Patents

Literature

120results about How to "Little heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light emitting device using led

InactiveUS20040190304A1Extended service lifeEffective coolingDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

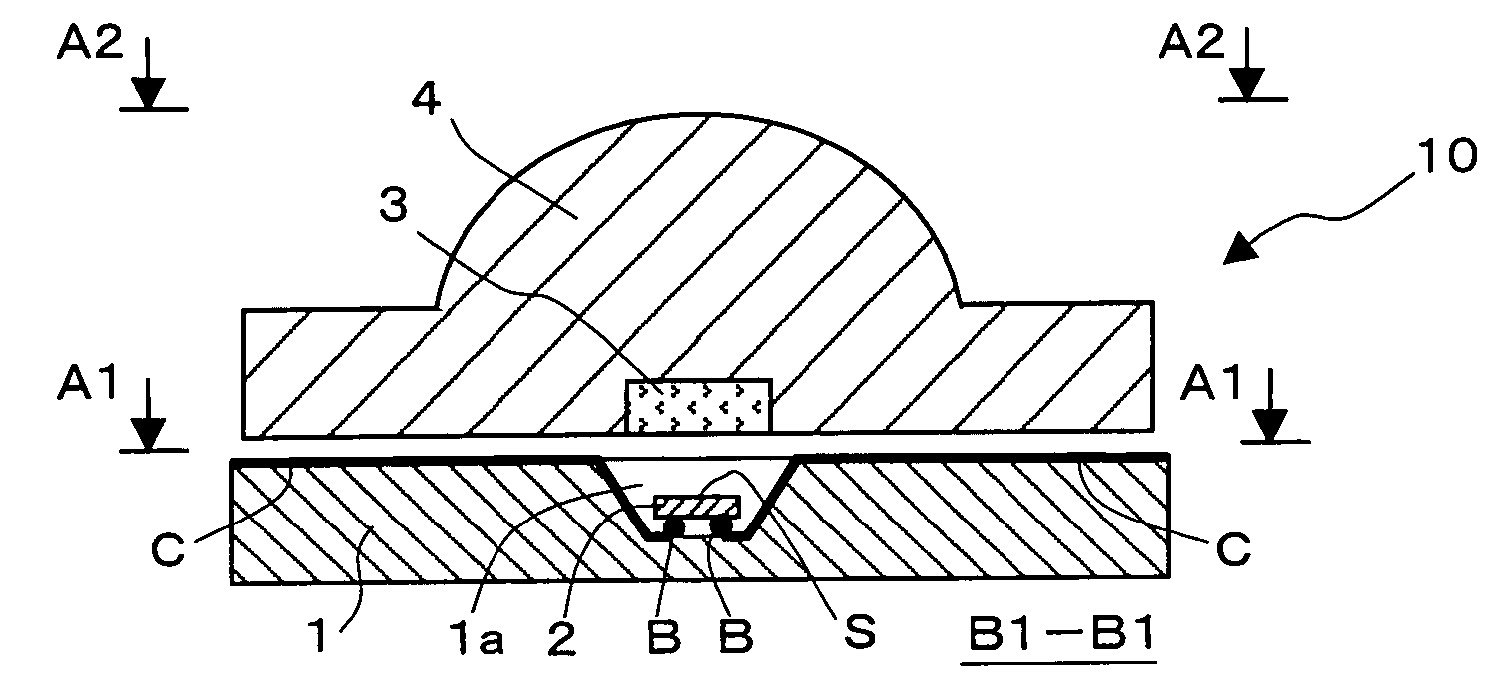

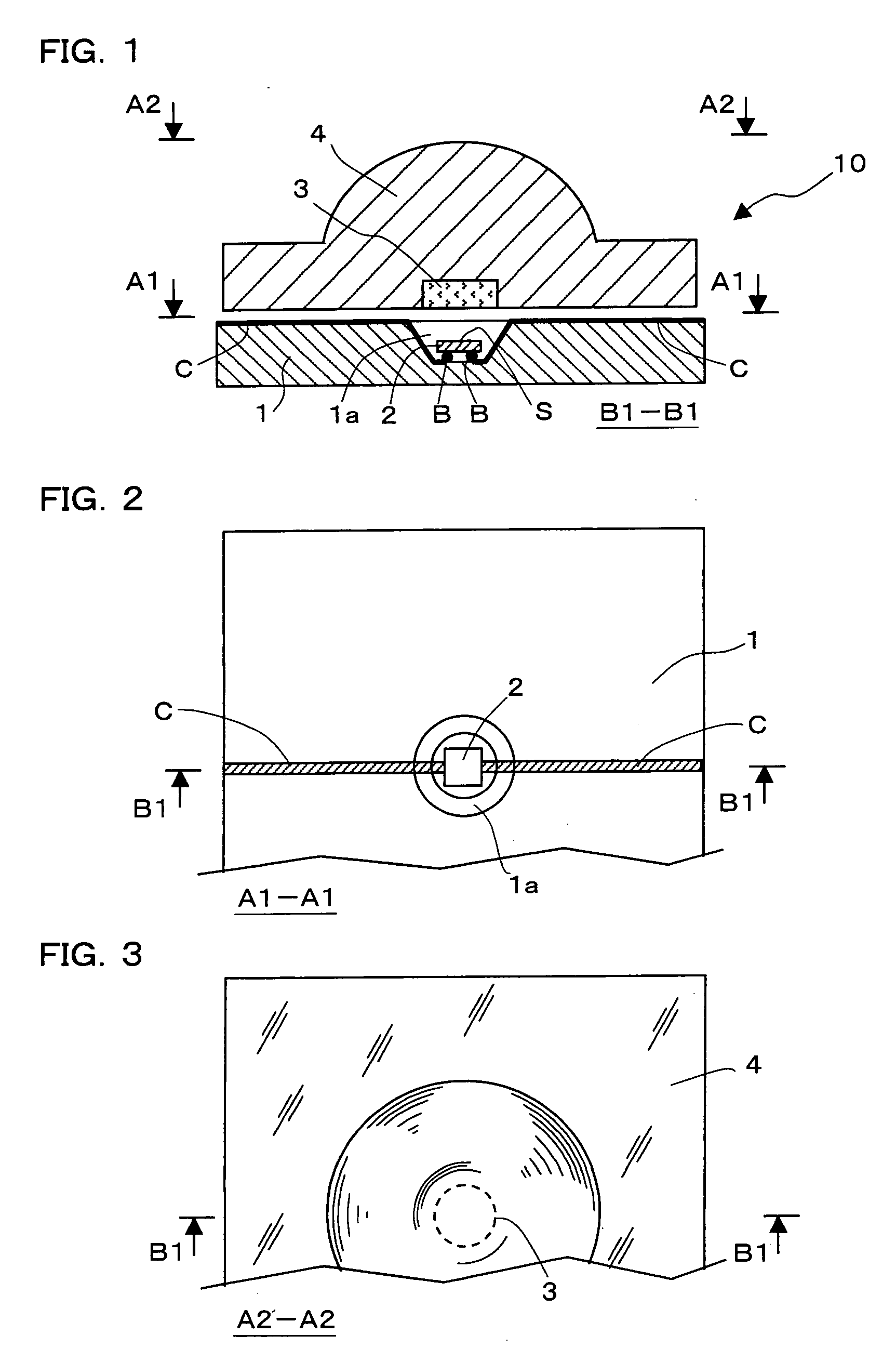

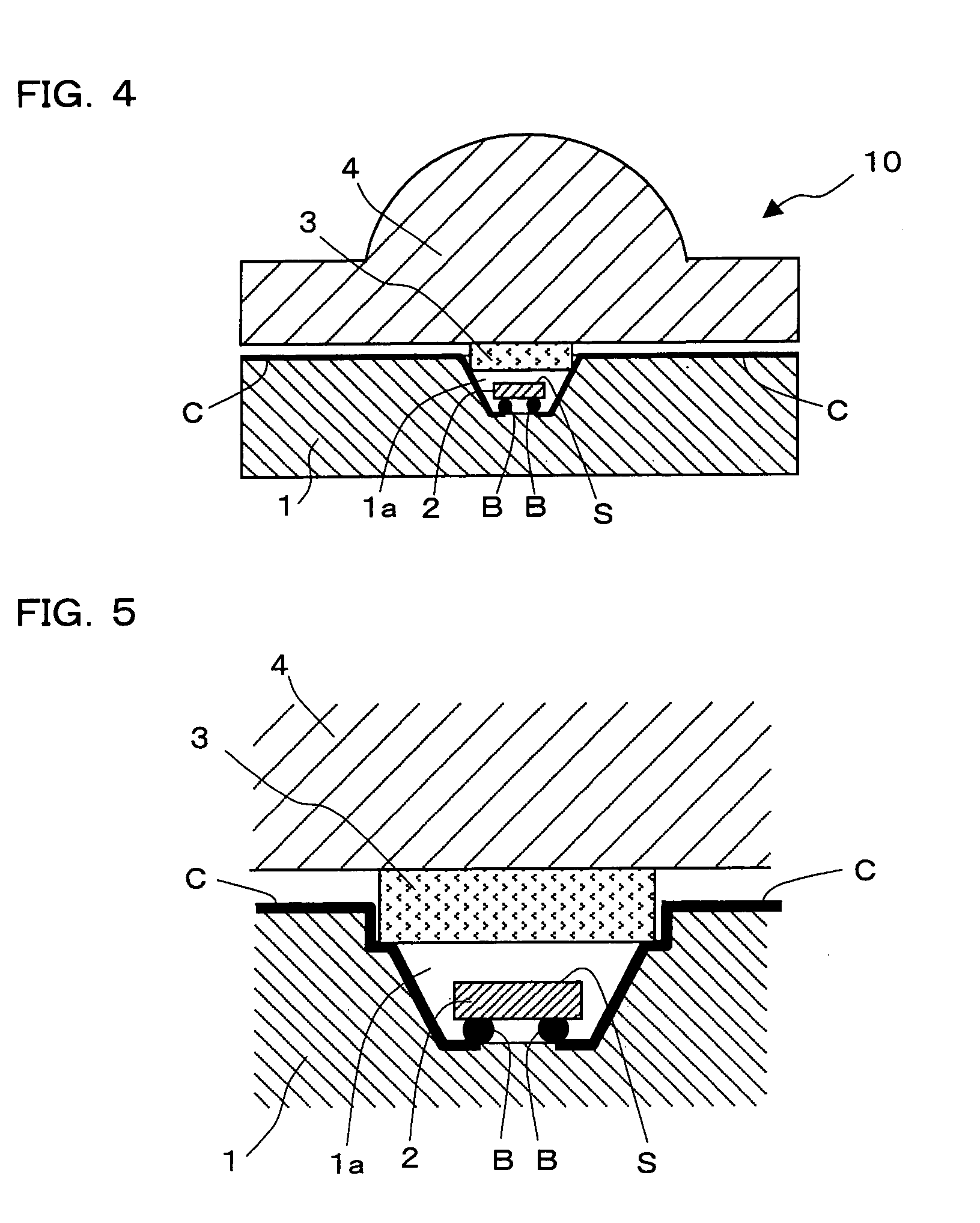

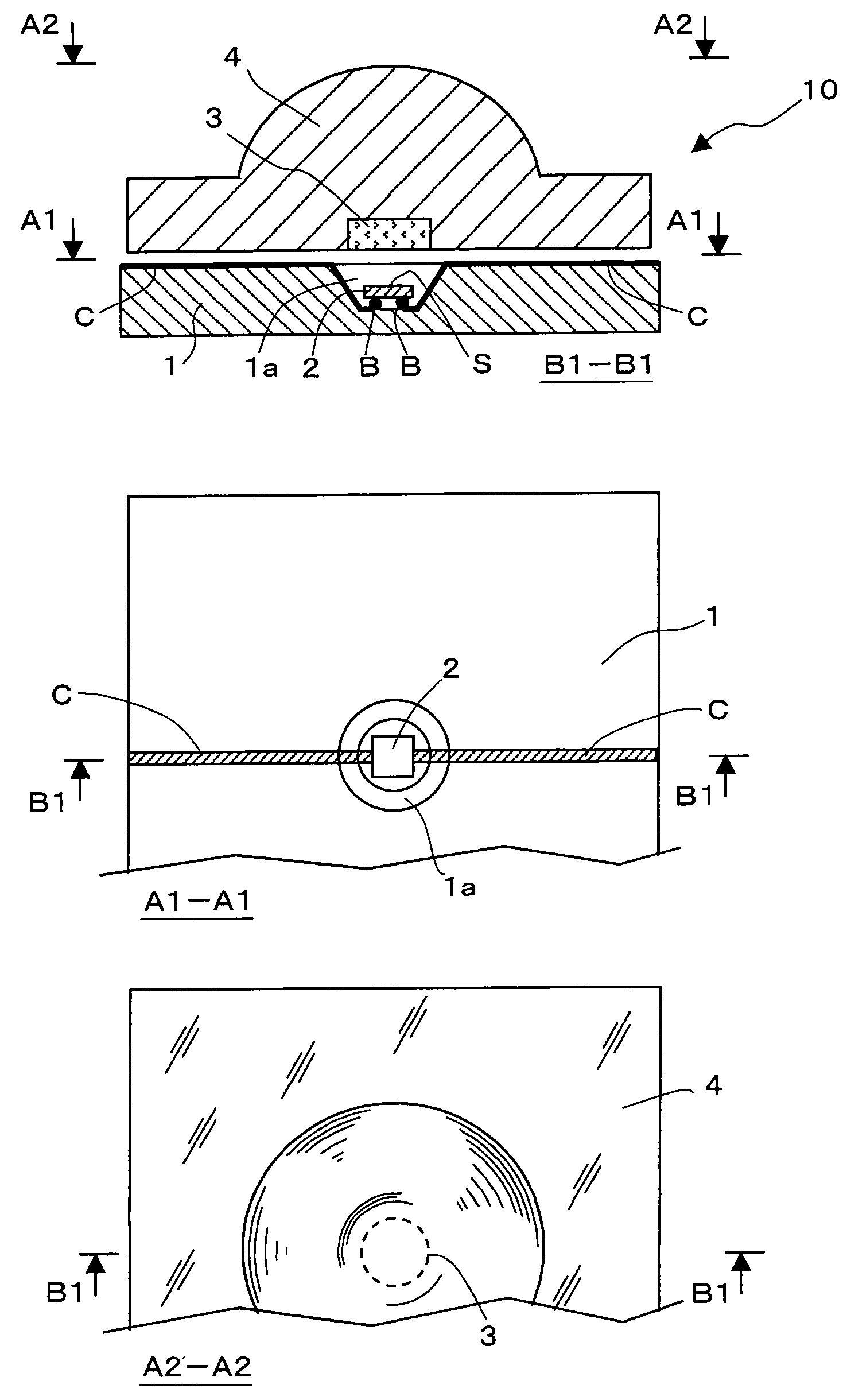

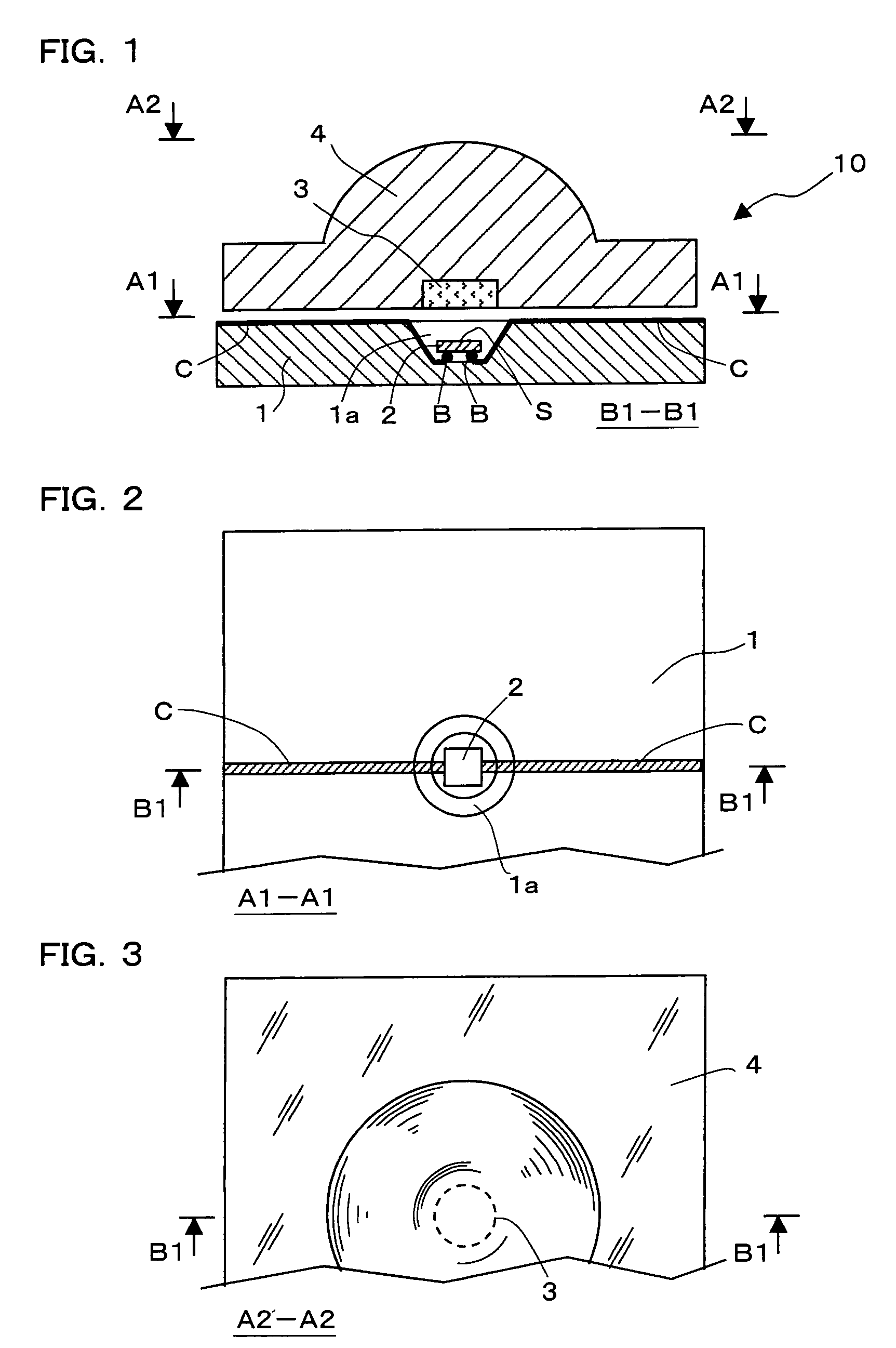

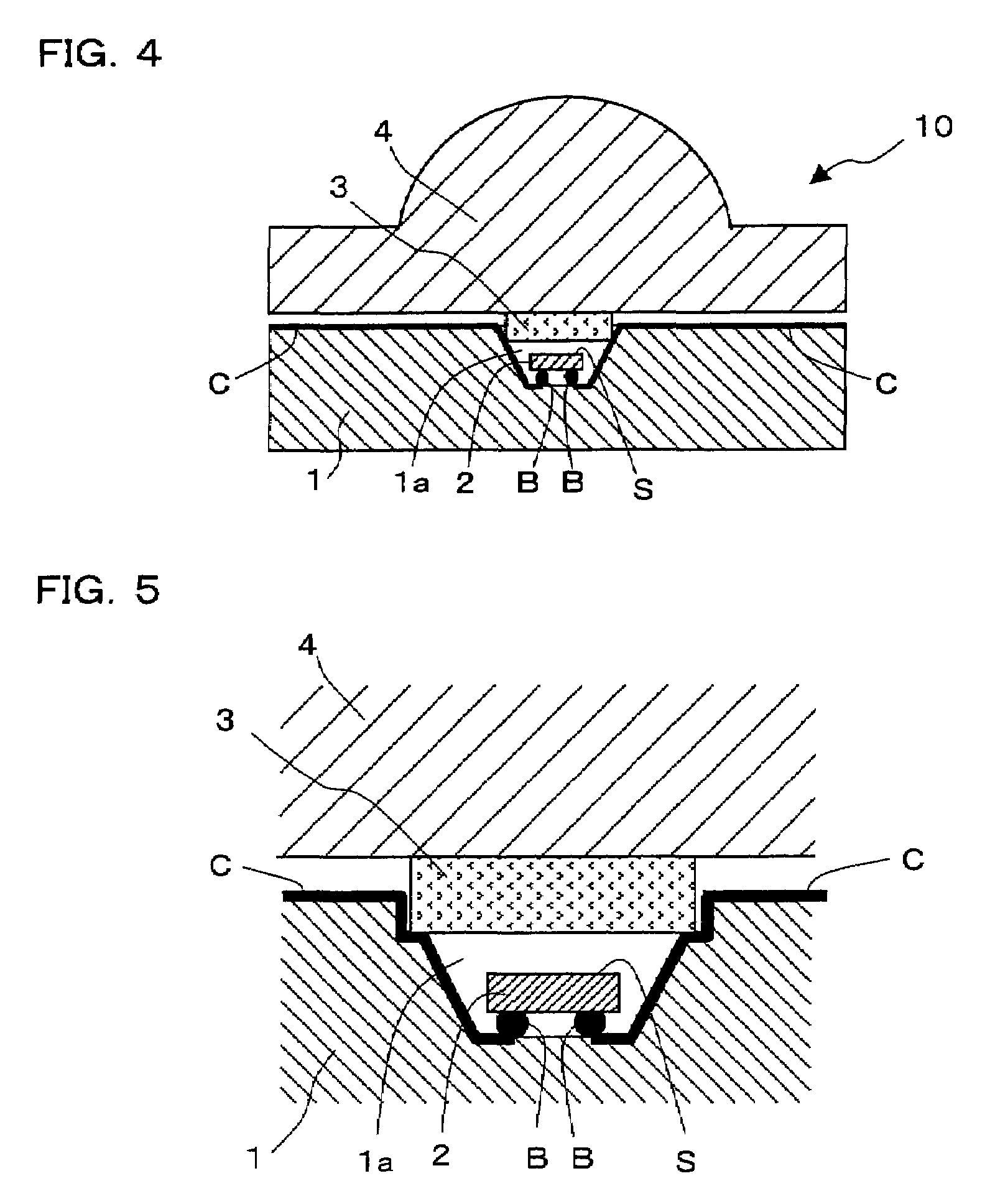

A light-emitting device (10) using an LED is proposed. This light-emitting device (10) is provided with a packaging substrate (1), a light-emitting element (2) which is mounted on this packaging substrate (1) with its face down, a fluorescent member (3) that is arranged face to face with a light-extracting surface (S) of the light-emitting element (2) without contacting the light-emitting element (2) and an optical member (4) which receives light that has been emitted from the light-emitting element (2) and made incident thereon through the fluorescent member (3), and aligns the incident light toward the outside of the device. Light, emitted from the light-emitting element (2), is made incident on the fluorescent member (3) to excite the fluorescent material so that the fluorescent material re-emits light having a wavelength different from that of the incident light. Those light rays, emitted from the light-emitting element (2), which have not been absorbed by the fluorescent member (3) and have passed through the fluorescent member (3) and those light rays that have been emitted from the fluorescent material are made incident on the optical member (4) and are aligned. Because the fluorescent member (3) is not made in contact with the light-emitting element (2), it does not receive the heat from the light-emitting element (2) through heat conduction, and consequently becomes less susceptible to degradation due to heat. Moreover, with the face-down mounting structure, the fluorescent member (3) and the optical member (4) can be placed closer to the light-emitting element (2) as long as they dose not contact the light-emitting element (2). Consequently, the service life of the fluorescent material or the fluorescent-material-mixed resin that tends to deteriorate can be lengthened, lights can be extracted more efficiently, and light rays can be properly aligned in a predetermined direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Light emitting device using LED

InactiveUS7084435B2Extended service lifeInhibit deteriorationDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

A light-emitting device which uses and LED having a light-emitting element being placed on a package substrate. The light-emitting element has a light-extracting surface. A fluorescent element which is formed by dispersing a fluorescent material in a transparent substance and is placed face to face with the light-extracting surface of the light emitting element and comprises a clearance gap in between. The light-emitting element generates light of a certain wavelength that emanates through the light-extracting surface into the fluorescent element where the wavelength is changed. The device further comprises an optical element which receives light from the light-emitting element through the fluorescent element and directs the light to the outside of the device.

