Drying equipment provided with stirring mechanism

A technology of drying equipment and stirring mechanism, which is applied in the direction of drying, drying machine, lighting and heating equipment, etc., which can solve the problems of insufficient heat, low drying efficiency of production materials, uneven internal temperature, etc., and achieve energy saving and energy saving Energy consumption, speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

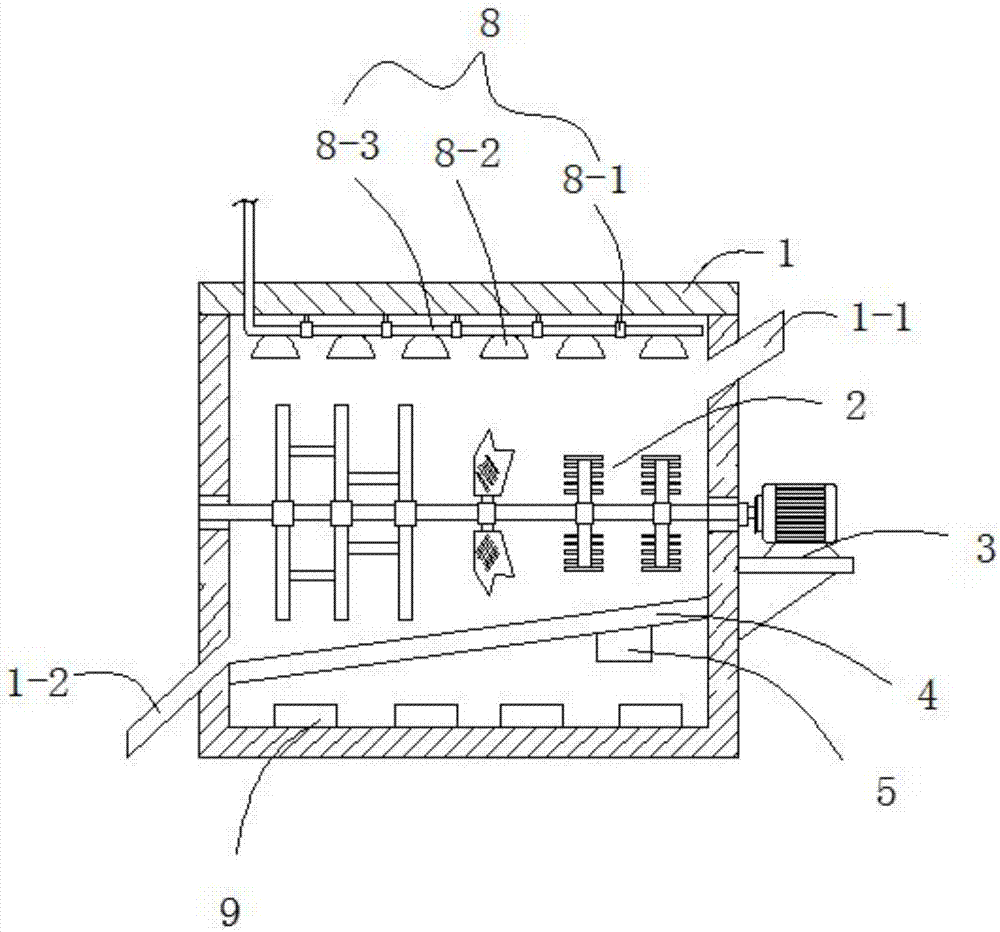

[0023] Such as Figure 1 to 2 As shown, this embodiment provides a drying equipment with a stirring mechanism, including a drying chamber 1, a feed port 1-1 and a discharge port 1-2 communicating with the interior of the drying chamber 1, characterized in that: The drying chamber 1 is provided with a vibrating baffle 4 obliquely, the discharge port 1-2 is located on the drying chamber 1 on the lower side of the vibrating baffle 4, and the vibrating baffle 4 divides the drying chamber 1 into upper materials The top of the upper material cavity is equipped with a return air system 8, the upper material cavity is equipped with a horizontal stirring mechanism 2, the upper material cavity is equipped with a driving mechanism 3 that drives the horizontal stirring mechanism 2 to rotate, and the lower heating cavity is arranged There is a heating element 9.

[0024] The return air system 8 includes a main return air pipe 8-3 that is clamped to the top of the upper material cavity throug...

Embodiment 2

[0027] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0028] The return air collecting cover 8-2 has a cone-like structure with a small upper part and a larger lower part.

[0029] A vibration mechanism 5 is provided under the vibration partition 4.

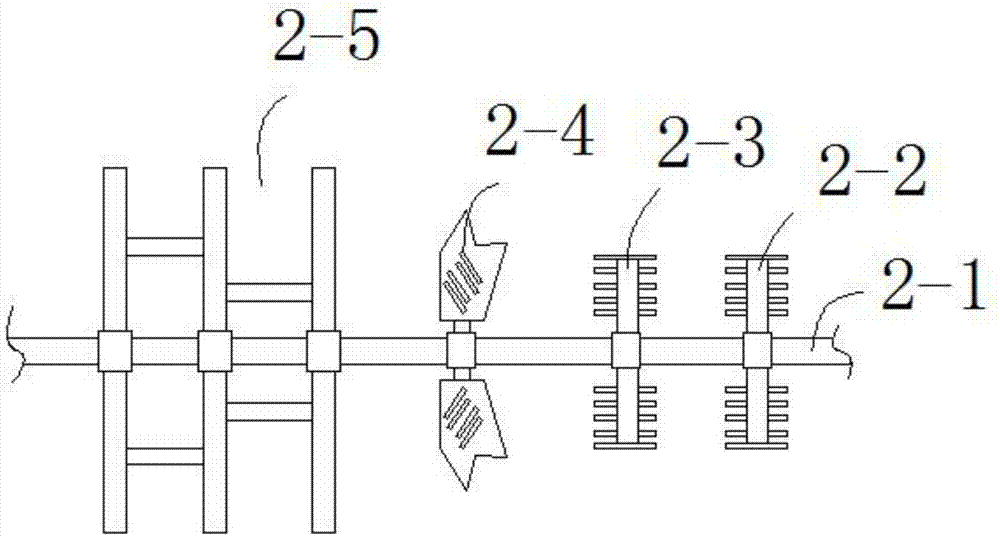

[0030] The said horizontal stirring mechanism 2 includes a horizontal stirring shaft 2-1, and a stirring assembly A2-5, a stirring assembly B2-4, a stirring assembly C2-3 and a stirring assembly D2-2 are arranged in order from left to right on the transverse stirring shaft. The stirring assembly C2-3 and the stirring assembly D2-2 have the same mechanism.

[0031] The stirring assembly C2-3 includes a stirring rod symmetrically arranged on the transverse stirring shaft 2-1, and a plurality of stirring teeth are provided on the stirring rod.

[0032] The mixing assembly B2-4 includes heterosexual mixing blades symmetrically arranged on the transverse mixing shaft 2-1, the heterosexual mixing blades are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com