Gas flow directing device for burners of cooking appliances

a technology of gas flow and burner, which is applied in the direction of gaseous heating fuel, combustion type, domestic stove or range, etc., can solve the problems of increasing the consumption of fuel, wasting heating energy from cooking utensils, and economically and ecologically inappropriate appliances, and achieves the effect of improving the burner's functioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In accordance with schematic figures indicated above, there will be described in more details some examples of possible embodiments of the present invention but in a merely exemplary and non-limitative manner since the device for directing the flow of gases generated by burner flames can be understood through different structural and dimensional details and aspects without diverting from the present scope of protection.

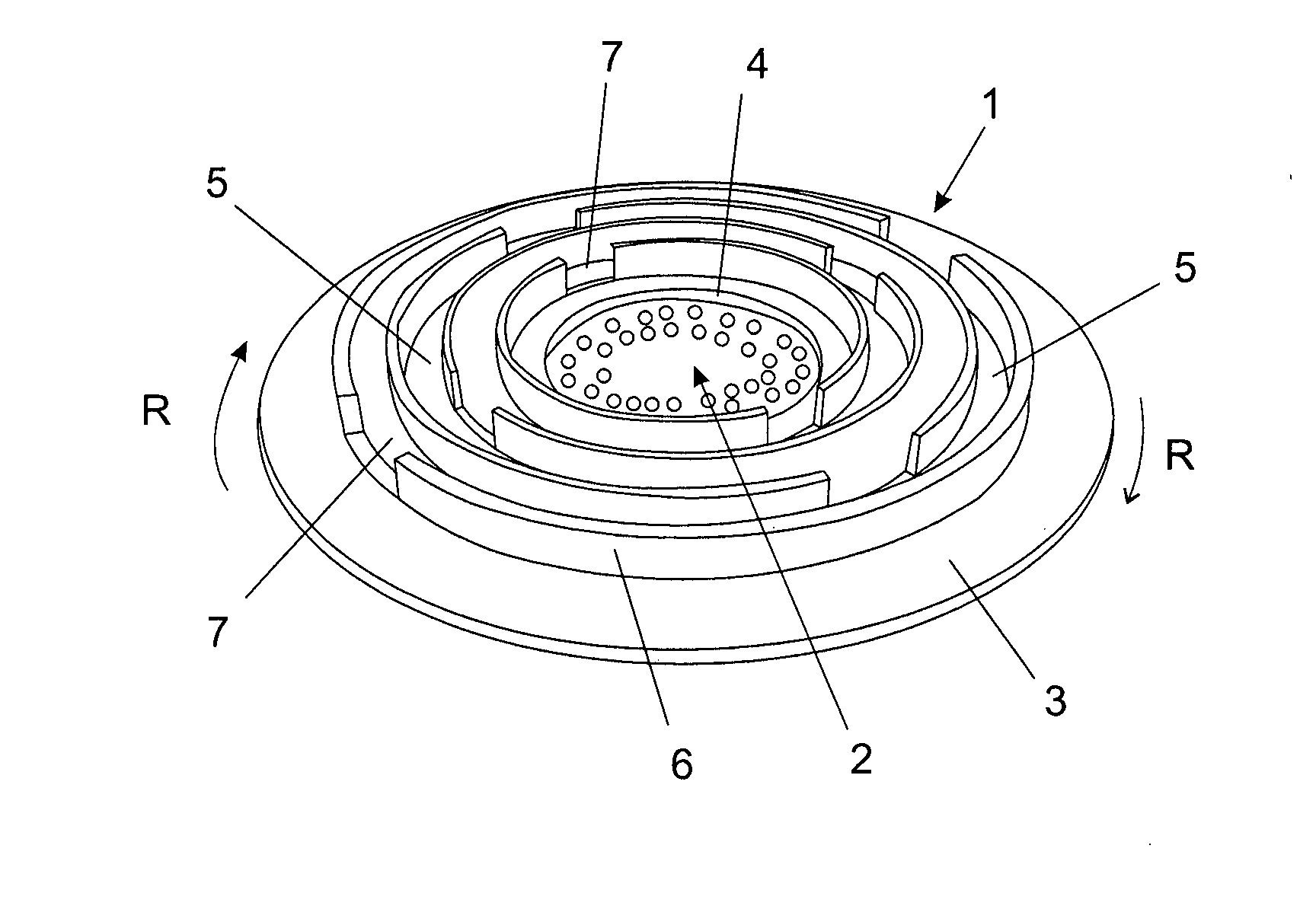

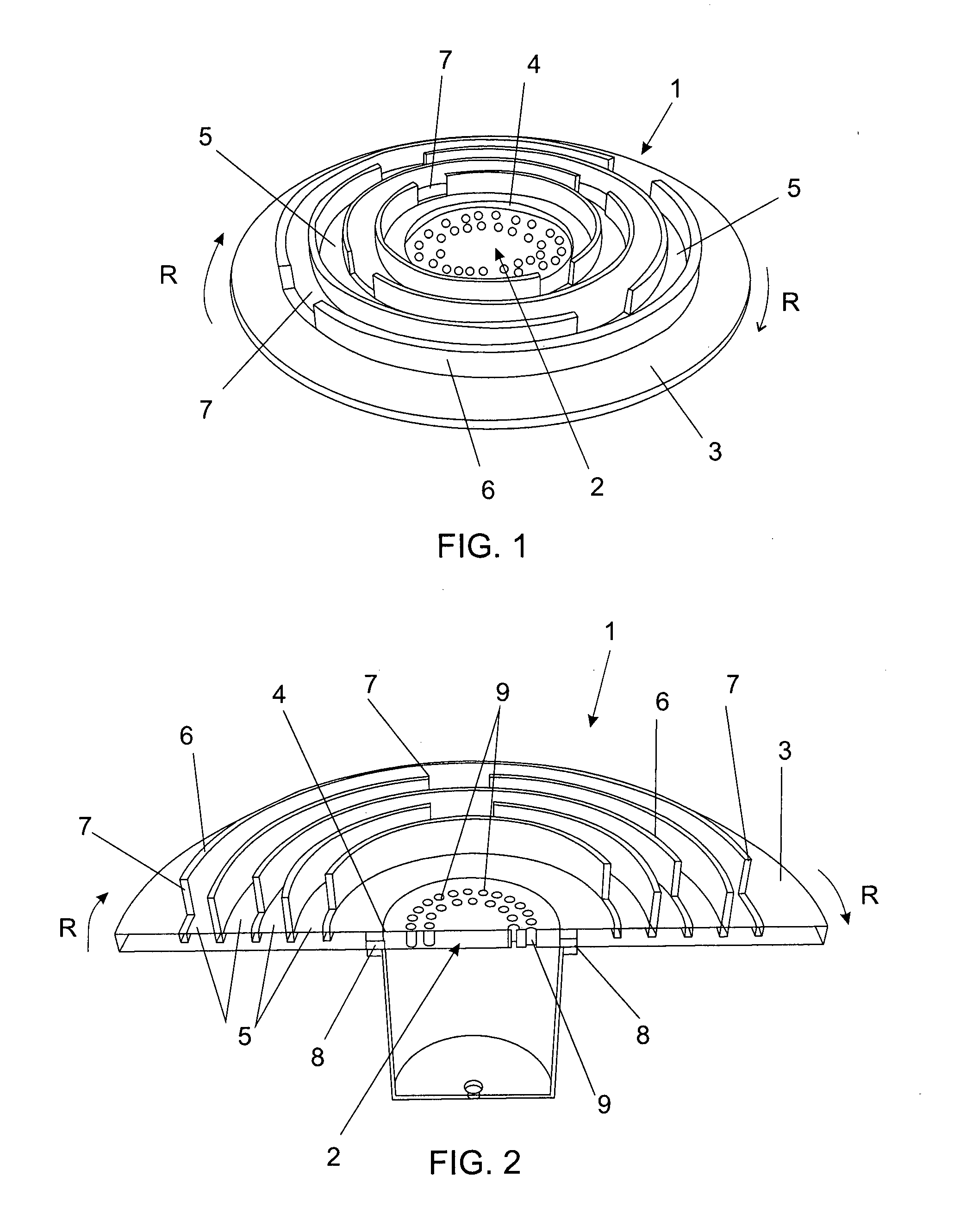

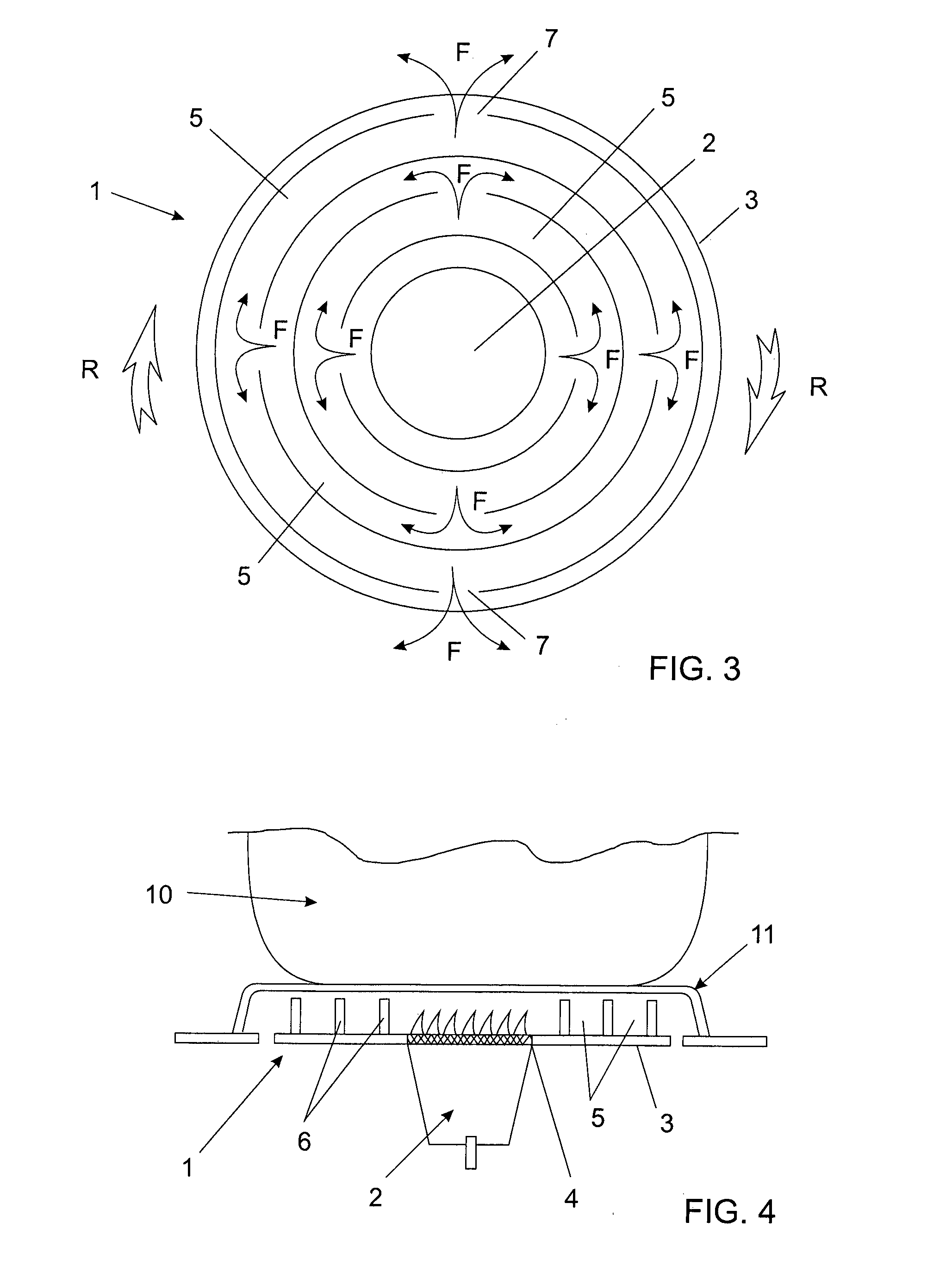

[0027]The gas flow directing device 1 of the present invention is an accessory that can be coupled with a burner 2 or alternatively it is possible that said burner comprises the directing device of the present invention. Thus, it is important to point out that said gas flow directing device can be either an entirely independent part of the burner or a part that constitutes the burner assembly of a cooking appliance.

[0028]In this sense, said gas flow directing device 1 comprises a base 3 comprising opening 4 for fitting it over the burner 2 wherein said base 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com