Owner:MATSUSHITA ELECTRIC WORKS LTD

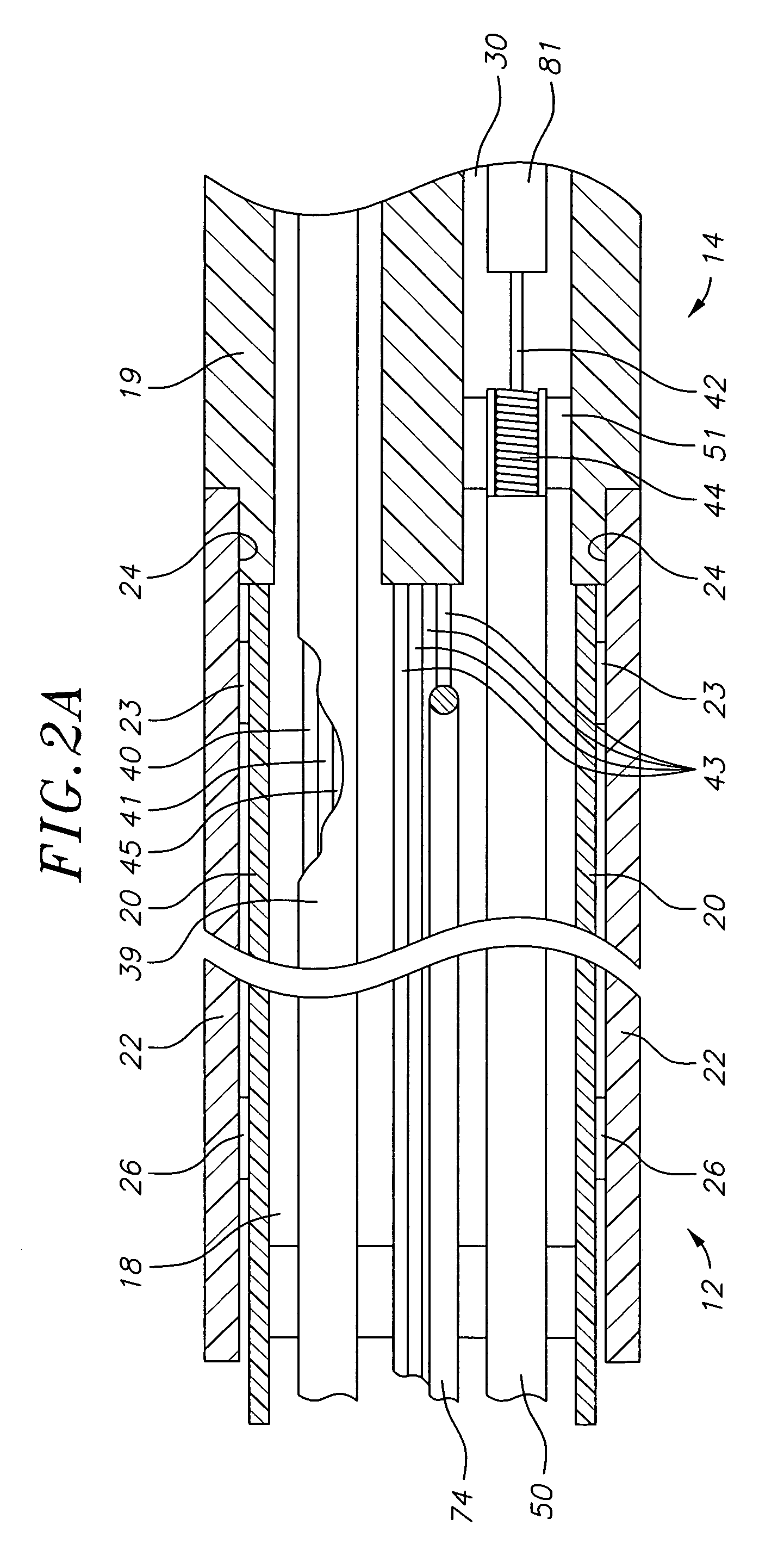

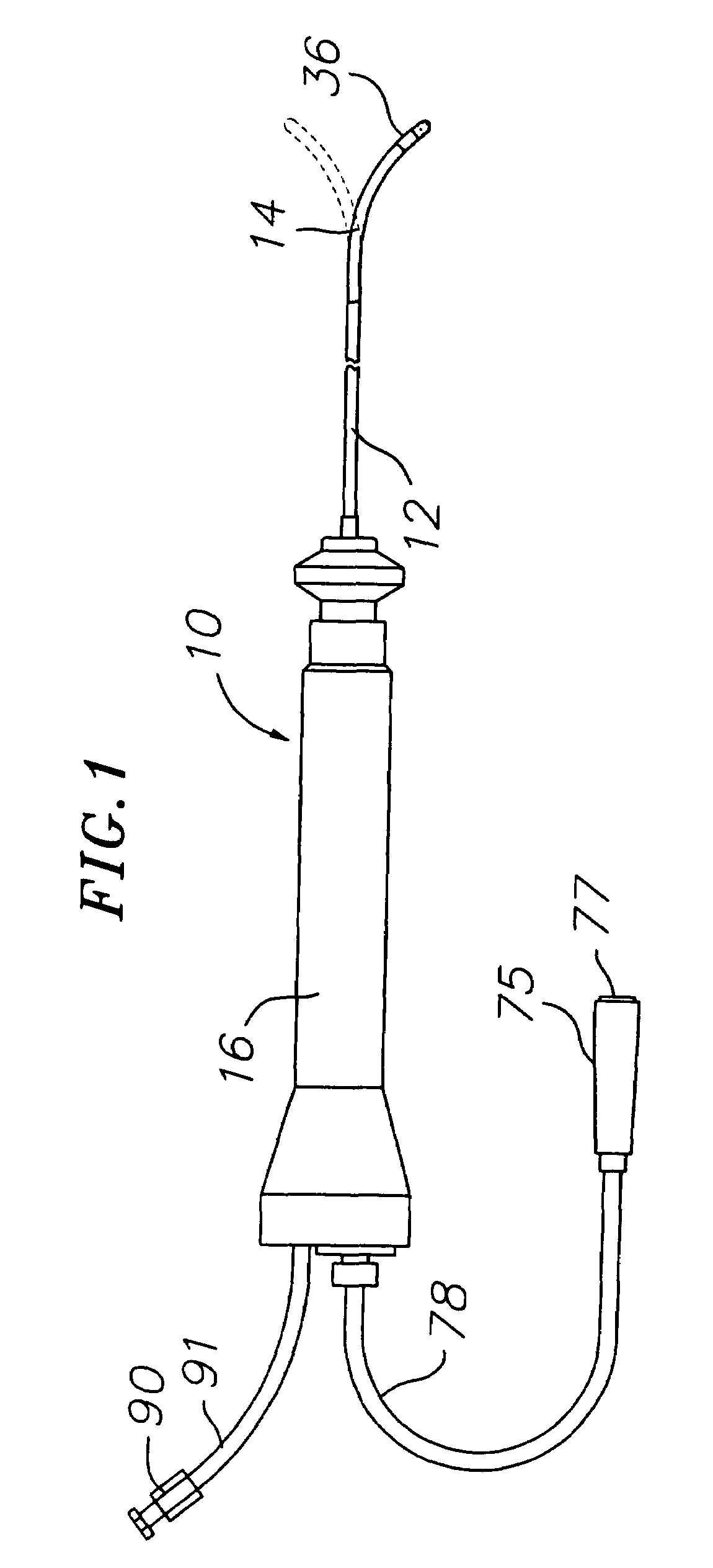

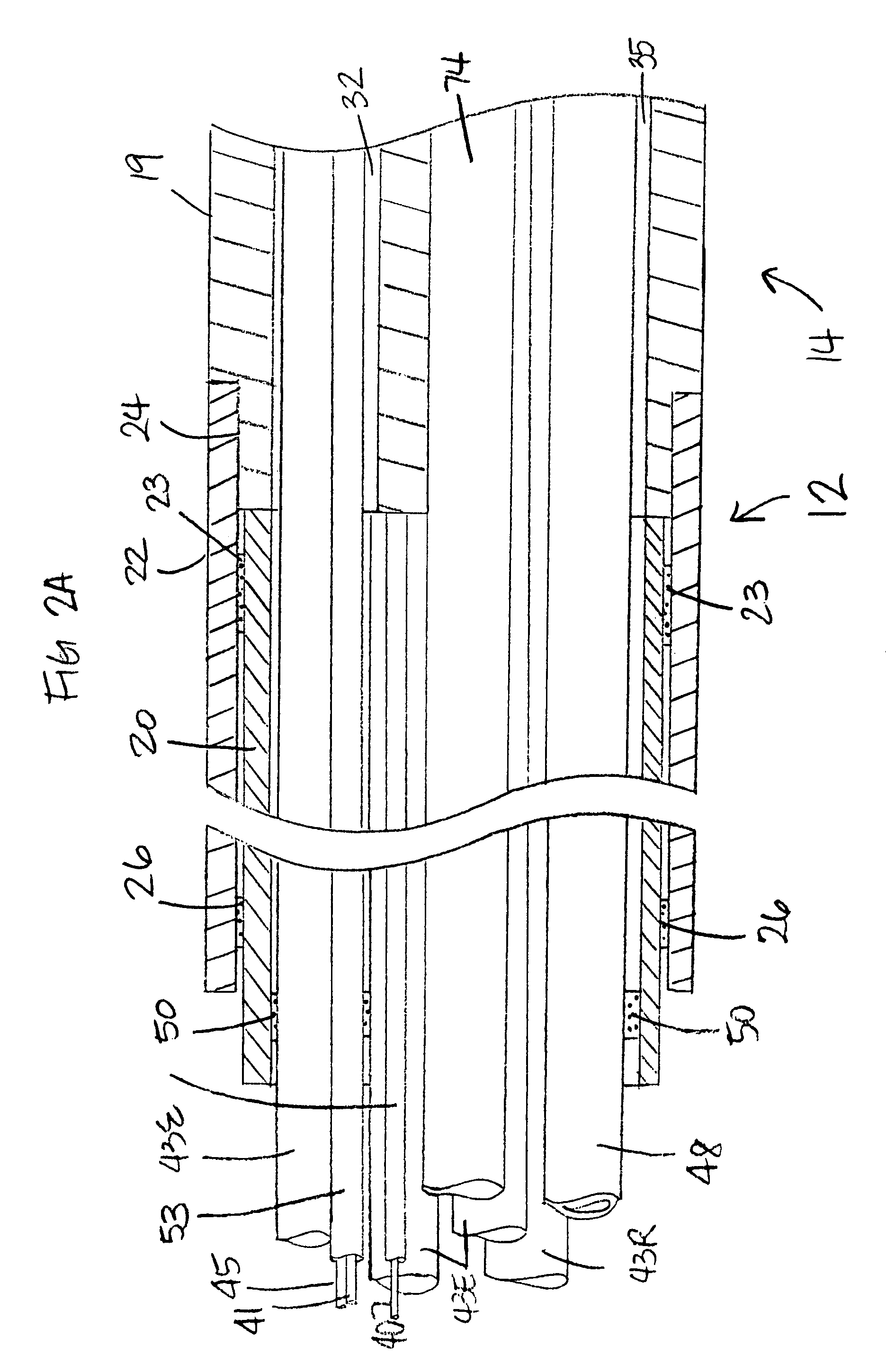

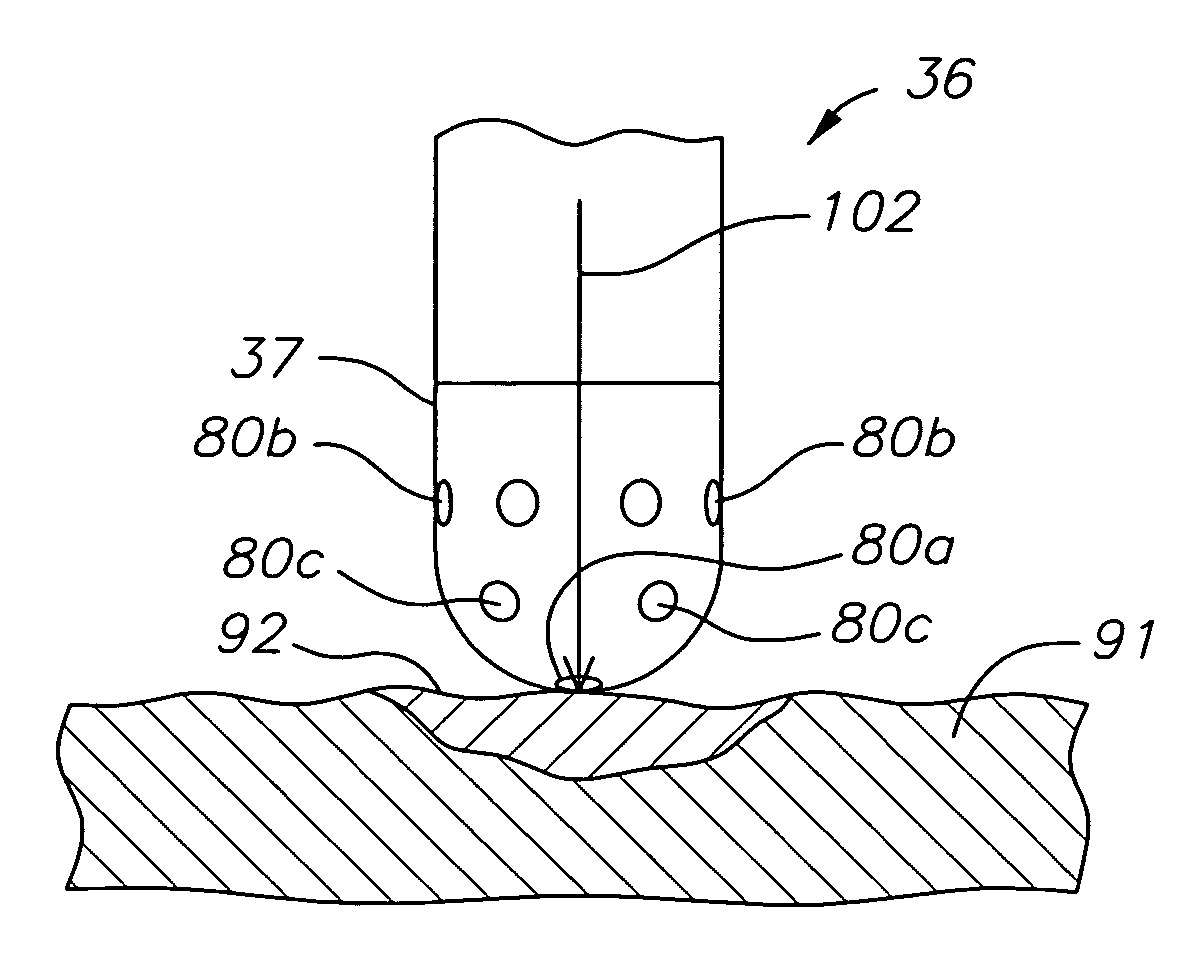

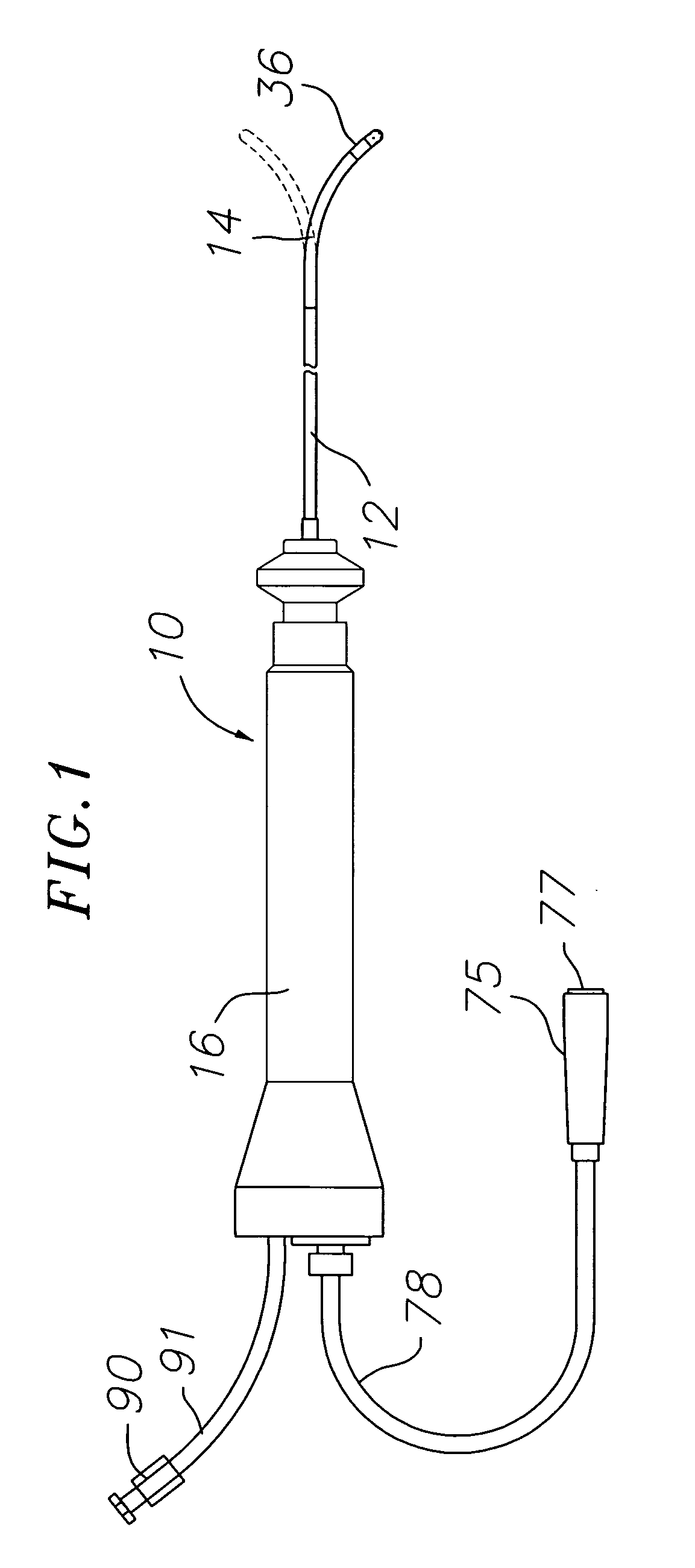

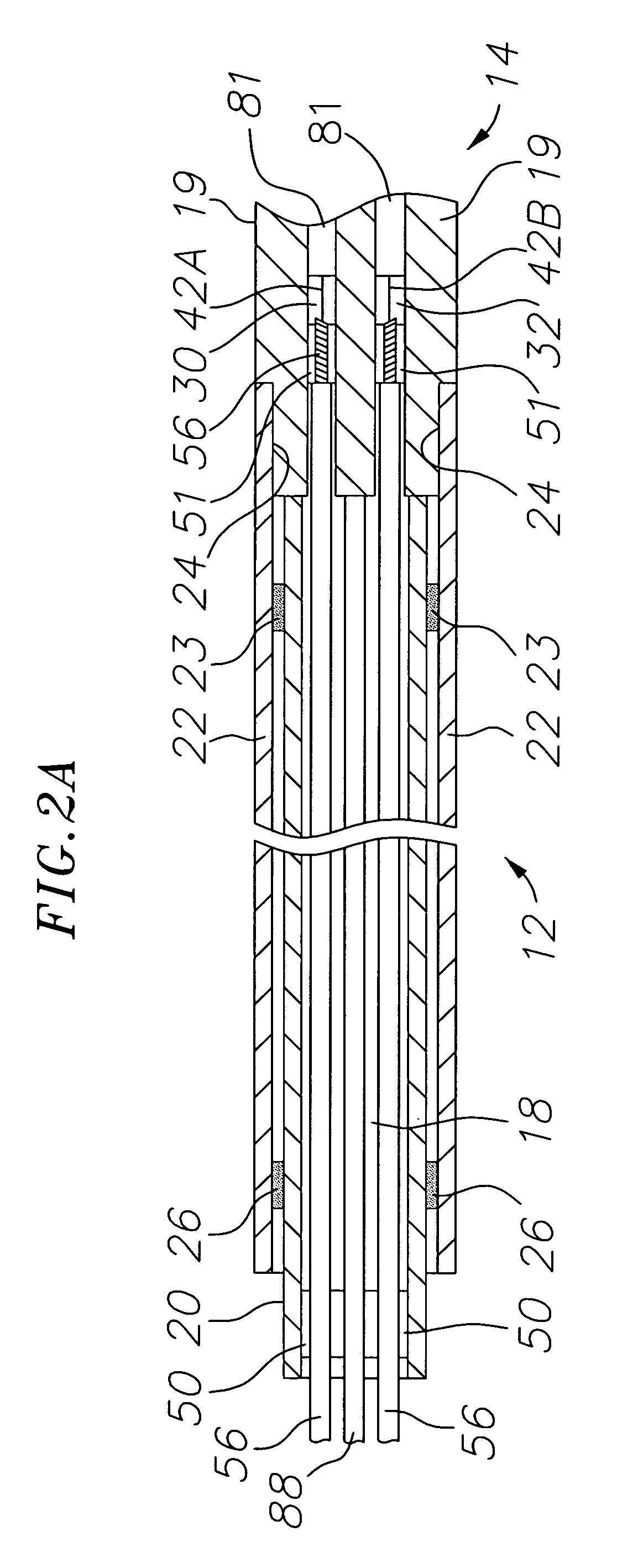

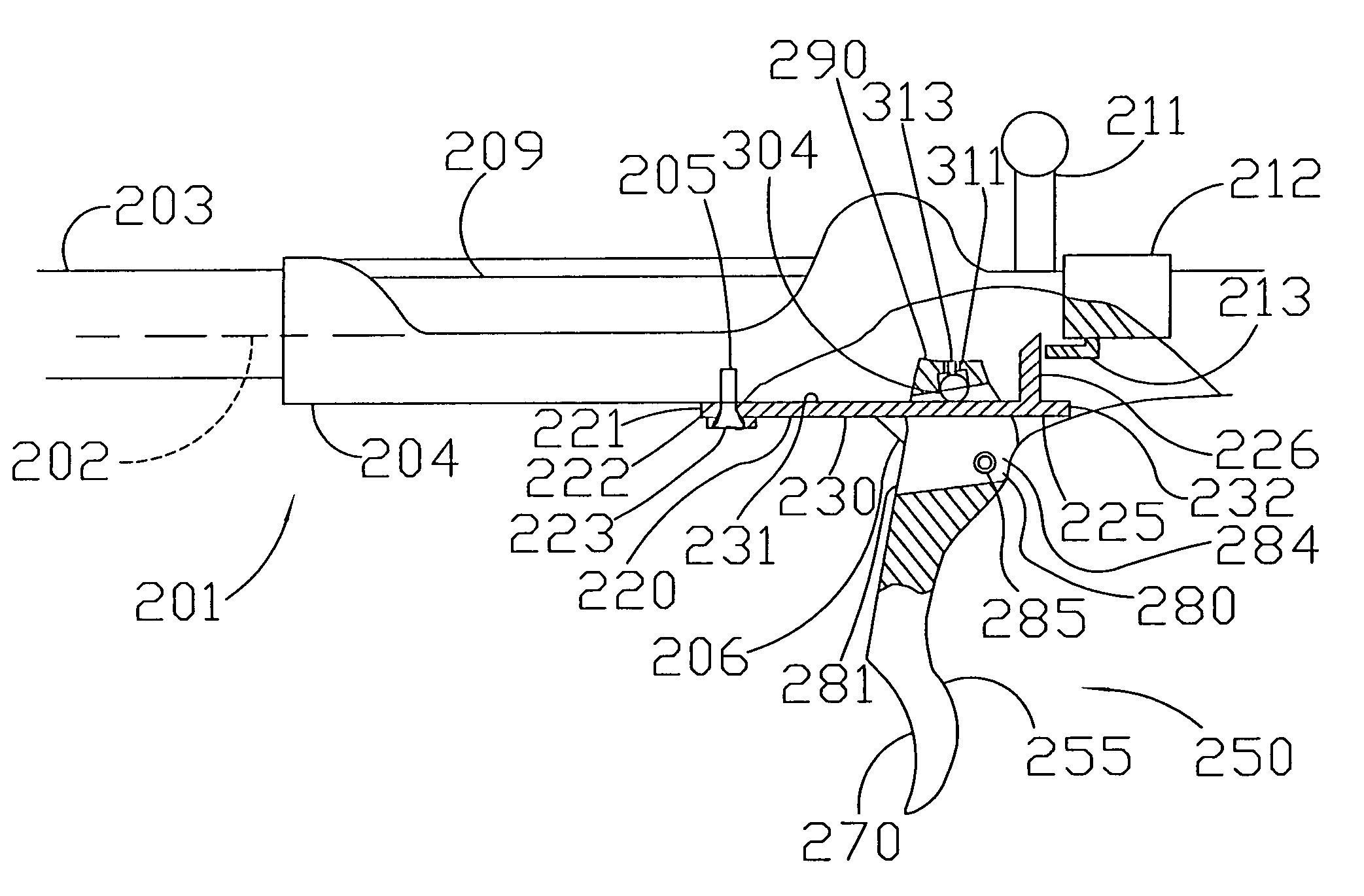

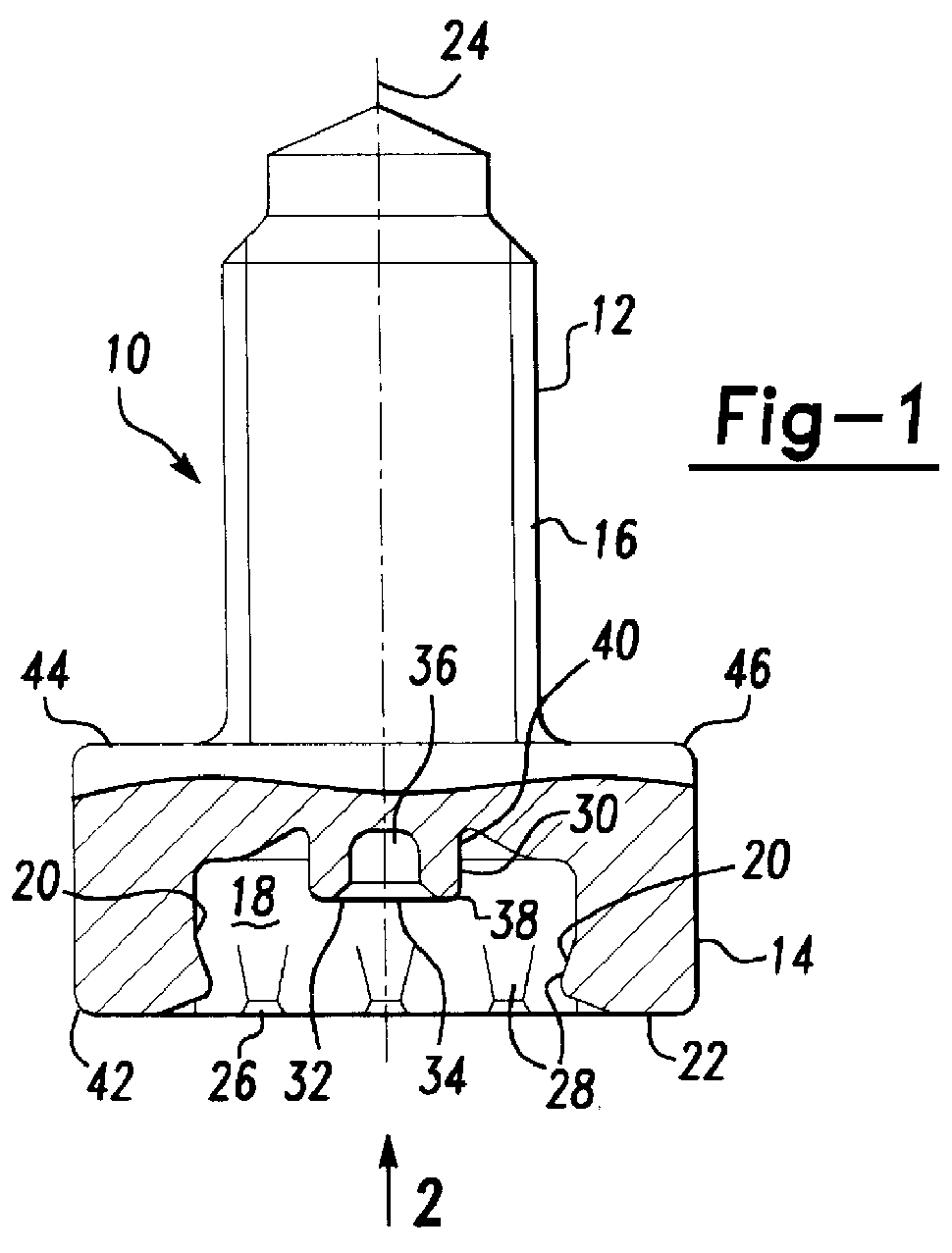

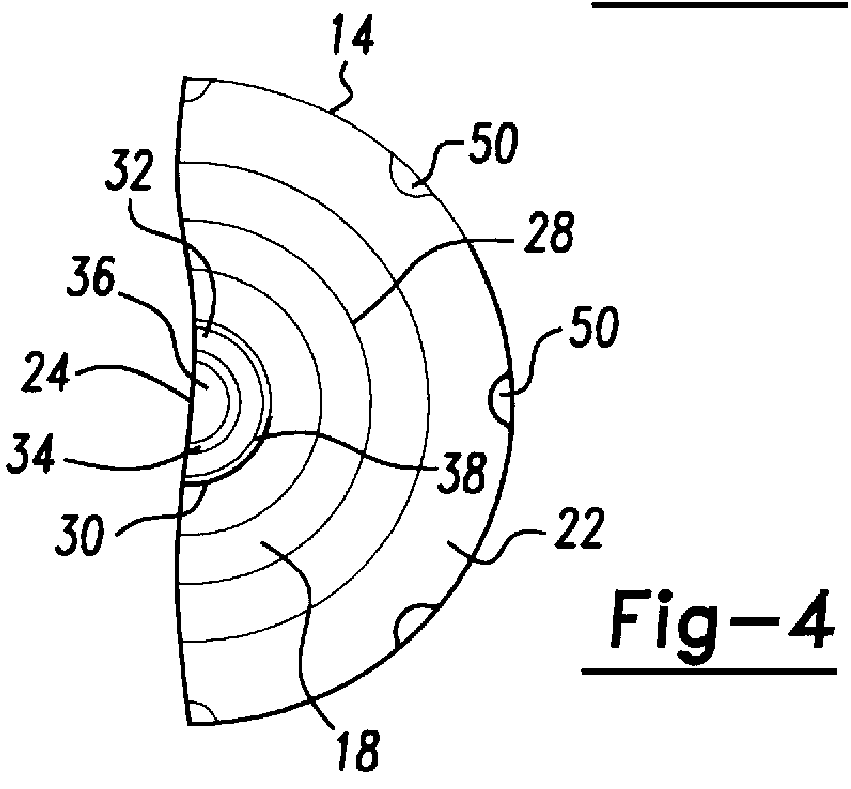

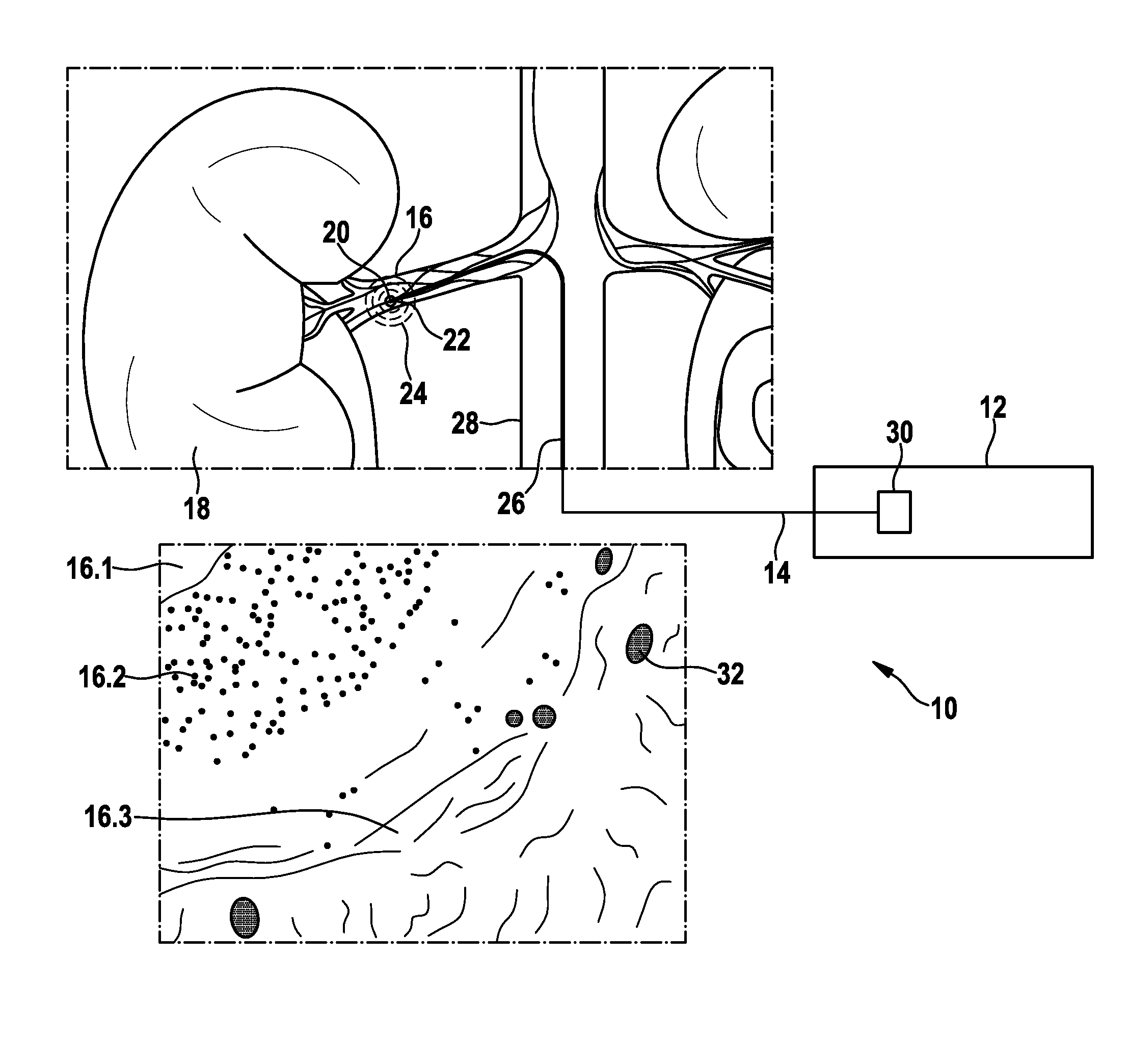

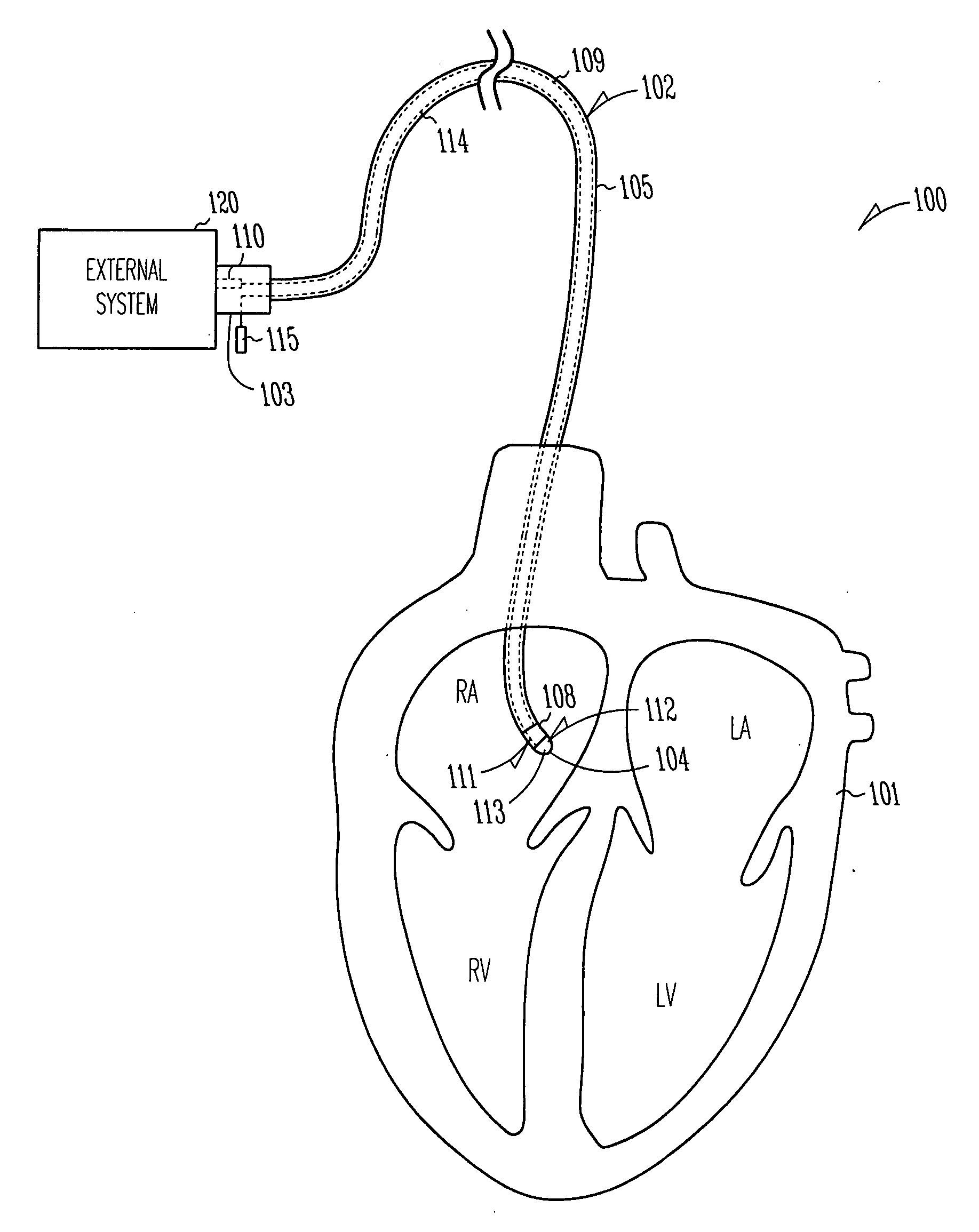

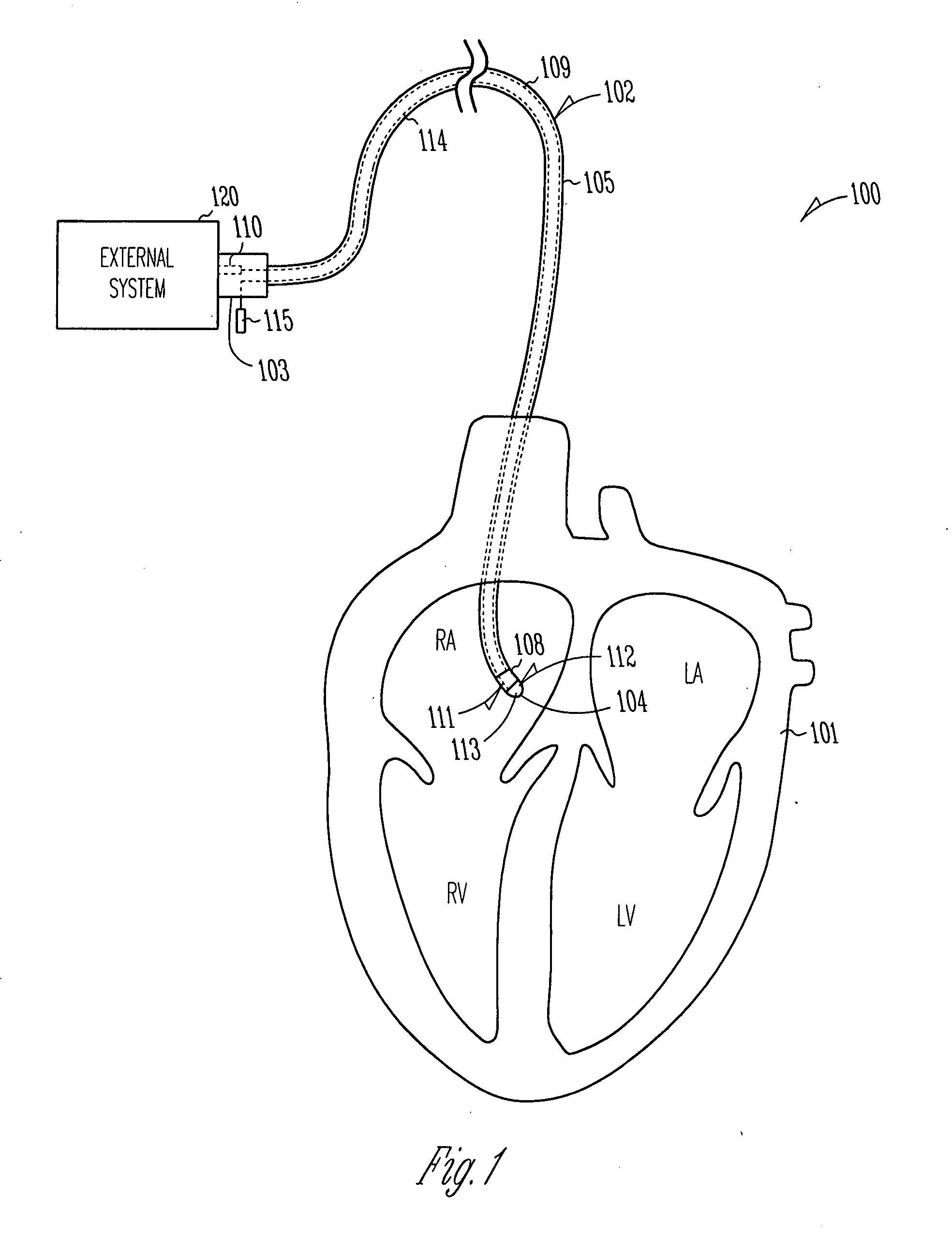

Catheter with multi port tip for optical lesion evaluation

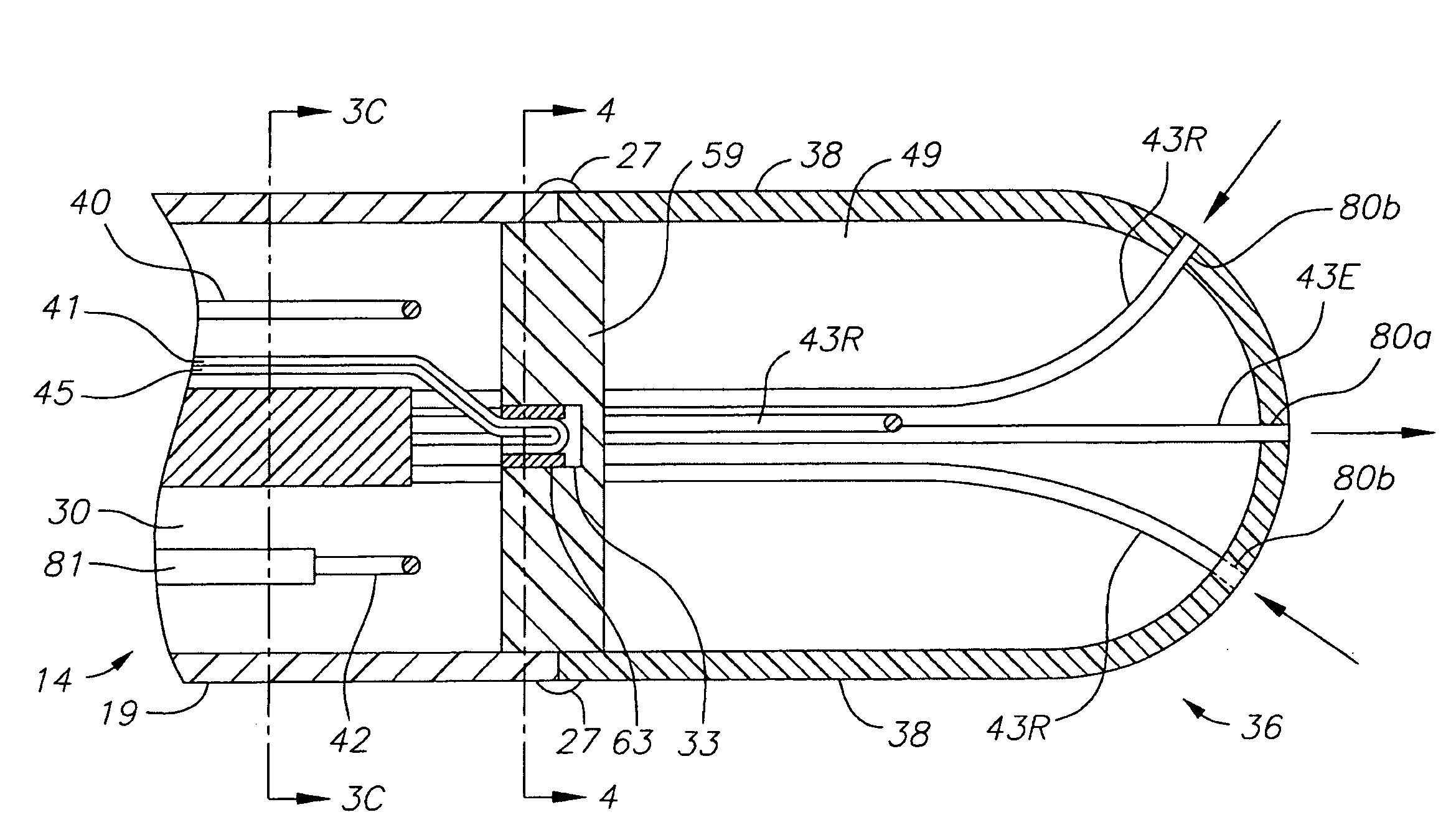

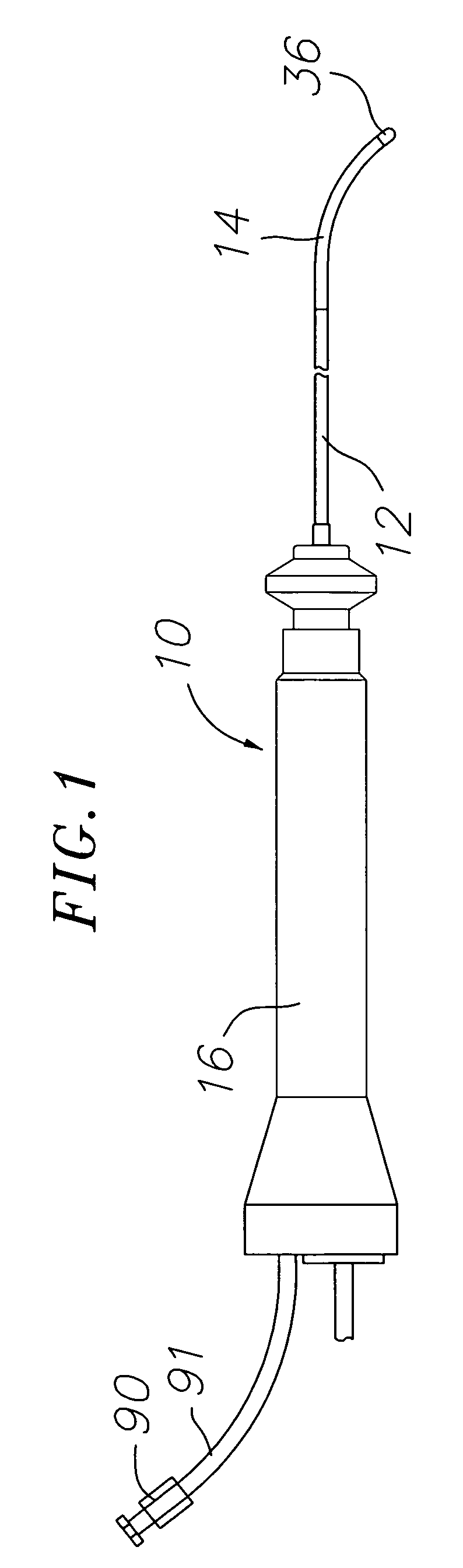

ActiveUS7662152B2Stress minimizationMinimize strainDiagnosticsSurgical instruments for irrigation of substancesDistal portionWaveguide

A catheter is adapted to ablate tissue and provide optically-based lesion qualitative and quantitative monitoring, comprising a catheter body and a tip electrode distal the catheter body adapted for ablating tissue, the tip electrode having a shell and an alignment member defining a hollow distal portion therebetween. In accordance with the invention, the catheter further includes a plurality of optical waveguides adapted to transmit optical energy to and from the tip electrode. A distal portion of each waveguide extends through the hollow distal portion and terminates in openings formed in the shell. Advantageously, the alignment member fixedly secures the distal portion of each waveguide against movement relative to the alignment member and the shell.

