Electric crucible furnace equipment for glass dissolution and manufacturing method thereof

An electric crucible and glass technology, applied in furnaces, boilers, furnace types, etc., can solve the problems of poor production stability, unfavorable market changes, and take a long time to increase the service life, improve the environment of high temperature operation, and avoid heat the effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

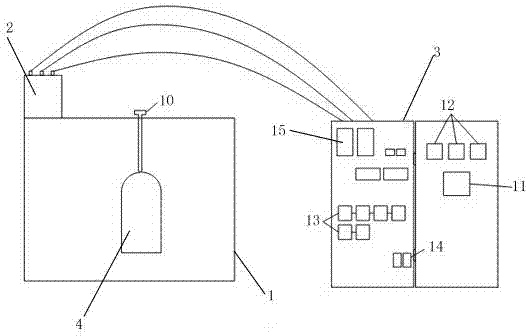

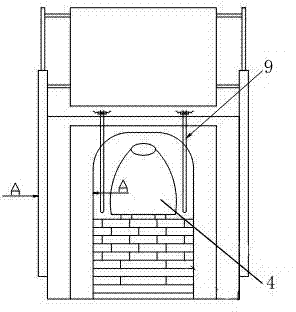

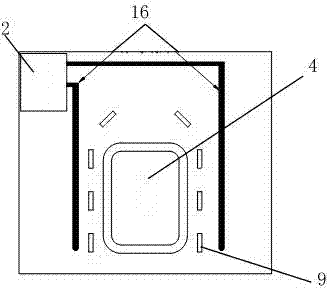

[0025] Such as Figure 1-4 As shown, the electric crucible furnace equipment for dissolving glass according to the present invention includes a furnace body 1, and three transformers 2 with different voltages are arranged on the top of the furnace body 1, and the transformer 2 is externally connected with an electric control cabinet 3. The cabinet 3 is respectively connected with the transformer and the electrical equipment on the furnace body 1; the innermost layer of the furnace body 1 is provided with a crucible 4, and the crucible 4 is provided with a four-layer insulation structure, which is a first-level insulation brick layer from the inside to the outside. 5. Secondary insulation brick layer 6, insulation cotton layer 7 and steel skin layer 8; multiple heating rods 9 are inserted inside the furnace body 1, and the end of the heating rod 9 protruding from the furnace body is connected to the output end of the transformer 9, and the furnace body 1 A thermocouple 10 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com