature, improve reliability and simplicity, and solve continuous problems. Difficulty in operation and the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

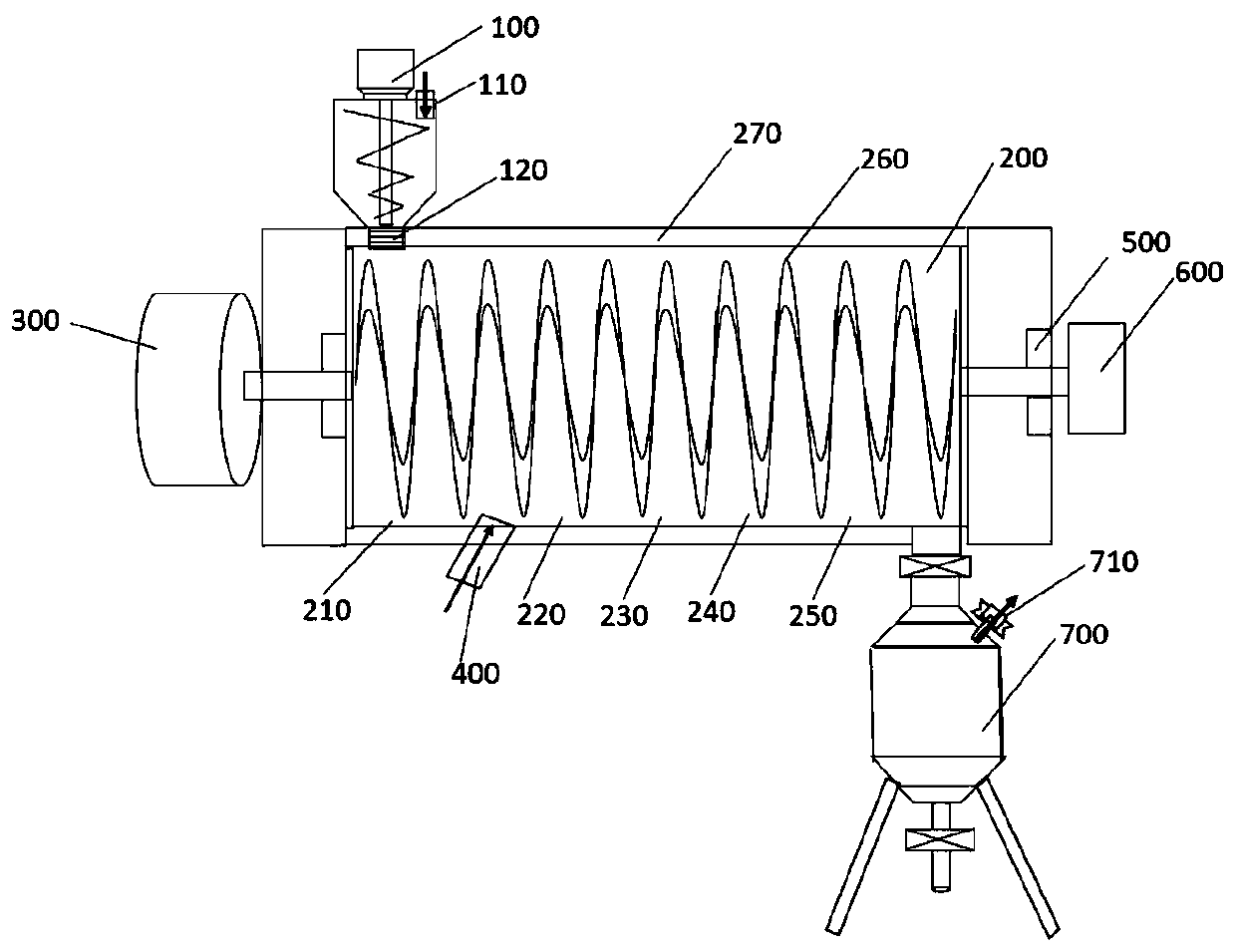

[0102] According to one embodiment of the present invention, the preparation method of prefoamed microcapsules of the present invention comprises the steps:

[0103] Feeding: the microcapsule dry powder is added into the feeding device 100 and transported to the feeding area 210 of the foaming device 200;