Owner:BIOSENSE WEBSTER INC

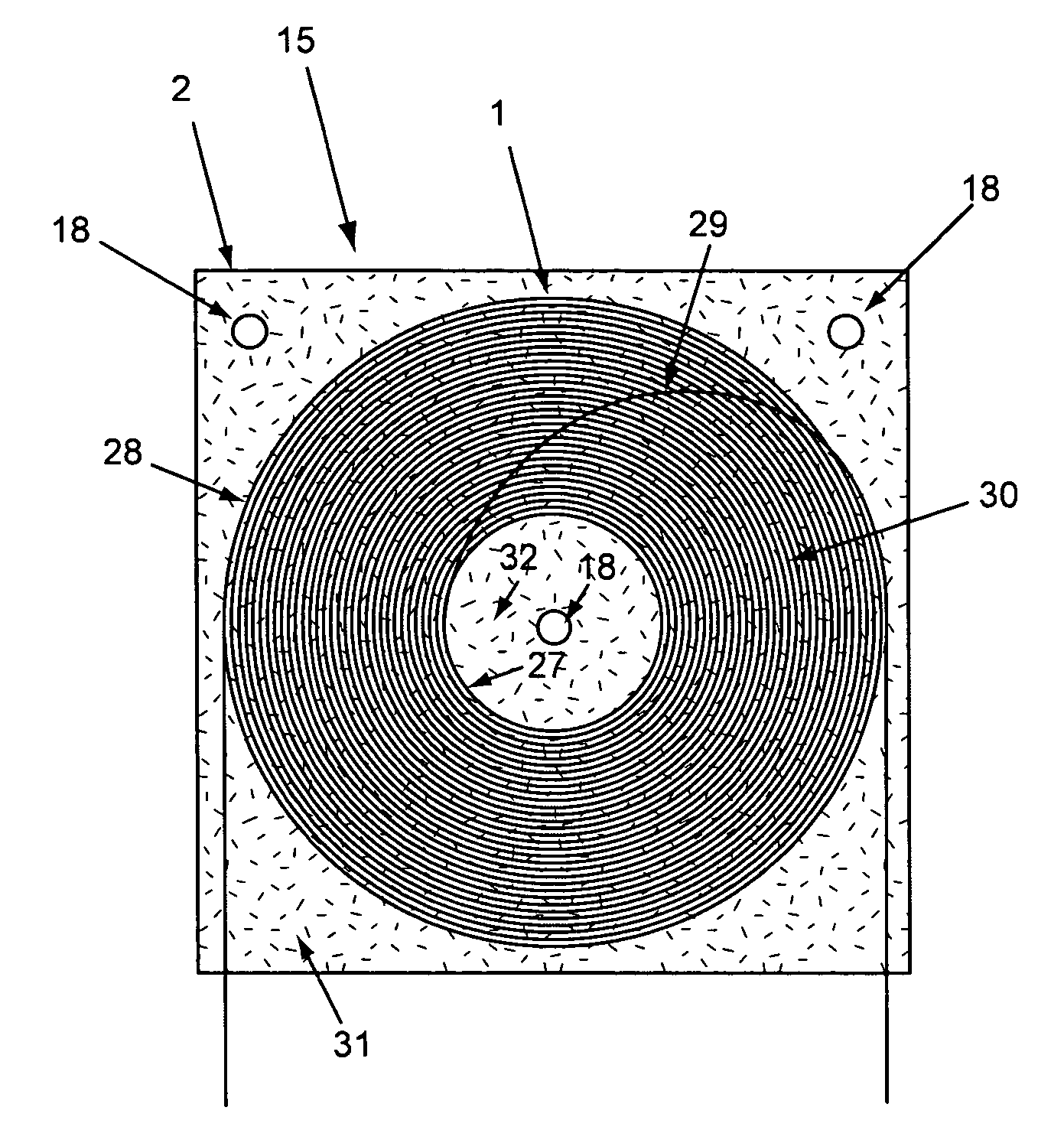

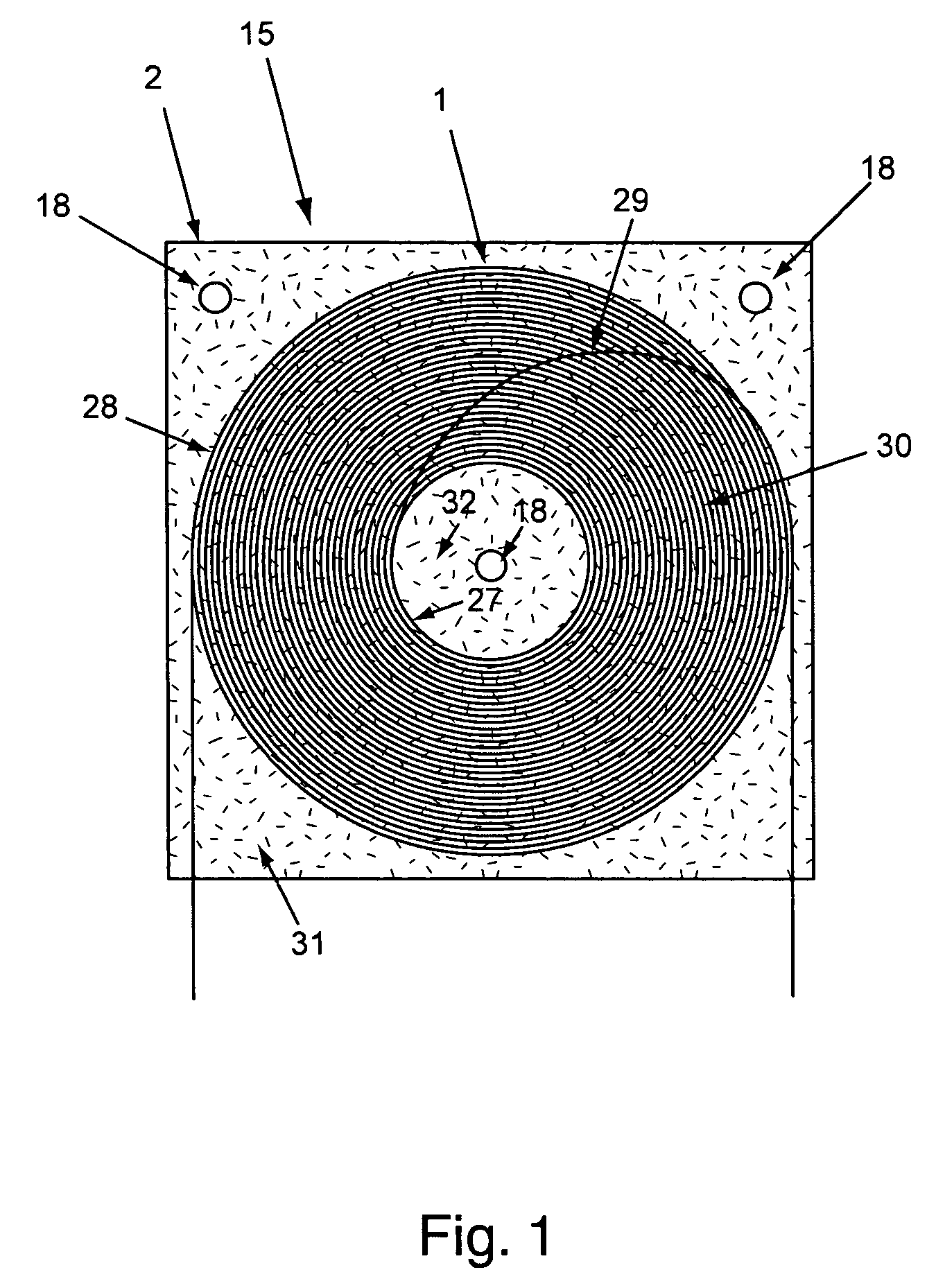

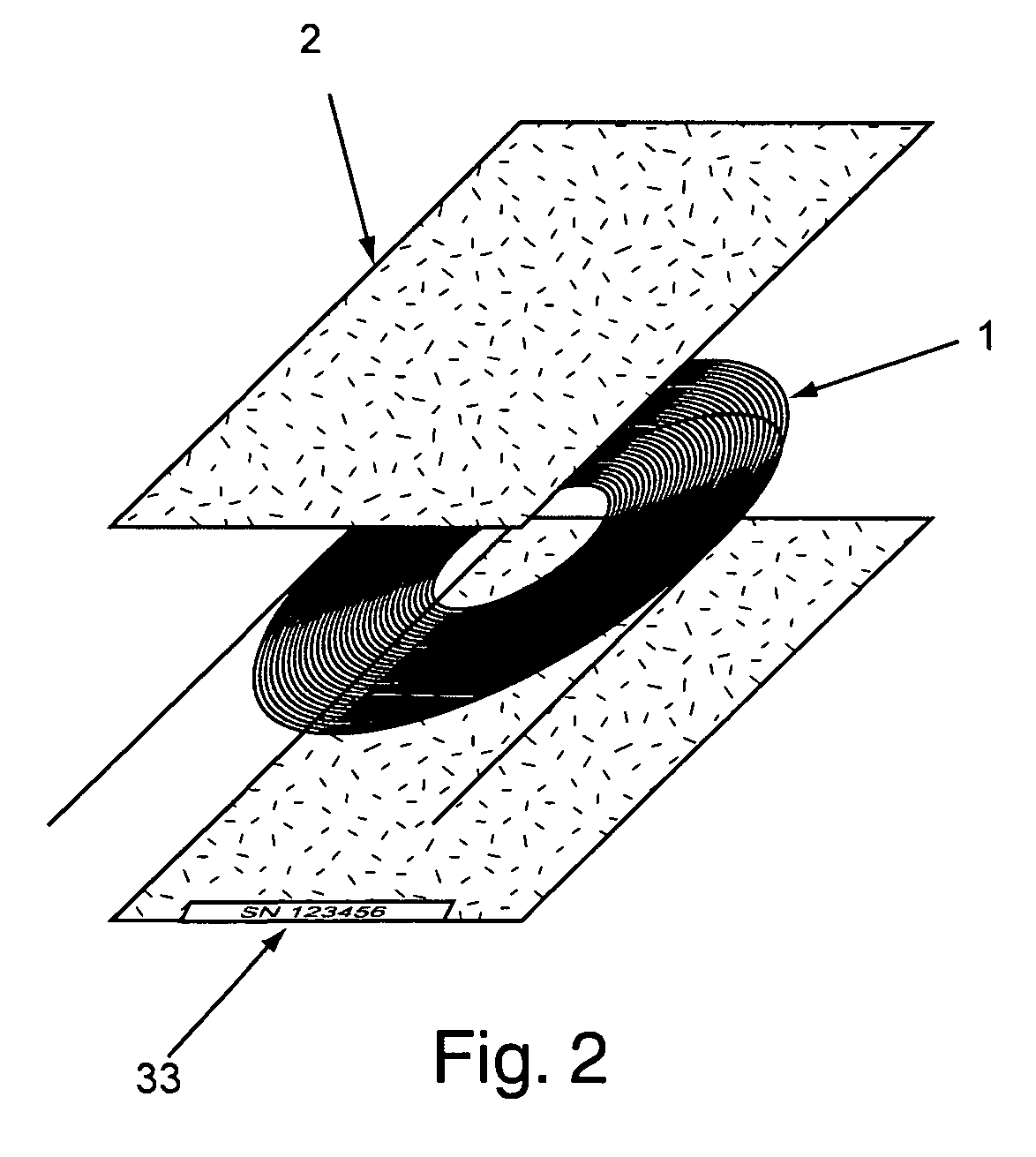

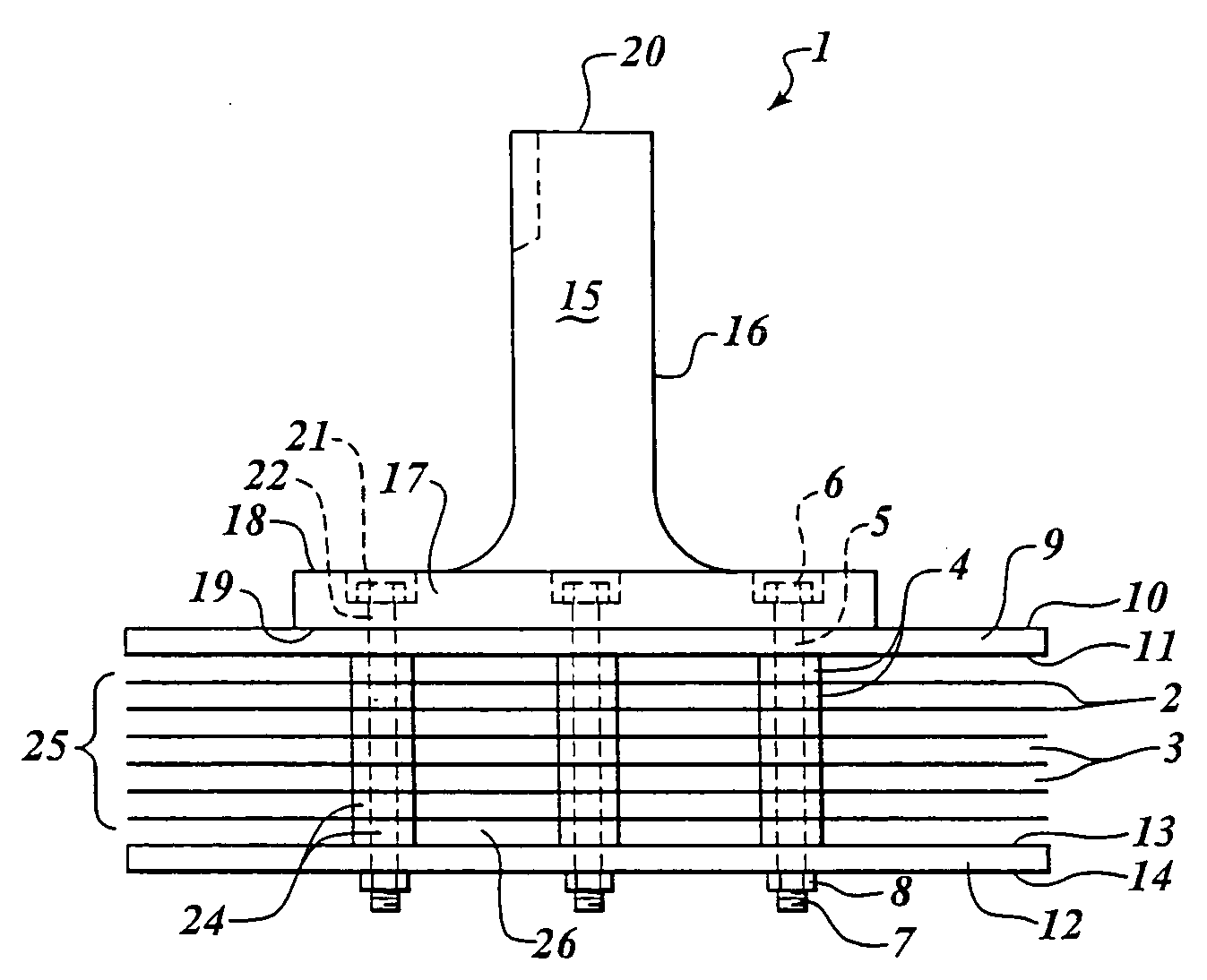

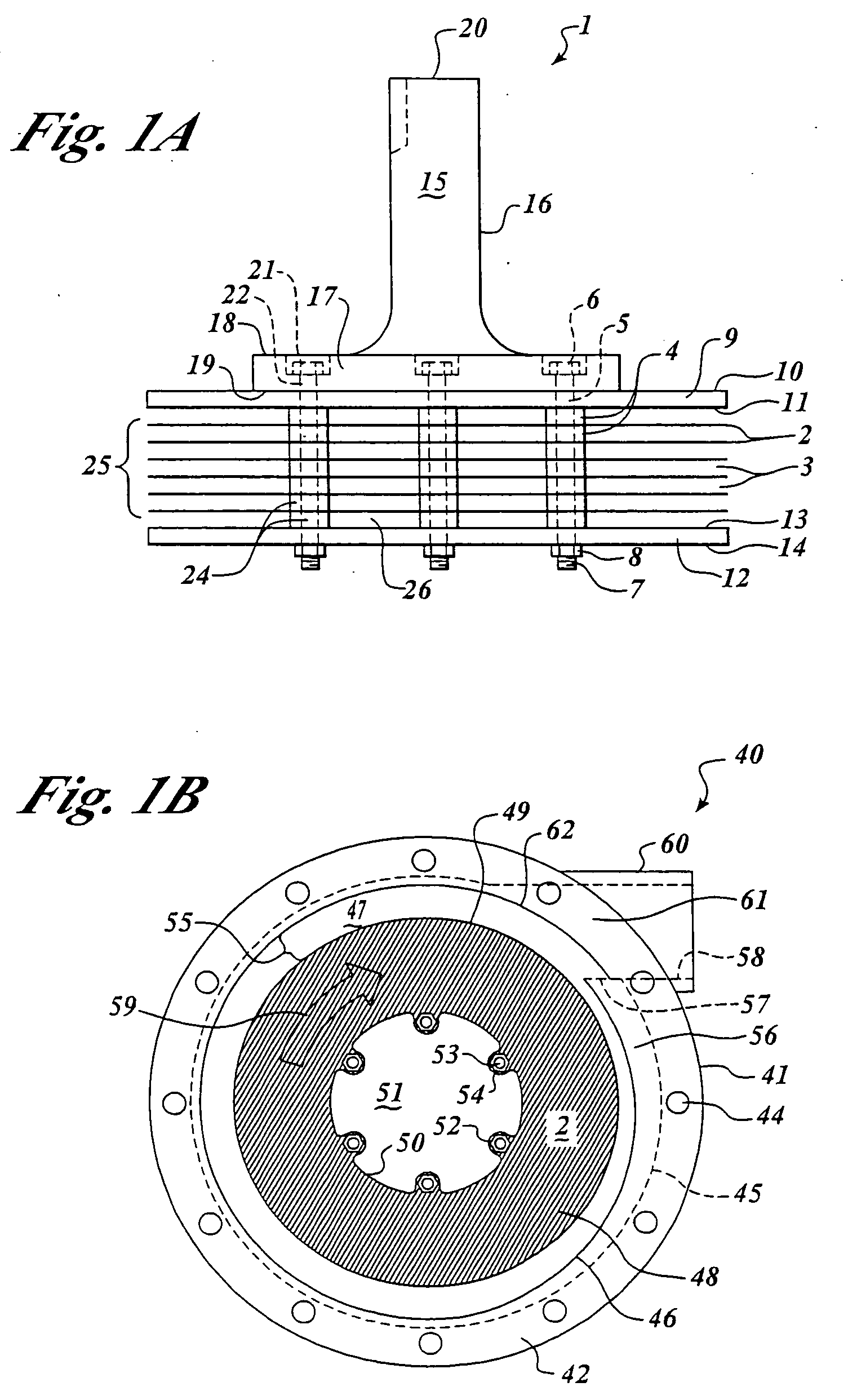

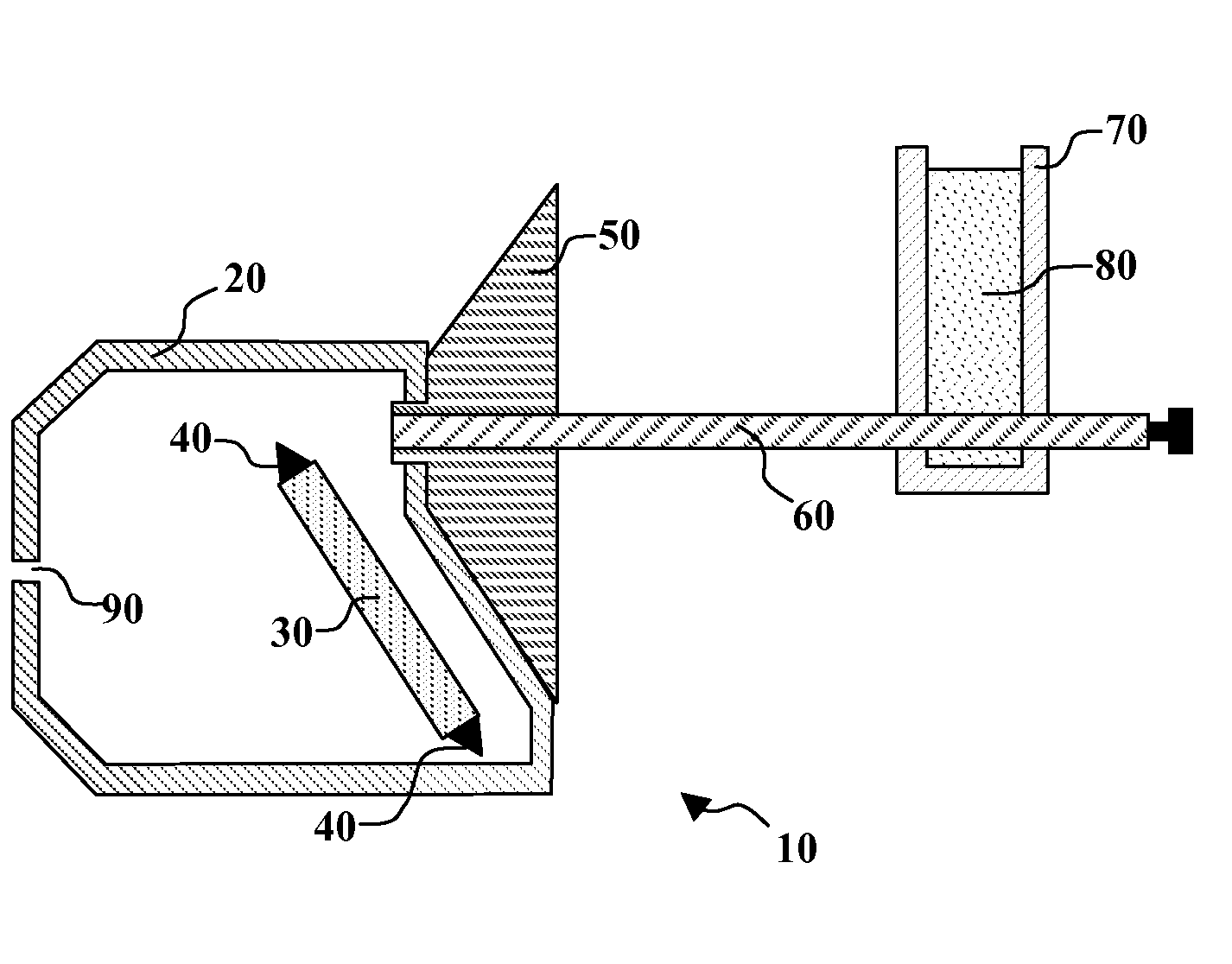

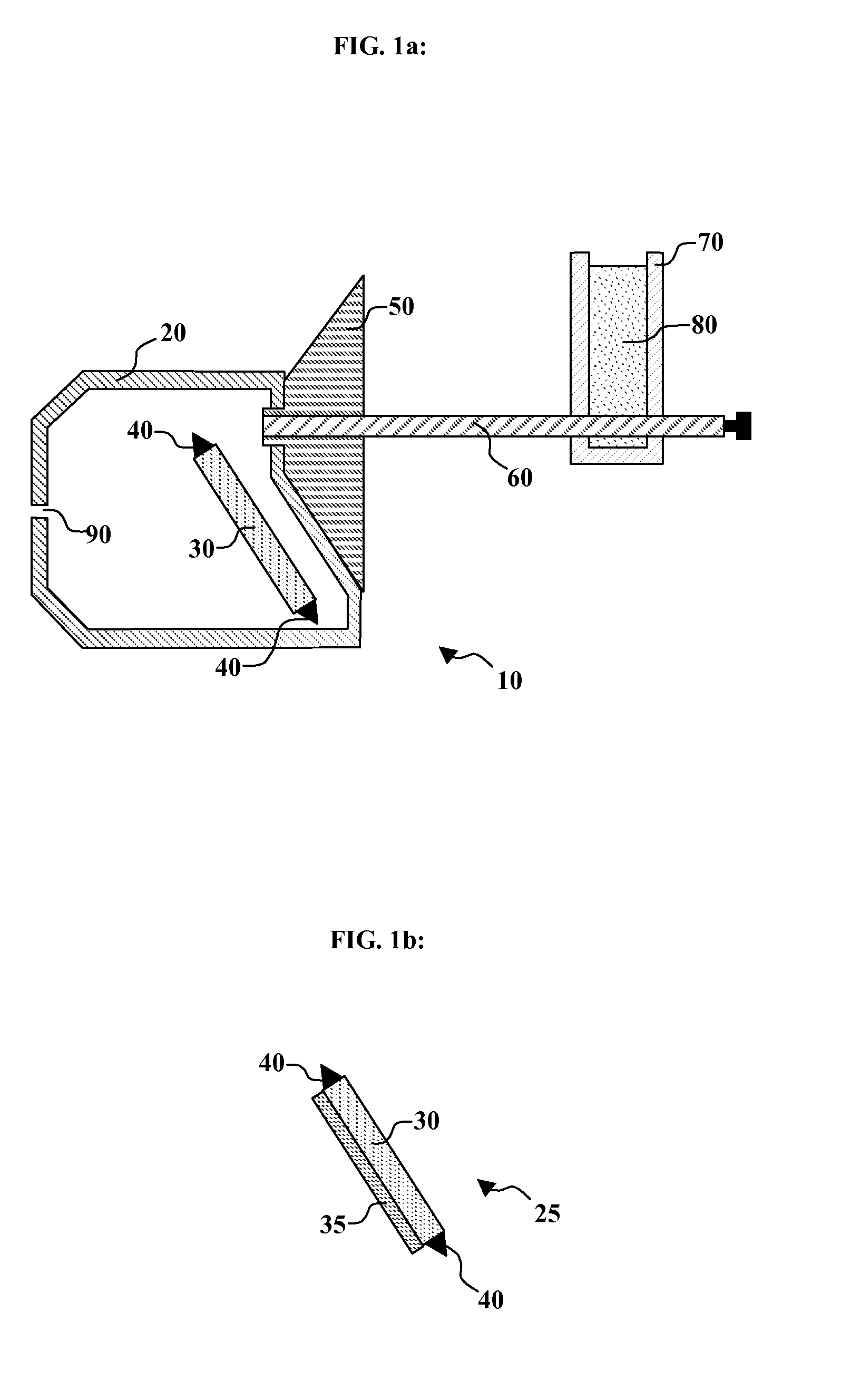

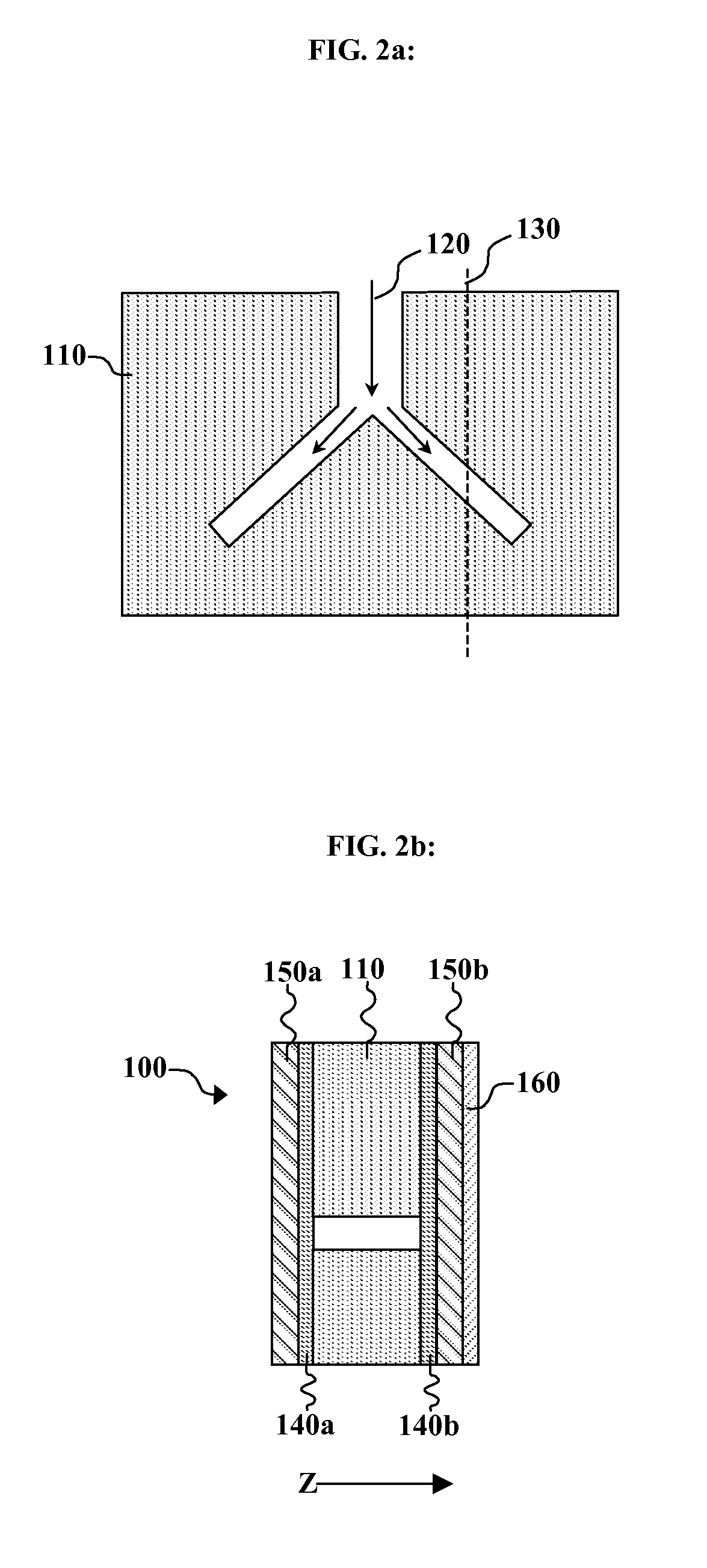

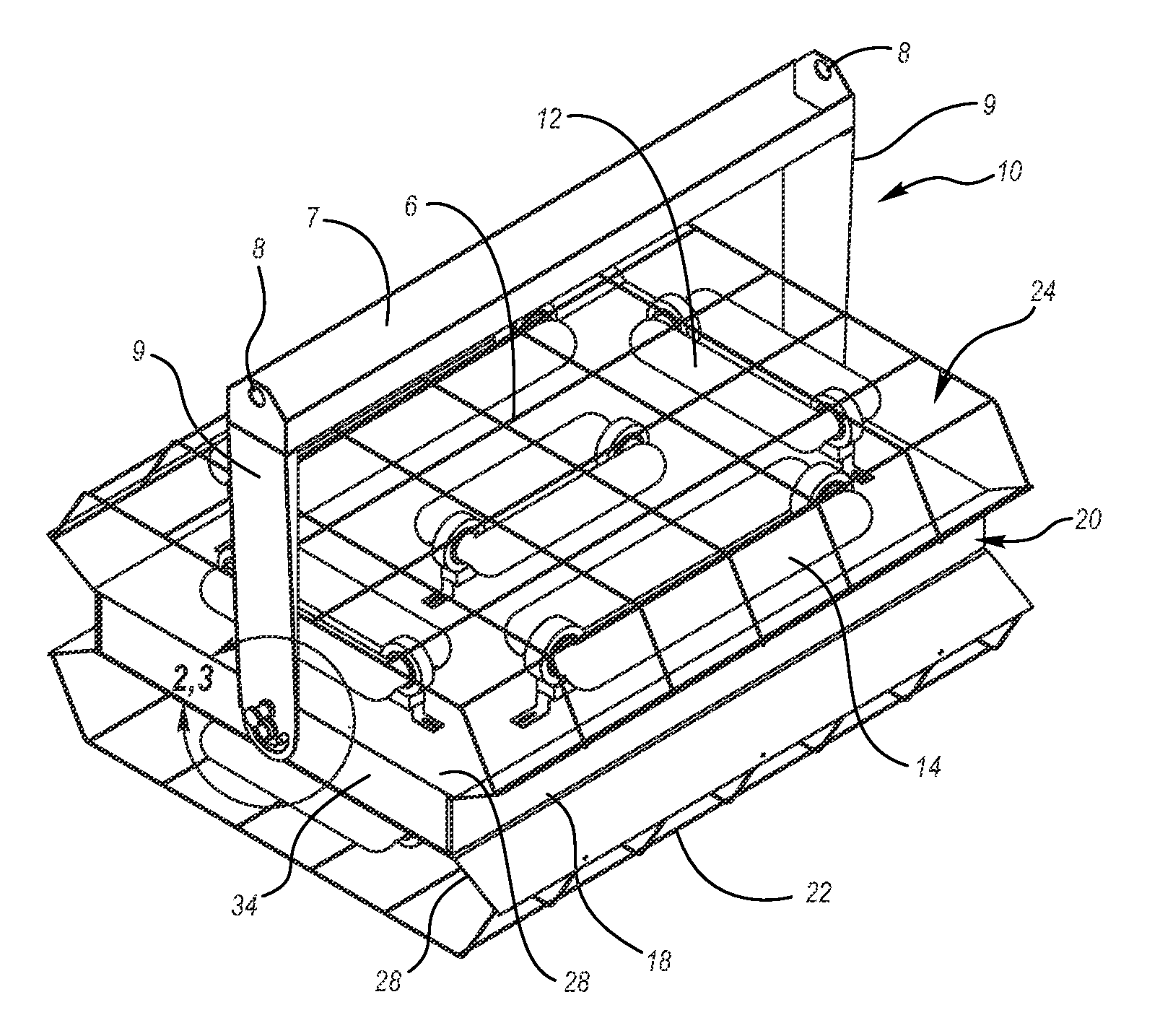

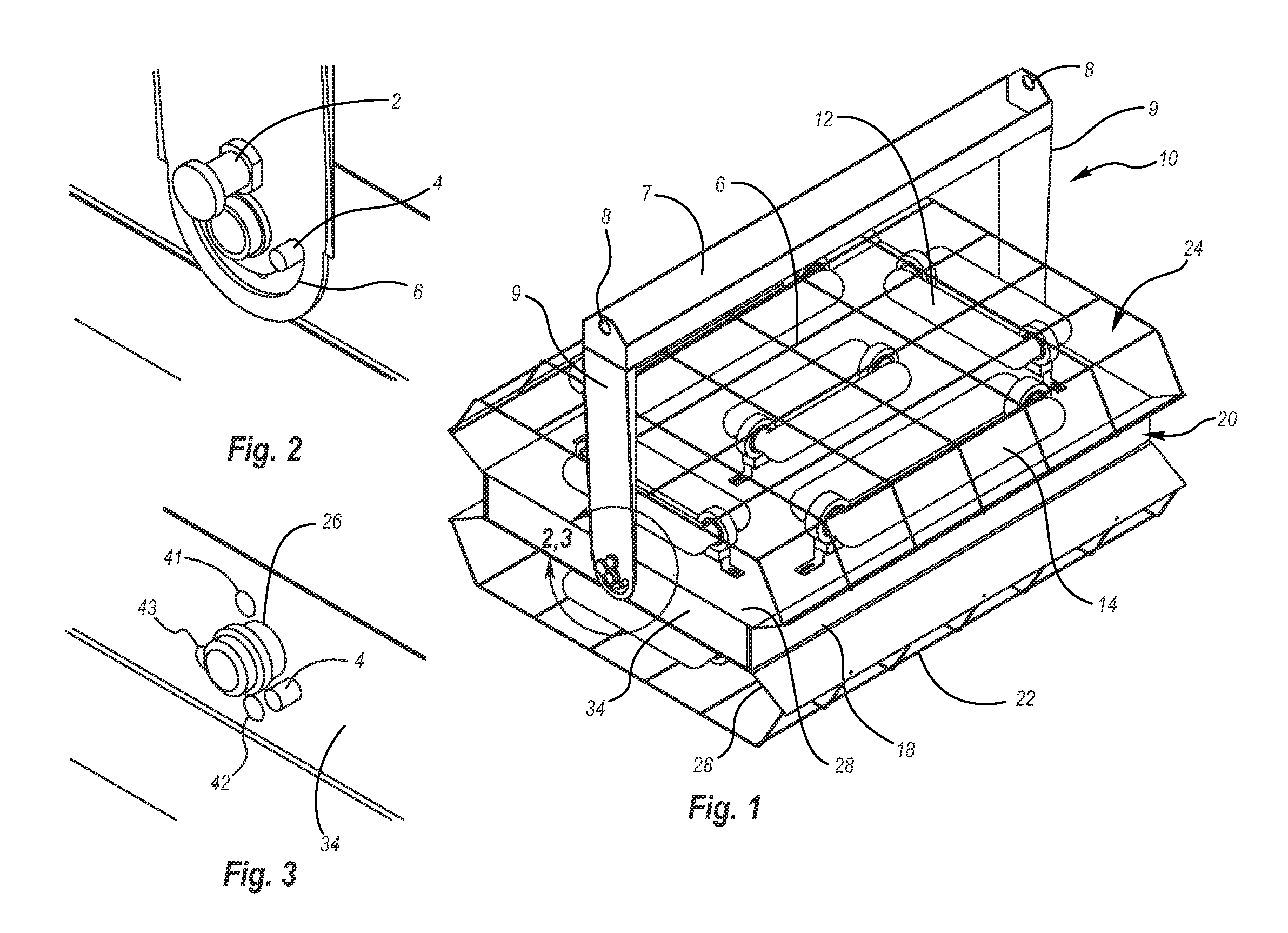

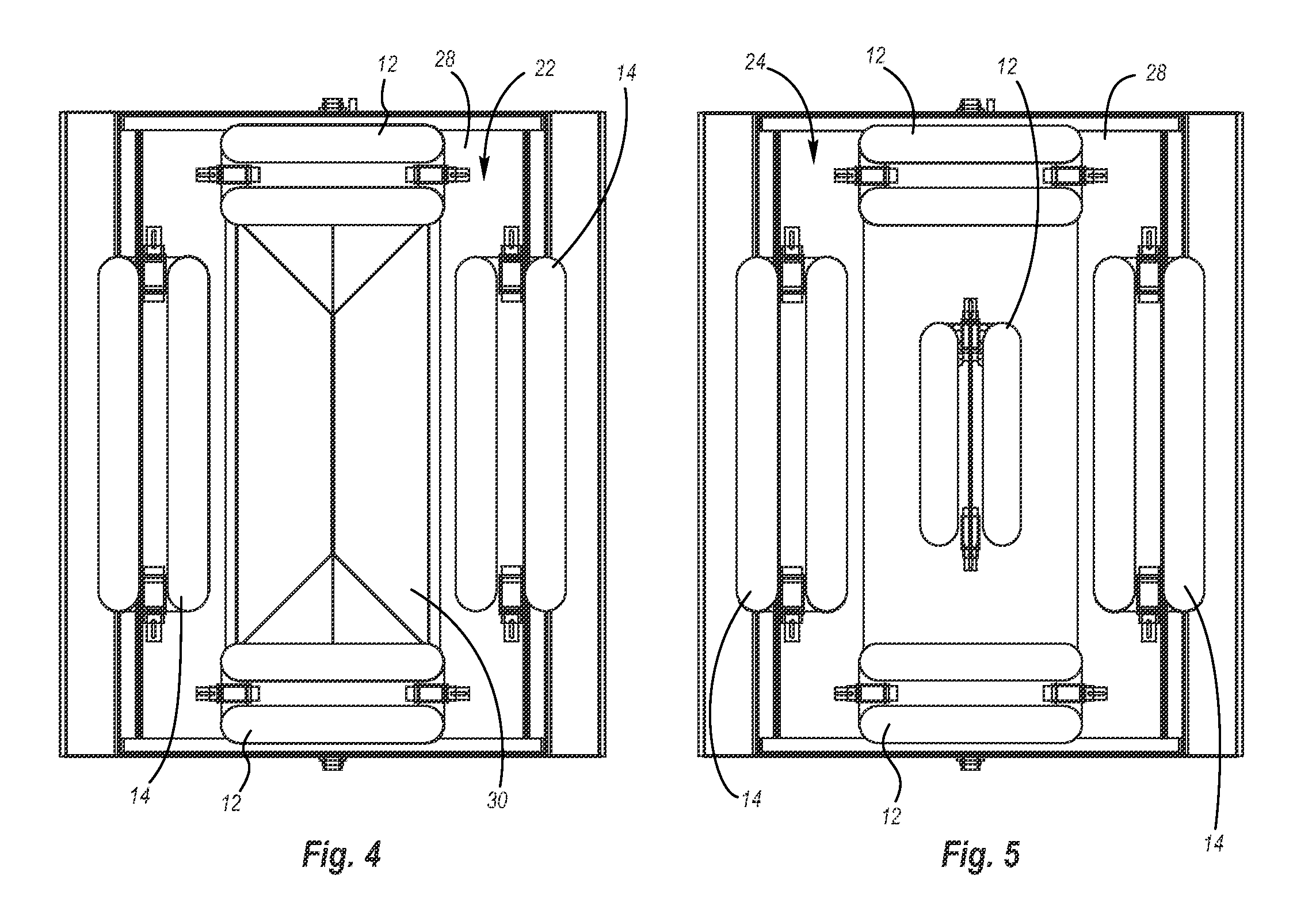

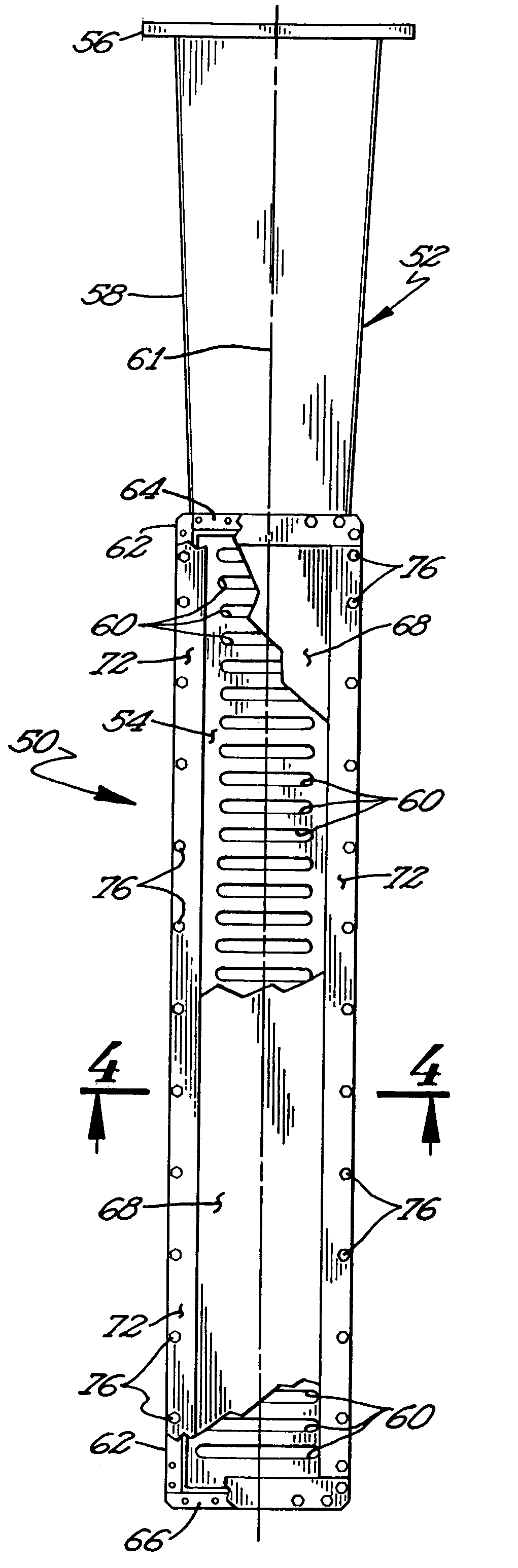

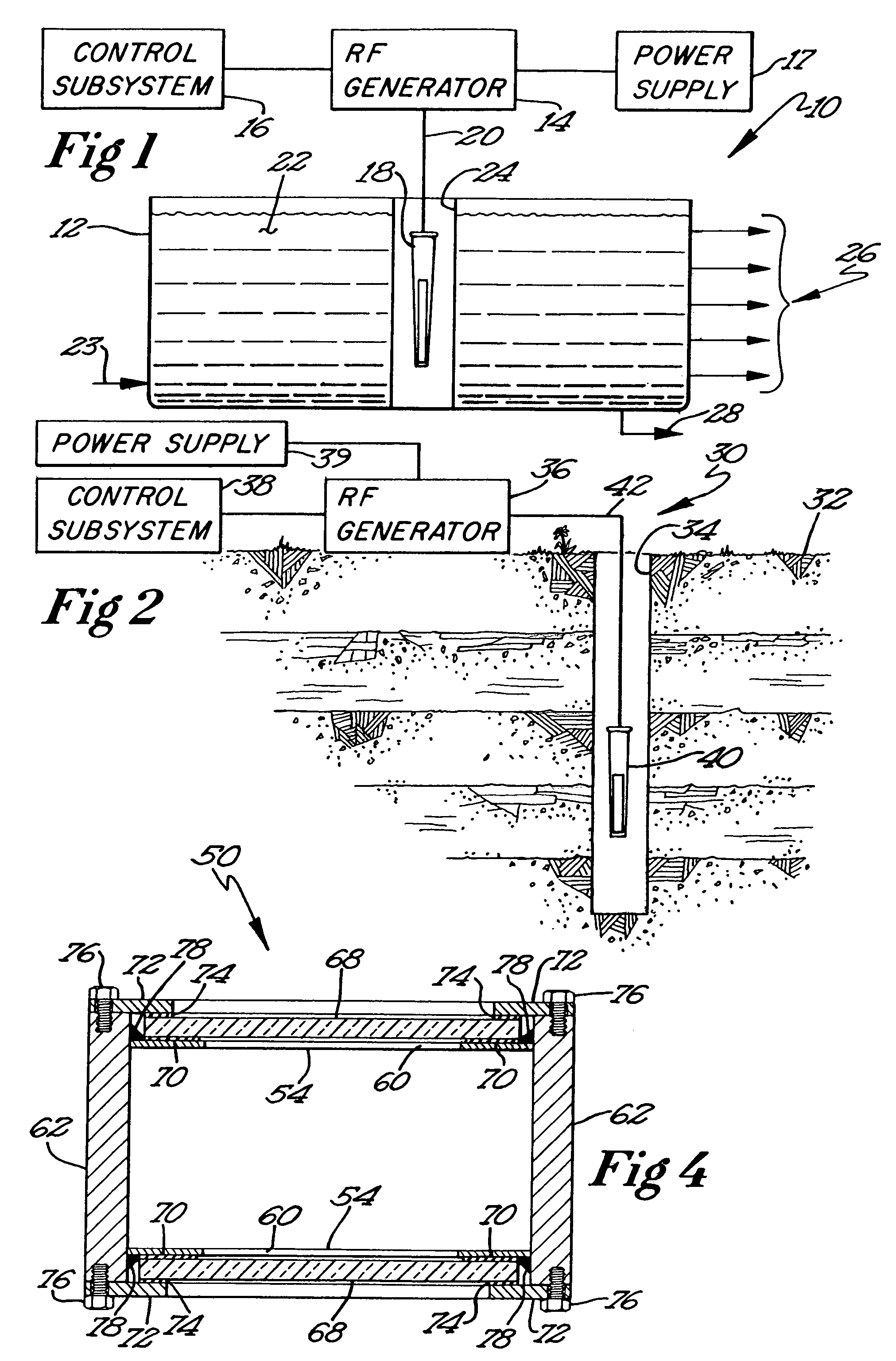

Flat spiral capillary column assembly with thermal modulator

InactiveUS20060283324A1Reduce the temperatureEfficient executionComponent separationDispersed particle separationCapillary gas chromatographyCapillary Tubing

The nature of this invention encompasses the creation of a capillary gas chromatography (GC) column assembly and a thermal modulator used to heat or cool the column assembly in a very thermally and chromatographically efficient manner. The GC column assembly described herein consists of capillary GC column material, such as fused silica or metal capillary tubing, which is constrained to lie in a flat, ordered, spiral pattern and then encased between two thin opposing surfaces. The resulting column assembly is flat, dimensionally stable and can be very efficiently thermally modulated. The resulting column assembly also takes up very little space, has very little thermal mass, and can be easily and accurately manufactured. The column assembly can be adapted for chromatographic use by affixing it to the surface of a thermal modulator described herein by means of adhesive force or by mechanical compression, and then by attaching the free ends of the exposed column material to the input and output ports of the chromatographic device. The temperature of the thermal modulator and capillary column assembly is to be controlled by the chromatographic device or by standalone temperature controlling electronics. The thermal modulator described herein contains an element for temperature modulation of the capillary column assembly to which it is attached and a temperature sensing element for providing accurate temperature feedback to the controlling electronics. The overall result of this when coupled to a chromatographic device is maximally efficient chemical separations in a small space with minimal power consumption.

Owner:ROQUES NED J

Ablation catheter with optically transparent, electrically conductive tip

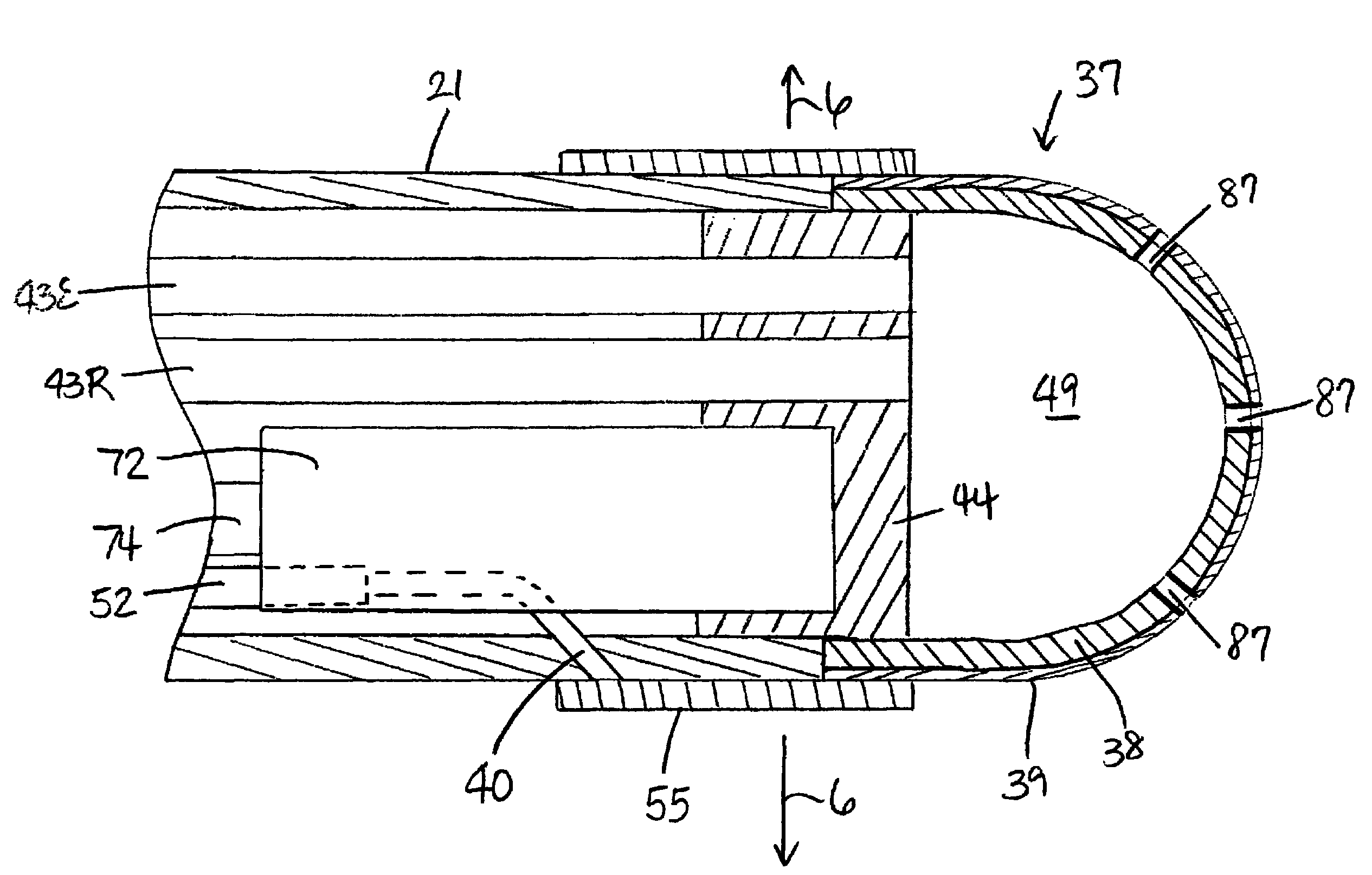

ActiveUS8123745B2Extended service lifeMinimize damageMaterial nanotechnologyNanomedicineRf ablationFluorescence

A catheter enables real-time light measurements, for example, without limitation, diffuse reflectance, fluorescence, etc., from biological materials, such as tissue (including blood), while performing RF ablation. The catheter tip design isolates illumination and collection paths such that light exits the catheter tip and travels through the tissue of interest (e.g., cardiac tissue or blood) before returning to the catheter tip. Such a design advantageously avoids saturation of the optical detector, and ensures diffusion of the illumination light within the medium of interest. The catheter has a catheter body and a tip electrode. The tip electrode has an exterior shell, an inner layer of diffuse material and a hollow cavity, wherein the inner layer is configured to transmit light outside the tip electrode to a tissue via a set of illumination openings in the shell wall and the hollow cavity is configured to receive light from the tissue via a set of collection openings in the shell wall and the inner layer. An inner surface of the inner layer has a reflective coating to isolate light injected into the inner layer from light collected in the hollow cavity. There are a first optical waveguide extending between the catheter body and the tip electrode to inject light into the inner layer and illuminate the tissue, and a second optical waveguide extending between the catheter body and the tip electrode to collect the recaptured light in the hollow cavity.

Owner:BIOSENSE WEBSTER INC

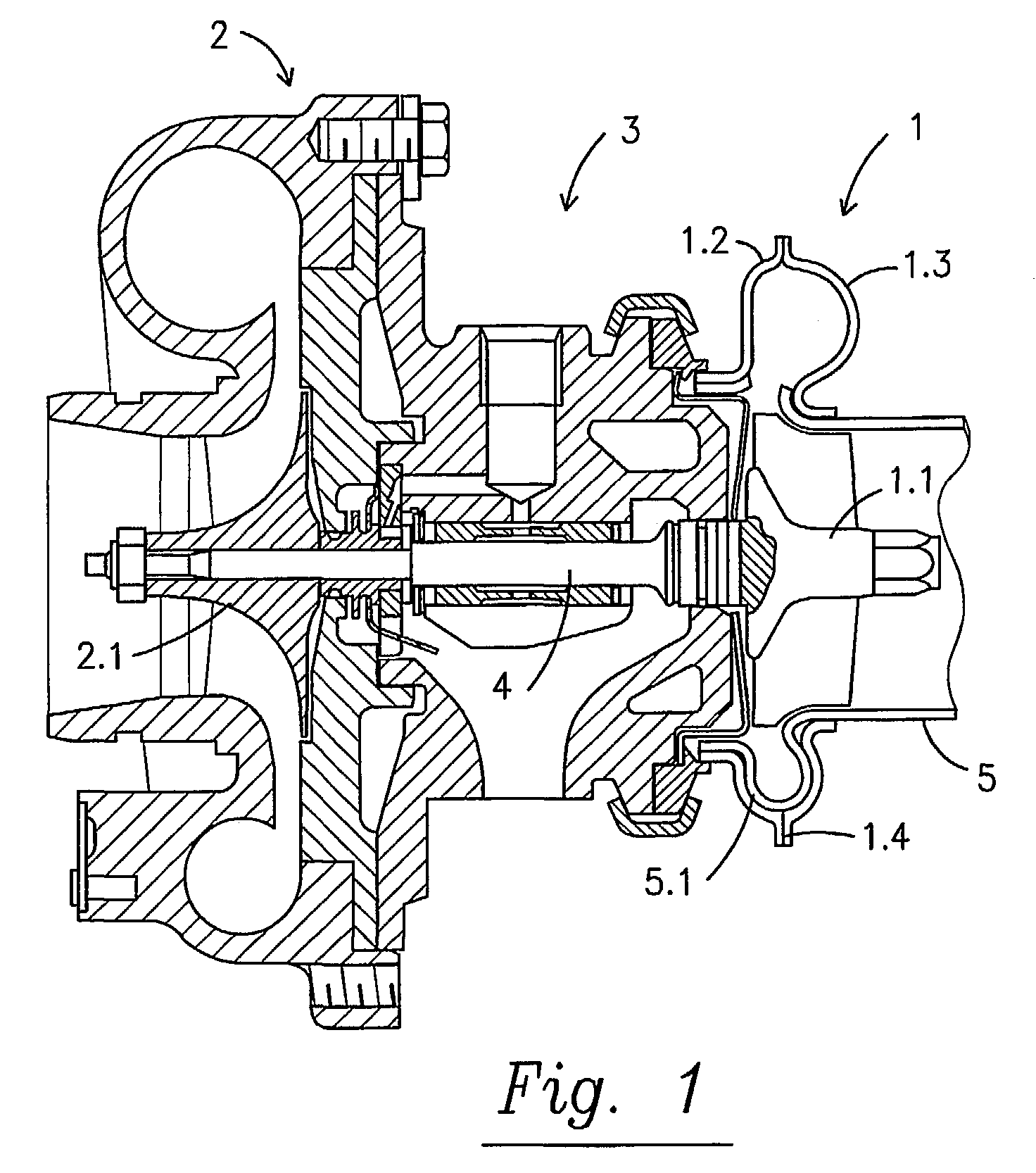

Impeller components and systems

InactiveUS20050019154A1Large capacityReduce fluid turbulenceCircumferential flow pumpsPump componentsImpellerMechanical power transmission

The present invention relates generally to systems and methods for facilitating the movement of fluids, transferring mechanical power to fluid mediums, as well as deriving power from moving fluids. The present invention employs an impeller system in a variety of applications involving the displacement of fluids, including for example, any conventional pumps, fans, compressors, generators, circulators, blowers, generators, turbines, transmissions, various hydraulic and pneumatic systems, and the like.

Owner:DIAL DISCOVERIES

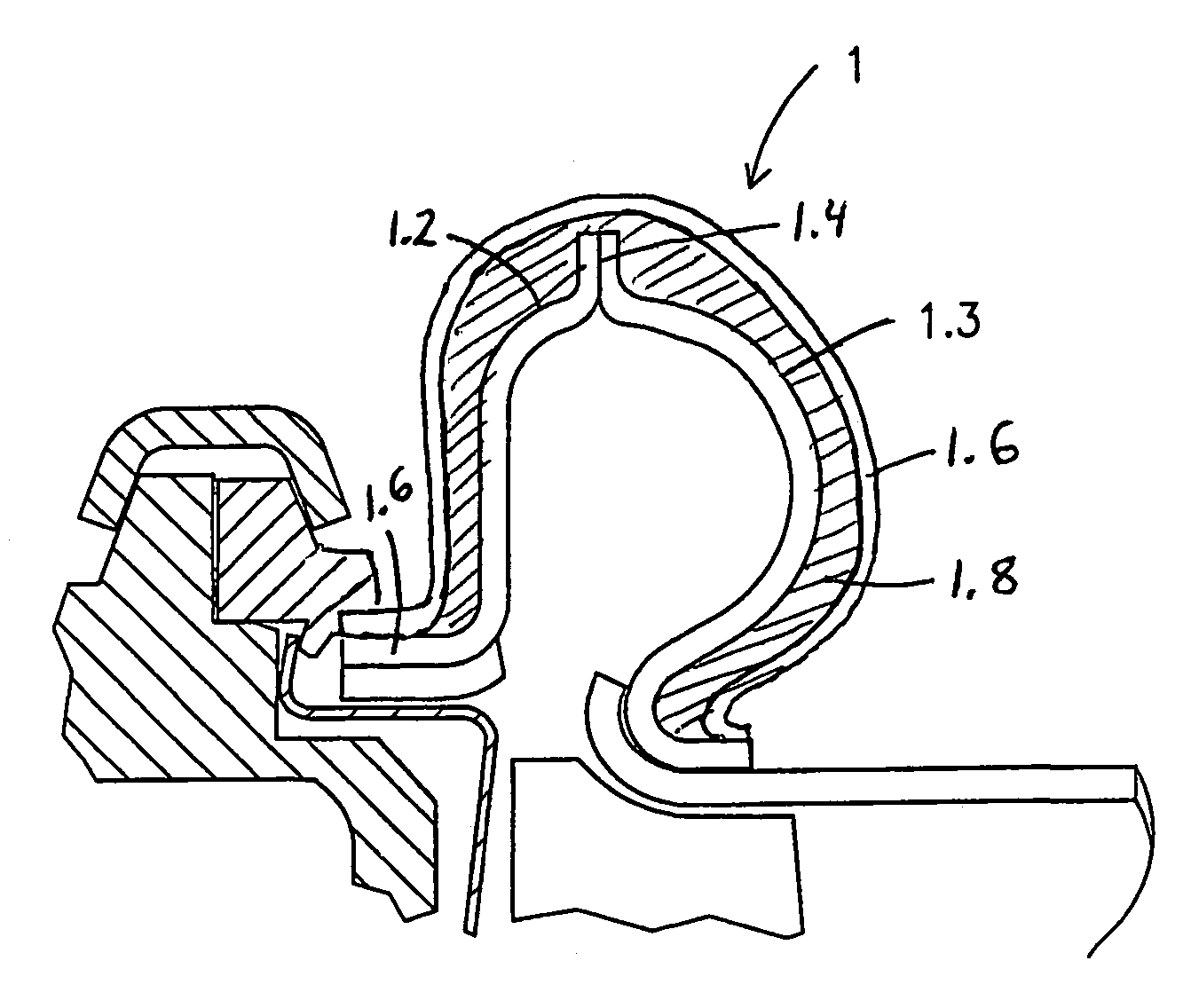

Casing assembly for the turbine of an exhaust turbochanger

InactiveUS7074009B2Reduce weightReduce wall thicknessPump componentsBlade accessoriesTurbochargerMetal

A spiral casing for a turbine of a turbocharger is made from thin (0,2 to 2 mm thick) sheet metal. The spiral casing can be made from two matching parts and can be insulated.

Owner:BORGWARNER INC

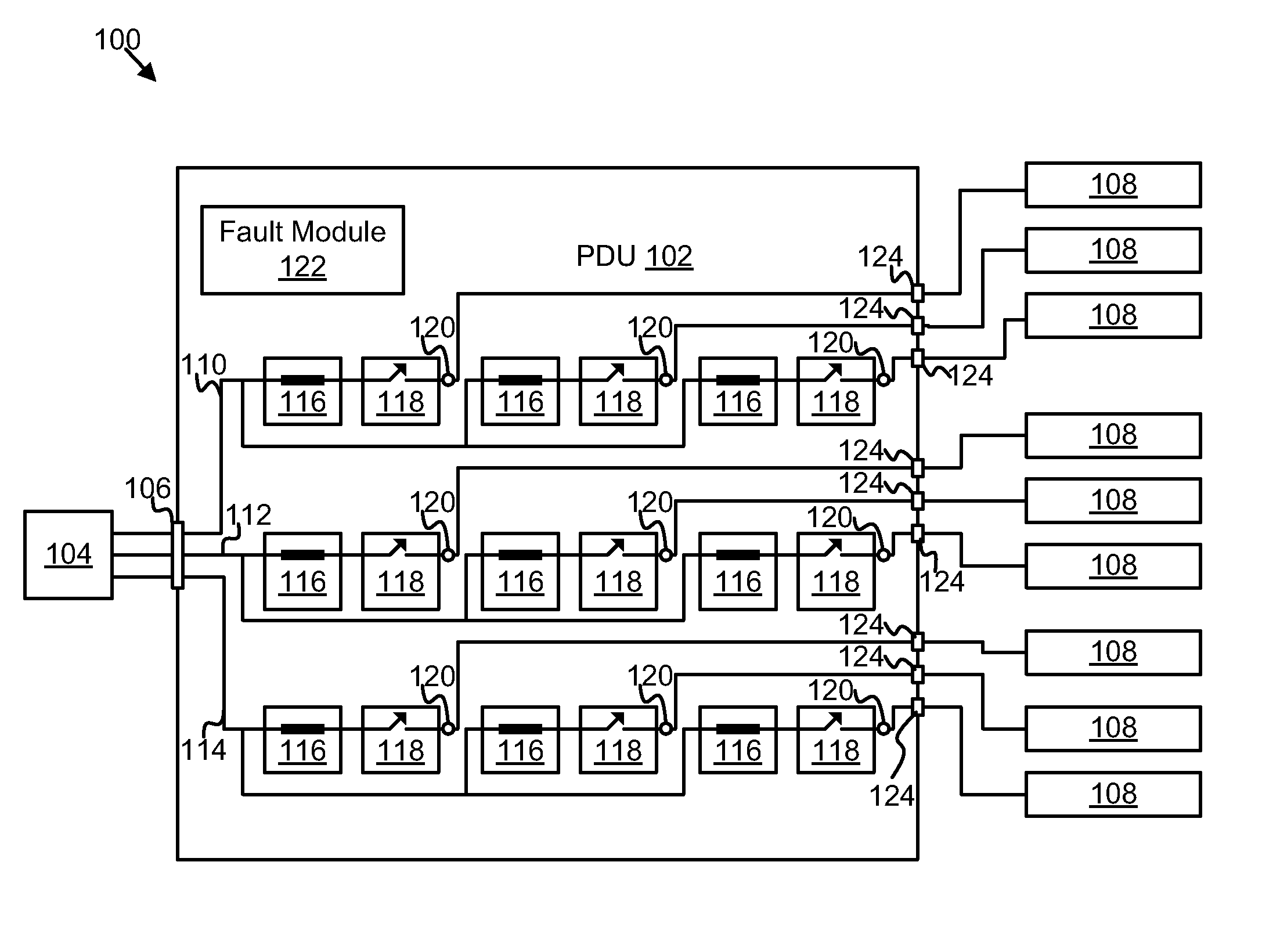

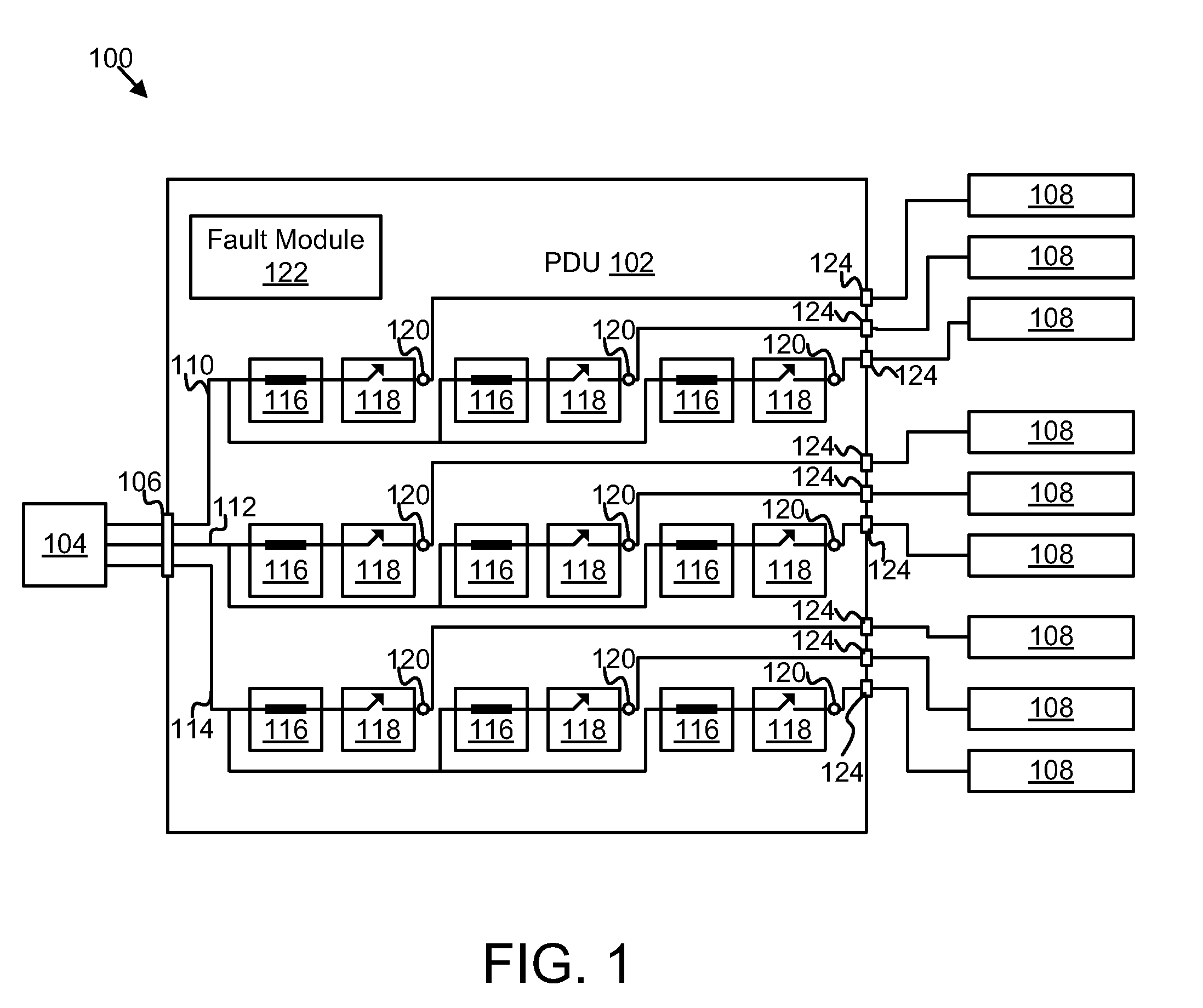

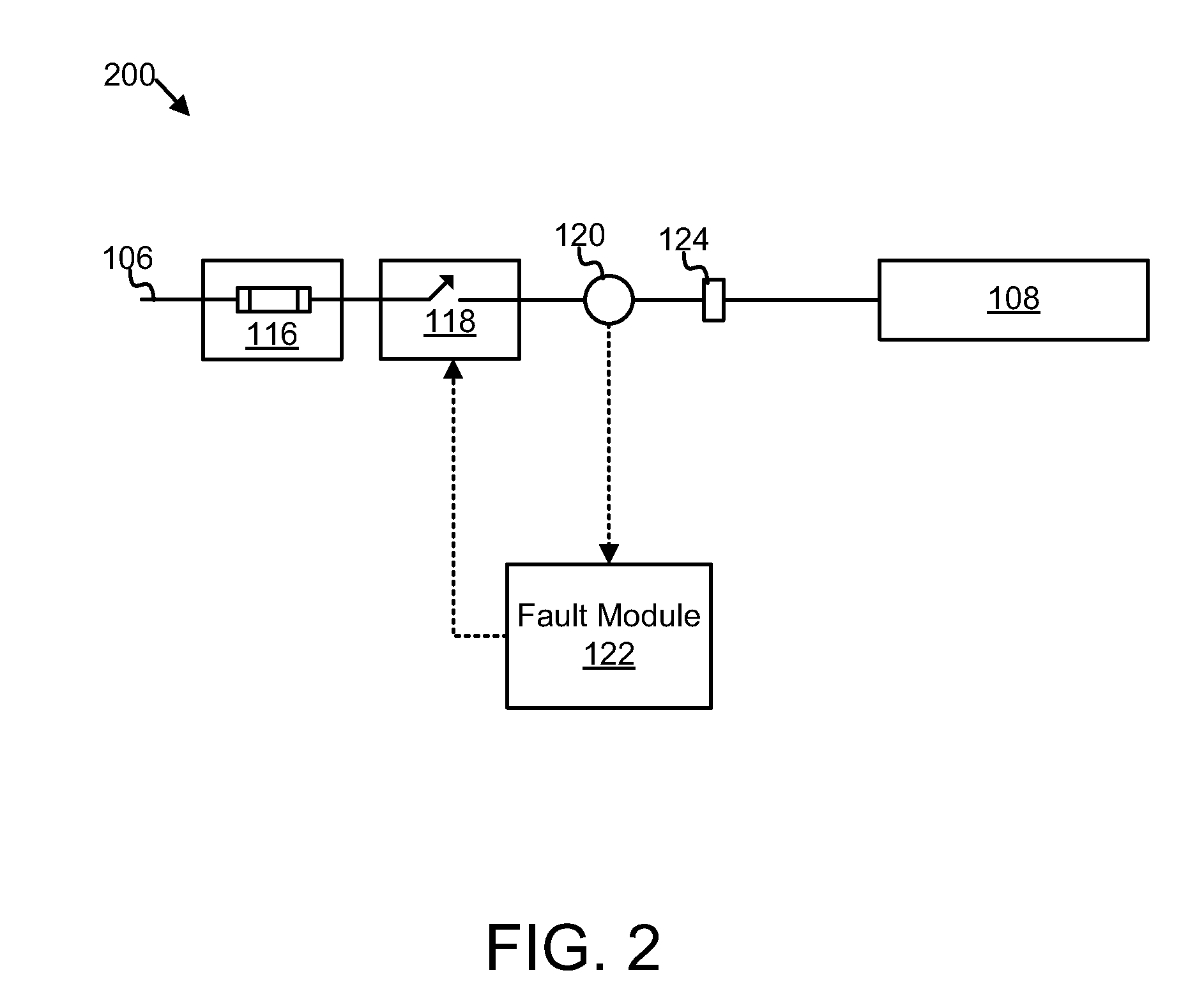

Power distribution unit branch protection

InactiveUS20110170223A1Low costSmall sizeElectric switchesArrangements responsive to excess currentElectrical FailureCurrent sensor

An apparatus and system are disclosed for protecting a power distribution unit from an electrical fault. A fuse interrupts a flow of electrical current in response to the electrical current rising above a current rating of the fuse. A current sensor measures the amplitude of the electrical current and outputs a current amplitude signal. A relay interrupts the flow of electrical current in response to an OFF signal. A fault module receives the current amplitude signal and sends the OFF signal to the relay in response to the amplitude of the electrical current exceeding a threshold value. The relay, the fuse, and the threshold value are selected so that a switching time of the relay is less than an opening time of the fuse for an amplitude of the electrical current between the threshold value and a maximum fault current value, so that the relay prevents the fuse from opening.

Owner:IBM CORP

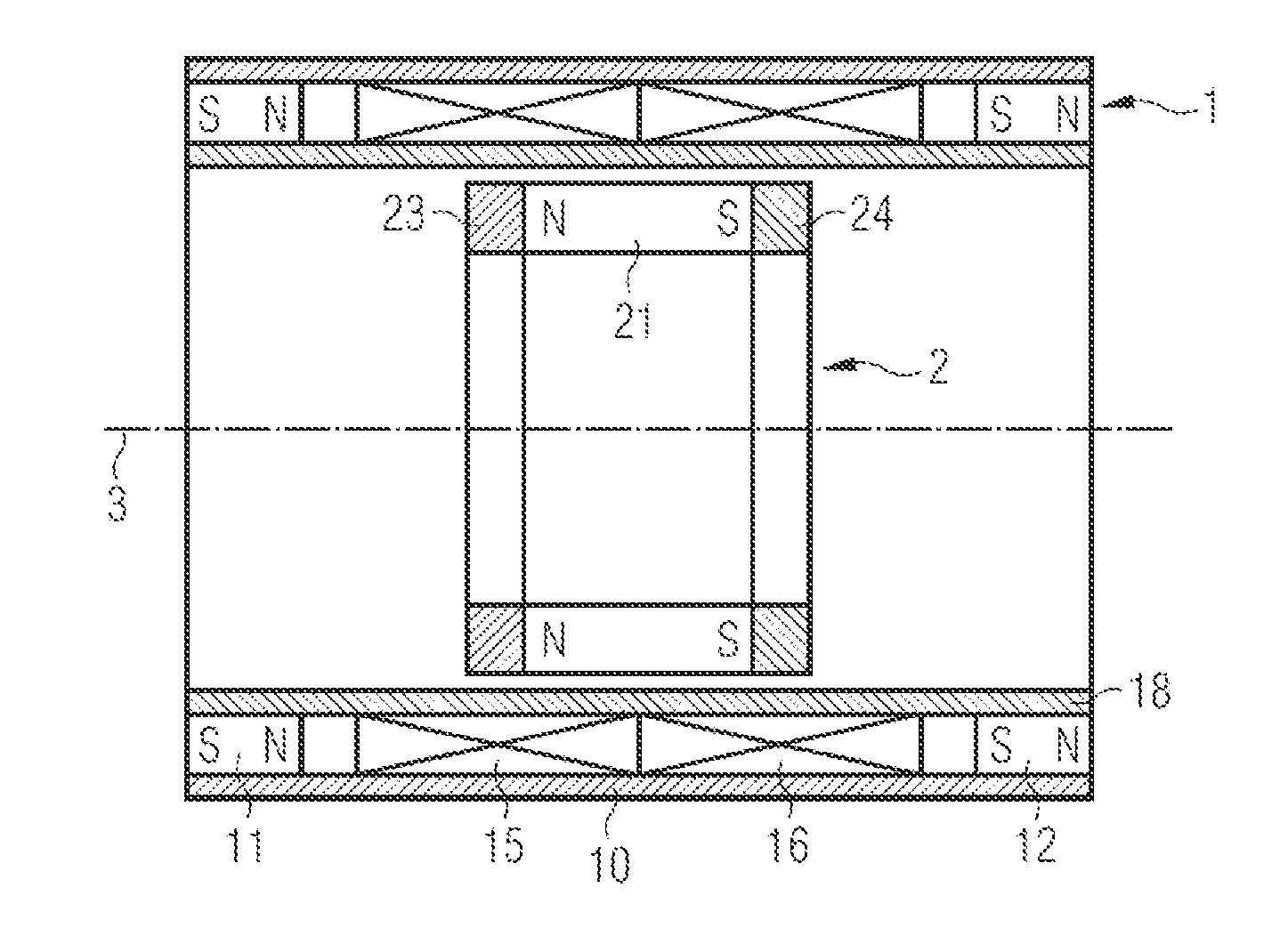

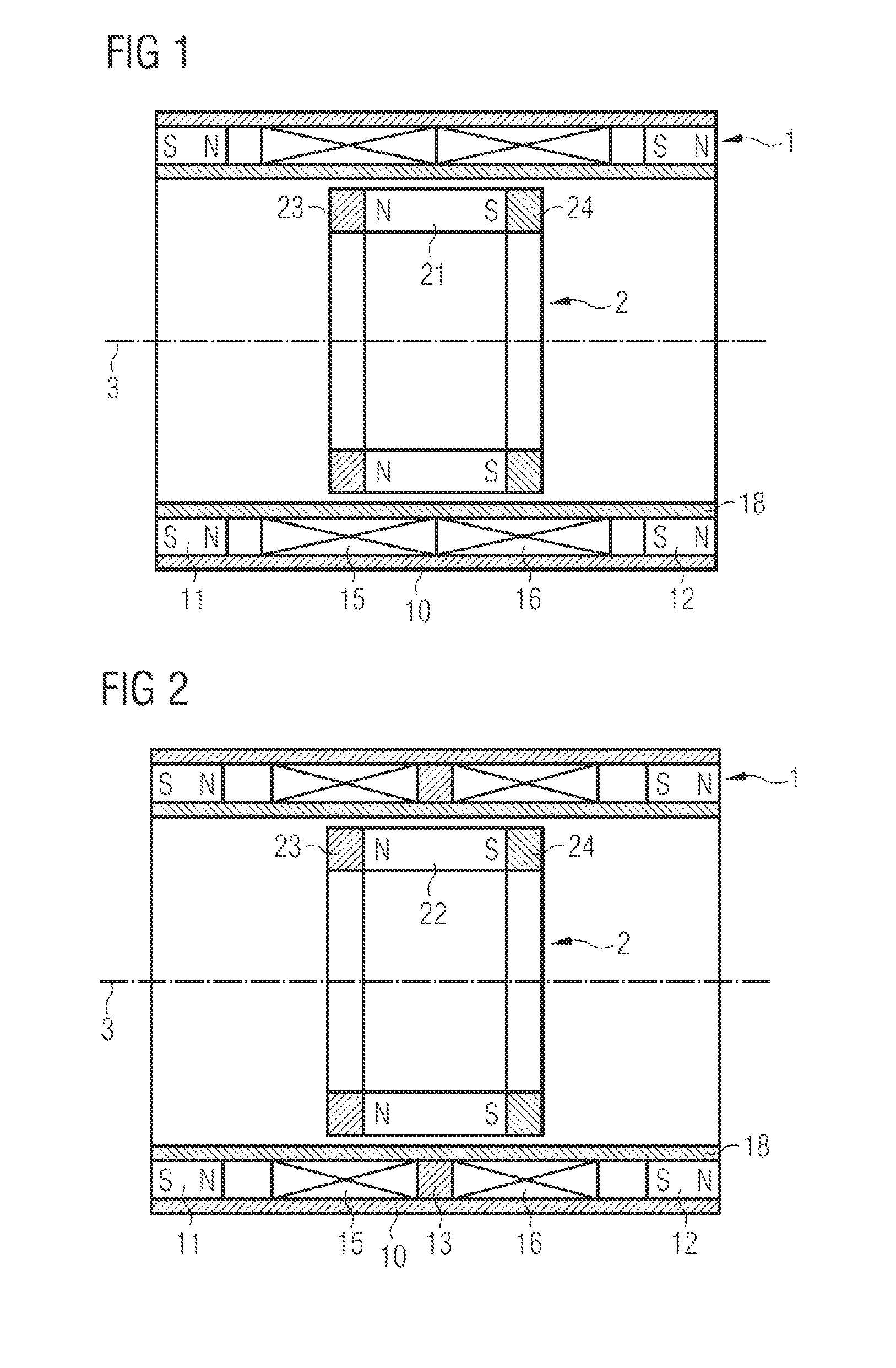

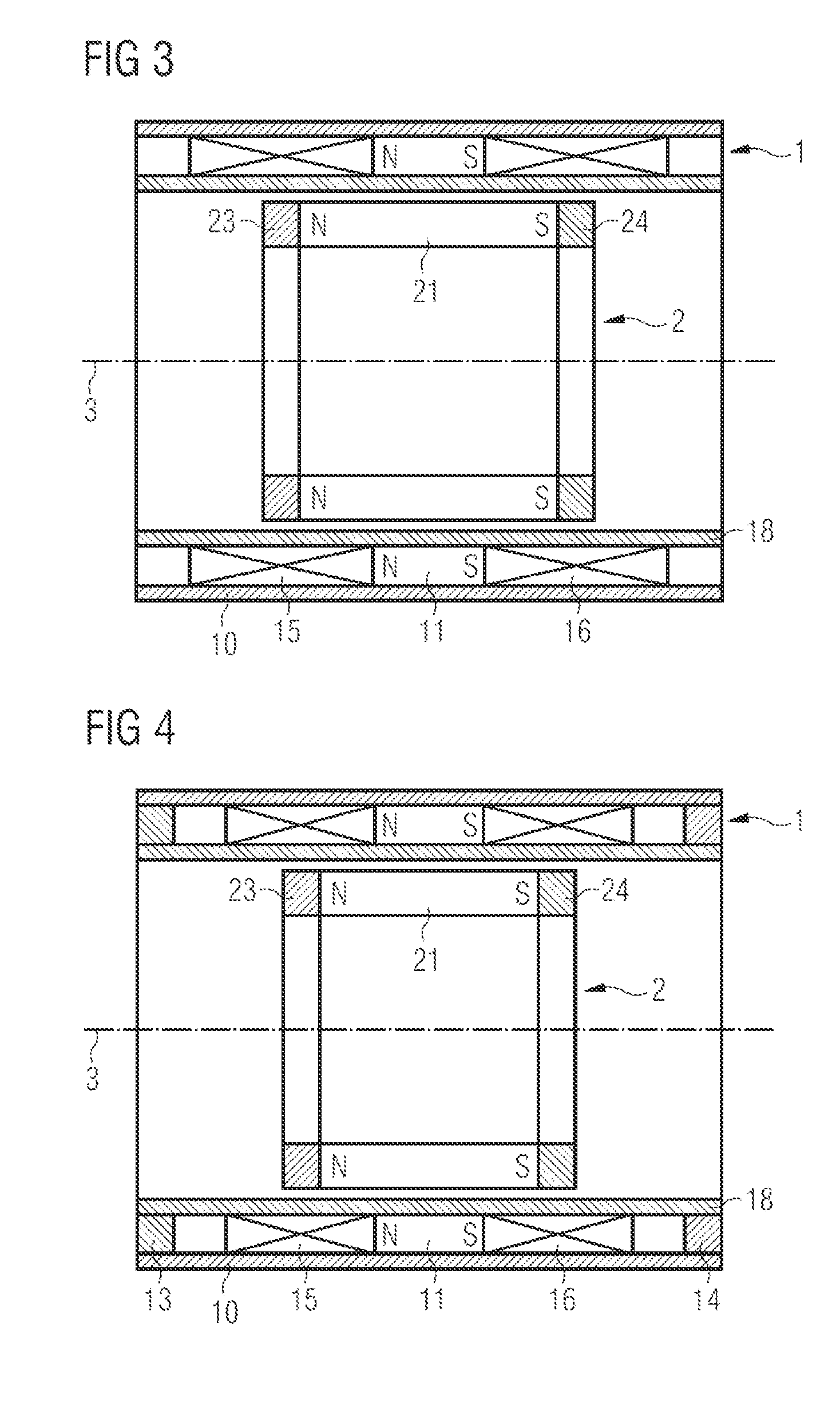

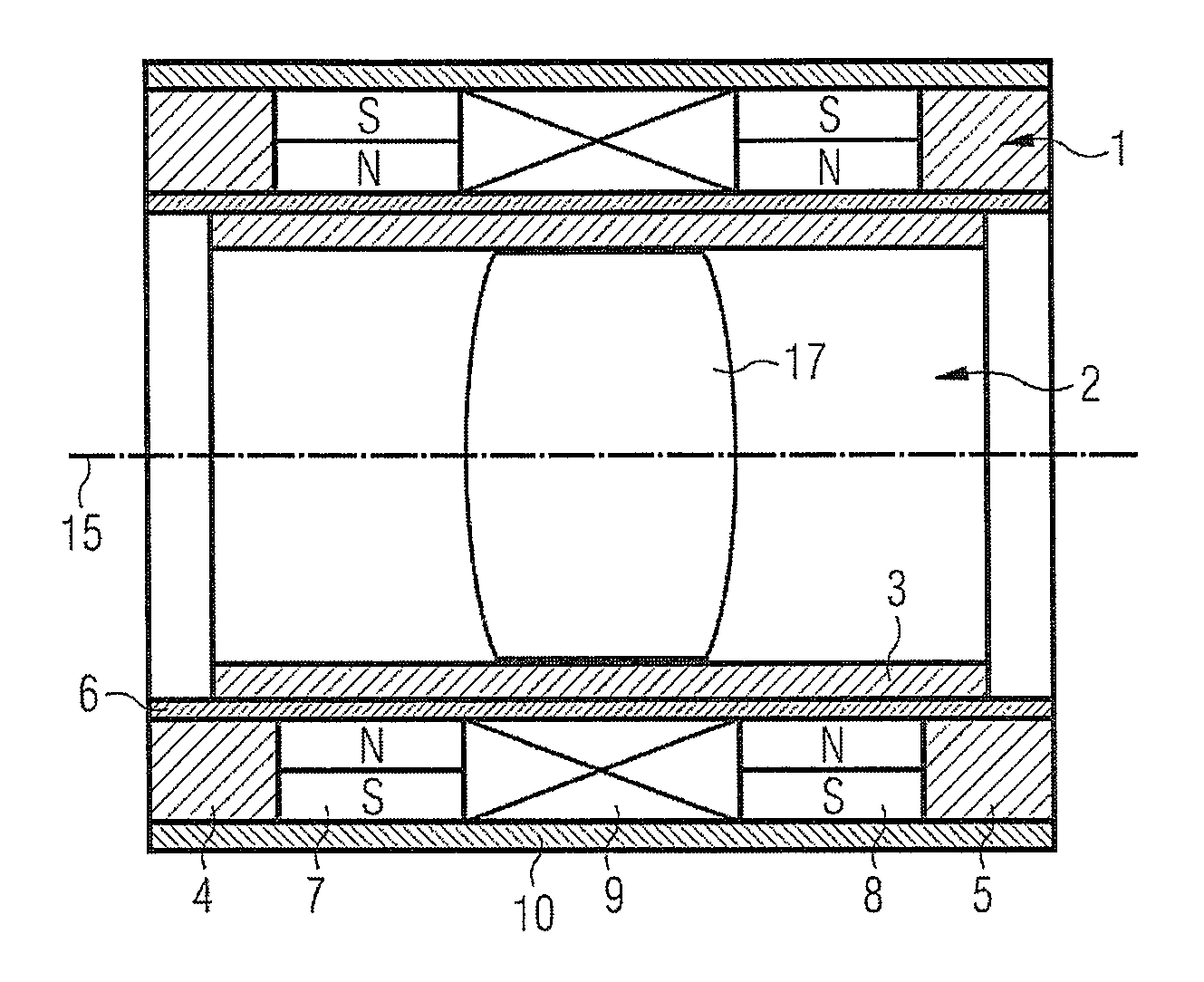

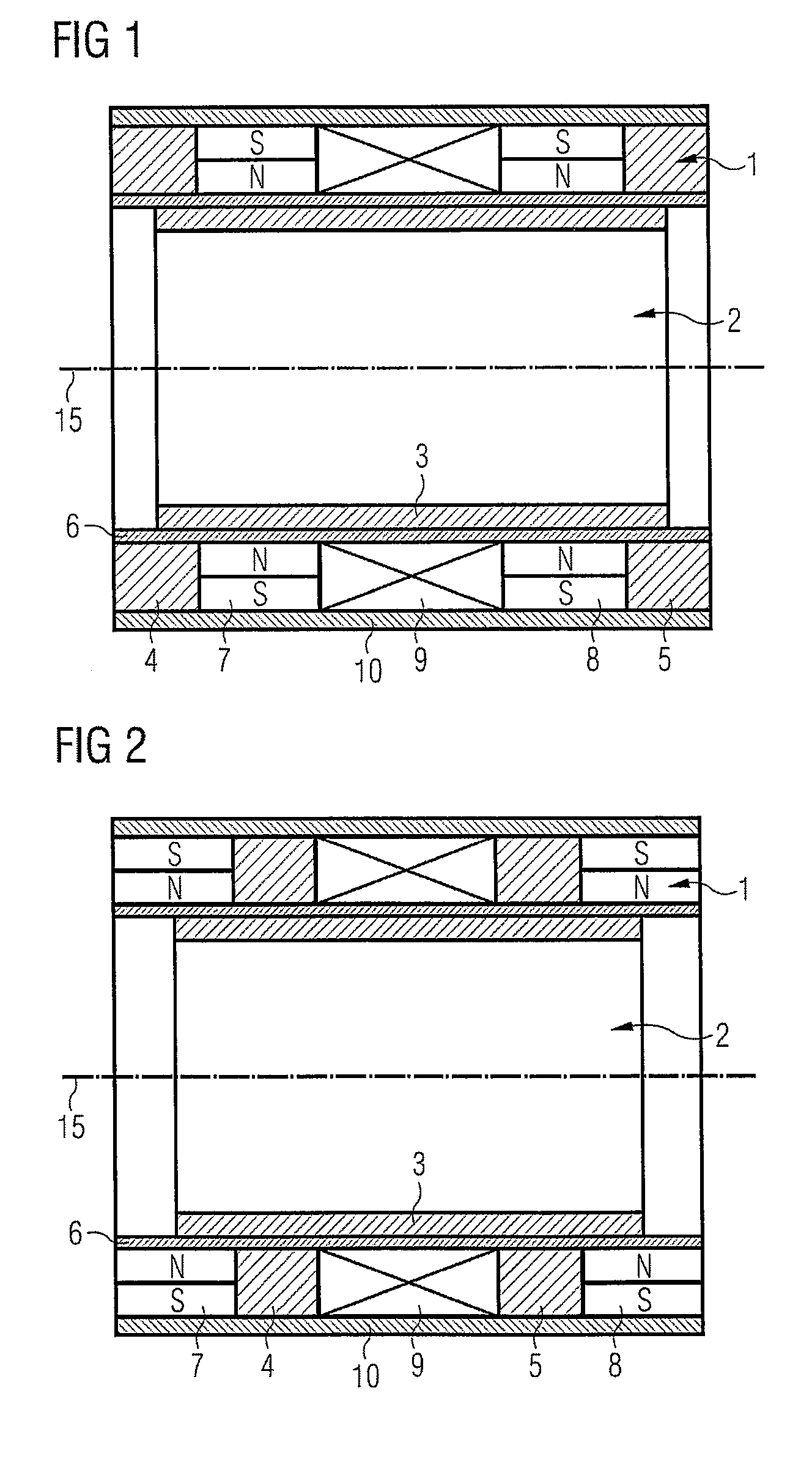

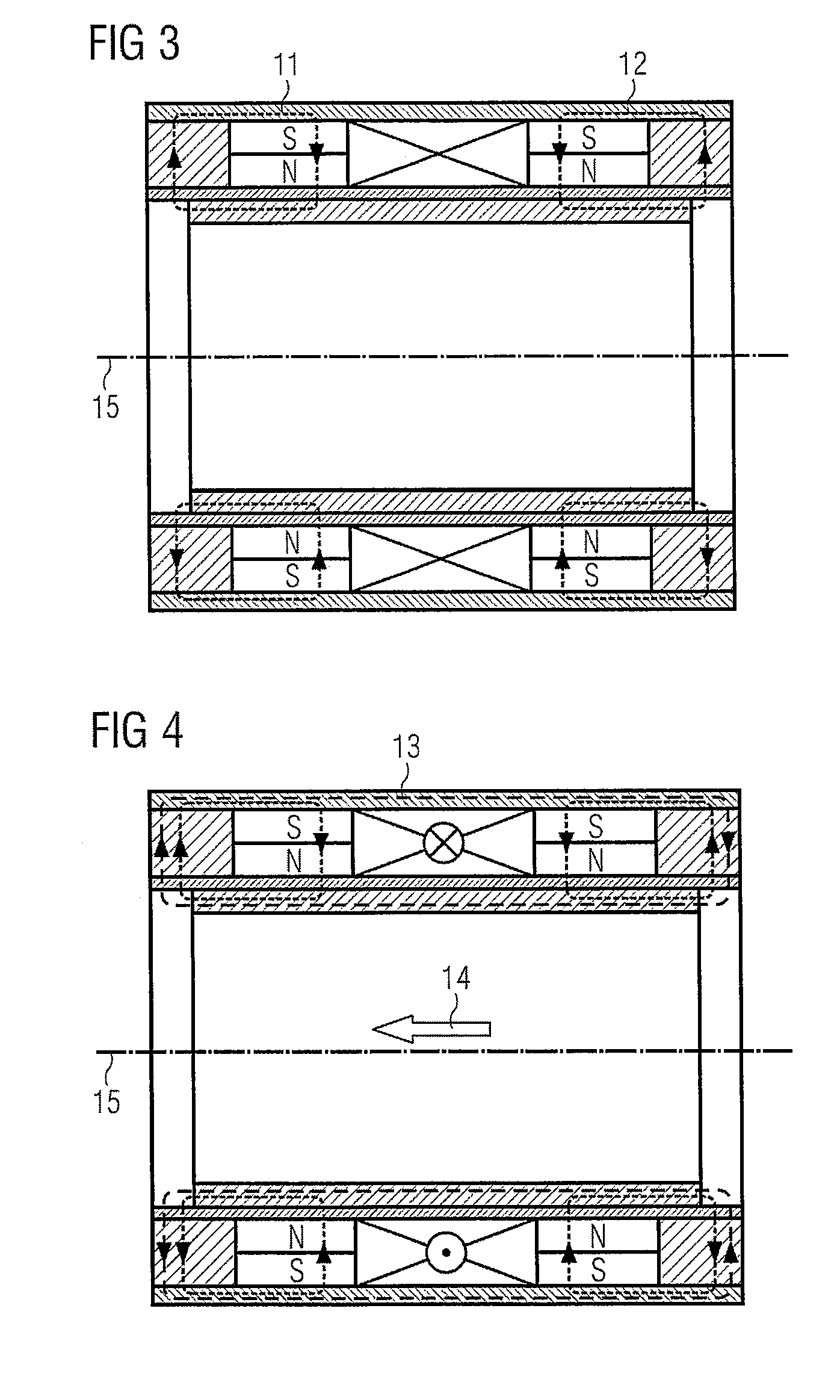

Linear motor with permanent-magnetic self-holding

A linear motor for optical systems, for example, endoscopes, is described. The motor has a stator with a magnetic guiding member and two adjacently disposed coils which are energized in opposite directions. Furthermore permanent magnets polarized in opposite directions and in the axial direction are provided on both sides of the pair of coils. The armature of the motor comprises a permanent magnet which is polarized in the opposite direction to the permanent magnet of the stator and is connected to a pole piece at each end. The pole pieces are arranged so that in the rest position each pole piece lies at the centre of one of the coils. By applying current to the coil, the armature can be displaced from a rest position in the longitudinal direction.