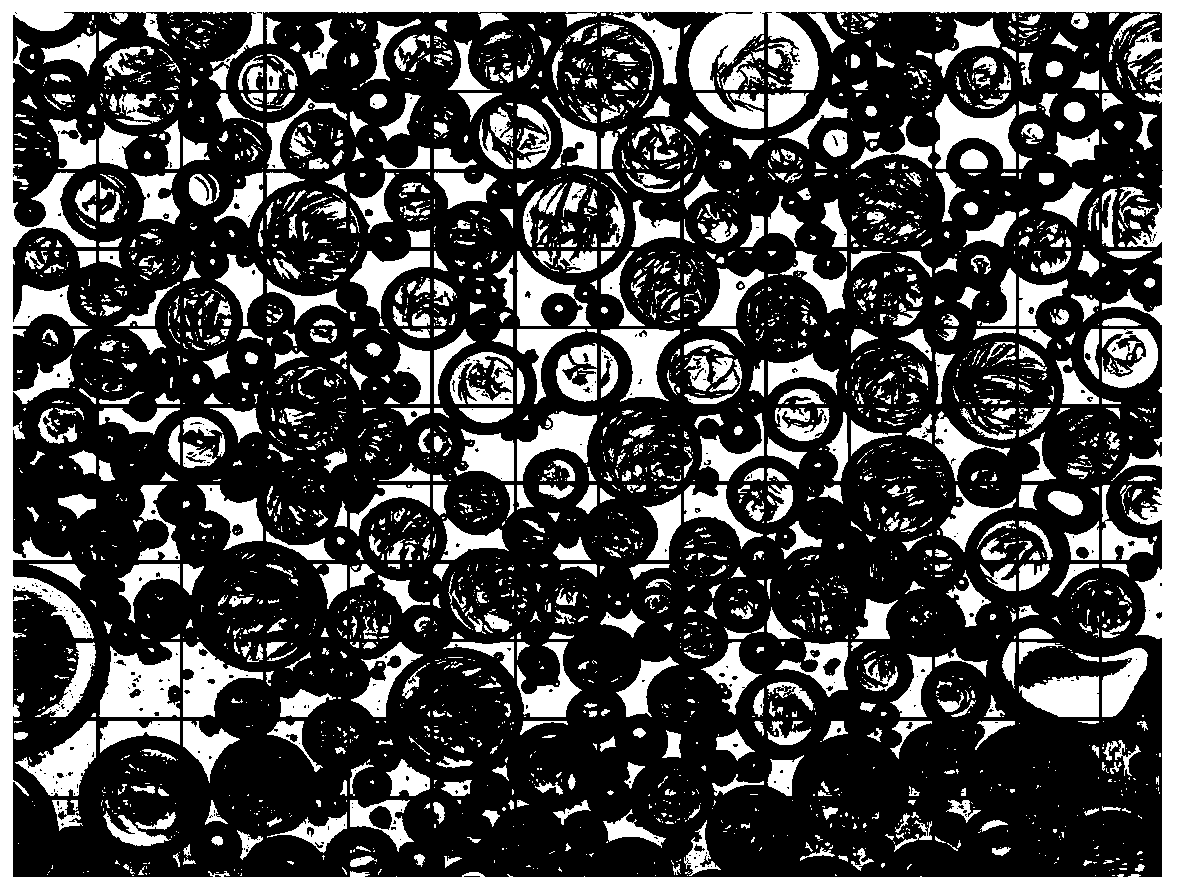

[0104] Dispersion: transport the microcapsule dry powder from the feeding area 210 to the dispersion area 220, under the buoyancy of the hot air generated by the cylinder blowing device 400, the microcapsule dry powder floats up and down with the airflow, The microcapsule dry powder is dispersed in the dispersion zone 220 of 270, thereby obtaining the microcapsule dry powder suspended in the cylinder 270;