Owner:KARL STORZ GMBH & CO KG

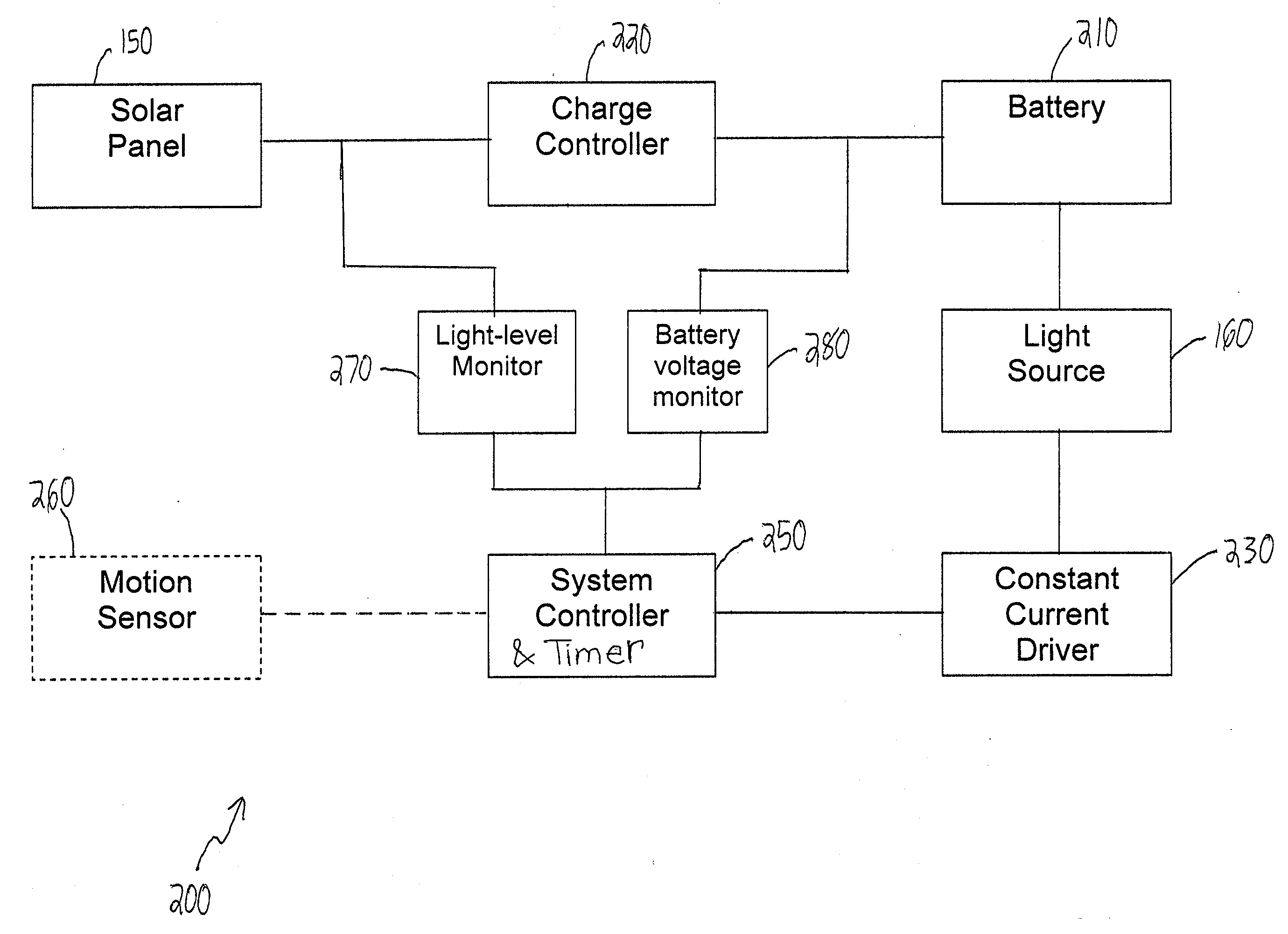

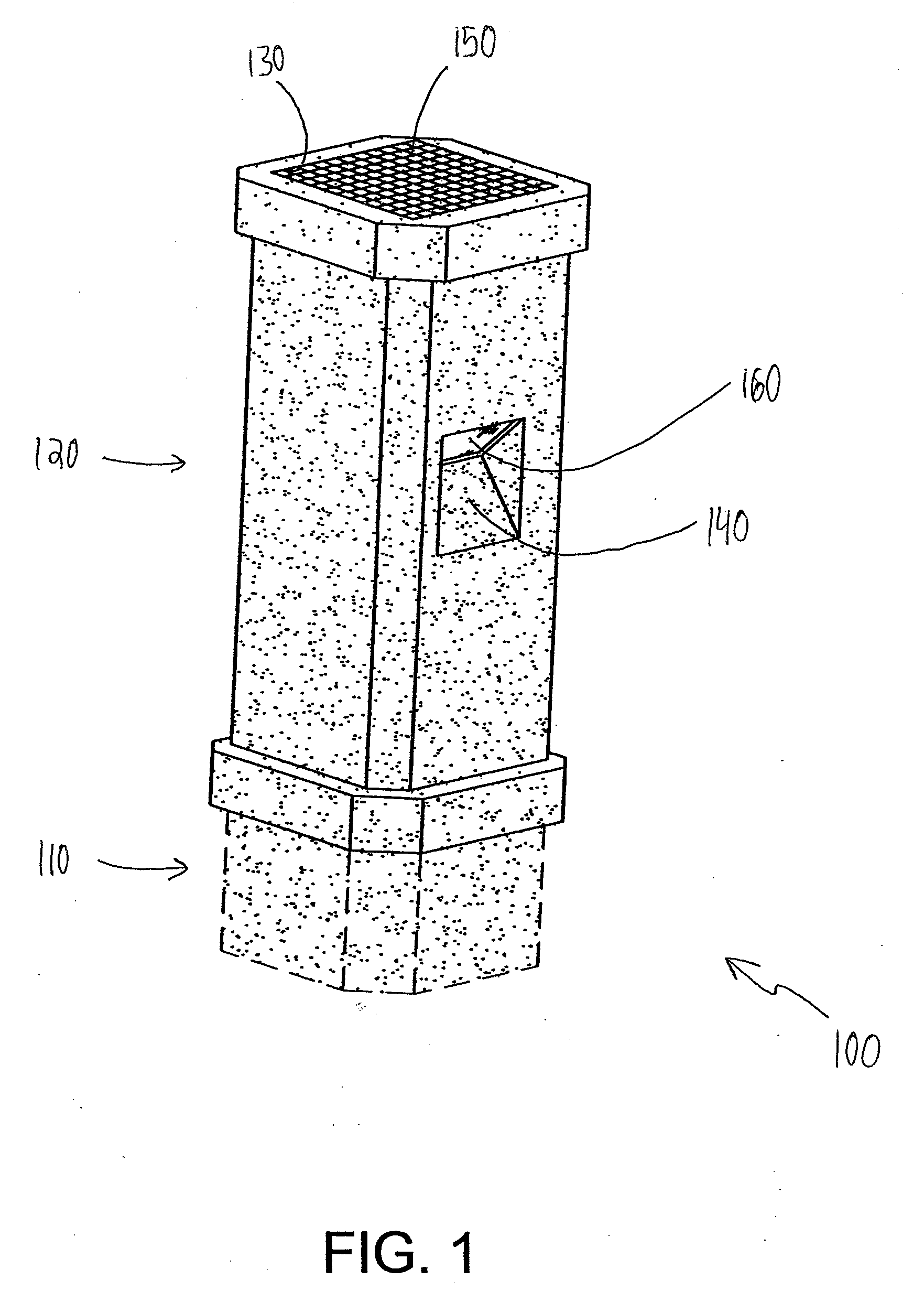

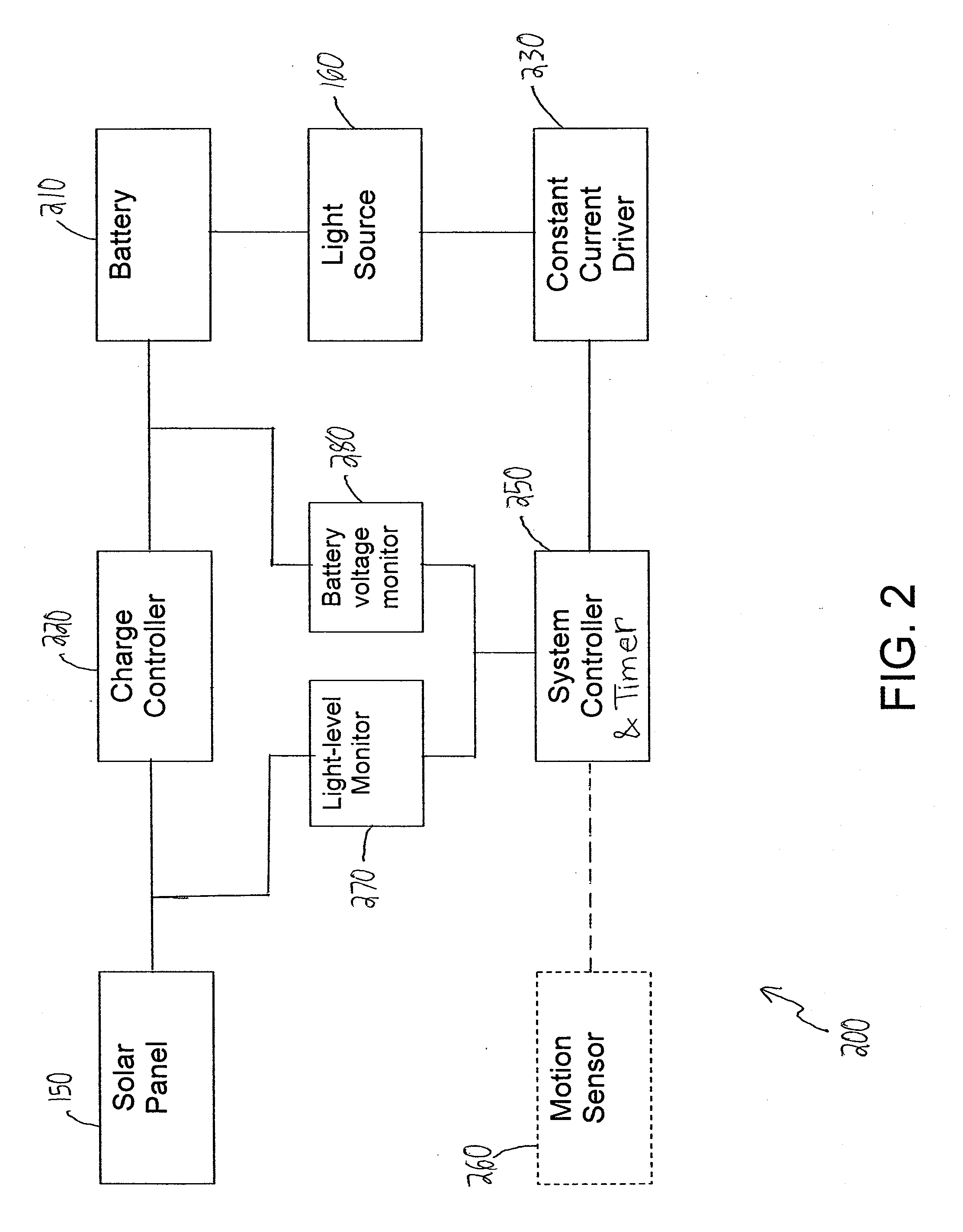

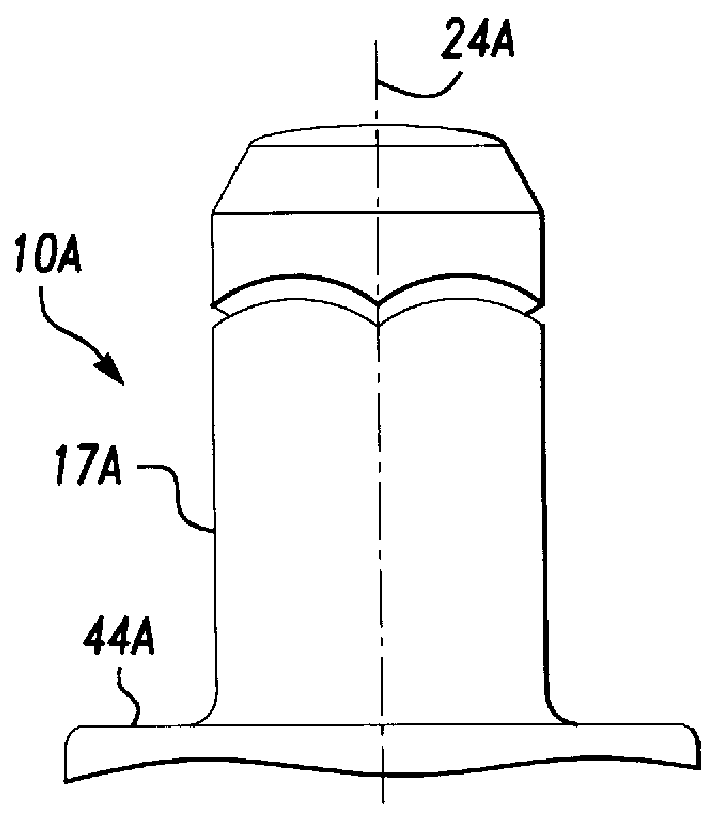

System and method for an outdoor lighting feature with an integrated solar panel

InactiveUS20110018448A1Increase efficiencyIncreases intensity and durationPoint-like light sourceWith electric batteriesLapse timeElectrical battery

A system and method for operating an outdoor lighting feature is provided, the outdoor lighting feature including a bollard, a solar panel disposed within a recess on the top of the bollard, a battery disposed within the bollard, the battery being electrically coupled to the solar panel and configured to receive and store energy from the solar panel, and a light source oriented to direct a light beam to a region external to the bollard, the light source being configured to draw an electric load from the battery. The system detects a change in an ambient light level, starts a timer and places a light source in a high-on state in response to the change in the ambient light level, monitors the timer, places the light source in a low-on state upon measuring a first predefined amount of lapsed time on the timer, and places the light source in an off state upon measuring a second predefined amount of lapsed time on the timer.

Owner:METCHEAR III CHARLES R +1

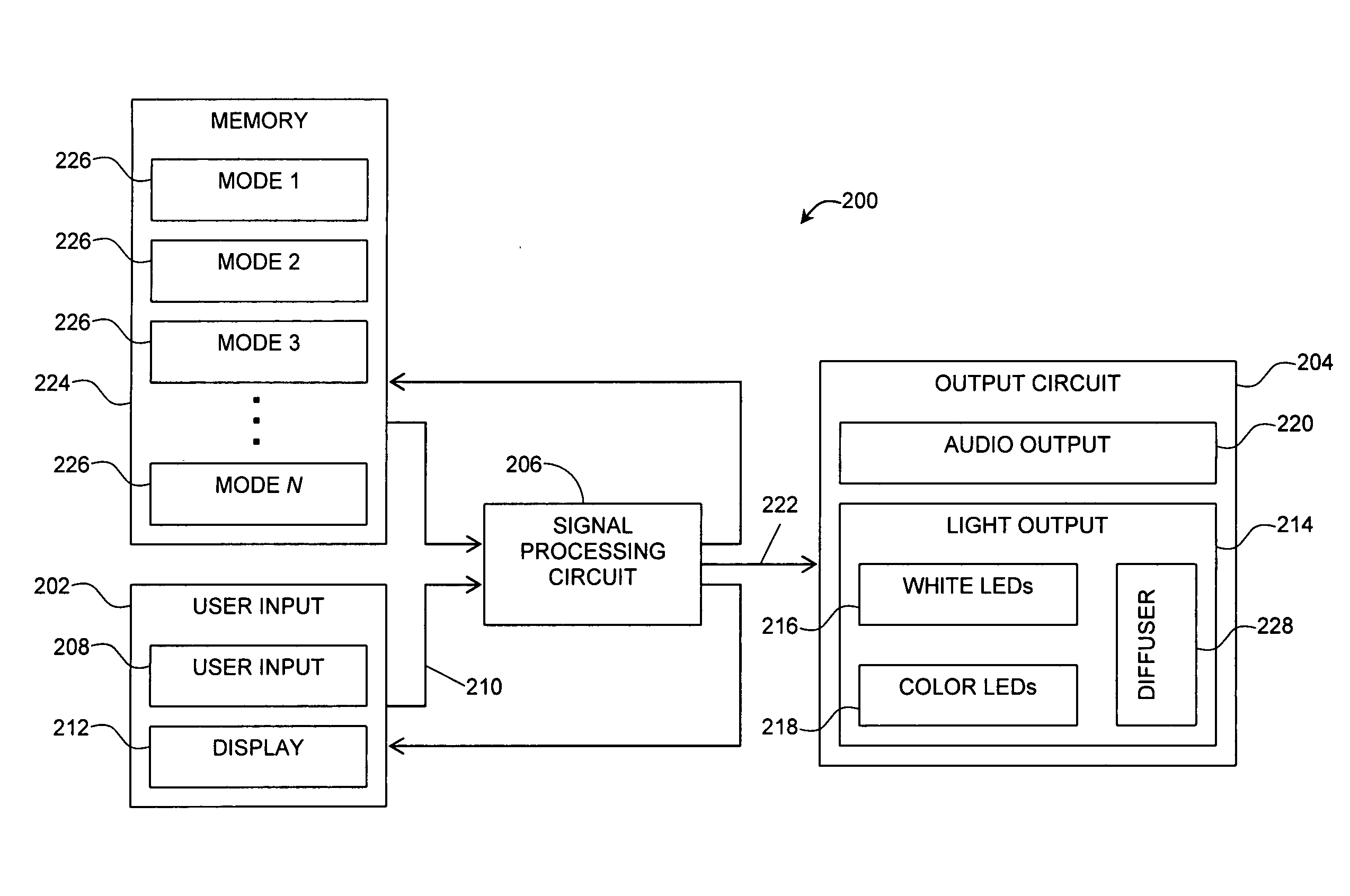

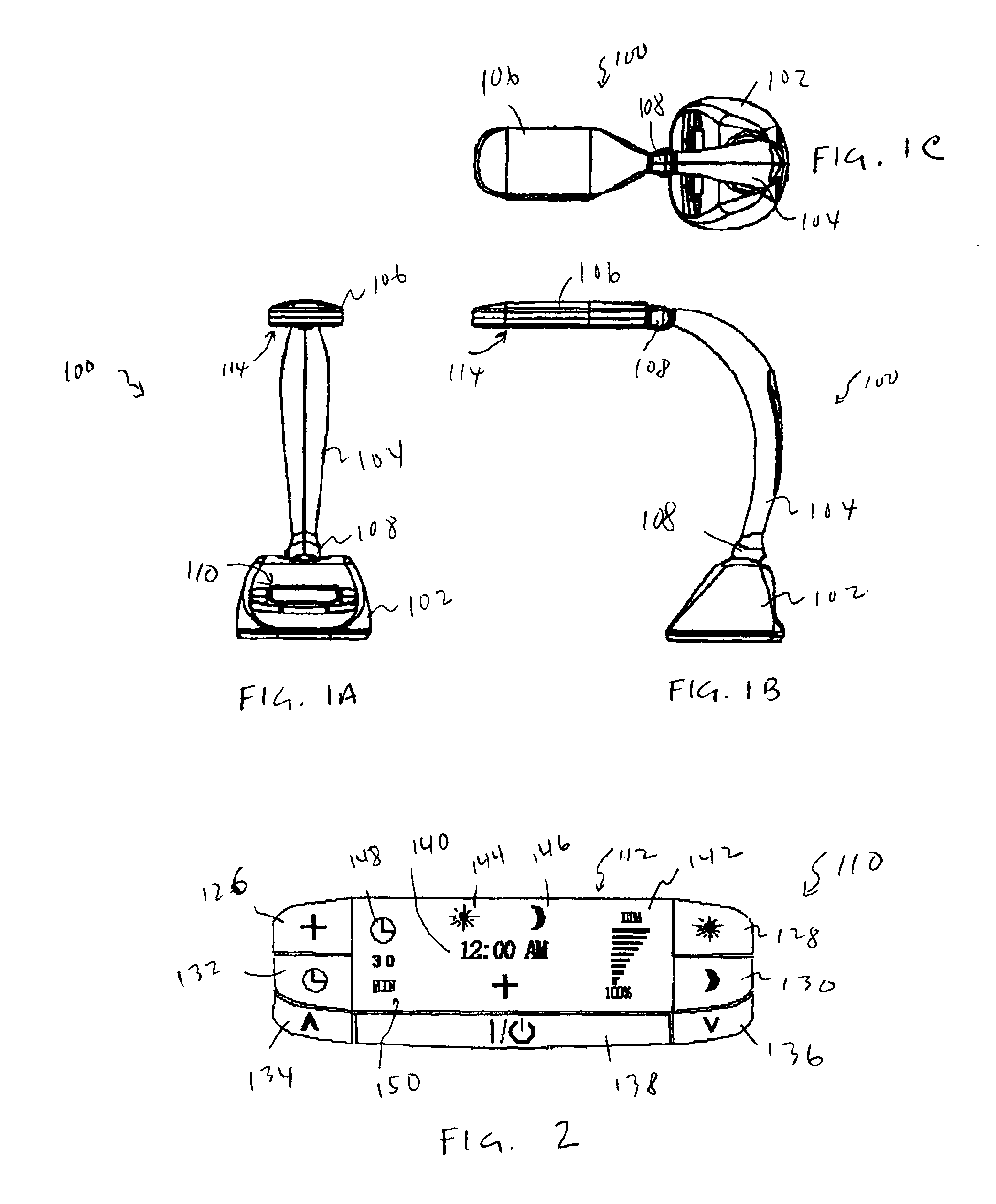

Programmable multifunction table lamp for light therapy

InactiveUS20060064144A1Easy to usePrevent speculationLight therapyLight therapySignal processing circuits

A lamp for providing light therapy includes an input circuit, an output circuit, and a signal processing circuit. The input circuit may include a user input for providing control signals to the signal processing circuit based on input at the user input from a user. The output circuit may include a light output configured to emit light at a level of at least 2,500 lux. The light output may include one or more white LEDs and may also include one or more color LEDs. The signal processing circuit is connected to the input circuit and the output circuit, and receives the control signals from the input circuit to control the output circuit based on the control signals. A memory may be provided in communication with the signal processing circuit. The memory may store a plurality of output modes, such as a light therapy mode. The light output may include a diffuser that is configured to diffuse the high-intensity light for effective use.

Owner:NATURE BRIGHT

Vaporization of thermally sensitive materials

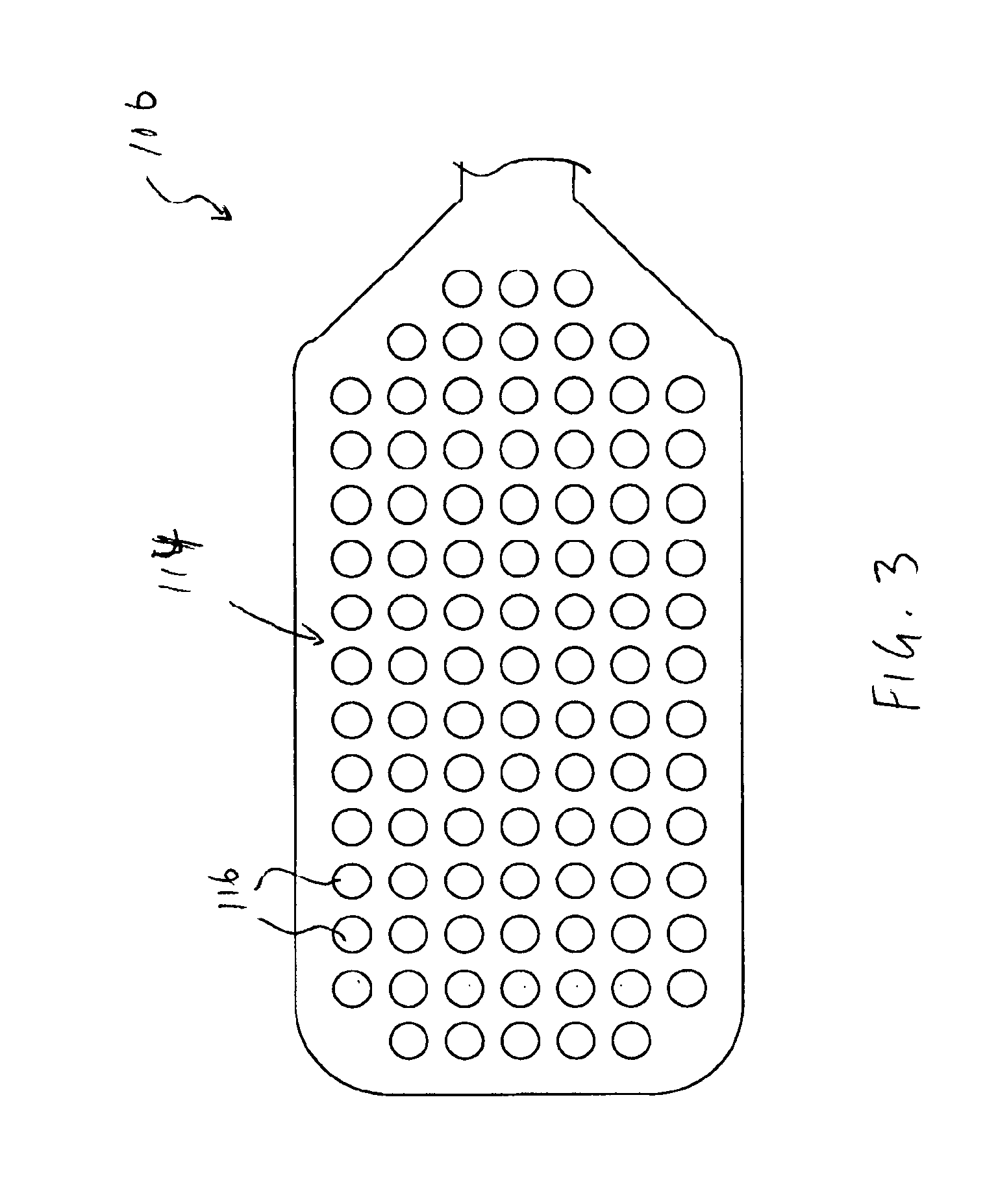

ActiveUS20090039175A1Heat dissipationLittle heatVacuum evaporation coatingSputtering coatingParticulatesHeat sensitive

A vaporizer for receiving and vaporizing particulate material, comprising: a heater having a reticulated material structure composed of ligands that define voids adapted to receive particulate materials, wherein the voids comprise greater than 85% of the volume of the reticulated material structure so that delivery of particulate material into the voids and conduction of vaporized material from the voids is facilitated; causes heat to be produced or conducted by the ligands to cause the particulate material in the voids to vaporize and be conducted through the voids.

Owner:GLOBAL OLED TECH

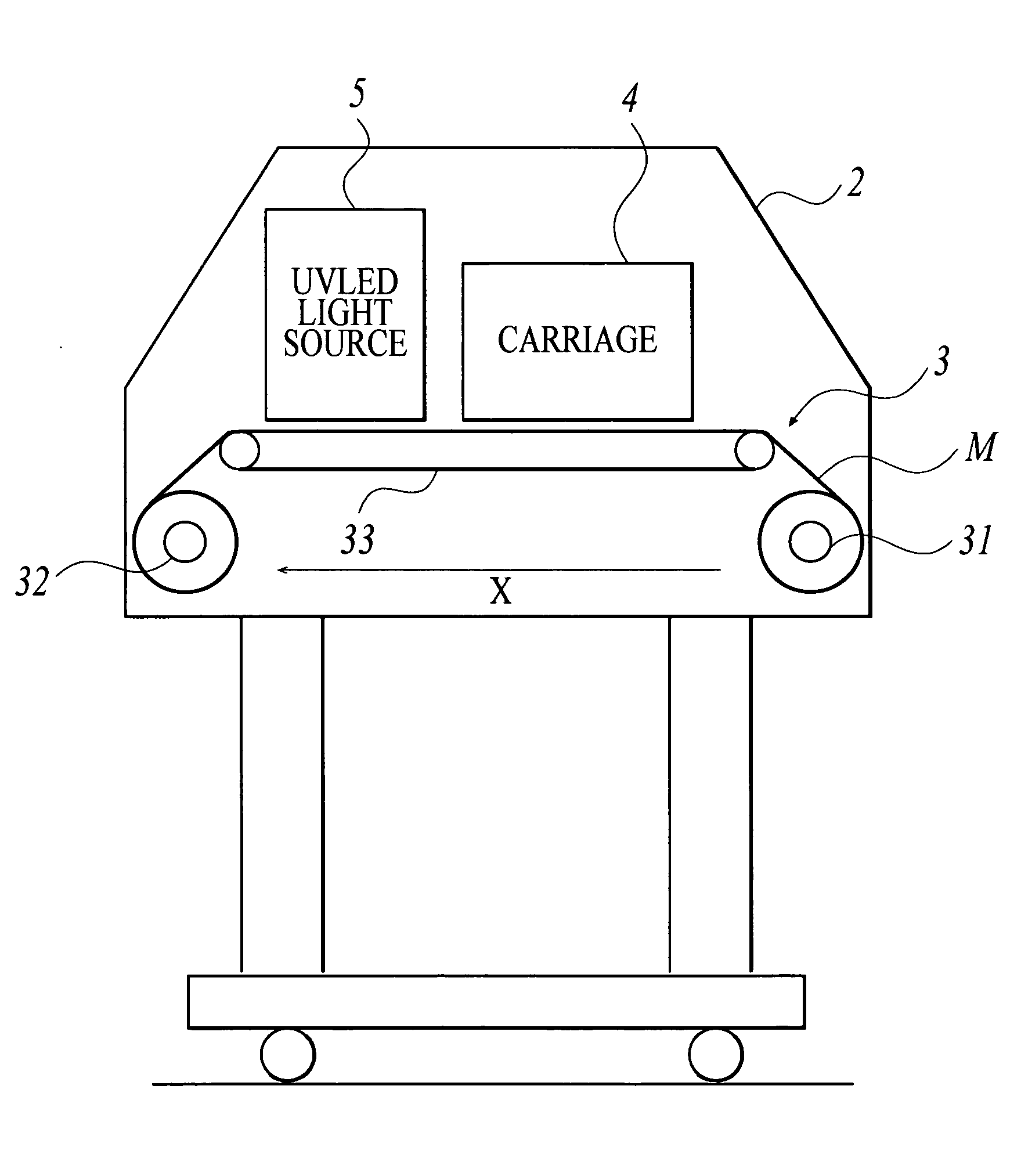

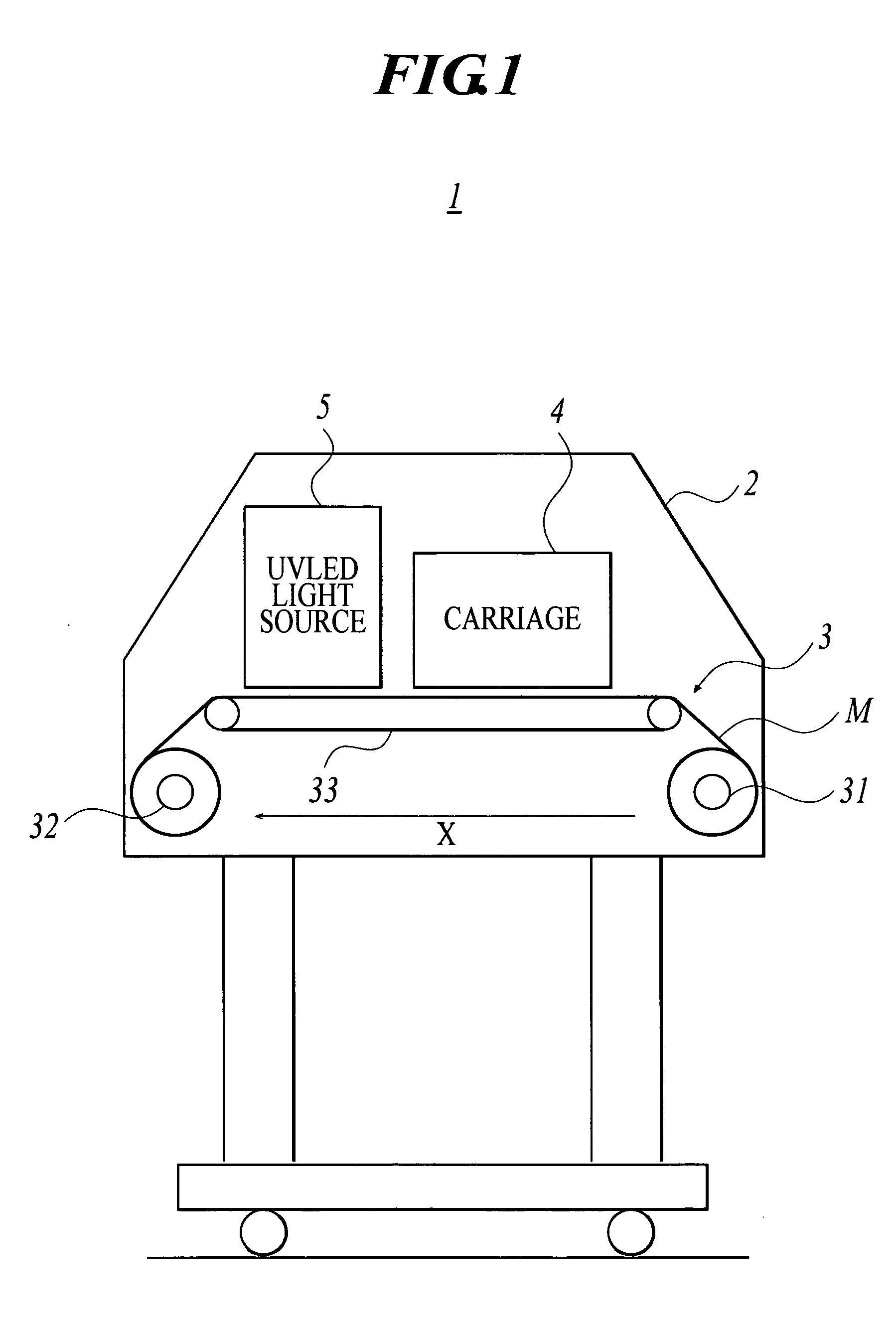

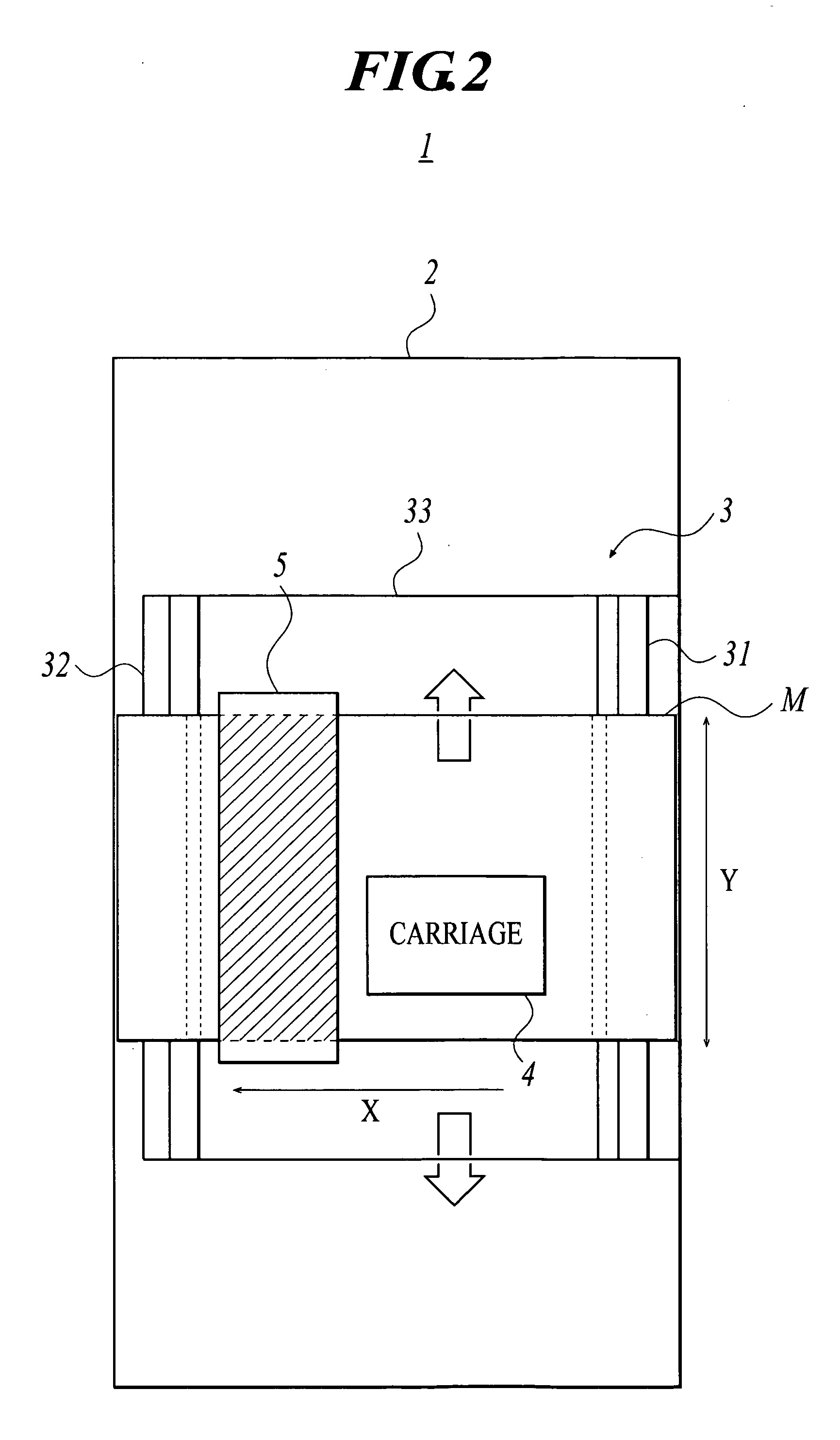

Ink jet printer

InactiveUS20050128274A1Reduce light intensityInhibition of polymerizationMeasurement apparatus componentsInksComputer printingUltraviolet

A small-sized ink jet printer capable of printing on various types of recording mediums at a lower cost, is provided. This is an ink jet printer that carries out printing by depositing UV ink which is curable by irradiation of an ultraviolet ray, on a recording medium, and irradiating ultraviolet rays on the recording medium. The printer has an UV irradiating unit to enable irradiation of an ultraviolet ray on the UV ink deposited on the recording medium. The UV irradiating unit has either a semiconductor laser or an LED, which enables emitting light the peak wavelength of which includes any one of wavelengths in an ultraviolet range which allow to cure the UV ink.

Owner:KONICA MINOLTA INC

Catheter with omni-directional optical lesion evaluation

ActiveUS8628520B2Improve lesionExtended service lifeDiagnosticsSurgical navigation systemsLight energyPositive pressure

A catheter is adapted to ablate tissue and provide lesion qualitative information on a real time basis, having an ablation tip section with a generally omni-directional light diffusion chamber with one openings to allow light energy in the chamber to radiate the tissue and return to the chamber. The chamber is irrigated at a positive pressure differential to continuously flush the opening with fluid. The light energy returning to the chamber from the tissue conveys a tissue parameter, including without limitation, lesion formation, depth of penetration of lesion, cross-sectional area of lesion, formation of char during ablation, recognition of char during ablation, recognition of char from non-charred tissue, formation of coagulum around the ablation site, differentiation of coagulated from non-coagulated blood, differentiation of ablated from healthy tissue, tissue proximity, and recognition of steam formation in the tissue for prevention of steam pop.

Owner:BIOSENSE WEBSTER INC

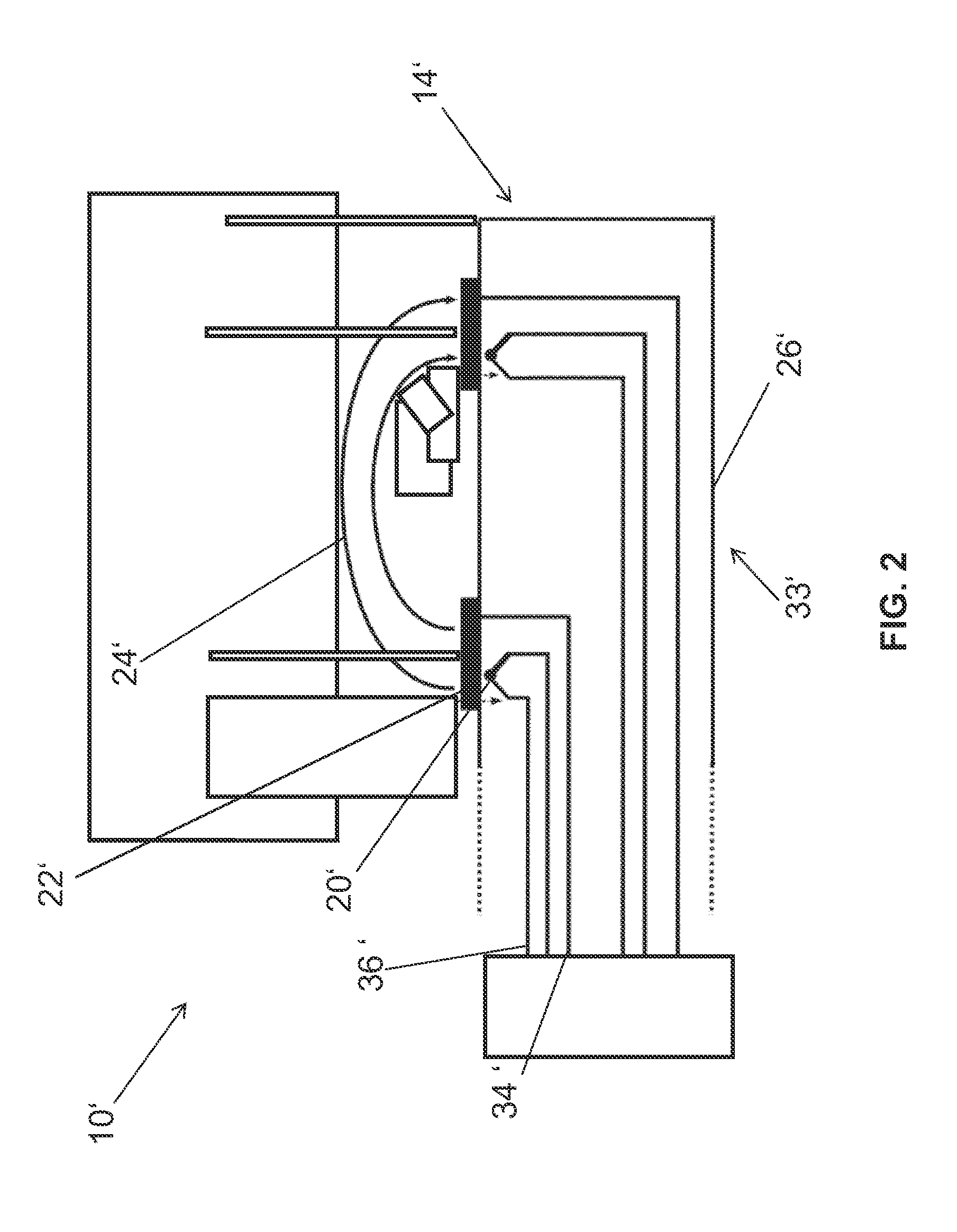

Rotating induction grow light system

InactiveUS9451743B2Extra costsAvoid a lot of laborMechanical apparatusLight source combinationsEngineeringGrow light

A rotating induction growth light system and method are disclosed. The rotating induction growth light includes a mounting bracket assembly and a light source assembly rotatably coupled to the mounting bracket assembly. The light source assembly has a first side subassembly and a second side sub assembly opposite the first side subassembly. The light source assembly is configured to rotate between a first position wherein the first side subassembly is facing away from the mounting bracket assembly and at least a second position wherein the second subassembly is facing away from the mounting bracket assembly. A method of providing light to a plant is disclosed, including: directing a vegetative side subassembly of a light source assembly toward a plant; and rotating the light source assembly until a flowering side subassembly is directed toward the plant, the flowering side subassembly positioned on the light source assembly opposite the vegetative side subassembly.

Owner:GLOBAL LIGHTING TECH LLC

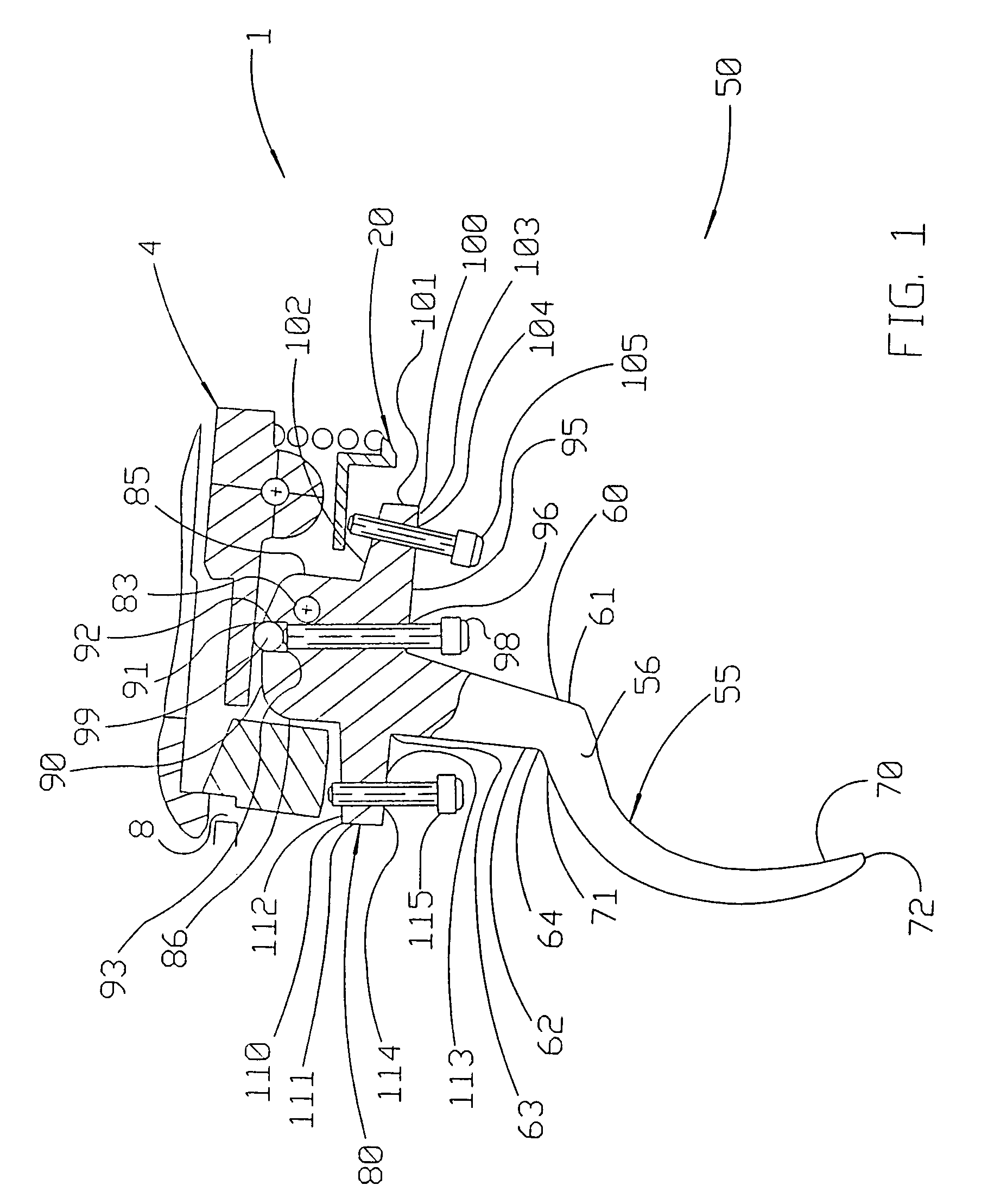

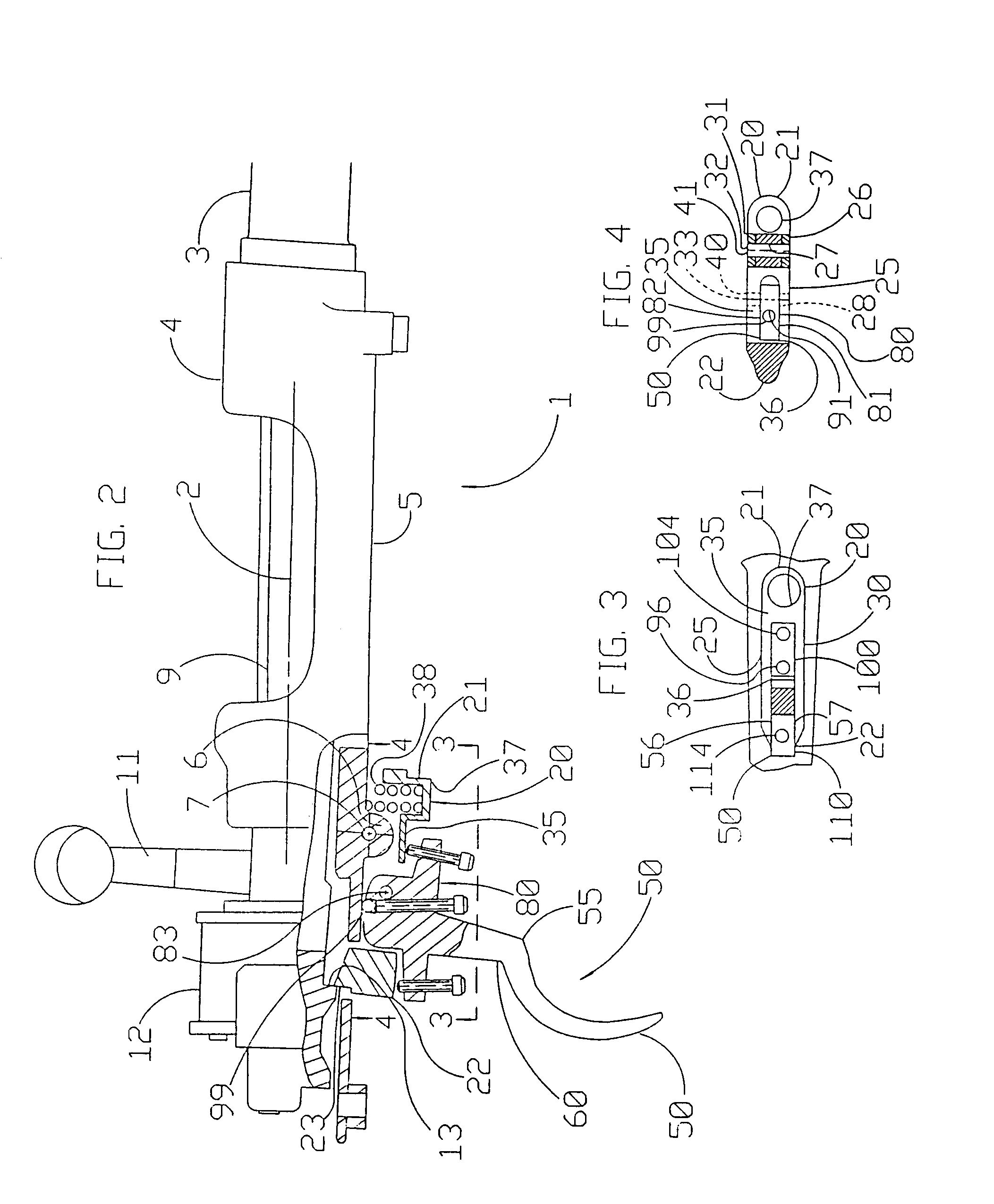

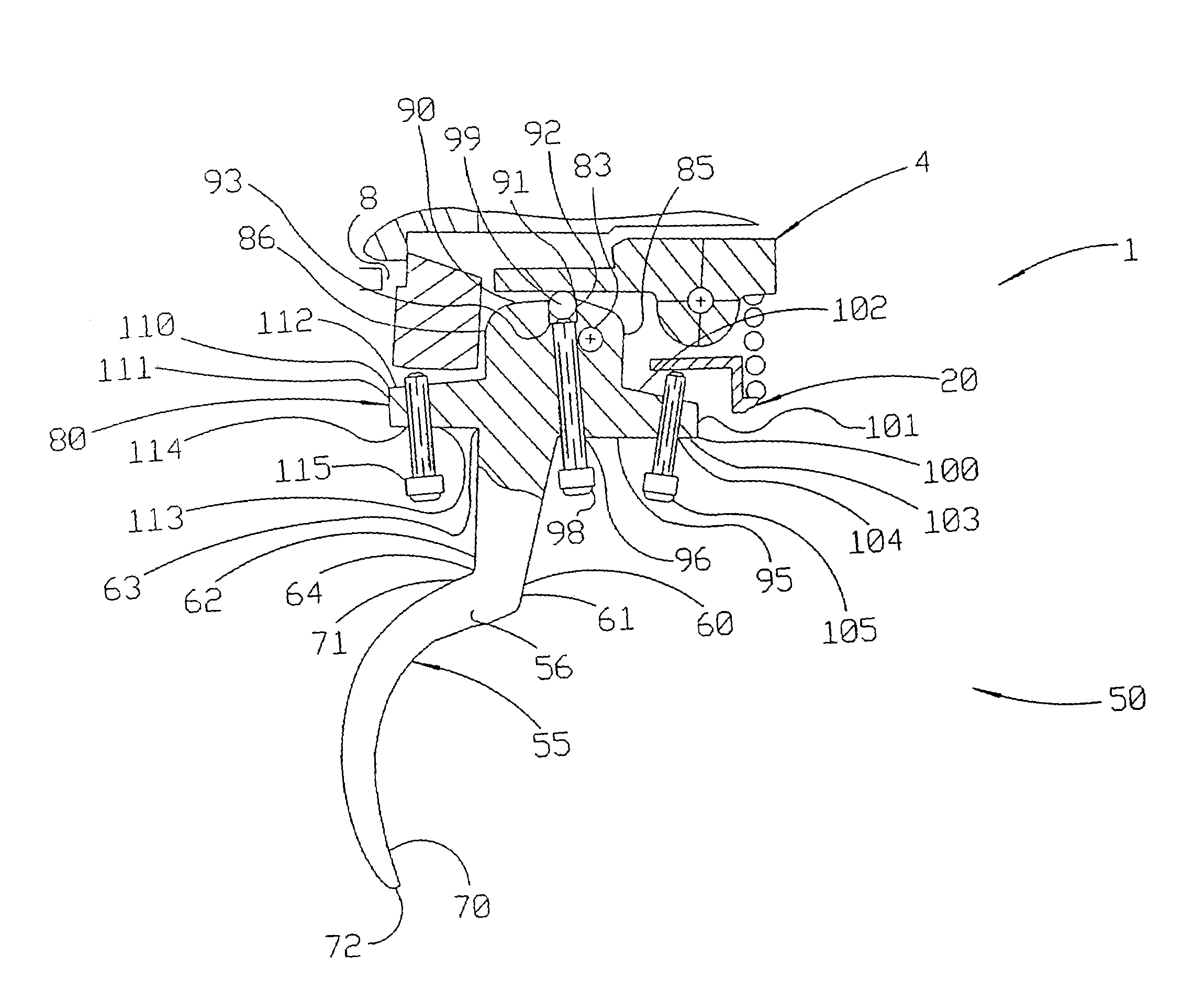

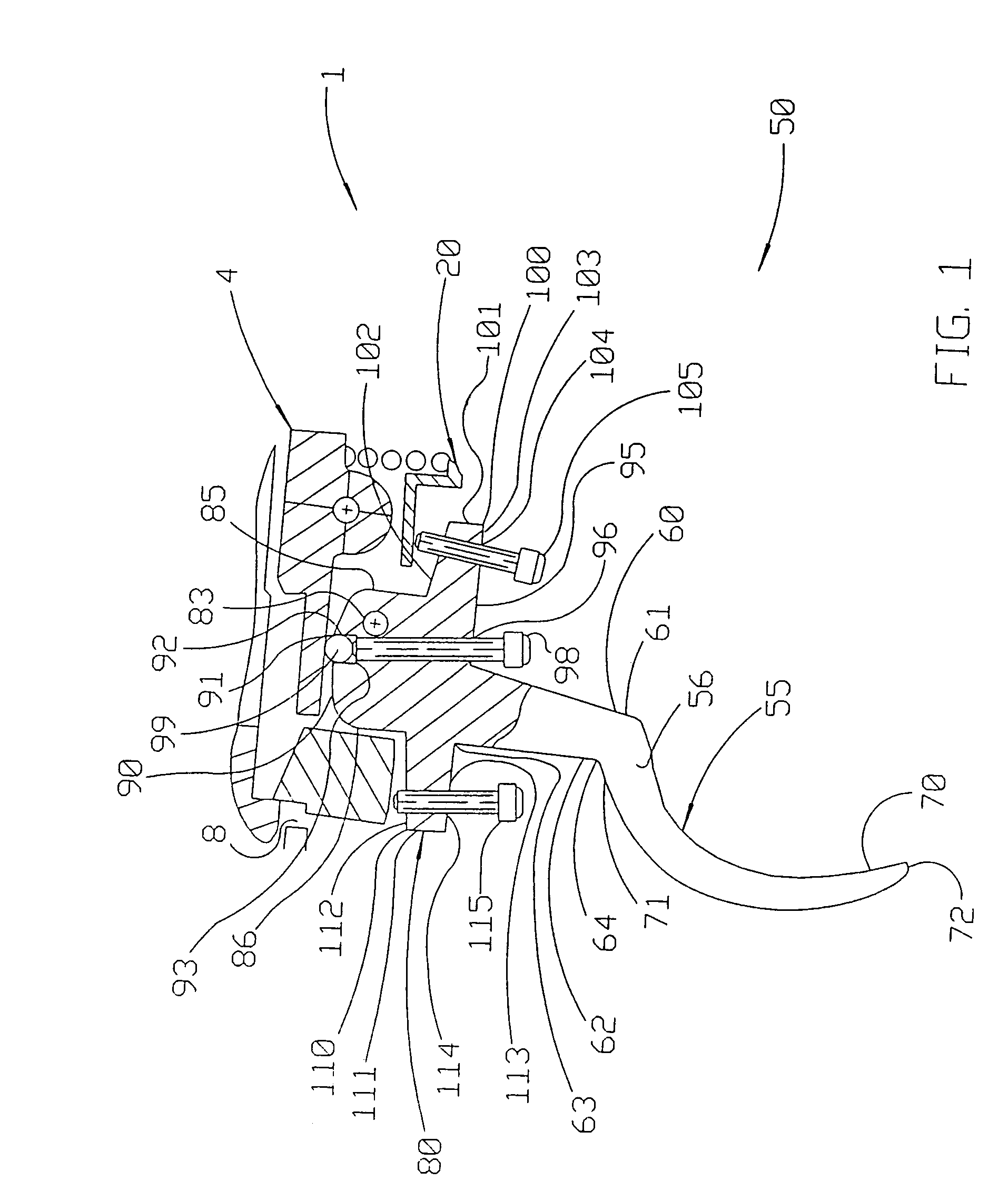

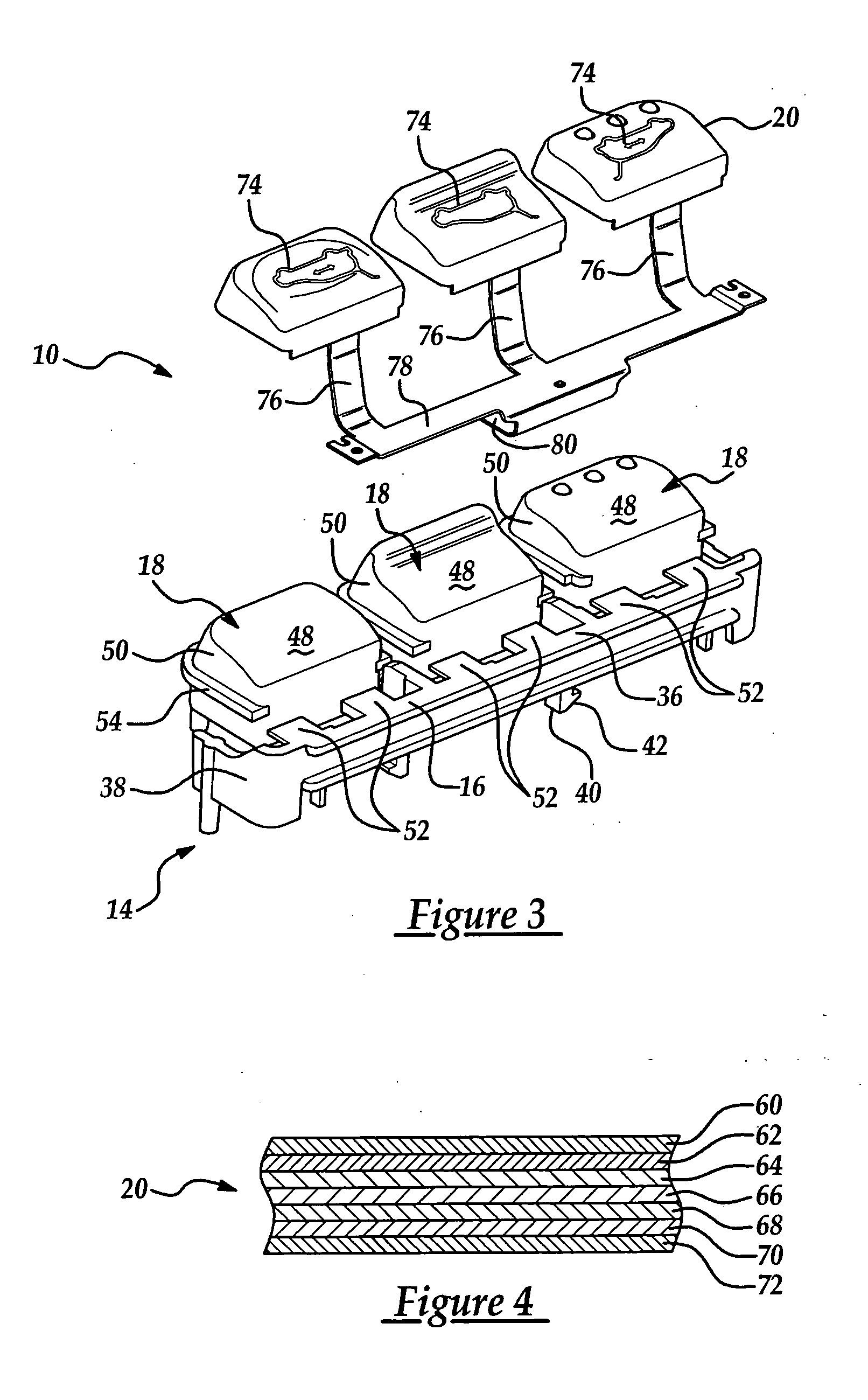

Gun trigger

InactiveUS7051467B1Less exacting tolerancePrecise positioningFiring/trigger mechanismsBreech mechanismsEngineeringMechanical engineering

The present invention relates to a gun trigger for use with a bolt-action gun. The trigger of the present invention has a finger element with an extension and a catch. The catch has a front strap and a rear strap. One or more openings are between the front and rear straps. One or more braces can be across the one or more openings. The trigger also has a head. A socket is formed in the top of the head, and a ball is received within the socket. The height of the ball relative the bottom of the socket can be adjusted. There is practically no friction between the trigger and a sear. The trigger of the present invention may be made by remanufacturing existing conventional triggers.

Owner:HUBER JOHN F

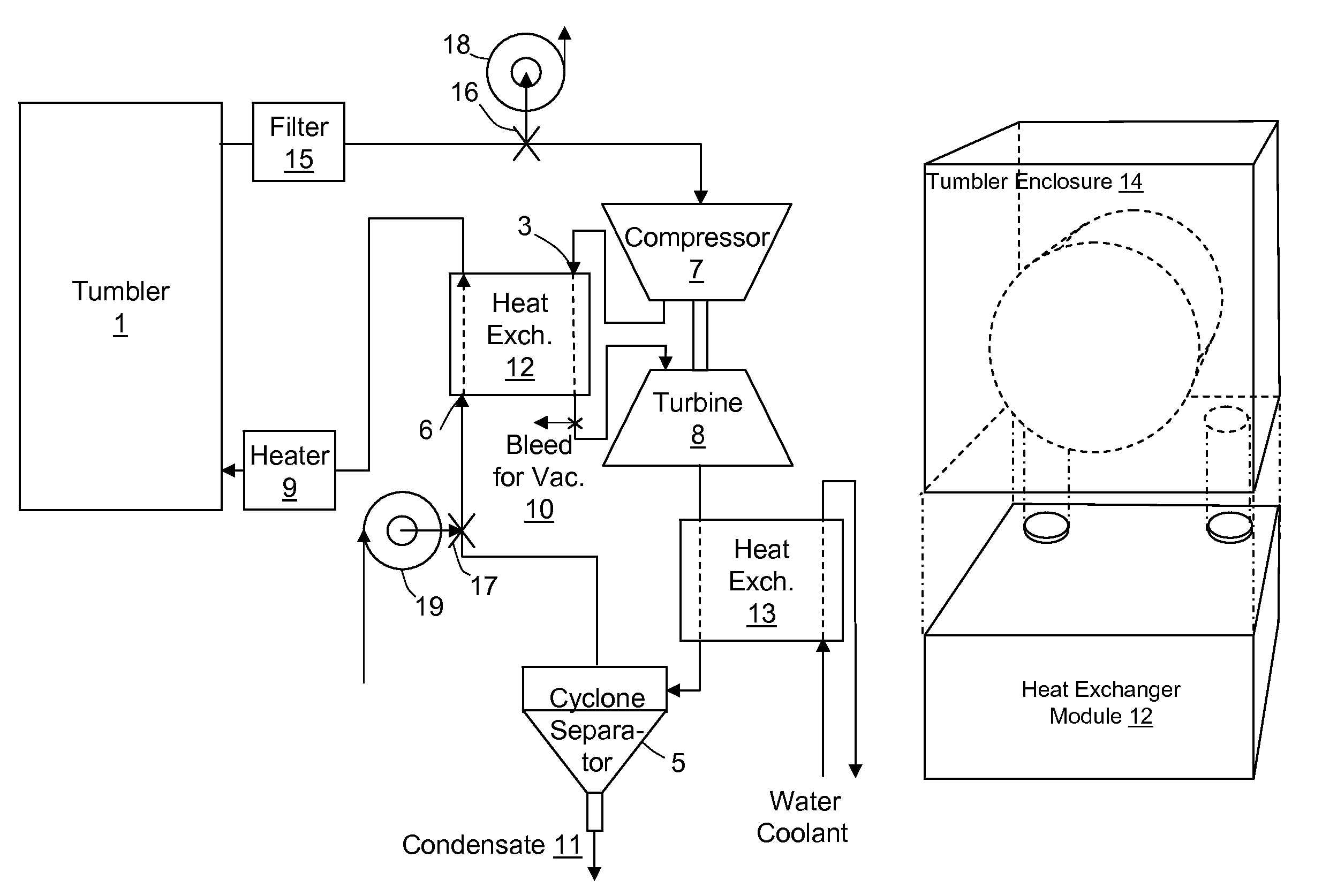

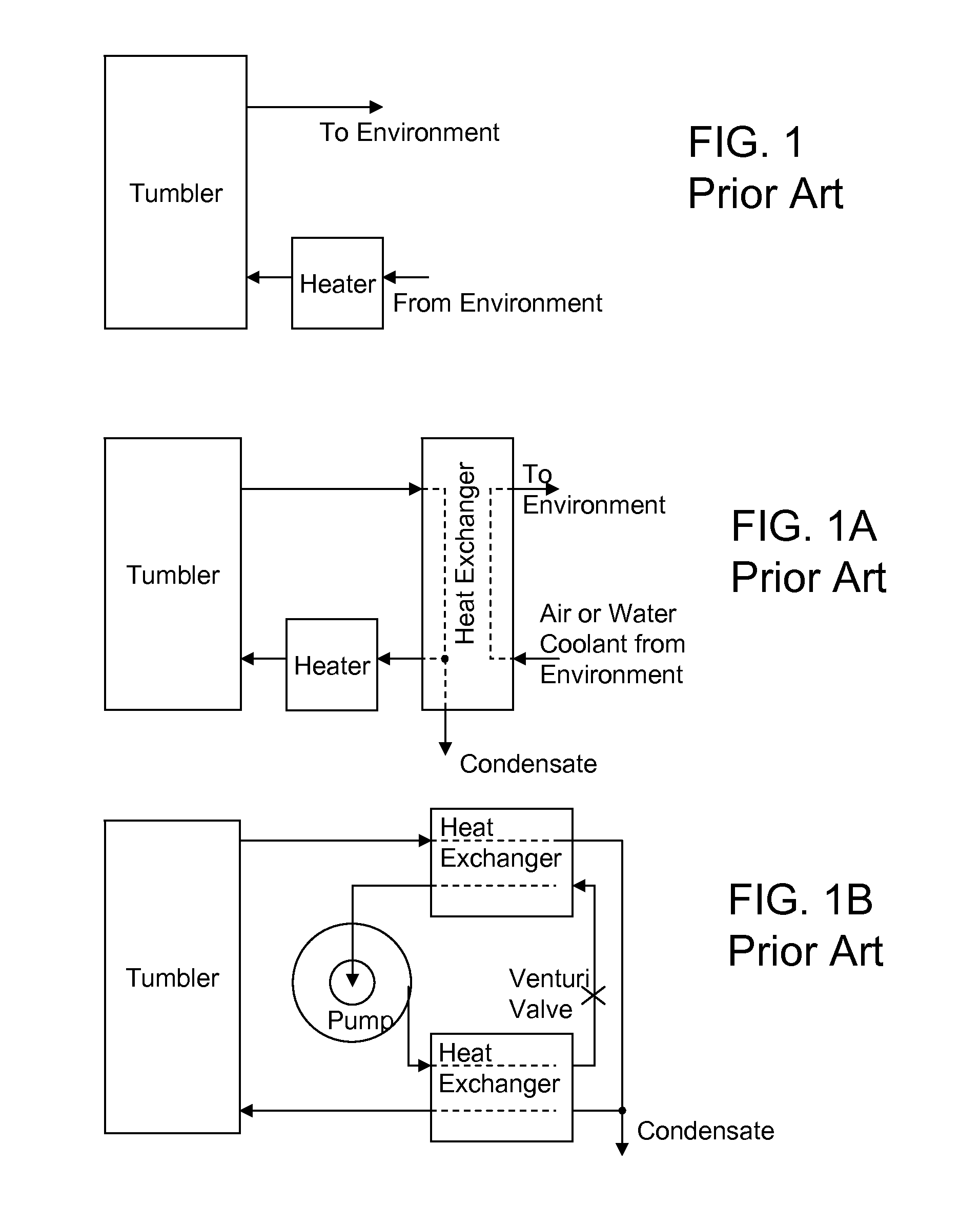

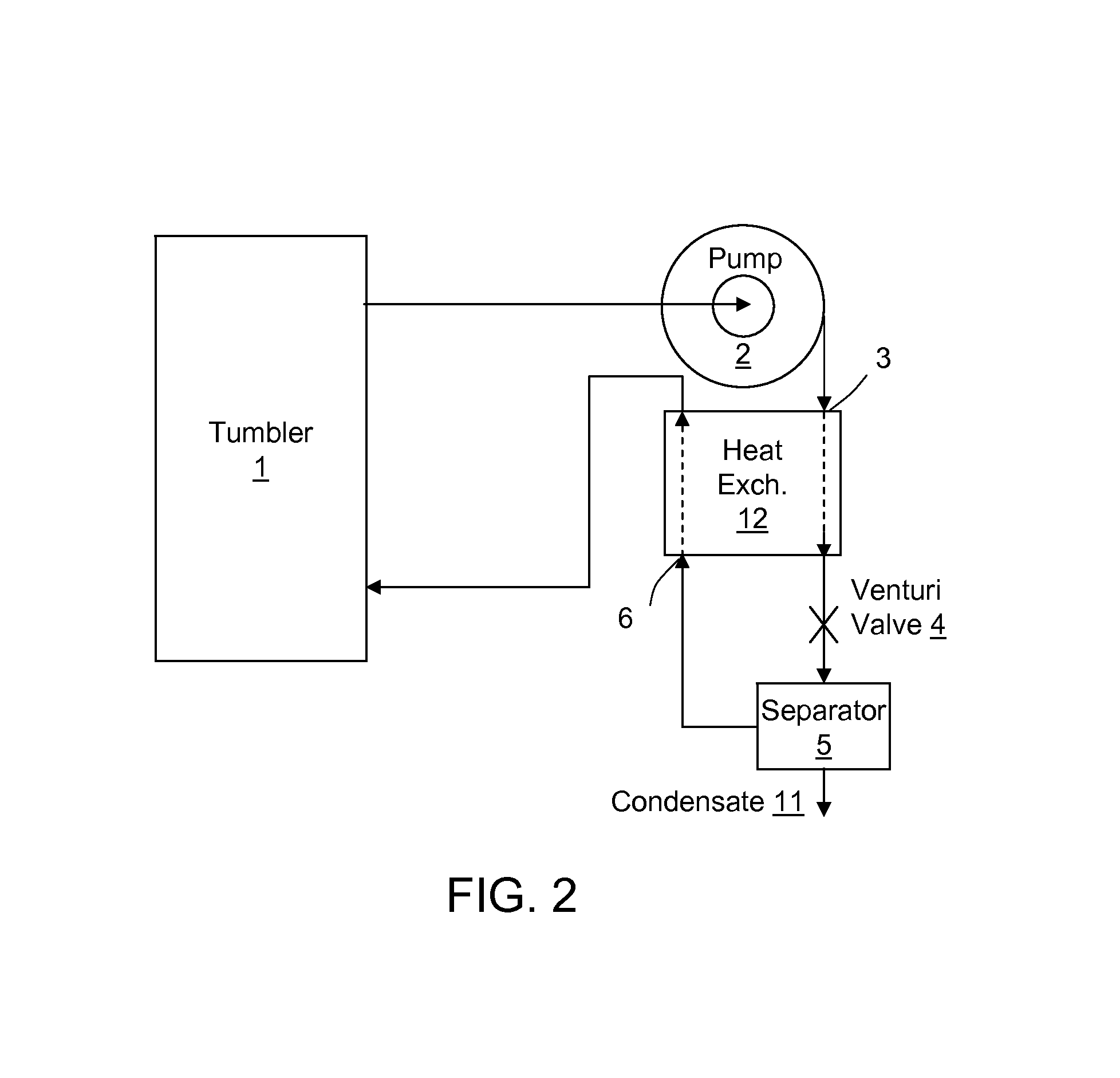

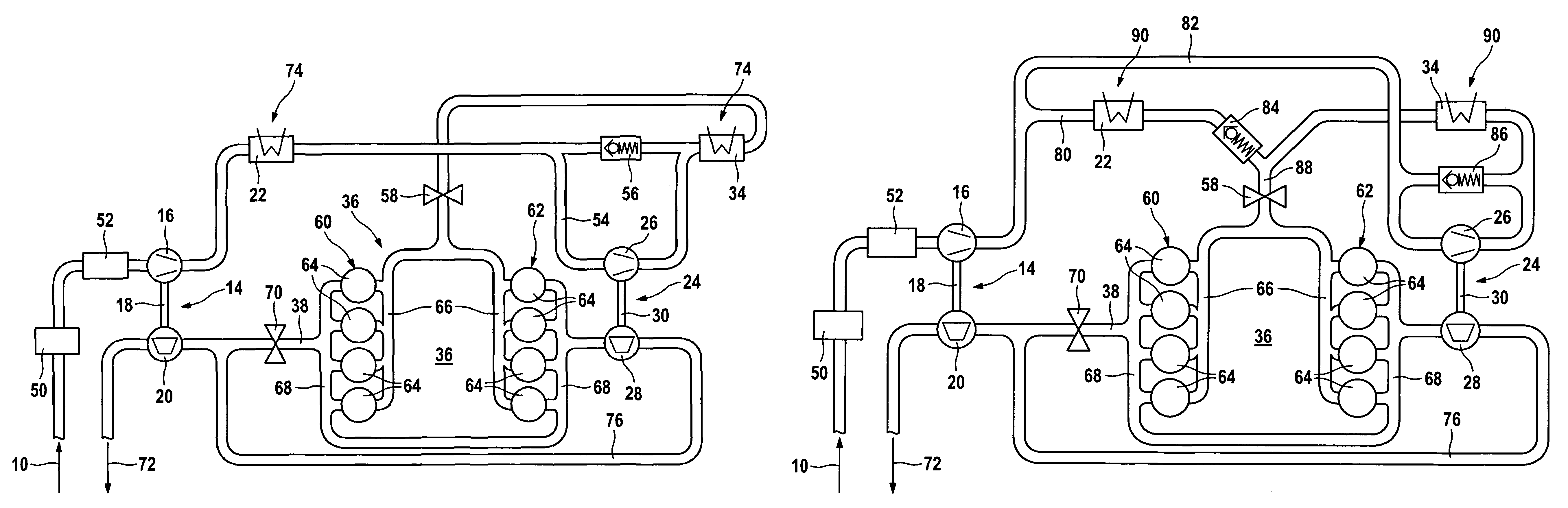

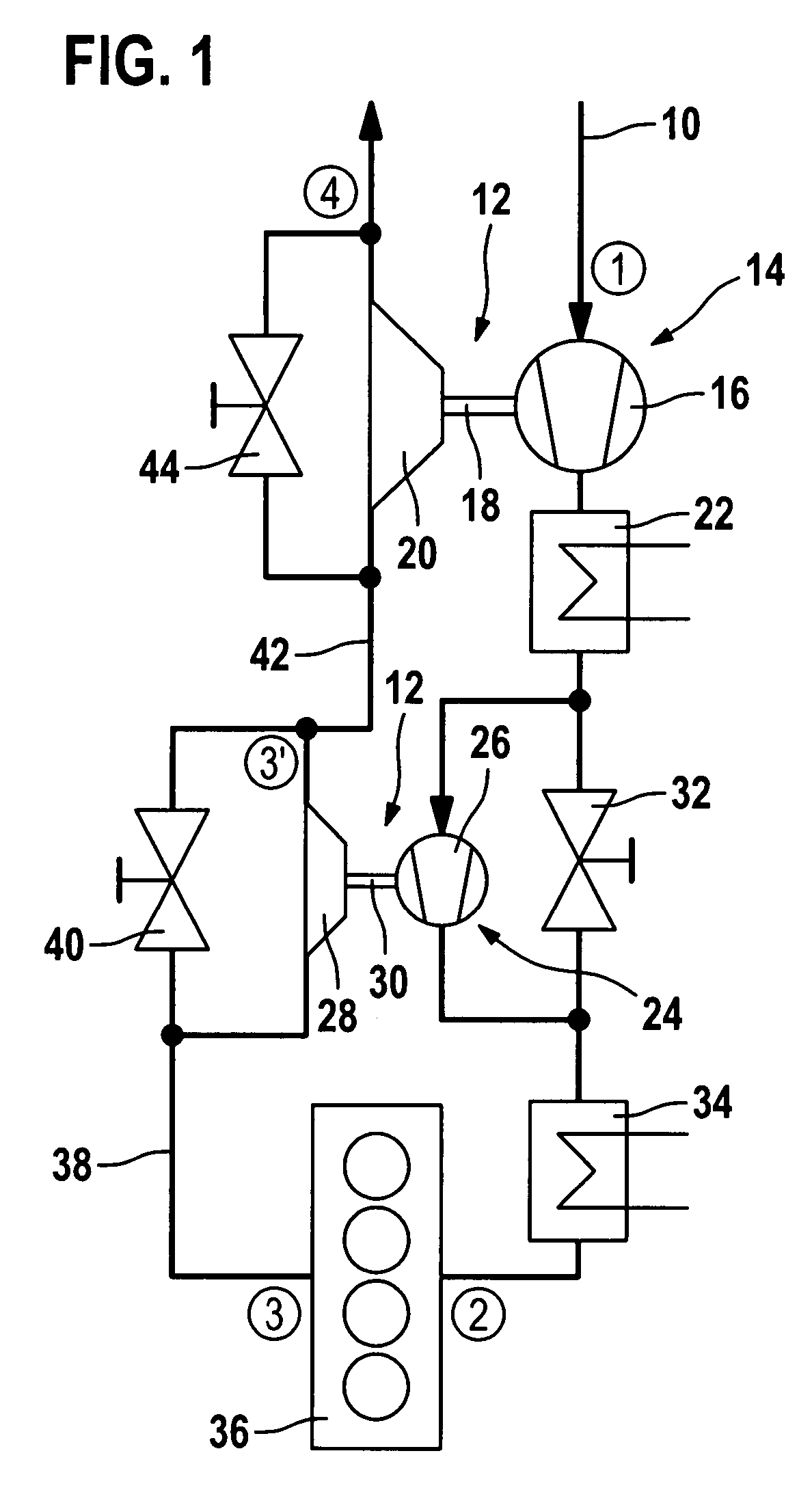

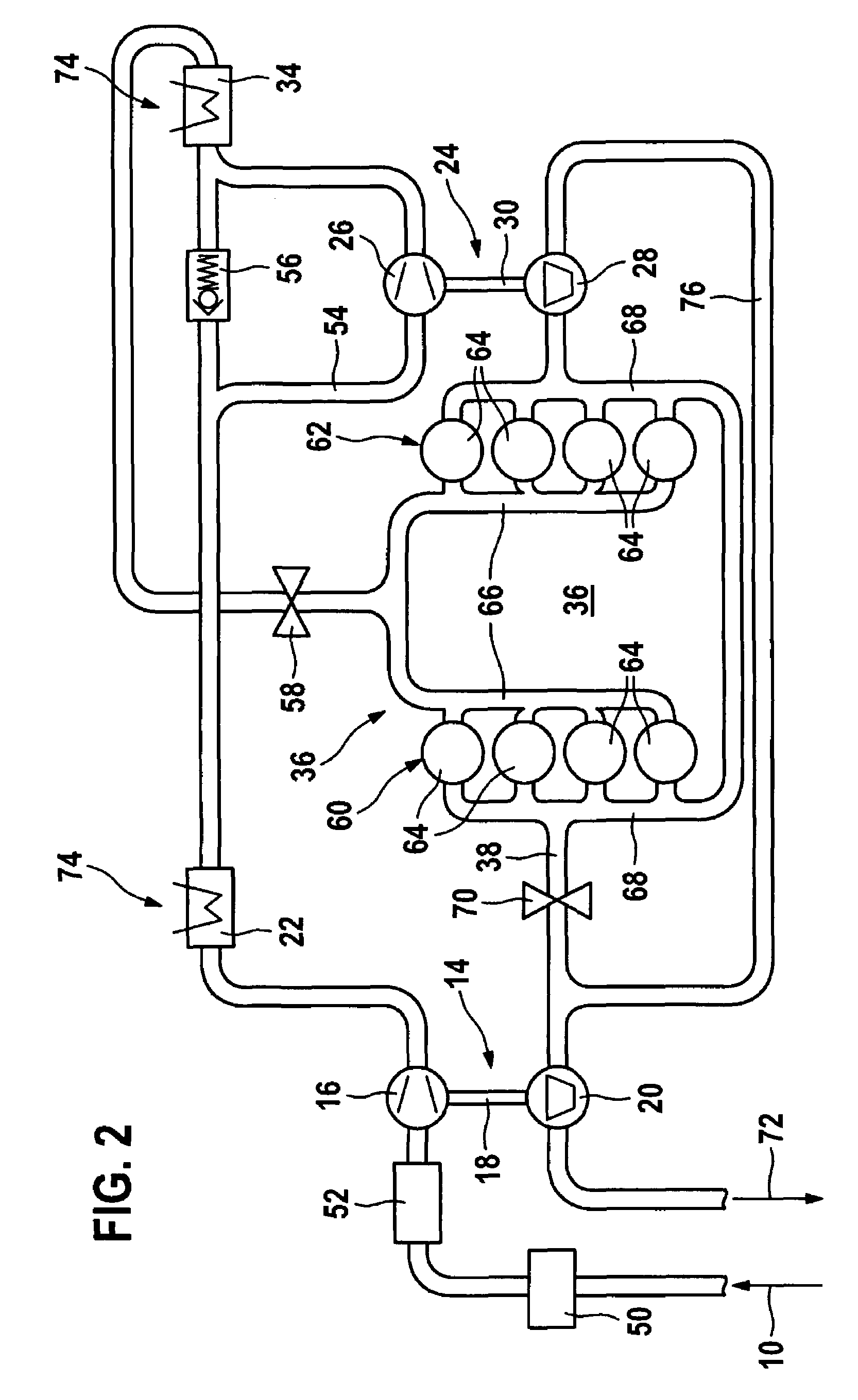

Air cycle heat pump dryer

InactiveUS8650770B1Simple and efficientLittle heatReciprocating combination enginesDrying solid materials with heatDew pointEngineering

This invention is a method and apparatus for drying wet objects, comprising passing air through the wet objects thereby having air absorb moisture from said wet objects; compressing the air adiabatically, thereby heating it; extracting heat from the air by passing it through the hot side of a heat exchanger thereby cooling it; expanding the air adiabatically, thereby cooling it further, below its dew point; separating the condensate from the air; restoring to the air all or part of the heat by passing it through the second side of the heat exchanger; and redirecting all or part of the air back to the wet objects thereby forming a loop in the flow of the air.