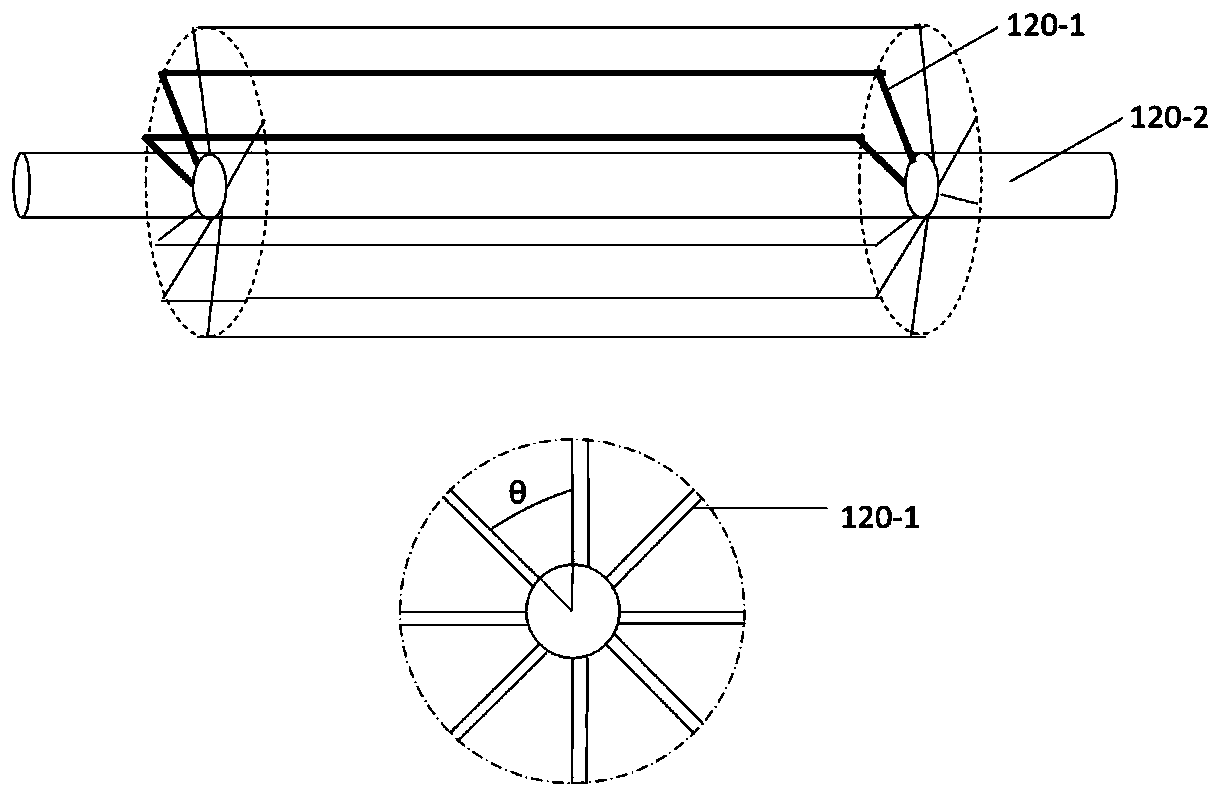

[0105] Preheating: the dry microcapsule powder is transported from the dispersion zone 220 to the preheating zone 230. At a certain temperature, the dry microcapsule powder has been preliminarily foamed to obtain incompletely foamed microcapsules. The shaft screw struct...

Embodiment 1

[0129] use figure 1 The shown pre-expanded microcapsule preparation device implements the method of the present embodiment, and described method comprises the following steps:

[0130] (1) first add microcapsule dry powder (wherein said microcapsule is a low-temperature microcapsule) in the conical feeding hopper of feeding device 100, feed rate is 100kg / h, and the vertical feeding screw device in described feeding device 100 The rotation speed is 50rpm.

[0131] Then the microcapsule dry powder is transported to the feed zone 210 of the foaming device 200 . The rotation speed of the driving shaft 300 fixedly connected with the one-piece continuous shaftless screw structure 260 of the foaming device 200 is 50 rpm.

[0132] (2) Then the microcapsule dry powder is transported from the feeding area 210 to the dispersion area 220, and the dispersion of the dry powder is completed under the action of the airflow in the blowing device 400 in the cylinder.

[0133] (3) Driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com