Owner:LEVY GEORGE SAMUEL

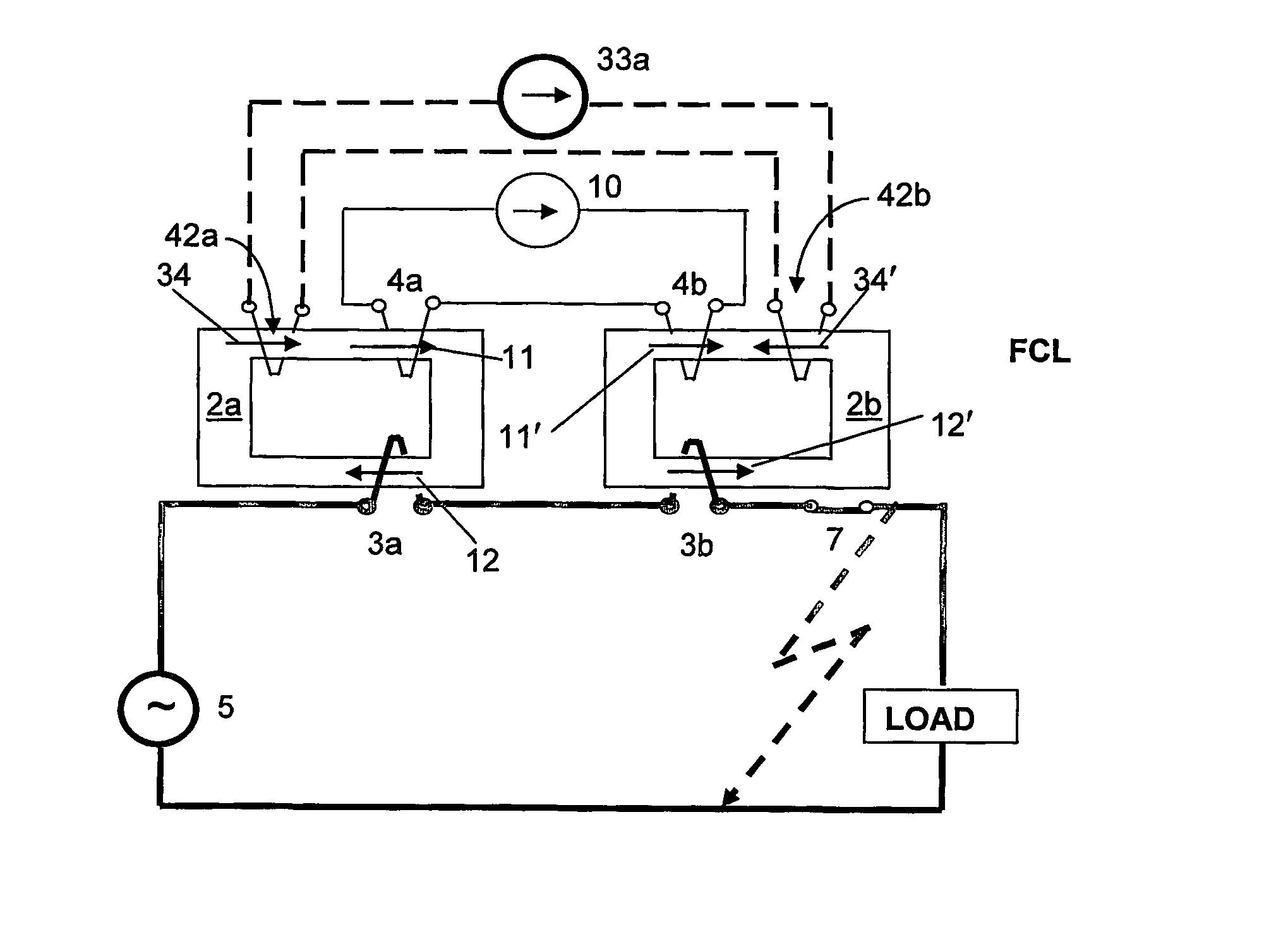

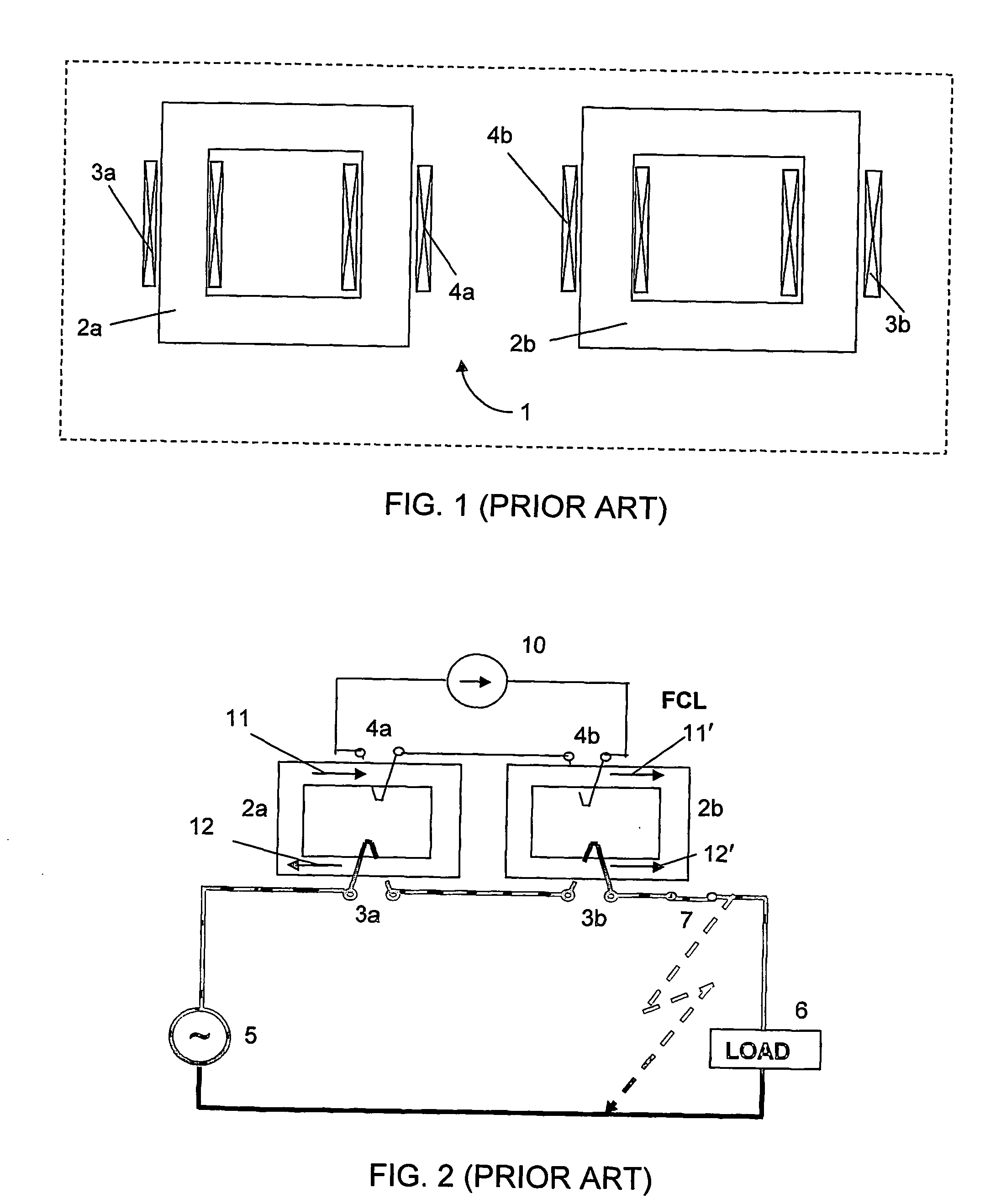

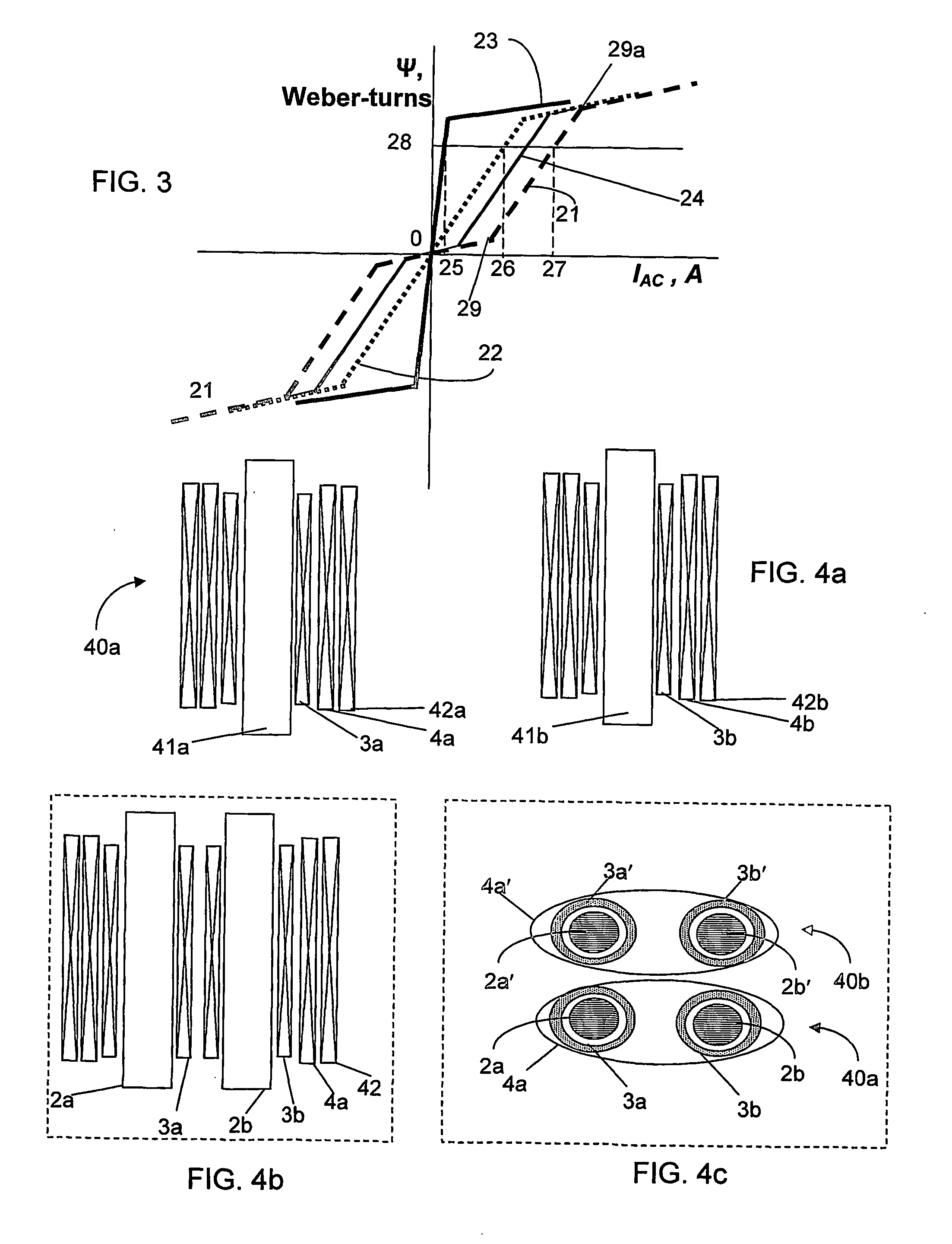

Fault current limiters (fcl) with the cores staurated by superconducting coils

InactiveUS20060158803A1Reduce weightDecrease dimensionEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageAlternating currentHigh pressure

A superconducting short circuit current limiter (40a) for an alternating current system includes AC reactors having superconducting direct current bias windings (4a, 4b) that at normal conditions maintain the reactor's cores in saturated state. There are at least two AC coils (3a, 3b) for each phase operating at opposite half periods or at both half periods. The reactor may also have an additional feedback coil (42a, 42b) that at least partly compensates for the bias field of the superconducting coil at fault conditions enhancing a limiting capacity of the reactor. The reactor's core can be configured for decreasing its dimensions and mass as compared with known devices and for decreasing core losses. High voltage / high current devices include several standard modules connected in series or / and in parallel. A positional relationship of the modules is defined for decreasing necessary numbers of Amp?re-turns of superconducting and non-superconducting coils.

Owner:BAR ILAN UNIV

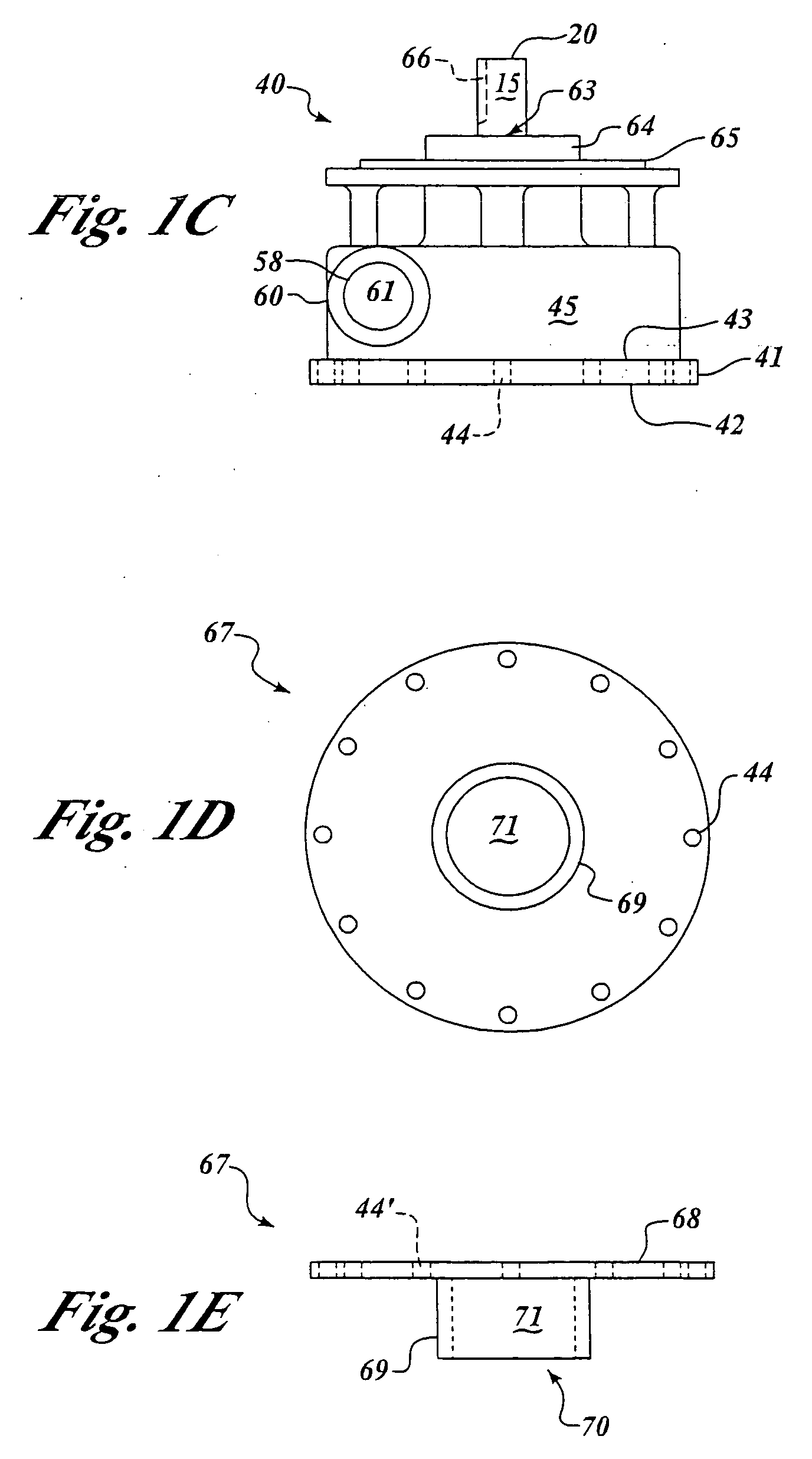

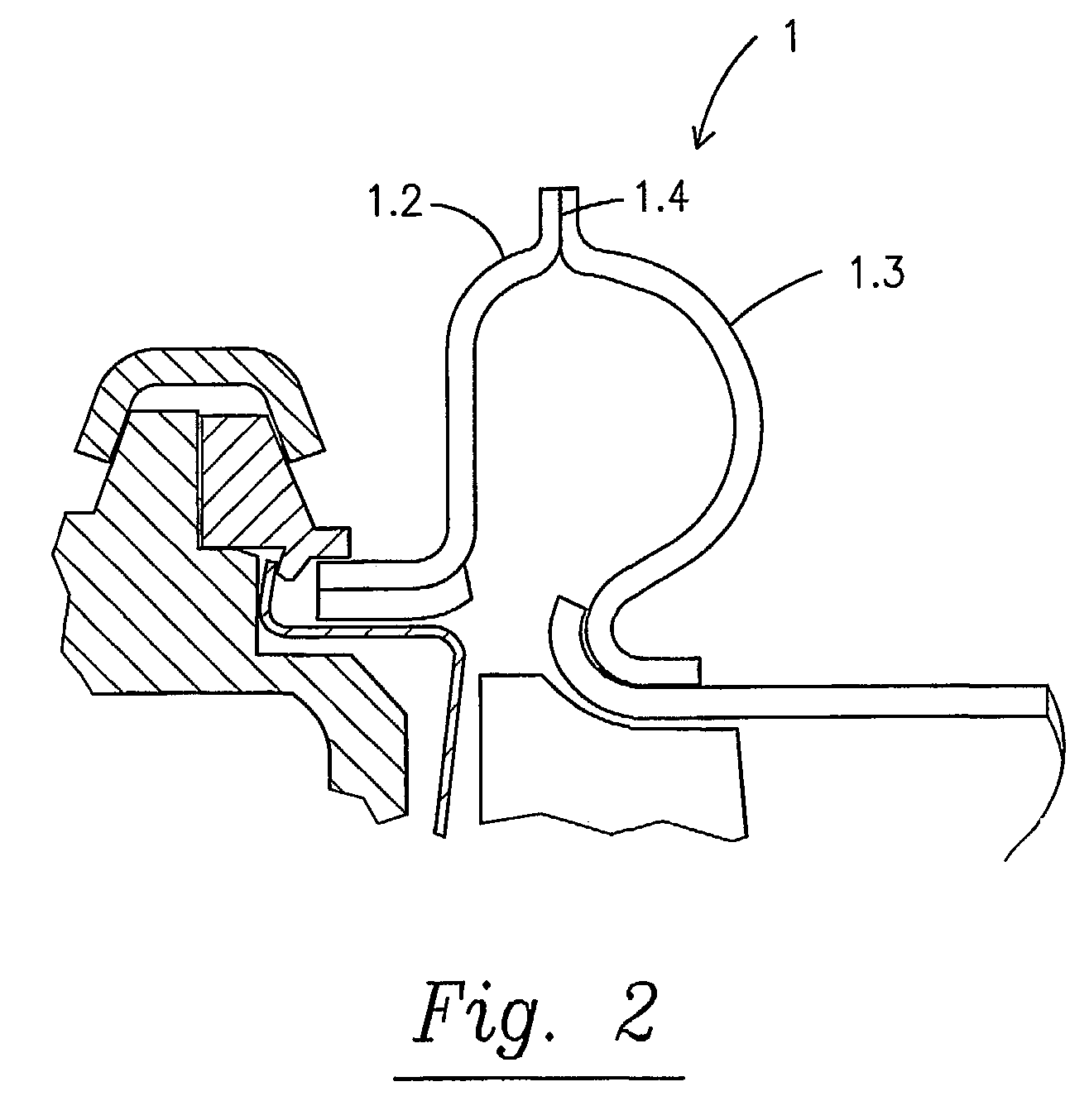

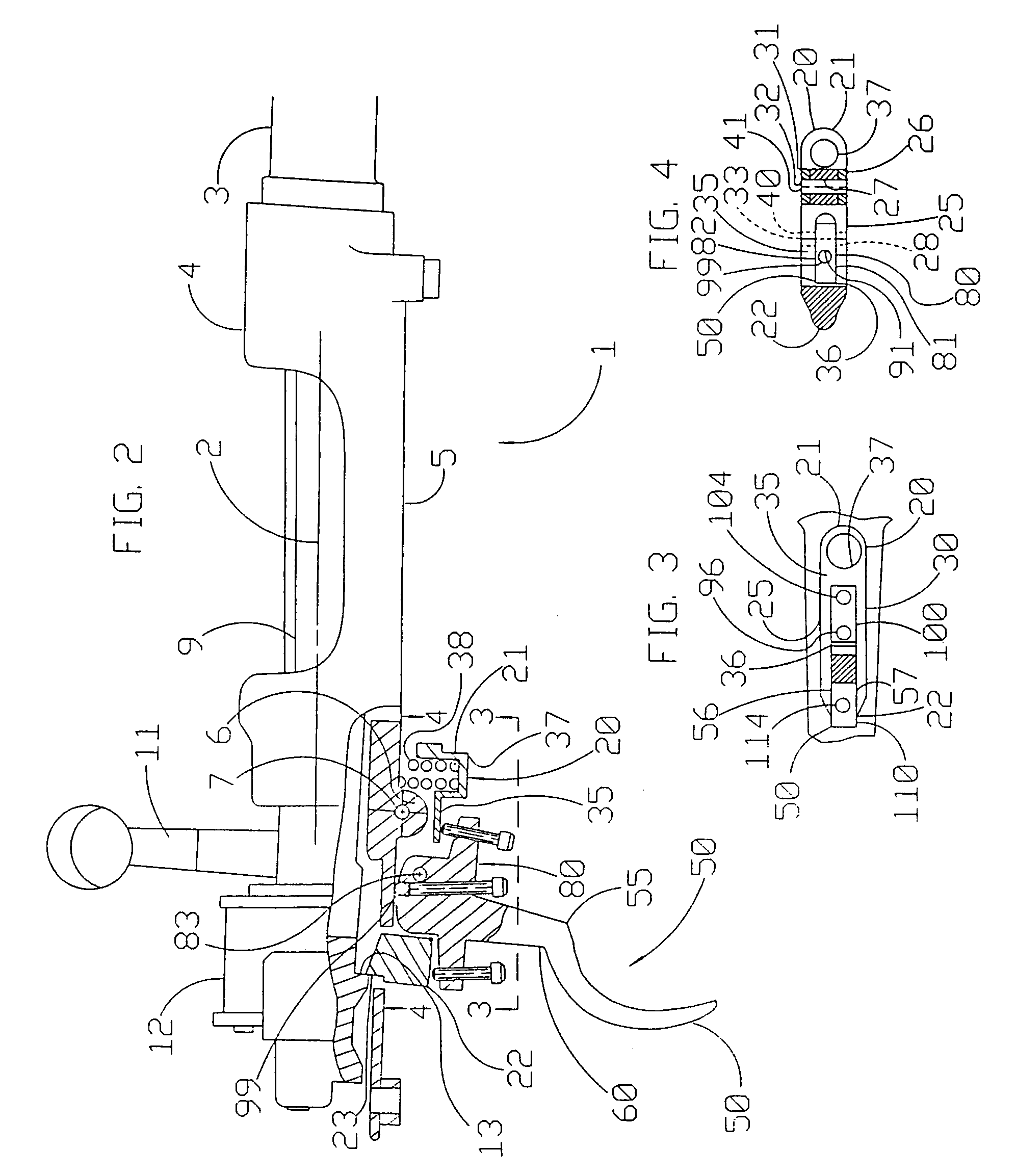

Press form element, method of installation and assembly

A functional element comprising a shaft part and a head part, or a hollow body part, for attachment to a sheet metal part, in particular for liquid-tight and / or gas-tight attachment to the sheet metal part, without penetrating or perforating the sheet metal part, is characterized in that the head or body part has at least one undercut feature either in an open hollow cavity at its end face confronting the sheet metal part and / or at its outer periphery and is formed in the regions which enter into contact with the sheet metal part with exclusively rounded shaping edges which, during the insertion of the element, cooperate with a shaping die button in order to provide a hooked engagement in form-fitted manner of the sheet metal material, with the undercut feature or with the undercut features. A method of attaching a functional element to a sheet metal part, a component assembly and also at least one die button and a setting head are disclosed and claimed.

Owner:HVB BANQUE LUXEMBOURG

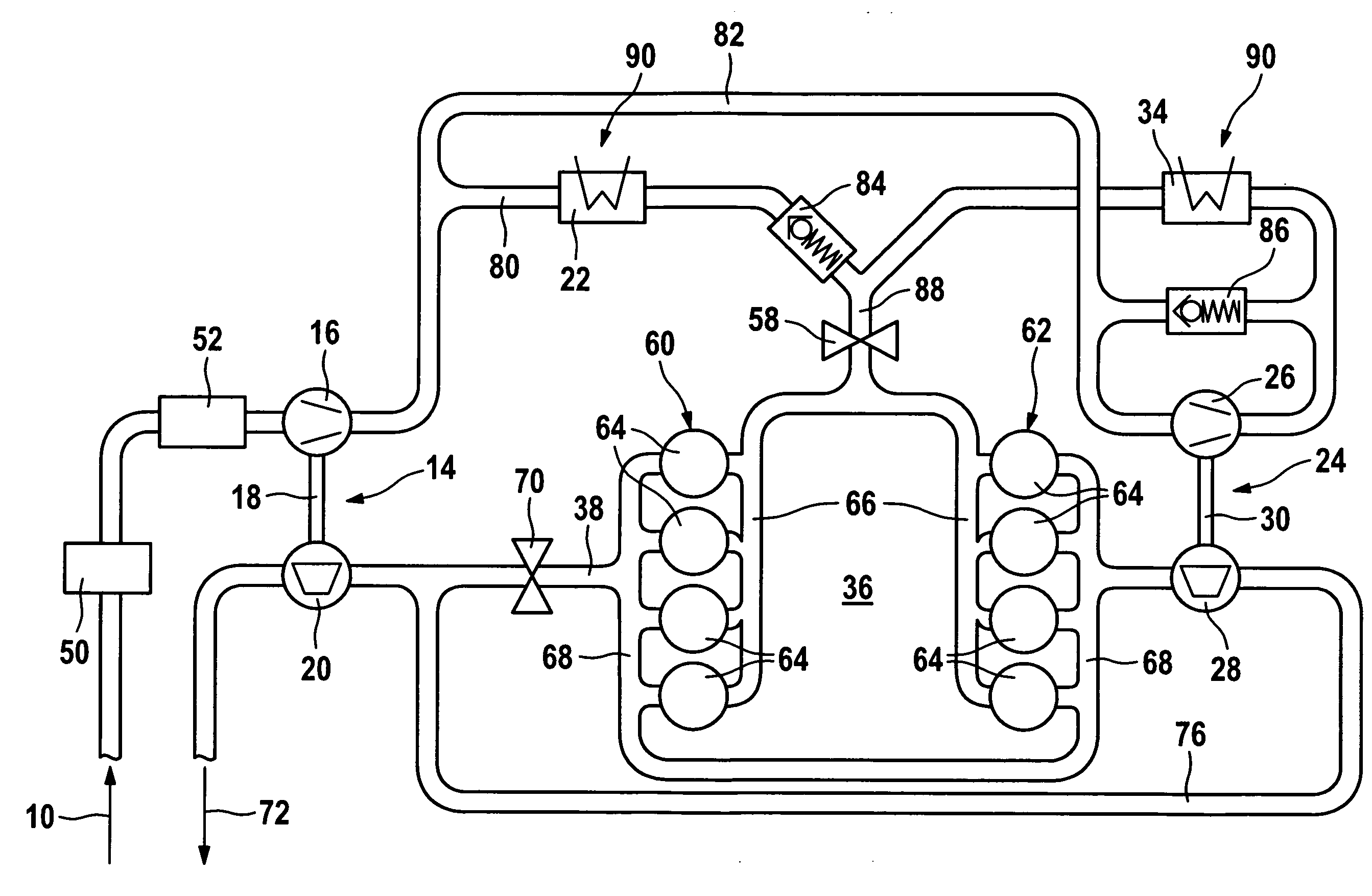

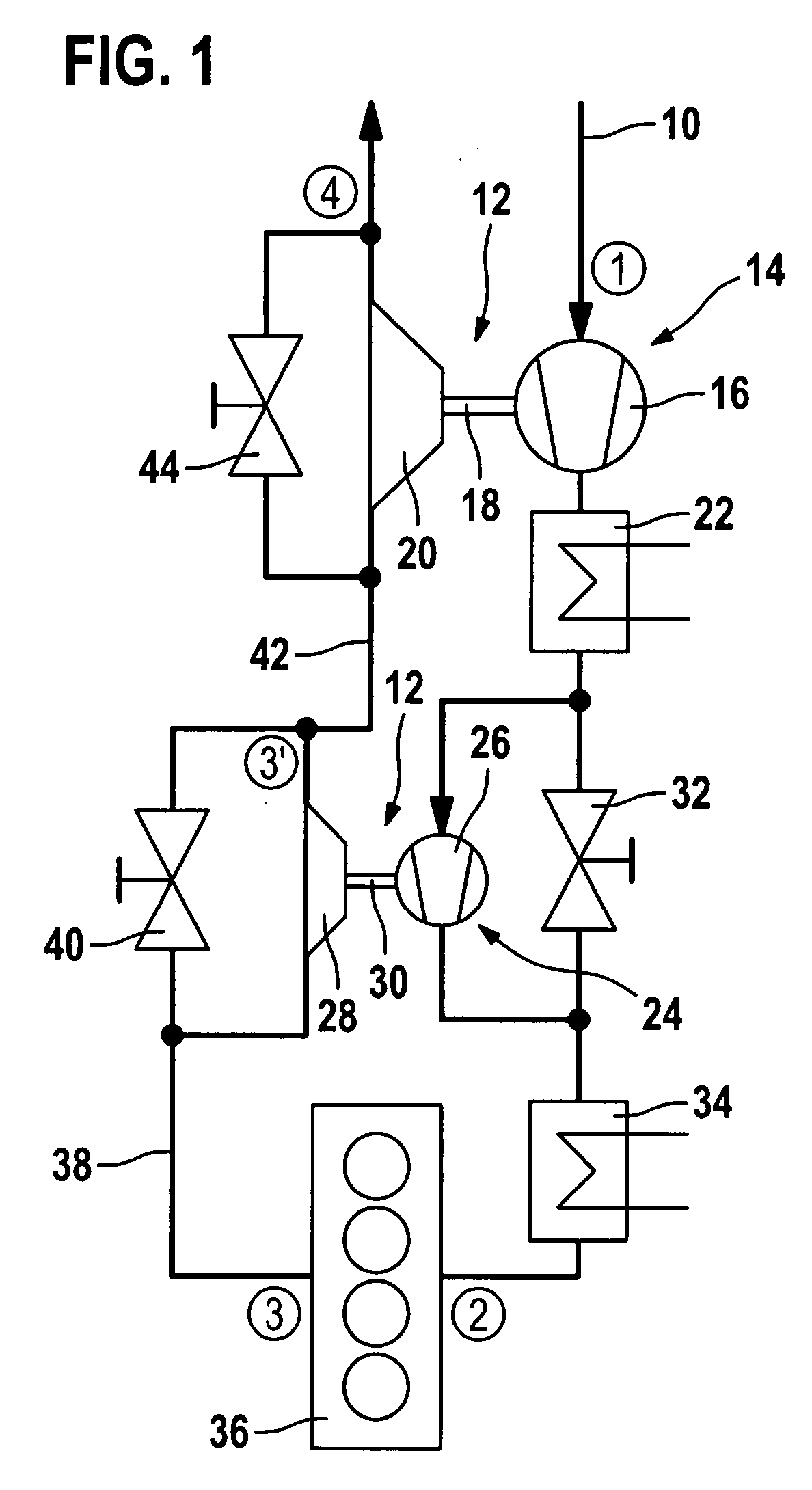

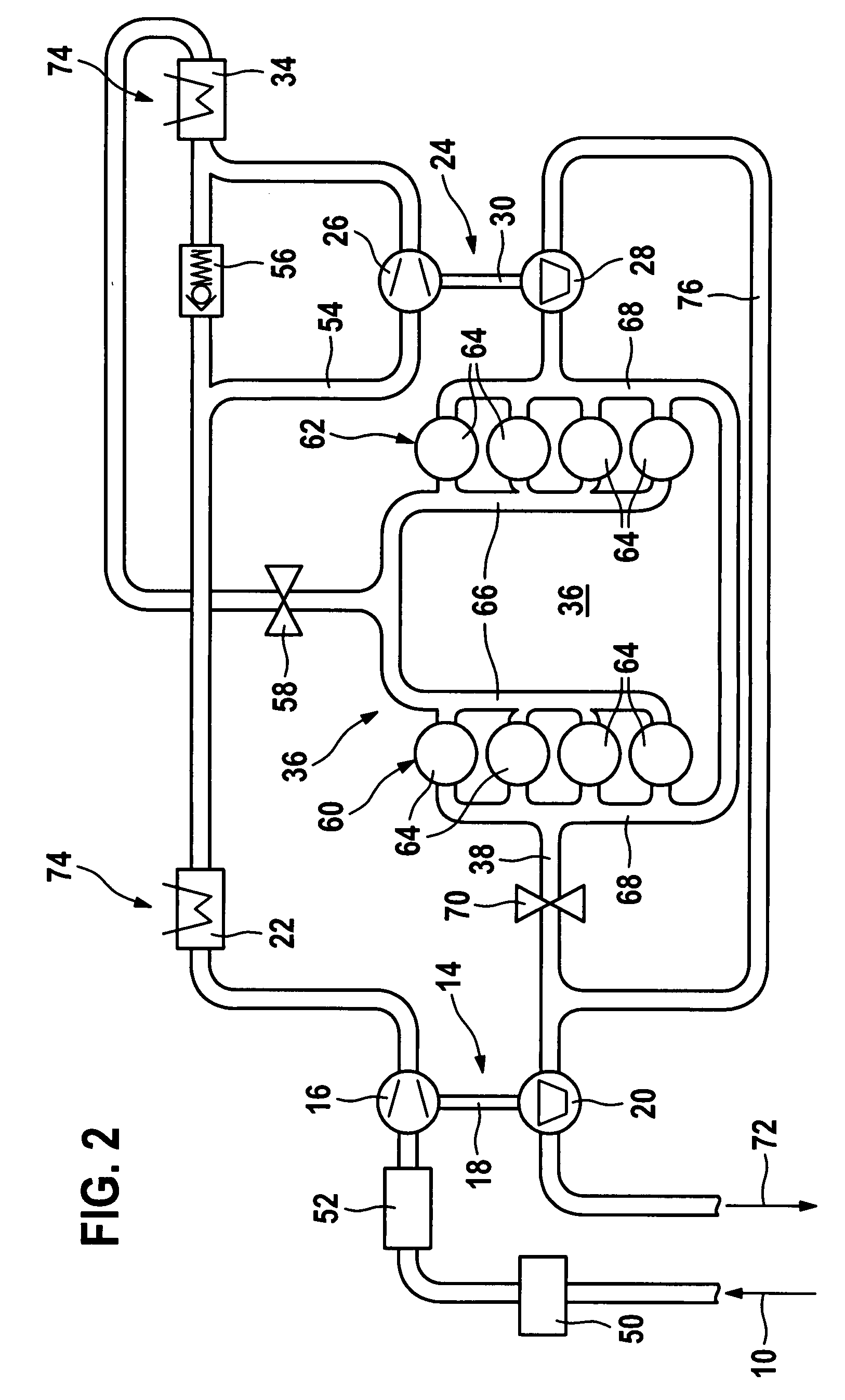

Supercharging system for two-stage supercharging of V-type internal combustion engines

InactiveUS20080034752A1Minimized pressure lossQuick buildInternal combustion piston enginesExhaust apparatusCombustionTurbocharger

A supercharging system, in particular an at least two-stage supercharging system, including a first stage and a second stage for an internal combustion engine having two cylinder banks. The at least two-stage supercharging system includes at least two charge air coolers. An exhaust gas turbocharger representing the first stage and an exhaust gas turbocharger representing the second stage are each situated next to one of the cylinder banks of the internal combustion engine.

Owner:ROBERT BOSCH GMBH

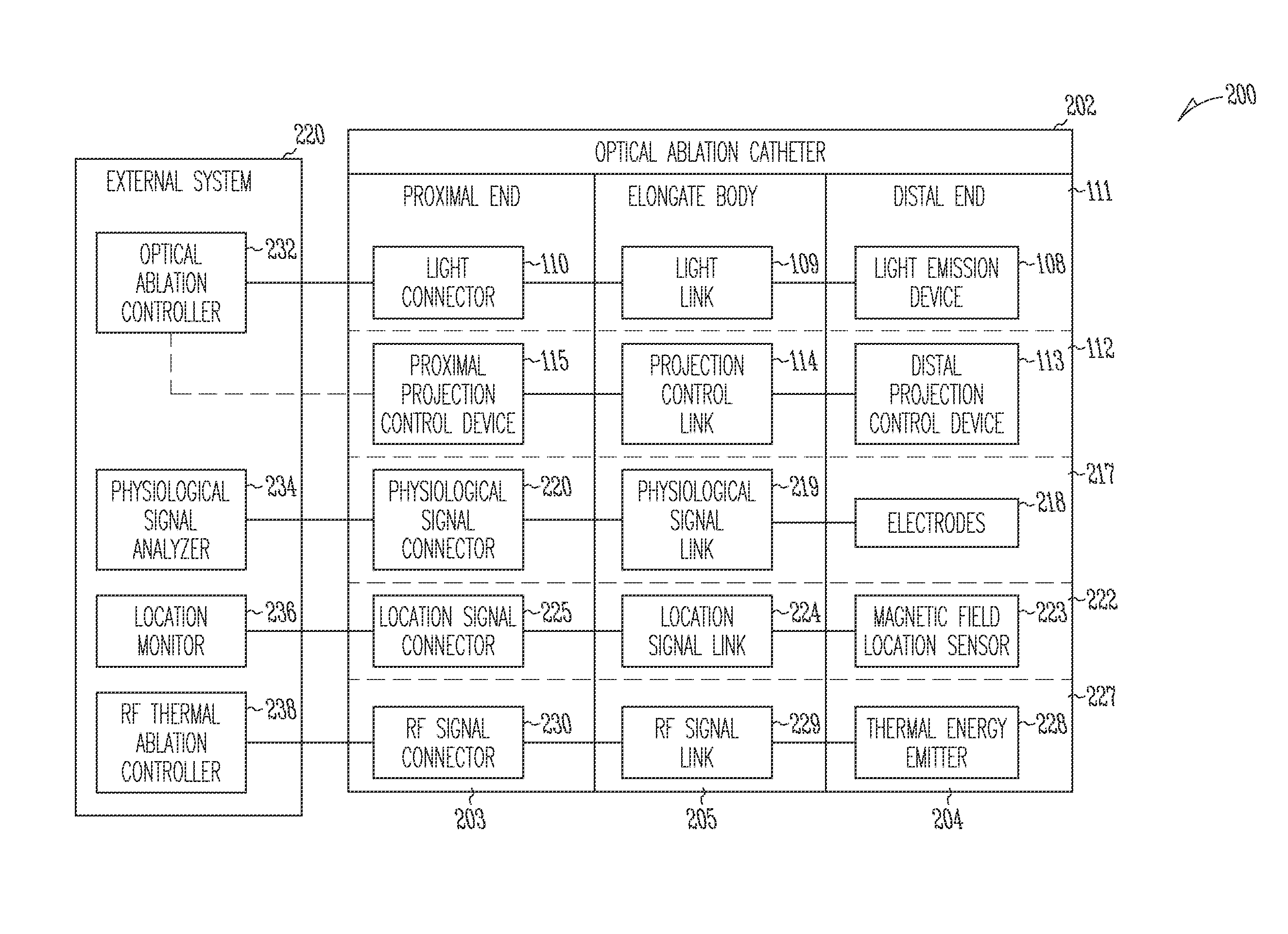

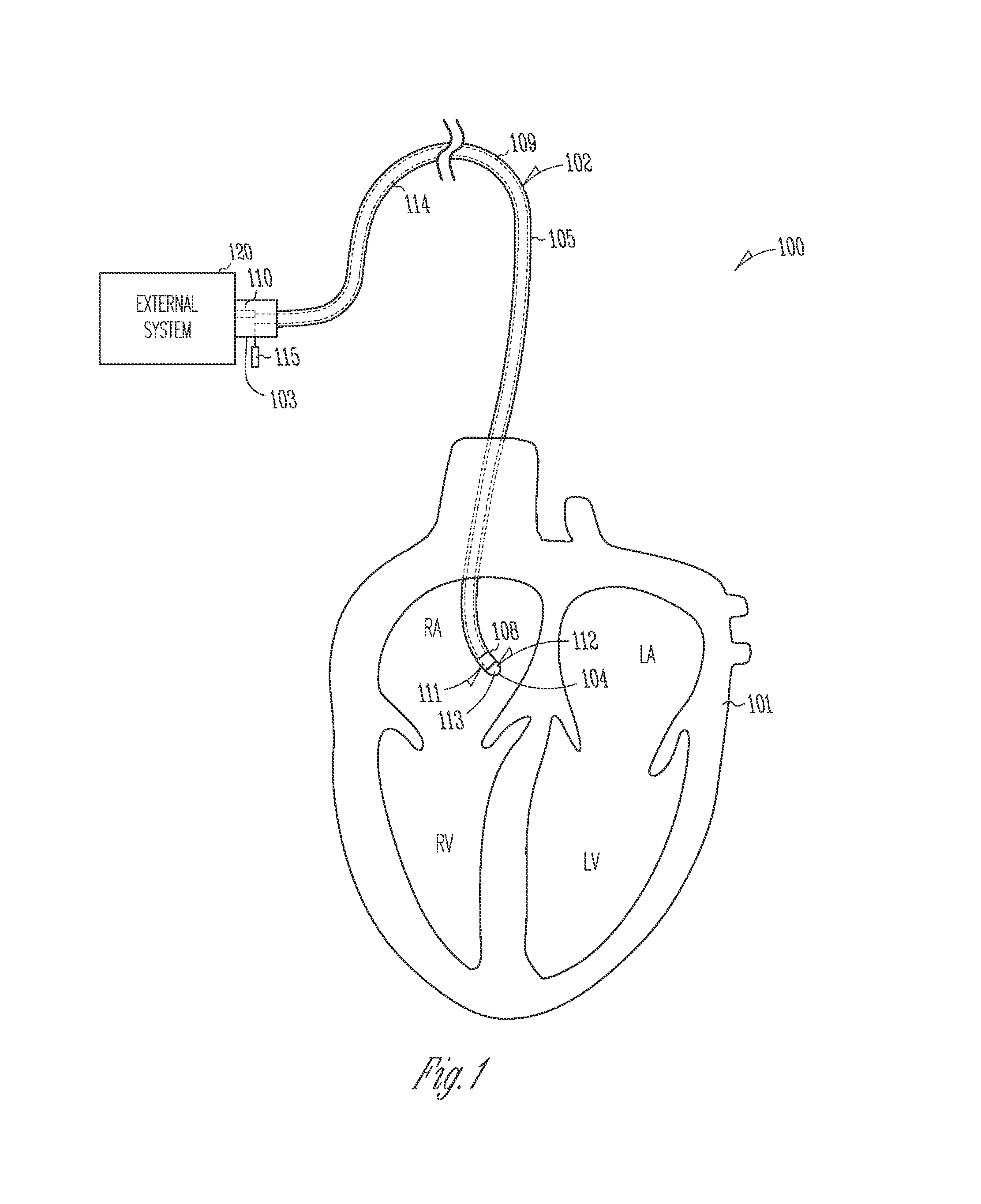

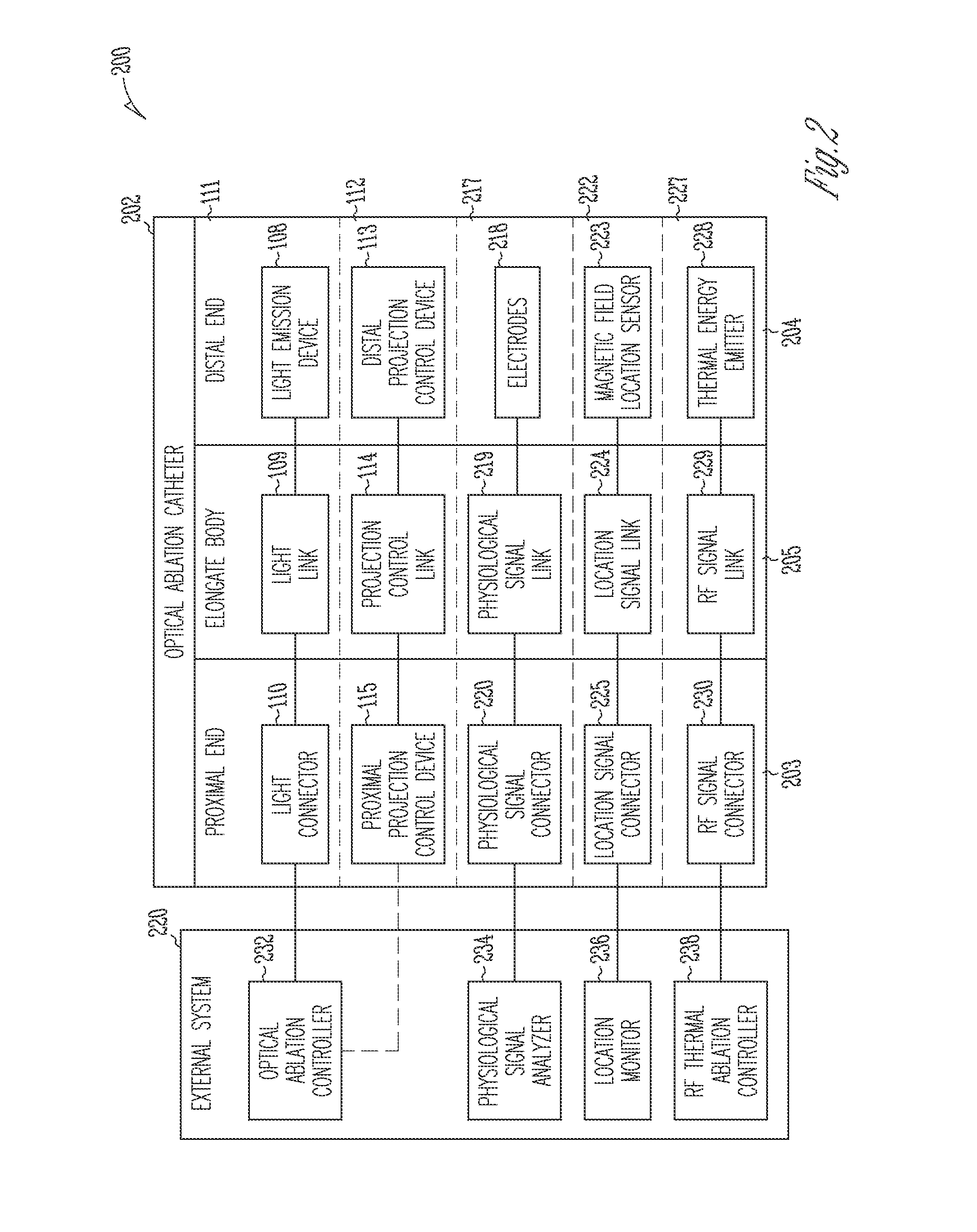

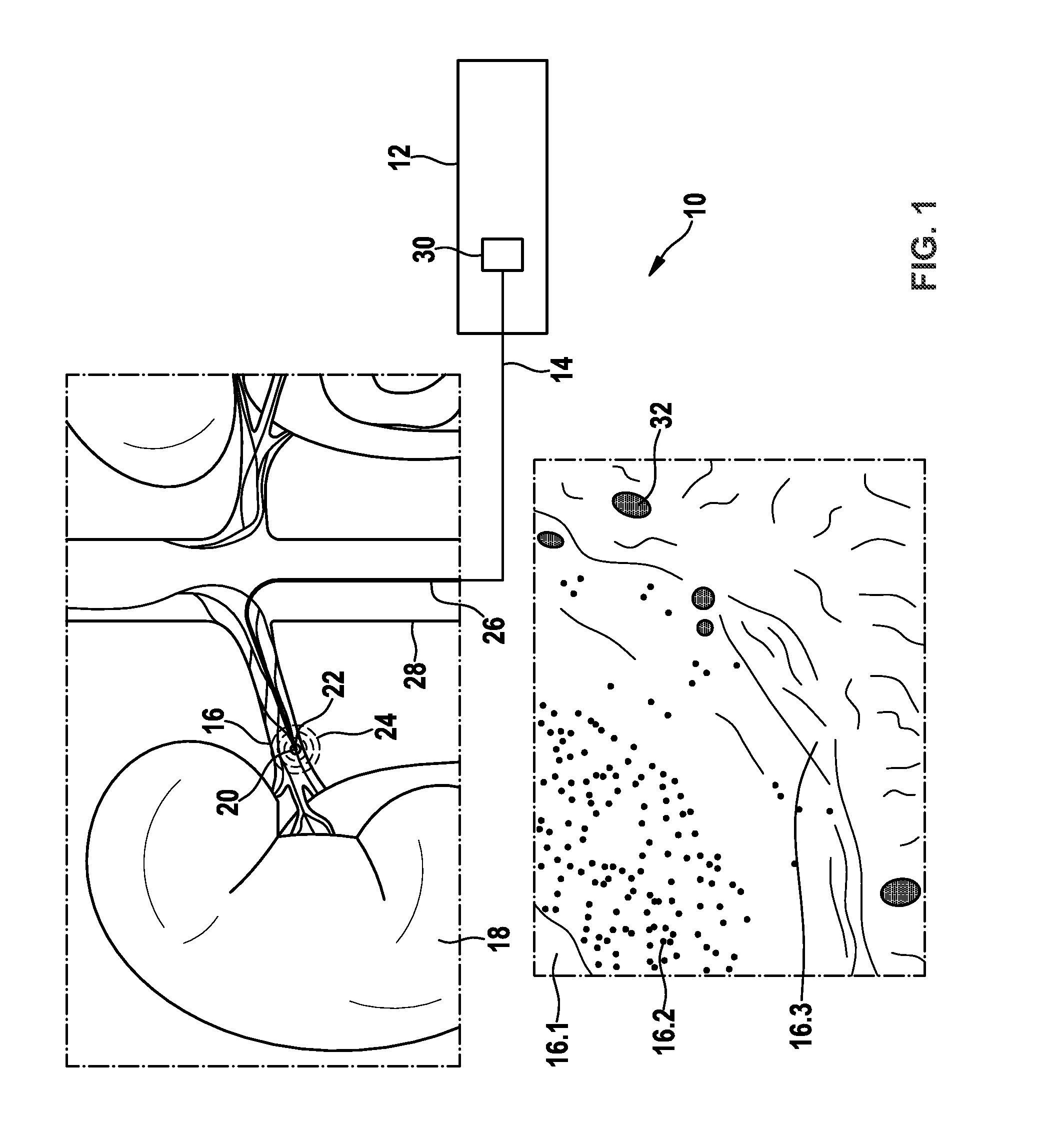

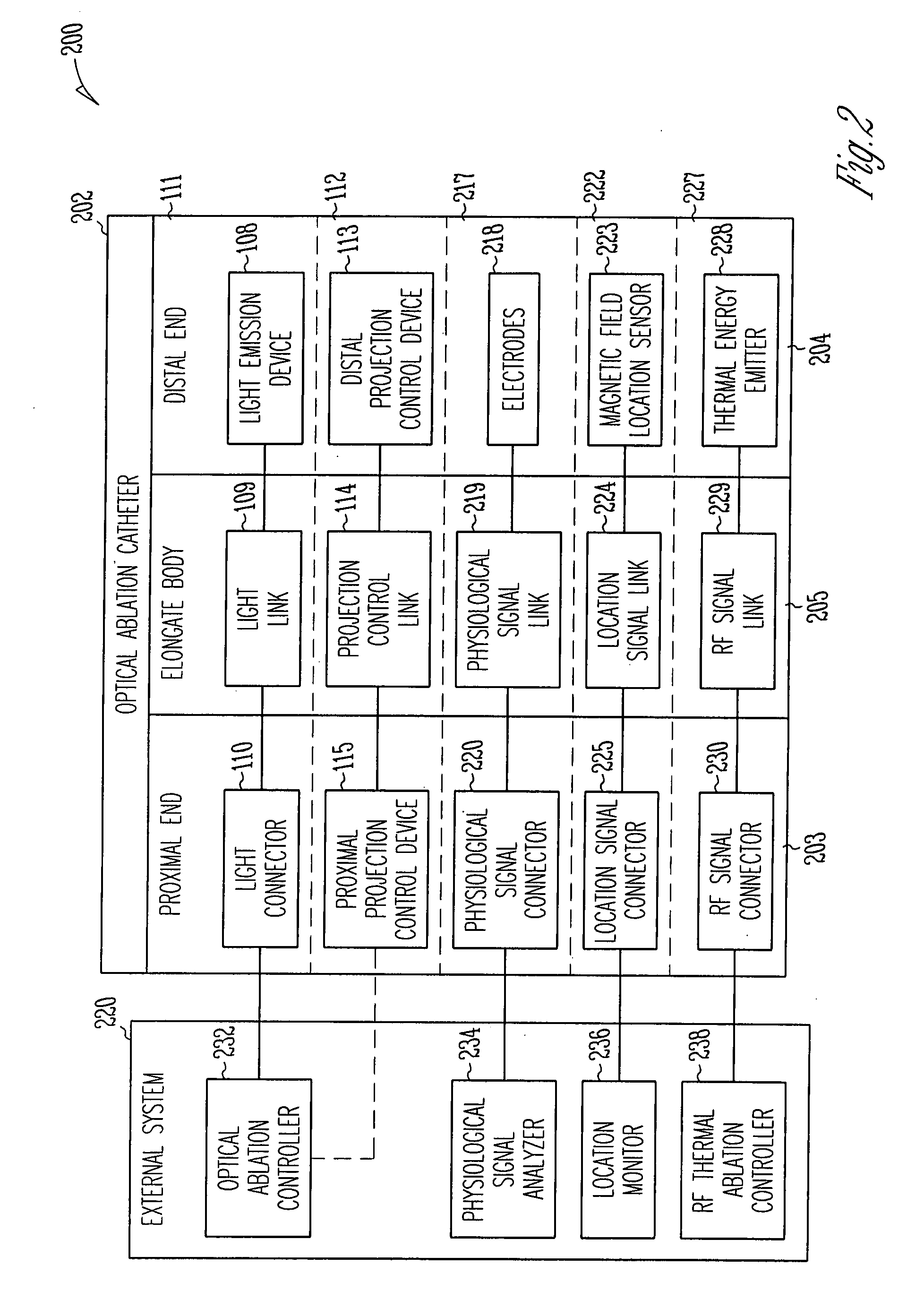

Systems and devices for photoablation

ActiveUS8480662B2Reduce the risk of blood clotsPrevent, inhibit or treat cardiac arrhythmiasSurgical instrument detailsLight therapyPhotoablationLight emission

The invention provides a catheter for optical ablation of tissue in a living body, the catheter including: a distal end; a proximal end; an elongate catheter body coupled between the distal end and the proximal end; a light emission device at the distal end and configured to emit an ablation light having characteristics selected to regulate an optically regulatable transcription control element operably linked to a nucleic acid sequence for a gene product, the expression of which gene product in cells directly or indirectly kills cells; and a projection control mechanism coupled to the light emission device and configured to control an effectively illuminated area where the optically regulatable transcription control element is effectively regulatable by the ablation light projected from the light emission device. Also provided is a system which includes the catheter, and methods to prevent, inhibit or treat AF which employ an expression cassette and / or one or more selected wavelengths of light.

Owner:CARDIAC PACEMAKERS INC

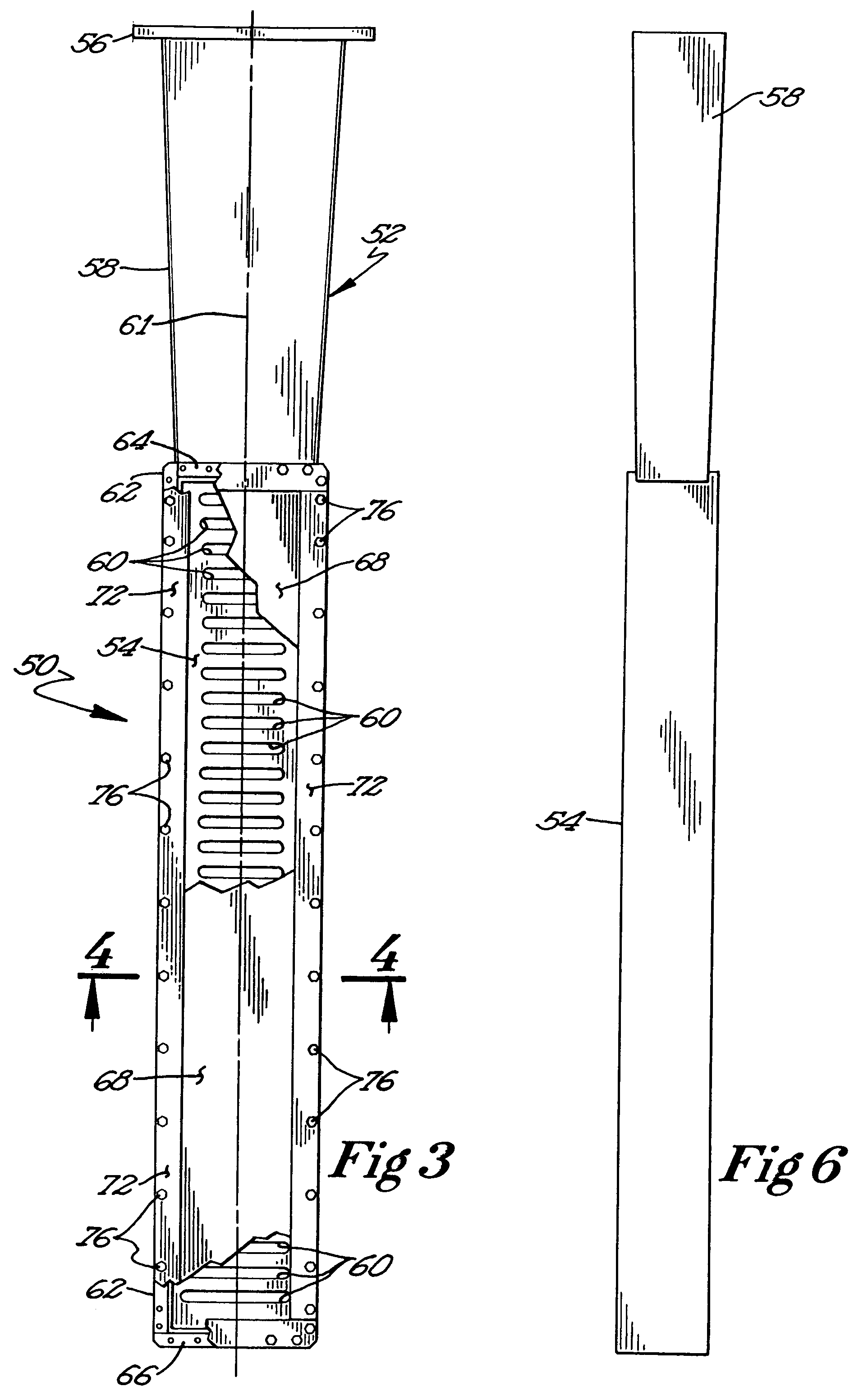

Microwave demulsification of hydrocarbon emulsion

InactiveUS7486248B2Promote demulsificationEfficiently delivers microwave energyWater/sewage treatment by irradiationSubaqueous/subterranean adaptionEmulsionMicrowave

Recovery of hydrocarbons, such as petroleum products, from a liquid or solid substrate is facilitated by the use of microwave energy to energize and separate molecular bonds between the hydrocarbons and the substrate. A radio frequency (RF) applicator delivers microwave energy to a treatment volume containing an emulsion of a hydrocarbon and a substrate. Delivering the microwave energy to the emulsion facilitates separation of the hydrocarbon and substrate molecules into layers. Hydrocarbons and other products can then be recovered from their respective layers. The treatment volume may be located either above or below ground. The RF applicator may include an antenna body with slots formed substantially parallel to one another in a substantially horizontal orientation. The RF applicator efficiently delivers microwave energy into the treatment volume. Substantially all of the power supplied to the RF applicator is radiated, with very little power reflected internally within the RF applicator.

Owner:INTEGRITY DEV

Medical device for evaluating a temperature signal

ActiveUS20150088119A1Decide more quickly whenQuicker interruption of energy transferDiagnosticsControlling energy of instrumentLimit valueMedical device

A medical device including an evaluation unit and an electrode line. The electrode line includes at least one temperature sensor. The temperature sensor delivers a temperature signal to the evaluation unit. The evaluation unit evaluates periodic fluctuations of a signal level of the temperature signal and generates an evaluation output signal qualifying constant wall touching of the electrode line according to whether periodic fluctuations of a signal level of the temperature signal lie below or above a predetermined limit value.

Owner:BIOTRONIK AG

Supercharging system for two-stage supercharging of V-type internal combustion engines

InactiveUS7703284B2Minimized pressure lossQuick buildInternal combustion piston enginesExhaust apparatusCombustionTurbocharger

A supercharging system, in particular an at least two-stage supercharging system, including a first stage and a second stage for an internal combustion engine having two cylinder banks. The at least two-stage supercharging system includes at least two charge air coolers. An exhaust gas turbocharger representing the first stage and an exhaust gas turbocharger representing the second stage are each situated next to one of the cylinder banks of the internal combustion engine.

Owner:ROBERT BOSCH GMBH

Gun trigger

InactiveUS7430827B1Less exacting tolerancePrecise positioningFiring/trigger mechanismsEngineeringMechanical engineering

The present invention relates to a gun trigger for use with a bolt-action gun. The trigger of the present invention has a finger element with an extension and a catch. The catch has a front strap and a rear strap. One or more openings are between the front and rear straps. One or more braces can be across the one or more openings. The trigger also has a head. A socket is formed in the top of the head, and a ball is received within the socket. The height of the ball relative the bottom of the socket can be adjusted. There is practically no friction between the trigger and a sear. The trigger of the present invention may be made by remanufacturing existing conventional triggers.

Owner:HUBER JOHN F

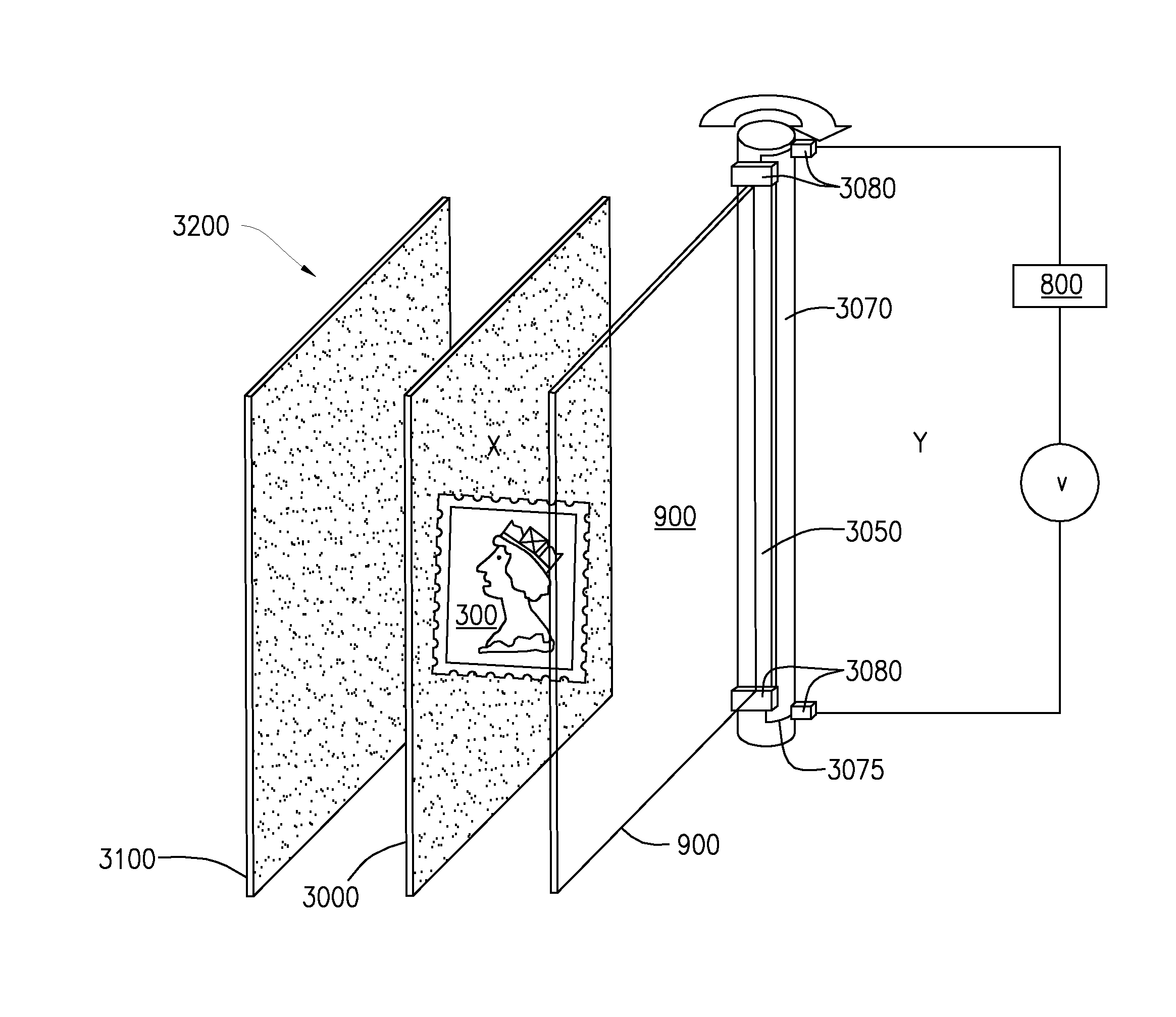

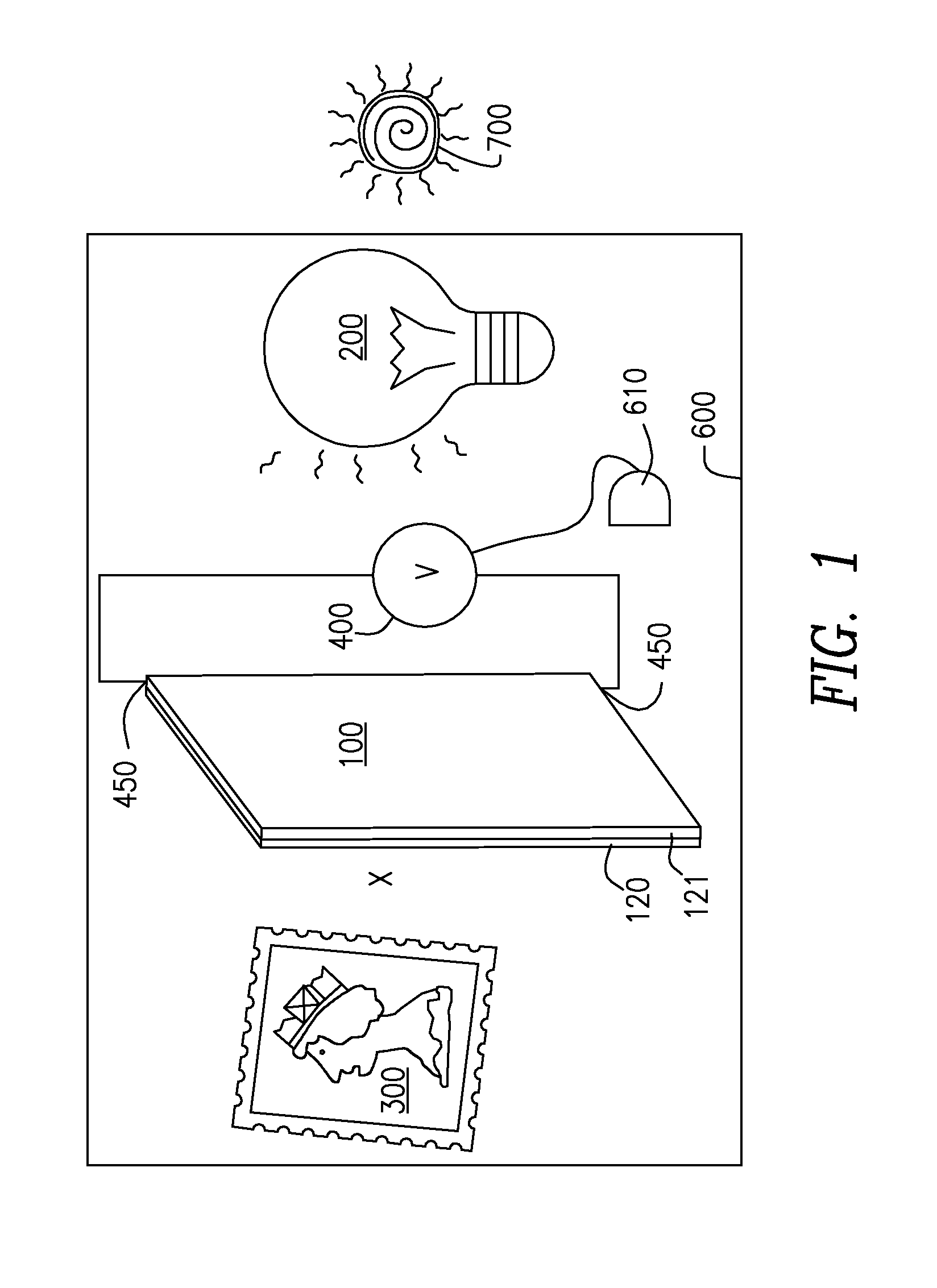

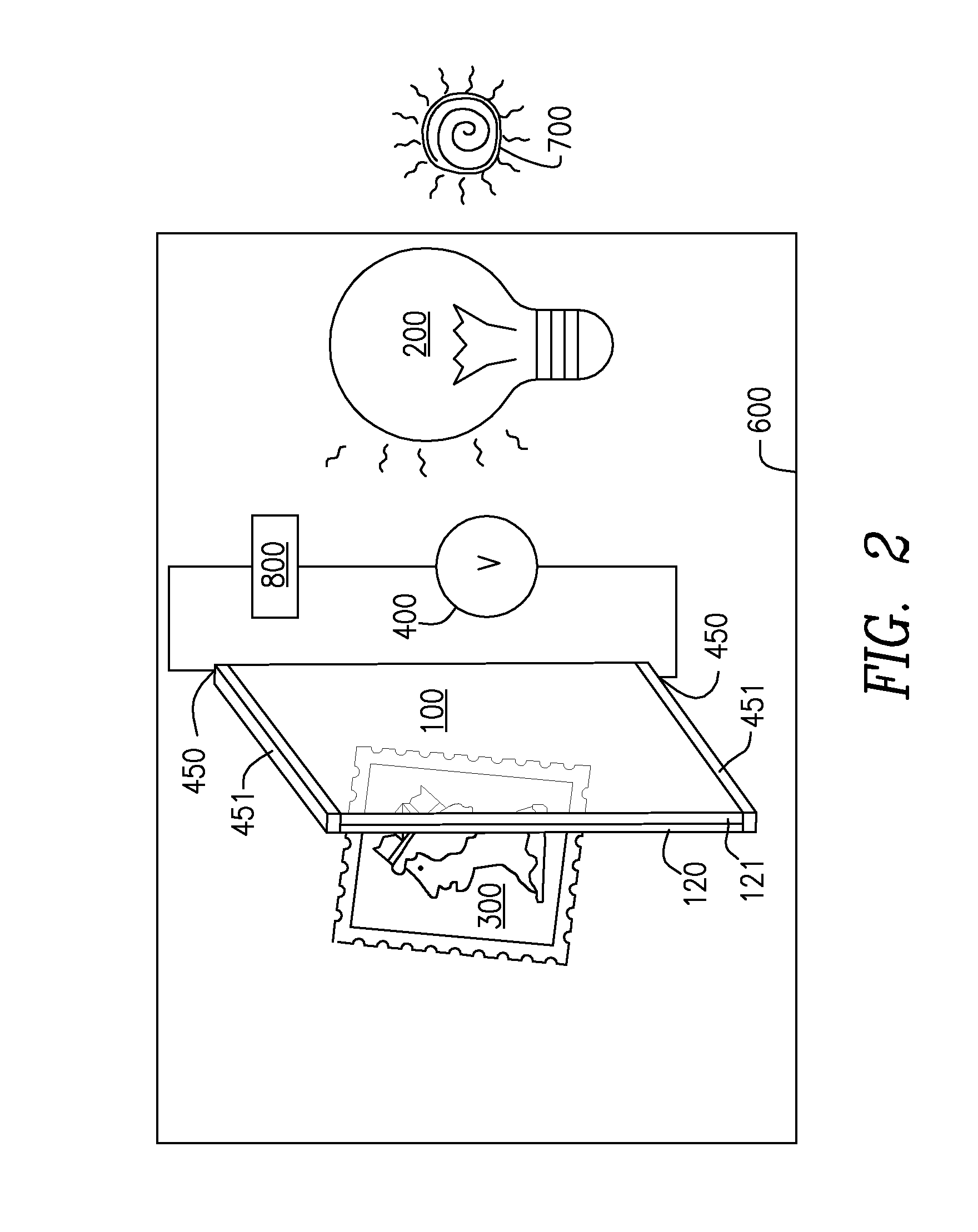

Method and device for protecting objects from degradation by light with suspended particle device light valves

ActiveUS20140320950A1Improve functionalityImprove performanceShow cabinetsPainting preservationSuspended particlesDisplay device

A display device comprising a Suspended Particle Device film or other material for controlling the amount of illumination transmitted to an object from one or more light sources to protect the object from degradation by light is described. The display is capable of being dark when the object is not being viewed and being highly transmissive when the object is to be viewed. If desired, the display device may be controlled so as to provide a substantially constant amount of illumination when the object is viewed or intended to be viewed. A method of protecting an object using the display device is also provided.

Owner:RES FRONTIERS

Systems and devices for photoablation

ActiveUS20090054883A1Avoid photolysisReduce the risk of blood clotsSurgical instrument detailsLight therapyPhotoablationLight emission

The invention provides a catheter for optical ablation of tissue in a living body, the catheter including: a distal end; a proximal end; an elongate catheter body coupled between the distal end and the proximal end; a light emission device at the distal end and configured to emit an ablation light having characteristics selected to regulate an optically regulatable transcription control element operably linked to a nucleic acid sequence for a gene product, the expression of which gene product in cells directly or indirectly kills cells; and a projection control mechanism coupled to the light emission device and configured to control an effectively illuminated area where the optically regulatable transcription control element is effectively regulatable by the ablation light projected from the light emission device. Also provided is a system which includes the catheter, and methods to prevent, inhibit or treat AF which employ an expression cassette and / or one or more selected wavelengths of light.

Owner:CARDIAC PACEMAKERS INC

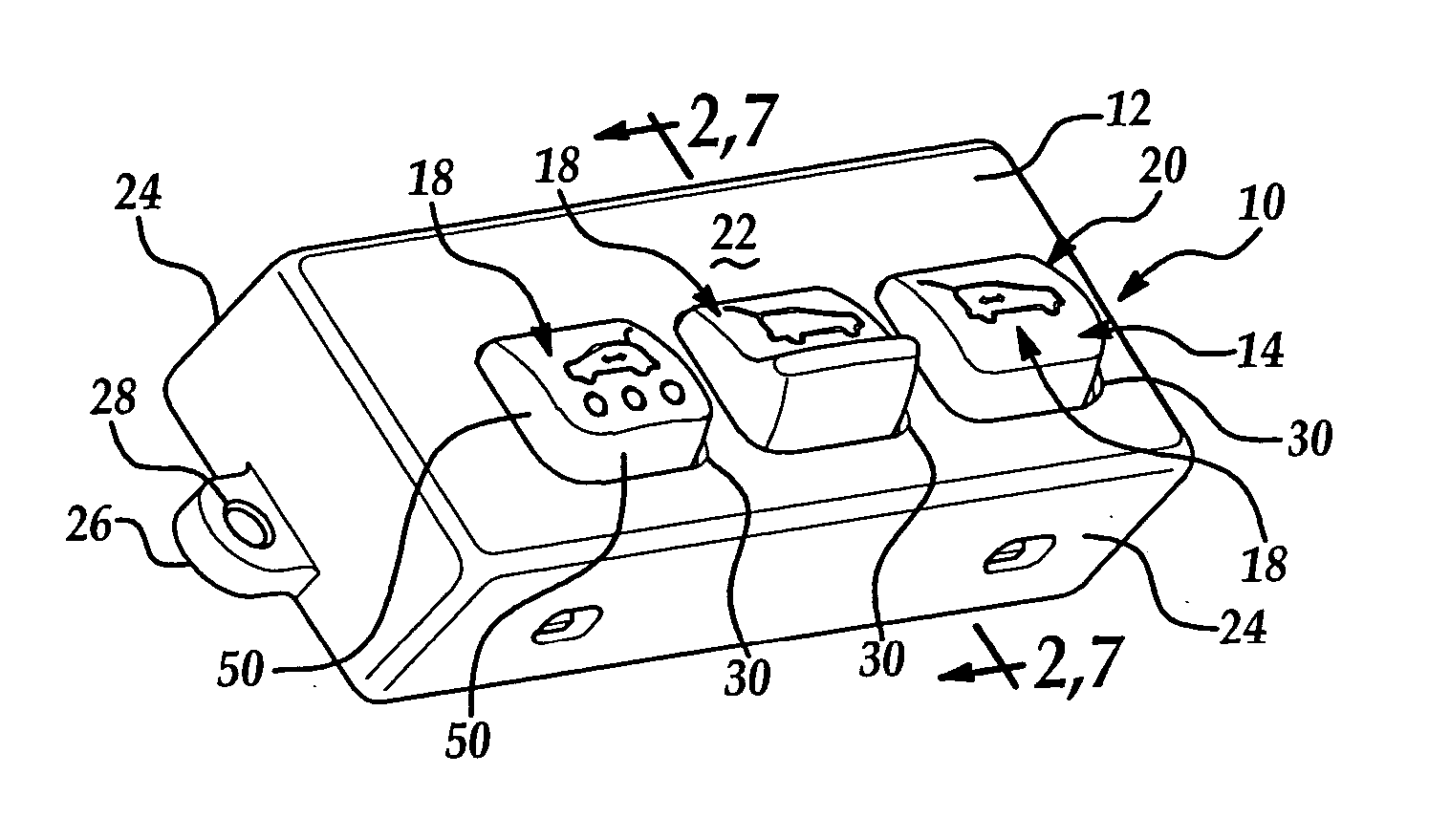

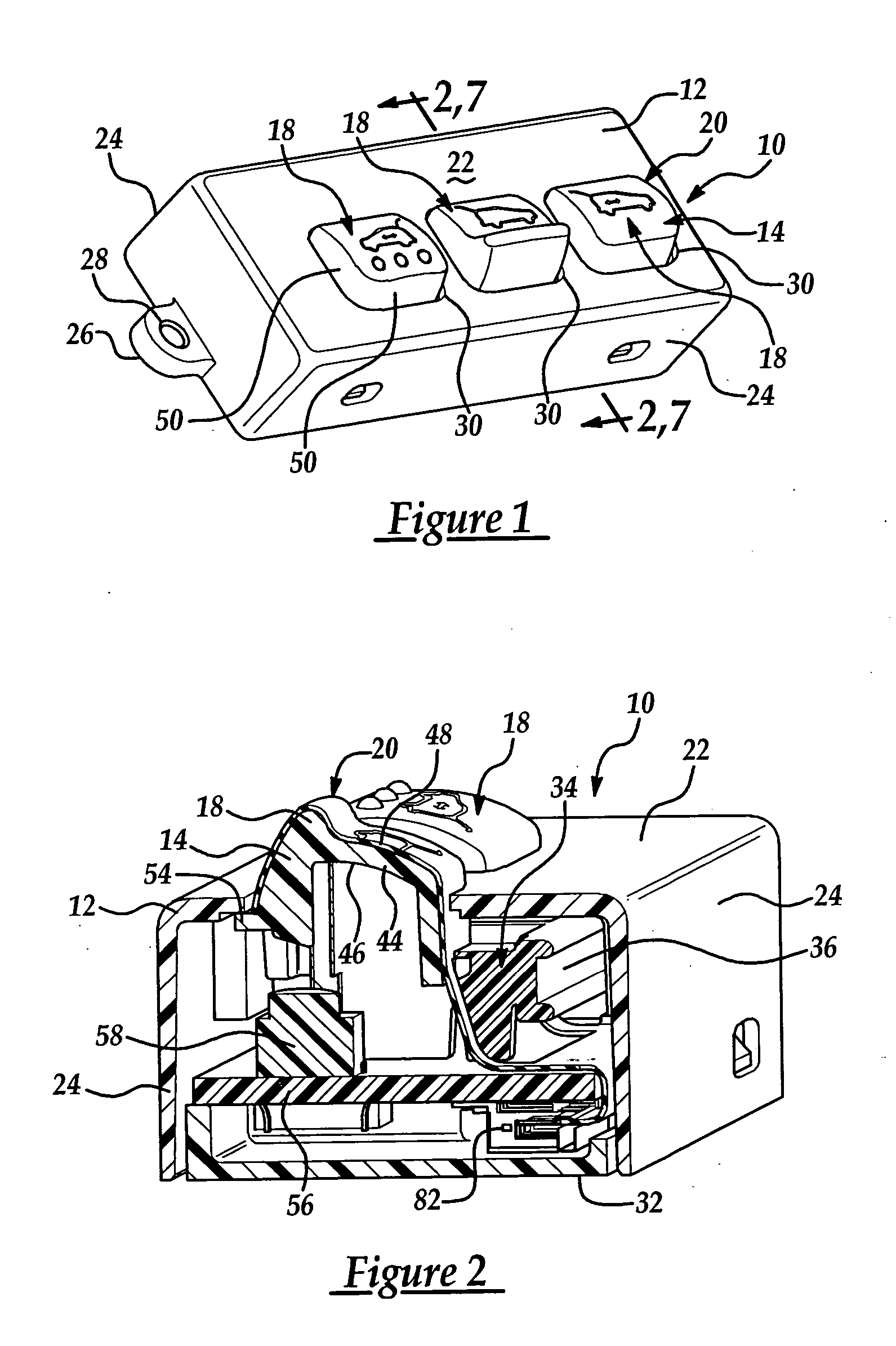

Control panel assembly with moveable illuminating button and method of making the same

InactiveUS20050252758A1Increase awarenessLess sensitive to shockEmergency actuatorsLegendsEngineeringElectroluminescence

A control panel assembly including at least one moveable button defining an outer surface. The control panel assembly also includes an electroluminescent film operatively supported on the outer surface of the button such that the electroluminescent film is adapted for selectively emitting light from the outer surface of the button. A method for making the control panel assembly is also disclosed.

Owner:LEAR CORP

Motor for optical systems

ActiveUS8264104B2Rapid and continuous and exact positioningLittle heatMagnetsTelescopesRest positionEngineering

A motor for optical systems, for example endoscopes, has a stator with two permanent magnets having poles which are disposed in the same direction and are magnetically interconnected by a flux return element. A coil is disposed between the magnets. Laterally of each magnet, a pole shoe is also magnetically coupled with the flux return element. A slider of the motor includes a yoke of a soft magnetic material, which yoke is in magnetic engagement with the permanent magnets of the stator. When the coil is excited with a current, the slider can be displaced from its rest position along a longitudinal direction.

Owner:KARL STORZ GMBH & CO KG

Lightweight, insulated, weather-resistant, building products, methods and structures using the same

ActiveUS20170211268A1Little heatSimple structureAnimal huntingConstruction materialBuilding productPolystyrene

Insulated building products, methods and structure using those products are disclosed. The embodiments described include building materials having a core of encapsulated polystyrene (EPS) which is completely coated with a polymer. The polymer coating provides protection and structural integrity to the foam such that structures made of EPS foam can support multiple human beings without incurring damage. Moreover, additional embodiments are provided in which additional structural integrity is provided by affixing one or more rigid materials to the EPS foam prior to coating. The results, as disclosed, are light-weight, portable building structures that provide protection from the weather and that can be easily heated or cooled.

Owner:RHINO BUILDING PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com